nexstyle 4OSA015BST Assembly instructions

Please read and save this guide before using your range hood.

Store the guide in a safe place so you will know where it is

when you want to refer to it.

stainless steel

range hood

Model#: 4OSA015BST

Itm./Atr. 653654

Installation

Guide and

User Manual

This uniT replaces Top

venTing range hoods only.

check your exisTing range

hood before insTalling.

2

IMPORTANT

Carefully check the unit prior to installation to ensure there is no damage.

Do not dispose of any packaging until you are satised with your new

range hood.

If you have any problems with this unit or there are

missing or damaged parts, please call toll free:

1-800-459-4409. DO NOT RETURN THE UNIT TO THE

PLACE OF PURCHASE before calling the toll free number

above.

IMPORTANT

This is a top venting range hood. Check your existing range hood

venting system to ensure your venting is compatible. This unit can’t

replace a back venting range hood.

IMPORTANT

• Read and save these instructions. Save this guide for local electrical

inspector’s use.

• Approved for residential appliances.

• For residential use only.

Installation must comply with all local codes.

• Requirement: 120V AC, 60Hz. 15 or 20 A Branch Circuit.

• Read all instructions before proceeding.

• Turn off power circuit breaker before wiring this appliance.

Installer: Must leave instructions for this unit with owner.

Homeowner: Please retain these instructions for future reference and

for local electrical inspector’s use.

3

a. iMporTanT safeTy

insTrucTions

Read all instructions before installing and operating this appliance.

insTallaTion

Do not install if the appliance is damaged.

1. The instructions in this manual are intended for qualied installers,

service technicians or other qualied persons. NEVER attempt to

install this appliance yourself.

2. Installing the unit without an electrical and technical background could

result in injury.

3. All electrical wiring must be properly installed, insulated and grounded.

Old duct work should be cleaned or replaced if necessary to avoid

the possibility of a grease re. Check all joints on duct work to insure

proper connection. All joints should be properly sealed.

4. Personal injury hazard. Because of the weight and size of the range

hood, two or more people are needed to move and safely install the

range hood. Failure to properly lift range hood could result in damage

to the product or personal injury.

5. SEVERE INJURY - Range hood may have very sharp edges. Please

wear protective gloves to remove any parts for installing, cleaning or

servicing.

Workman Safety Gloves

4

operaTions

1. Read all instructions in this manual before operating this appliance.

2. Always leave safety grills and lters in place. Without these components,

operating blowers could catch on to hair, ngers and loose clothing.

3. NEVER dispose of cigarette ashes, ignitable substances, or any

foreign objects in blowers.

4. NEVER leave cooking unattended. Use caution when cooking with oil.

Overheating may cause oil to reach its ash point and ignite. Used oil

will ignite at lower temperatures than fresh oil.

5. Constantly monitor deep-fryers during use, as overheated oil may ignite.

cleaning

Do not operate blowers when lters are removed.

1. The saturation of greasy residue in the blower and lters may cause

increased ammability. Keep this appliance clean and free of grease

and residue build-up at all times to prevent possible res.

2. Filters must be cleaned periodically and kept free from accumulation

of cooking residue (see cleaning instructions inside). Old and worn

lters must be replaced immediately.

3. NEVER disassemble parts to clean without proper instructions. Parts

should be disassembled by qualied persons only.

4. DO NOT spray any liquid cleaner on hood surface including lights and

control switch. To clean the range hood, spray liquid cleaner directly

onto cleaning cloth for hood cleaning.

The manufacture and distributors decline all responsibility in the event of failure to

observe the instructions given here for installation, maintenance and suitable use

of the product. The manufacturer and distributors further decline all responsibility

for injury due to negligence and the warranty of the unit automatically expires due

to improper installation and/or maintenance.

safeTy noTe:

Remove PVC lm before installation. Always wear workman safety gloves

for installation, cleaning, light bulb changing and dismantling to reduce

the risk of injury.

5

b. before you sTarT...

It is very important for your safety and the safety of others that you follow

the many important safety messages in this manual and on your appli-

ance. Always read and obey all safety messages. All safety messages

will tell you what the potential hazard is, how to reduce the possibility of

injury, and what can happen if the instructions are not followed.

WARNING

* Electrical grounding is required for this range hood.

* Check with a qualified electrician if you are not sure whether the range

hood is properly grounded.

* Failure to follow electrical requirements may result in a fire.

* A fuse in the neutral or grounding circuit could result in electrical shock.

* If the hot/cold water pipe is interrupted by plastic nonmetallic gaskets or

other materials, DO NOT use for grounding.

* * DO NOT ground to a gas pipe.

READ AND SAVE THESE INSTRUCTIONS

WARNING : TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING CAREFULLY:

1) Use this unit only in the manner intended by the manufacturer. If

you have any questions, contact the distributor, importer or the

manufacturer.

2) Before servicing or cleaning the unit, switch power off at the junction

box and lock the panel door to prevent power from being switched on

accidentally. If the junction box door cannot be locked, securely fasten

a prominent warning sign to the panel door.

3) Installation work and electrical wiring must be done by qualied

person(s) in accordance with all applicable codes and standards,

including re-related construction.

4) Sufcient air is needed for proper combustion and exhausting of gases

through the ue (duct cover) of fuel burning equipment to prevent

back drafting. Follow the heating equipment manufacturer’s guidelines

and safety standards such as those published by the National Fire

Protection Association (NFPA) and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local

code authorities.

6

5) When cutting or drilling into the wall or ceiling, ensure that you do not

damage electrical wiring and hidden utilities.

6) Fans must always be vented to the outdoors.

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCT WORK.

CAUTION: FOR GENERAL VENTILATION USE ONLY. DO NOT

USE THE RANGE HOOD FANS TO EXHAUST HAZARDOUS OR

EXPLOSIVE VAPORS.

WARNING: TO REDUCE THE RISK OF INJURY IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:

(Based on “kitchen re safety tips” published by the NFPA)

1) SMOTHER FLAMES with a close-tting lid, cookie sheet, or metal tray,

then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the

ames do not go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2) NEVER PICK UP A FLAMING PAN - you may be burned.

3) DO NOT USE WATER, including wet dishcloths or towels - a violent

steam explosion will result.

4) Use an extinguisher ONLY if:

a) You know you have a class ABC extinguisher, and you already know

how to operate it.

b) The re is small and contained in the area where it started.

c) The re department is being called.

d) You can ght the re with your back to an exit.

5) DO NOT spray any liquid cleaner on hood surface including lights and

control switch. To clean the range hood, spray liquid cleaner directly

onto cleaning cloth for hood cleaning.

CAUTION: TO REDUCE RISK OF FIRE AND TO PROPERLY

EXHAUST AIR, BE SURE TO VENT AIR OUTSIDE - DO NOT VENT

EXHAUST AIR INTO SPACES WITHIN WALLS, CEILINGS, ATTICS,

CRAWL SPACES, OR GARAGES.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT USE THIS HOOD WITH ANY EXTERNAL SOLID

STATE SPEED CONTROL DEVICE.

WARNING: NEVER ALLOW CHILDREN TO BE UNATTENDED

WHEN THE RANGE HOOD IS OPERATING.

7

WARNING: DO NOT CONNECT RANGE HOOD TO EXISTING

DUCTS CARRYING COMBUSTIBLE FUMES/MATERIALS

(BOILER, FIREPLACES ETC.)

WARNING: TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

1) Never leave cooking unattended as boil-overs may ignite. Heat oils

slowly on low or medium settings.

2) Always turn hood fans on when cooking at high heat or when cooking

aming foods. (i.e. Crêpes Suzette, Cherries Jubilee, Peppercorn Beef

Flambé).

3) Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or lter.

4) Use proper pan size. Always use cookware appropriate for the size of

the surface element.

To get the best performance, the vertical clearance between the cook-

top and the range hood should range from 46 cm – 75 cm (18 in to 29.5 in).

The minimum distance from the cooking surface to the range hood is

46 cm (18 in) for electric ranges, and 75 cm (29.5 in) for gas ranges. If

your gas range species a different distance use the greater distance of

the two.

grounding insTrucTions

This appliance must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire

for the electric current. Connect the unit using an approved and properly

sized 2-wire plus ground copper wire.

Warning: IMPROPER GROUNDING CAN RESULT IN A RISK

OF ELECTRIC SHOCK. CONSULT A QUALIFIED ELECTRICIAN

IF THE GROUNDING INSTRUCTIONS ARE NOT COMPLETELY

UNDERSTOOD OR IF DOUBT EXISTS AS TO WHETHER THE

APPLIANCE IS PROPERLY GROUNDED.

CAUTION: THE RANGE HOOD HAS A THERMALLY PROTECTED

SYSTEM FOR THE MOTOR, WHICH WILL SHUT DOWN

AUTOMATICALLY IF THE MOTOR IS OVERHEATED. IF THE

OVERHEAT PROTECTION TRIPS, DISCONNECT THE POWER

AND WAIT FOR 20 MINUTES UNTIL THE MOTOR COOLS DOWN.

8

c. elecTrical reQuireMenTs

OBSERVE ALL GOVERNING CODES AND ORDINANCES

WARNING

* Electrical grounding is required for this range hood.

* Check with a qualified electrician if you are not sure whether the range

hood is properly grounded.

* Failure to follow electrical requirements may result in a fire.

* A fuse in the neutral or grounding circuit could result in electrical shock.

* If the hot/cold water pipe is interrupted by plastic nonmetallic gaskets or

other materials, DO NOT use for grounding.

* * DO NOT ground to a gas pipe.

IMPORTANT: It is the customer’s responsibility to contact a qualied electrical in-

staller and assure that the electrical installation is adequate and complies with the

National Electrical Code, or CSA standards and all local codes and ordinances.

1. Save installation instructions for electrical inspector’s use.

2. If codes permit and a separate ground wire is used, it is recommended that

a qualied electrician determine if the ground path is adequate.

3. DO NOT use an extension cord or adapter plug with this appliance.

4. RISK OF ELECTRICAL SHOCK - This range hood must be properly grounded.

5. The range hood must be connected with copper wire only.

6. The range hood should be connected directly to the junction (or circuit

breaker) box through exible, armored or nonmetallic sheathed copper cable.

Allow some slack in the cable so the appliance can be moved if servicing is

ever necessary.

7. A UL listed or CSA approved conduit connector must be provided

at each end of the power supply cable (at the range hood and at the

junction box).

8. When making the electrical connection, cut a 3.2 cm (1-1/4 in.) hole

in the wall. A hole cut through wood must be sanded until smooth.

A hole through metal must have a grommet.

9. When cutting or drilling into the wall or ceiling, do not damage

electrical wiring and other hidden utilities.

10. Wire sizes must conform to the requirements of the National

Electrical Code ANSI/NFPA 70 - latest edition*, or CSA Standards

C22.1-94, Canadian Electrical Code Part 1 and C22.2 No. 0-M91 -

latest edition** and all local codes and ordinances.

11. Connect three wires according to colour (Black to Black, White to

9

White, and Green to Yellow/Green) to house wires and cap with wire

connectors.

WARNING

ELECTRICAL SHOCK HAZARD

Do not perform service on an electrically live system. Disconnect the main

electrical supply before servicing this device. Touching electrical connectors or

other exposed electrical circuitry inside this range hood when they are energized

could result in death, serious bodily injury, or property damage.

White (N)

Black (L)

Yellow/Green

(G)

BLACK ( Live )

WHITE ( Neutral )

GREEN/YELLOW/GREEN ( Ground )

* National Fire Protection Association Batterymarch Park Quincy, Massachusetts 02269

** CSA International, 178 Rexdale Boulevard, Toronto, Ontario, CANADA, M9W 1R3

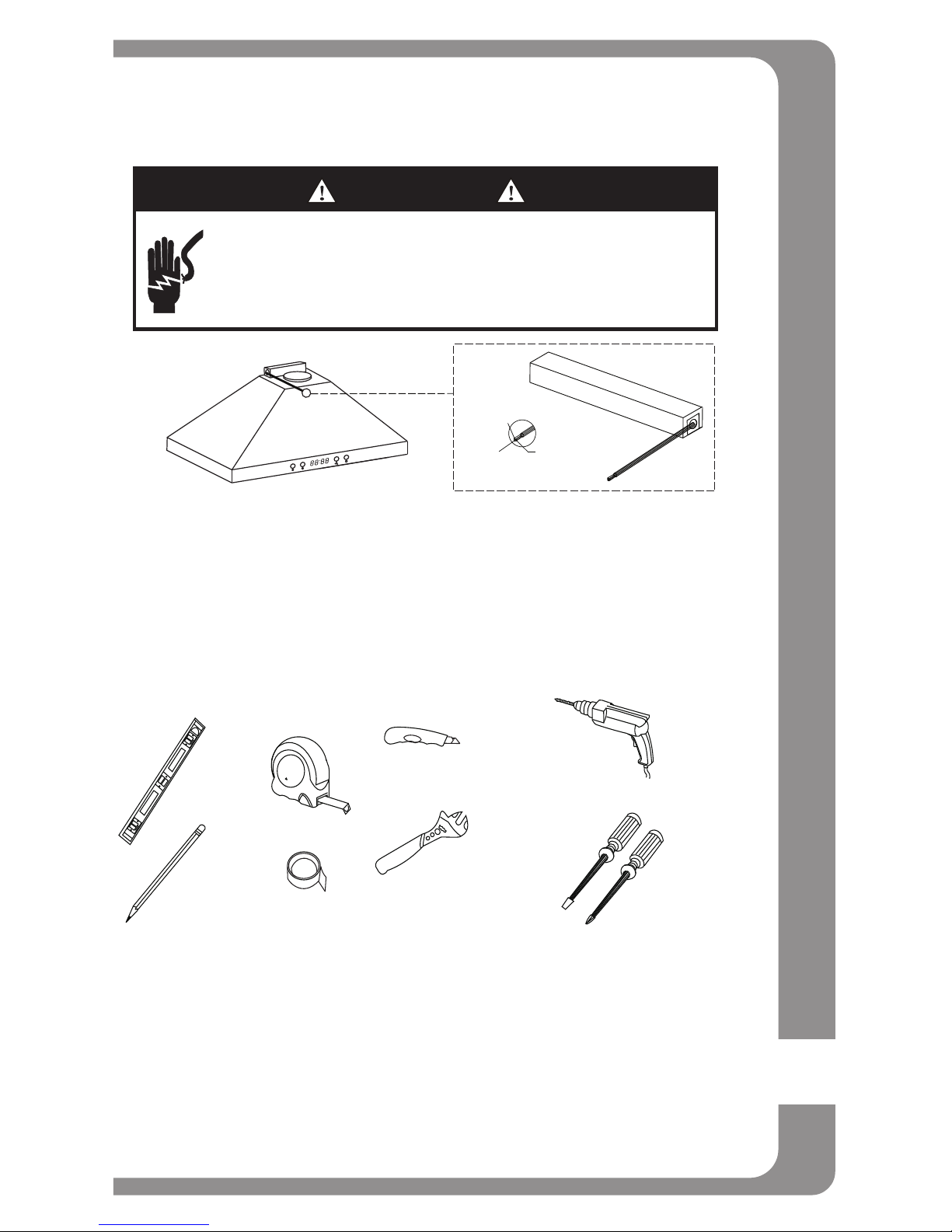

d. lisT of MaTerials

TOOLS FOR INSTALLATION:

marker or

pencil

measuring tape

level

powered

screwdriver

or drill

utility knife

Philips

screwdrivers

flat-blade

screwdrivers

tape

adjustable

wrench

Notice:

1. Remove the range hood from the carton packaging and place on a

at surface for assembly.

2. Check carefully to ensure there are no missing parts or mounting hardware.

3. DO NOT REMOVE THE PLASTIC COVERING ON THE DUCT COVERS AT

THIS TIME as it protects the duct covers from scratches during installation.

10

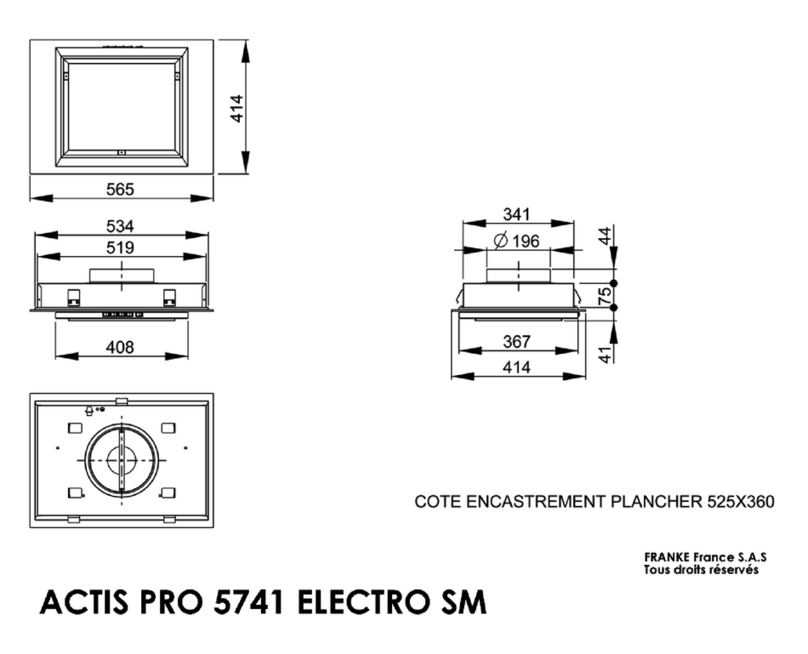

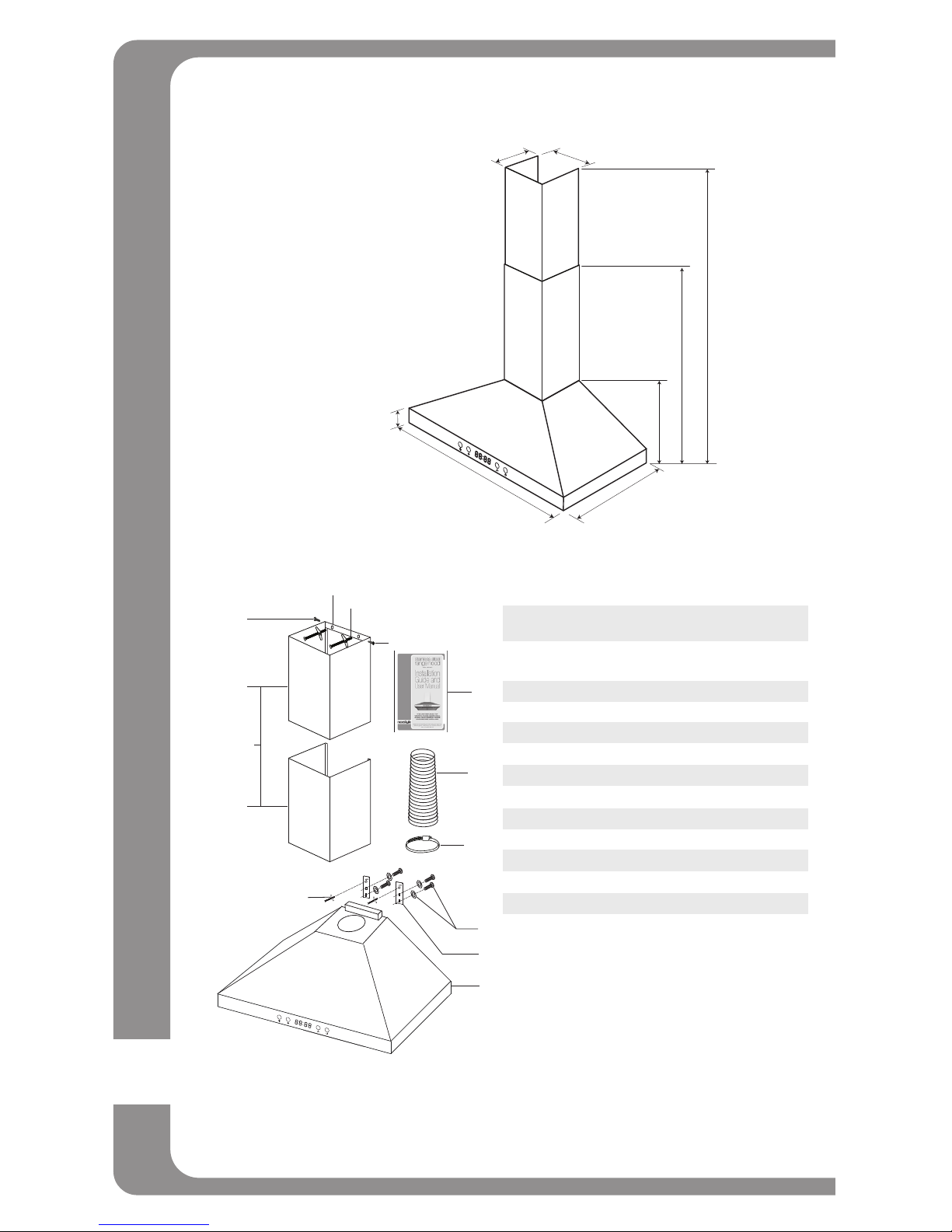

DIMENSIONS

750 mm

(29.5 in)

222 mm

(8.7 in)

220 mm

(8.7 in)

500 mm

(19.7 in)

50 mm (2 in)

260 mm

(10.2 in)

860 mm

(33.9 in)

1460 mm

(57.5 in)

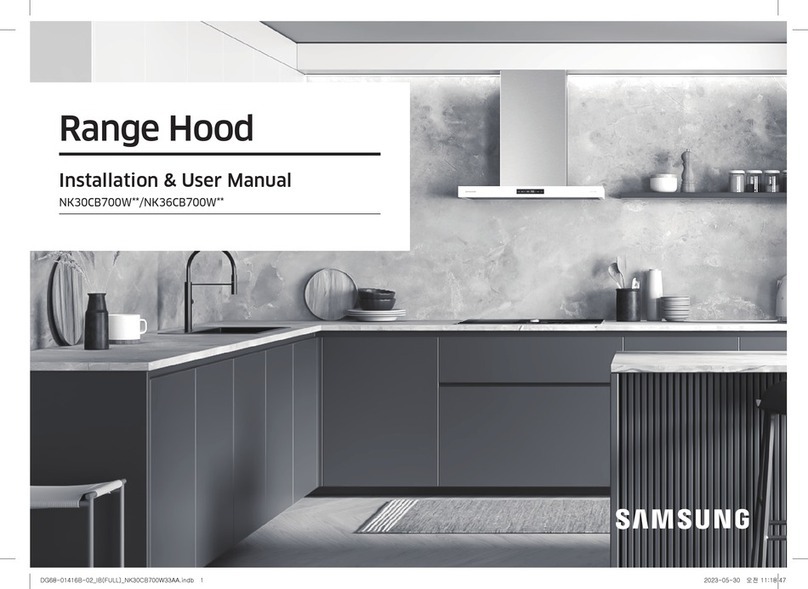

PARTS

7

7

2a

2

2b

3

12

11

6

Part Qty Product Components

1 1 Hood body, complete with: controls, lights,

blower, filters, damper

2 1 set Telescopic Chimney

2a 1 Upper Chimney

2b 1 Lower Chimney

3 1 Aluminum Exhaust Duct

5 2 Hood brackets

6 1 Chimney support bracket

7 2 M4 x 8mm Tapping Screws

9 4 Toggle Bolts

10 4 M5 x 16mm Screw/Washer

11 1 Duct Clamp

12 1 Instruction Manual

9

1

5

10

11

Parts Bag

Aluminum

Exhaust Duct

Hood Body x 1 Installation

Guide x 1

M4 x 8mm

Tapping Screws

x 2

Duct Clamp

x 1

Toggle Bolts

x 4

M5 x 16mm

Screw/Washer

x 4 Sets

Hood

Brackets

x 2

Chimney Support

Bracket x 1

Duct Cover

x 1 set

WARNING

* Proper installation is your responsibility - Have a qualified technician install this range hood.

* Read the entire installation guide and user manual thoroughly, and understand instructions and warnings.

* PERSONAL INJURY HAZARD - Because of the weight and size of the range hood, two or more people

are needed to move and safely install the range hood. Failure to properly lift range hood could result in

damage to the product or personal injury.

* All openings in ceiling and wall where range hood will be installed must be sealed.

* Range hood location should be away from strong draft areas (windows, doors and strong heating vents).

* SEVERE INJURY - Rotating fan can cause severe injury. Stay clear of fan when motor is running.

* SEVERE INJURY - Range hood may have very sharp edges. Please wear protective gloves to remove

any parts for installing, cleaning or servicing.

NOTE:

• Before making cuts, make sure there is proper clearance within the ceiling or

wall for exhaust vent.

• Check your ceiling height and the hood height maximum before you select and

install your hood.

• The hood should be installed between 46 cm (18 in) and 75 cm (29.5 in) above

the counter top.

• Toggle bolts are provided to secure the hood to most wall types. However,

a qualied technician must verify suitability of the bolts, screws and drywall

anchors with your wall type.

• Put a thick, protective covering over your counter top, cook top or range to

protect from damage and dirt. Remove any hazardous objects around the area

when installing.

• Due to the size and weight of this range hood, the supports must be rmly

attached to the wall.

• For plaster or sheet rock walls, the support must be attached to the studs.

If this is not possible, a support structure must be built behind the plaster or

sheet rock. The manufacturer assumes no responsibility for injury or damage

caused by improper installation.

12

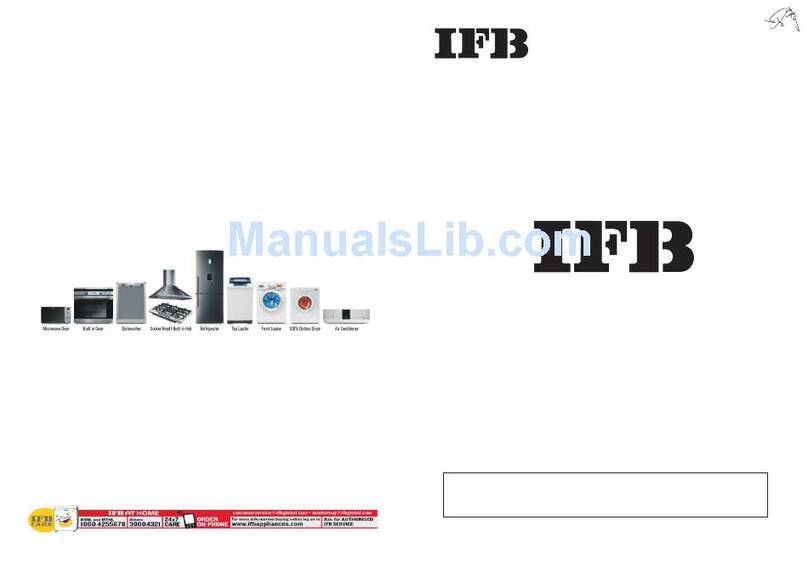

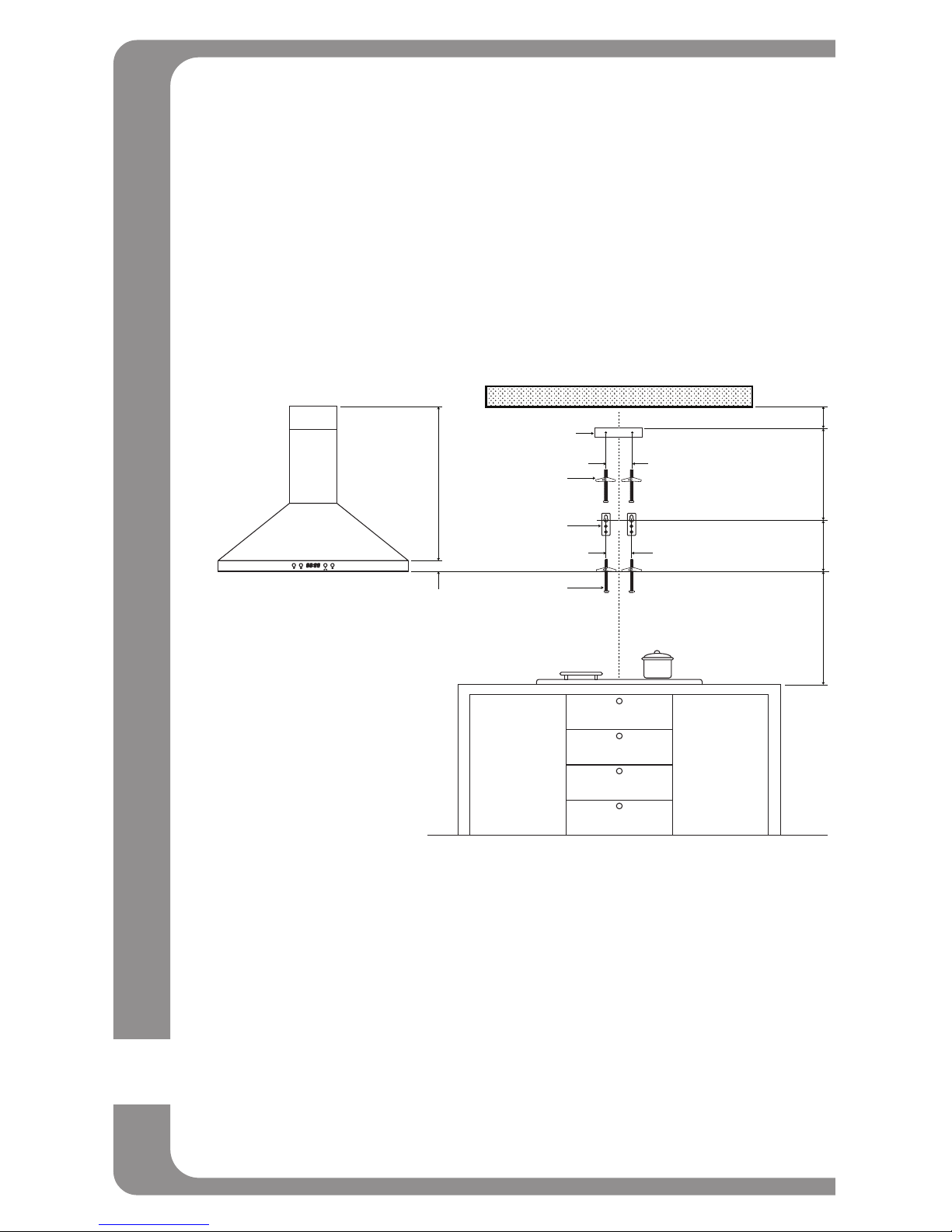

e. insTallaTion

NOTE: Carefully remove the plastic protective lm from all exterior sur-

faces of the hood and chimney prior to nal installation.

NOTE: At least two people will be required to mount the hood.

WALL DRILLING AND BRACKET INSTALLATION

1. Draw a vertical line on the supporting wall up to the ceiling, or as

high as practical, at the centre of the area in which the hood will be

installed.

5 cm

(2 in)

Part # 6

Part # 5

Part # 9

18.6 cm

(7.3 in)

13.6 cm

(5.36 in)

Min. 2 cm (0.8 in)

28.4 cm

(11.2 in)

46-75 cm

(18 - 29.5 in)

YX

Part # 9

2. Draw a horizontal line at 46 cm (18 in) above an electric stove or 75

cm (29.5 in) above a gas stove.

3. Place chimney support bracket (Part# 6) on the wall as shown about

2 cm (0.8 in) from the ceiling or upper limit aligning the centre (notch)

with the vertical reference line.

4. Mark the wall at the centre of the holes in the bracket.

5. Place the hood brackets (Part# 5) on the wall as shown aligning the

center notches to the vertical reference line.

6. Mark the wall at the center of the holes in the bracket.

13

7. Drill pilot holes at the center points of the top bracket (Part #6) and

the center points of the 2 hood brackets (Part #5).

8. Screw the 4 toggle bolts (Part #9) into wall leaving the head of the

bolts approximately 6.4 mm (0.25 in) away from the wall surface.

WALL

6.4 mm

(0.25 in)

WARNING

Because of the weight and size of the range hood,

two or more people are needed to move and safely

install the range hood. Failure to properly lift range

hood could result in damage to the product or

personal injury. Hood may have very sharp edges.

Please wear protective gloves if it is necessary to

remove any parts for installation.

PERSONAL INJURY HAZARD

MOUNTING THE HOOD BRACKETS

1. Attach the 2 hood brackets (Part #5) to the back of the hood body

with 4 screws and washers (Part #10).

Part# 1

Part# 5

Part# 10

DAMPER INSTALLATION

The dampers are installed at the factory. If they have come loose dur-

ing shipping, the following is how to replace them. Caution: Edges are

sharp. Wear safety gloves. Insert one end of the damper into the hinge

slot at the top of the hood body. Gently bend the damper and carefully

insert the second end of the damper into the hinge slot. Be very careful

when installing the dampers. Applying to much force or not bending the

damper enough may damage or break the damper hinge ends.

14

ATTACHING ALUMINUM DUCT

1. Place the aluminium duct clamp through one end of the aluminum

duct and slide it down over the damper assembly.

2. Tighten the screw on the duct clamp until tight.

3. Seal all joints with duct tape

CAUTION

This edge is sharp.

Wear safety gloves

ATTACHING HOOD BODY TO WALL

1. CAUTION: At least 2 people are required to lift and install this

range hood. Lift the hood body (Part #1) into position engaging

the 2 brackets (Part #5) with the 2 lower toggle bolts (Part #9).

CAUTION: Make sure the range hood is securely fastened to the

wall before releasing.

2.

Connect the duct to the exterior exhaust system. Make sure all joints are

secure and airtight. Use duct tape to make all joints secure and airtight.

3. Remove the plastic covering on the chimney extensions (duct

covers). Be very careful of sharp edges on the chimneys. Wear

protective gloves while installing duct cover to prevent personal injury

and prevent scratches on cover during installation

4. Place the chimney extensions on the oor, then lower the upper

chimney into the lower chimney. You should now have both chimney

extensions together as one unit.

upper

chimney upper

chimney

lower

chimney

lower

chimney

15

5. Place the chimney onto the hood body, ensuring it ts into the gap

on the top of hood body.

6.

Slide the chimney extensions upward and secure the upper chimney to

the chimney support bracket using two 4 mm x 8 mm tapping screws.

CAUTION: Minimize movement of the chimney extensions to avoid

scratches.

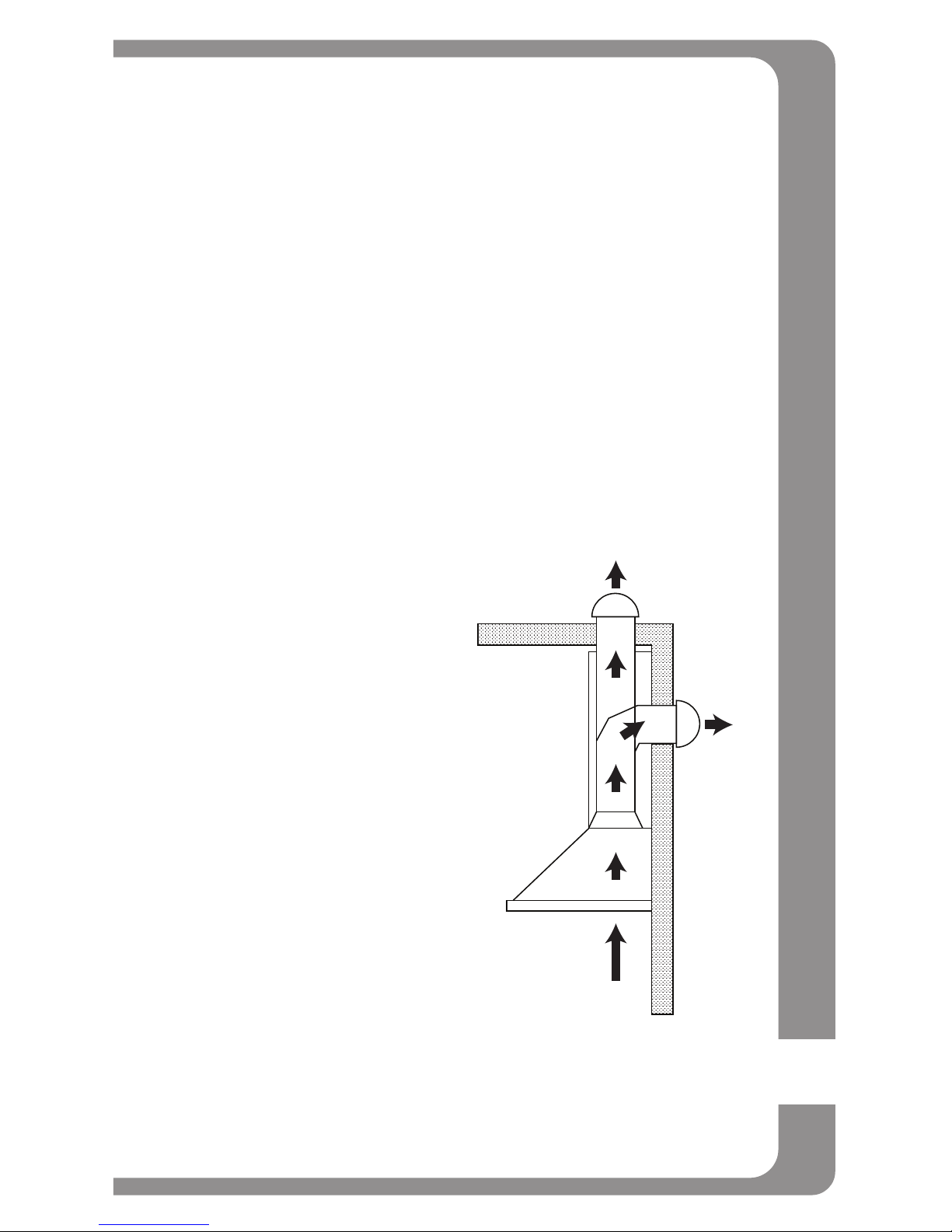

EXHAUST VENTING

Ducted mode air exhaust system

Caution: To reduce the risk of re, use metal duct work only.

1. Decide where the duct work will run

between the hood and the outside.

2.

A straight, short duct run will allow the

hood to perform most efciently.

3. Long duct runs, elbows, and

transitions will reduce the performance

of the hood. Use as few of them

as possible. Larger ducting may be

required for best performance with

longer duct runs.

4.

Attach an adequate length of 15 cm

round duct to the air outlet adapter

(Not supplied).

5. The air must not be discharge into a

ue that is used for exhausting fumes

from appliances burning gas or other

fuels. Follow all regulations concerning

the discharge of air.

6. Install a roof/wall cap. Connect round

metal duct work to cap and work back

towards hood location. Use duct tape

to seal the joints between duct work

sections.

16

ELECTRICAL CONNECTION

Electrical wiring must be done by a qualied person(s) in accordance

with all applicable electrical and building codes. Turn off electrical power

at the power source before wiring.

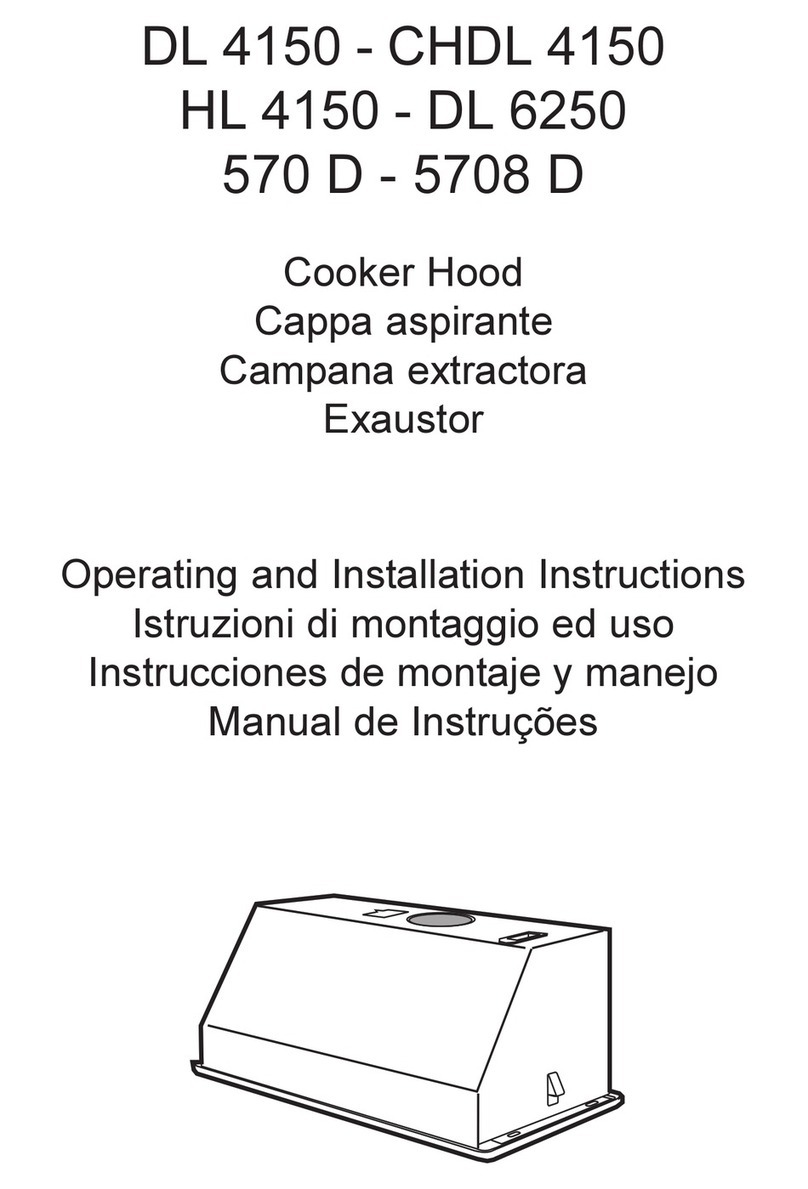

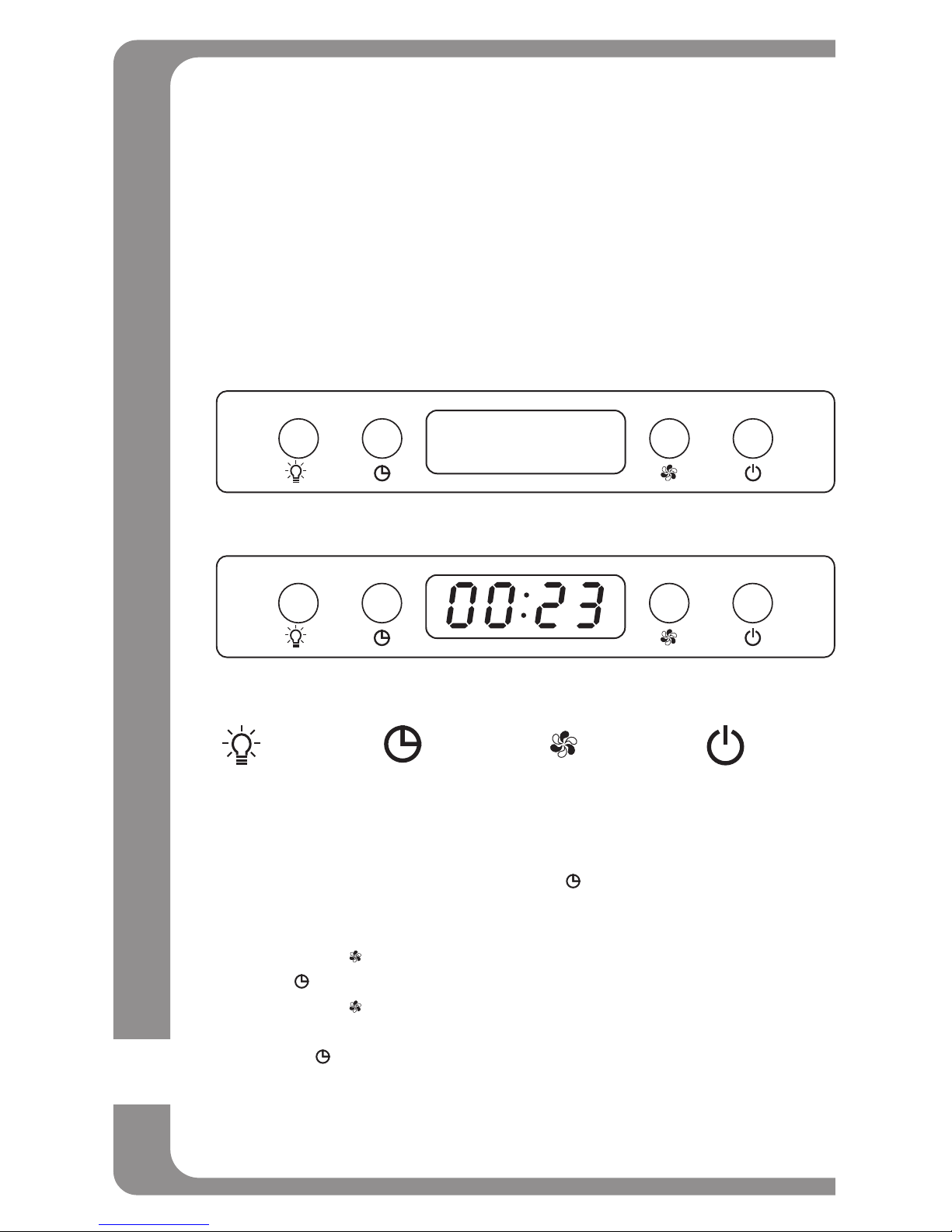

CONTROL PANEL

The LED screen and switches appear and function as shown below.

Please refer to specic function instructions for information on how to

use the range hood’s various features.

In stand-by mode

In use

LIGHT CLOCK SPEED ON/OFF

24 HOUR CLOCK SETTING

1. When the range hood is plugged in for the rst time, the entire

screen will ash for 2 seconds, then only the clock (00:00) will ash.

2. To set the time, press and hold the “ ” for more than 2 seconds

until the rst set of 00’s start to ash.

(00:00 = Hour : Minute, it is 24 hour setting)

3. Press the “ ” to change the hour. Once the hour is correct, press

the “ ” and the second set of 00’s will ash.

4. Press the “ ” until the desired minutes appear. This is a 24 hour

clock where 00:00 = Hour : Minutes.

5. Press “ ” again to conrm the time setting. If during the setup

process no button is pressed for more than 5 seconds, the clock

will revert to the previous time setting.

17

FAN OPERATION

1. Press the “ ” to start the blower. The blower will start on the high

speed setting.

2. Press the “ ” again to turn the fan to low speed.

3. Press the “ ” twice to turn off the range hood fan. This will not turn

off the light, if the lights is on, press the “ ” once.

DELAY SHUT-OFF

1. With the fans running, press the “ ” once.

2. Set the delay time using the same procedure as setting the clock.

3. Once the correct delay time is set, press the “ ” to commence the

timer count down.

4. When the timer reaches 00:00, the blower will stop and the system

will beep 1 time.

5. To cancel the delay shut-off during count down, press the “ ”

once.

NOTE: The delay shut-off will only turn off the blower. If the lights are

on they will remain on after the timer reaches 00:00 and the fan shuts

down. The fan MUST be running to start the delay shut-off feature.

LIGHT “ ”

1. When the light is off, press the “ ” briey to turn on the lights.

2. When the light is on, press the “ ” briey to turn off the lights.

MainTenance

Prior to any maintenance operation ensure that the range hood is discon-

nected from the power supply.

Cleaning Exterior Surfaces:

- The range hood should be cleaned regularly internally and externally.

- Clean periodically with hot soapy water and clean cotton cloth. Do not

use corrosive or abrasive detergent (e.g. Comet Power Scrub , EASY-

OFF oven cleaner), or steel wool/scoring pads, which will scratch and

damage the stainless steel surface.

- For heavier dirt use a liquid degreaser.

- After cleaning, you may use a non-abrasive stainless steel polish/

cleaner to polish and buff out the stainless luster and grain. Always

rub lightly with a clean cotton cloth, and go with the grain.

18

Cleaning Aluminum Grease Filter/Stainless Steel Filter-less Grill:

- The metal lters tted by the factory are intended to lter out residue

and grease from cooking. It need not be replaced on a regular basis

but must be kept clean.

- This must be cleaned once a month using non-abrasive detergents,

either by hand or in the dishwasher, which must be set at a low

temperature on a short cycle.

- When washed in a dishwasher, the grease lter may discolour

slightly, but this does not affect its ltering ability.

- Dry lters and re-install before using hood.

WARNING: FAILURE TO CARRY OUT THE BASIC STANDARDS

OF CLEANING OF THE RANGE HOOD AND REPLACEMENT

OF THE FILTERS MAY CAUSE FIRE RISKS. WE THEREFORE

RECOMMEND THAT YOU FOLLOW THESE INSTRUCTIONS.

Replacing Filters:

- Should lters wear out due to age or prolonged use, replace with an

aluminum grease lter (with stainless steel clips).

- Note: Also replace a damaged lter that has punctures or a bent or

broken frame.

19

REPLACING LIGHT BULBS:

WARNING: DISCONNECT RANGE HOOD FROM ELECTRICAL

SOURCE AND BE SURE LIGHTS ARE COOL.

WARNING

BURN HAZARD

Light bulbs can become extremely hot when turned on. DO NOT touch bulb until switched off and cooled.

Touching hot bulbs could cause serious burns.

SEVERE INJURY

Rotating blower fan can cause severe injury. Stay clear of fan when motor is running.

Should the light bulb burn out due to age or prolonged use, replace

with MAX. 35W/JDR 16, GU10 twist and lock base lamps.

If new lights do not operate, make sure the light bulb is inserted correctly.

1. Turn off the range hood.

2. Ensure the lights are cool to the touch.

3. Turn bulb anti-clockwise to remove.

4. Install a new GU10 twist and lock base lamp (MAX. 35W/JDR 16)

and turn clockwise to install the light bulb. Do not release the bulb

until you are sure the bulb has been securely installed.

Rotate clockwise

and push in to install

Rotate anti-clockwise

and pull out to remove

20

TroubleshooTing

1. If the range hood does not operate after installation:

- Check if all power has been turned back on and all electrical wiring

is properly connected.

- Check that the power connection for the unit is properly connected.

- Make sure the wiring between the switch board and control board

are connected properly.

2. The range hood vibrates when the blower is on:

- The range hood might not have been secured properly to the wall.

- Check if the motor is secured in place. If not, then tighten the motor

in place.

- Check if there is a damaged blower wheel. If so, change the blower

wheel.

3. The blowers seems weak:

- Check that the duct size used is at least 15.2 cm (6 in.). Range

hood WILL NOT function efciently with insufcient duct size.

- Check if duct is clogged or if damper unit is not opening properly. A

tight mesh on a side wall cap unit might also restrict air ow.

4. The lights work but the blower is not spinning, is stuck or is

rattling:

- The blower might be jammed or scraping the bottom.

- The motor is defective, possibly seized - change the motor.

- The thermal protection system detects if the motor is too hot to

operate and shuts the motor down. In this case the motor will

function properly after the thermal protection system cools down

(approx. 20 min.).

5. The hood is not venting properly:

- Make sure the distance between the cook top and the bottom of

the hood is between 46 cm (18 in) for electric ranges and 75 cm

(29.5 in) for gas ranges.

- Reduce the number of elbows and length of duct work. Check if

all joints are properly connected, sealed and taped.

- Make sure the power is on high speed for heavy cooking.

- Wind from opened windows or doors in the surrounding area are

affecting the ventilation of the hood. Close all windows and doors

to eliminate the outside air ow.

- Check if the direction of duct opening is against the wind. If so,

adjust the direction of the duct opening.

- Check if the wrong size of ducts are being used.

Table of contents

Other nexstyle Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Maico

Maico ER 60 VZ 15 Mounting and operating instructions

Imperial Kitchen Ventilation

Imperial Kitchen Ventilation WH1900 Series Installation instructions & warranty information

TSI Instruments

TSI Instruments ALNOR LOFLO BALOMETER owner's manual

Amica

Amica OKC651S instruction manual

NEFF

NEFF D76E21N0GB installation instructions

FALMEC

FALMEC EXPLOIT Instruction booklet