NextWave Digital SHARK LCD User manual

SHARK®LCD Pendant Control

User’s Manual

®

2Shark HD 500 Series User’s Manual

Copyright 2020 Next Wave CNC - All Rights Reserved.

SHARK is the registered trademark of Next Wave CNC.

Ready2Control is copyrighted by Next Wave CNC.

Virtual Zero Unlimited is patented by Next Wave CNC.

All other trademarks are the property of their respective

owners. Information in this manual is subject to change

without notice.The most recent version of this manual can

be found at www.NextWaveCNC.com/downloads-links

Next Wave CNC, LLC,

600 W. Boundary St.,

Perrysburg, Ohio 43551 USA

(419) 318-4822

Please read this manual carefully. It provides

important setup and operational information for

your SHARK CNC and software. This manual

has been written with the assumption that you

are experienced with the basic operation of a

computer as well as the technical knowledge

required to safely operate power tools.

3

v.12/2020

Product Warranty ………………………………….………… 4

Safety ….….……………………….………….…………….… 4

System Requirements ……….………….…...…..……......... 5

Technical Support …….…………….……..….…………..…. 5

License and Registration information ……..….….………… 5

Pendant Parts and Connection…….….…....….………… 6

Registration process ……………..…………..….………… 8

Main Control Screen ……….…………..……..….………… 13

X and Y Axis Edit screens………….……..……….………… 15

Z and A Axis Edit screens……………..…..………………… 16

Setup Menu screen ……………….....….…..….…..……… 18

Setting Jog Speeds ……………..………..….…………… 19

LCD Brightness, LCD Beep Sound ………..…………… 20

Noisy Environment, Reverse Spindle Polarity ………… 21

Model number ……………..……………………………… 22

Display Metric ……………..……………….……………… 23

Safe Height ……………..….………………..…….……… 24

File Char Delay ……………..….…………………….…… 25

Apps Menu screen …………………………..…..….....…… 27

Touch Plate Calibration ..…………..……....….………… 28

Virtual Zero ………………………………....…….……… 30

Boundary Monitor and Center Finder ……….…..……… 47

Job Array ……………..……………………....…………… 48

Homing X & Y Axes ………………………….…………… 50

Digitizer ……………..….…………………..……………… 55

Laser…………..…………..…………………..…………… 57

4th Axis ……………..………………….….…..…………… 59

Factory Restore, Unregister LCD, Reset LCD ………… 60

About LCD, About Controller ……………..…..………… 60

LCD Maintenance and Firmware updates ……………… 62

Ready 2 Control panel ………….…………………………… 63

Table of Contents Page

4Shark HD 500 Series User’s Manual

This warranty does not apply to problems arising from normal wear

and tear, misuse, abuse, negligence, accidents, unauthorized repairs,

alterations, or lack of maintenance. This warranty is void if the SHARK

LCD Pendant or any portion of it is modified without the prior written

permission from Next Wave CNC, or if the machine is located or has

been used outside of the country where the machine was purchased.

Please contact Next Wave CNC to take advantage of this warranty. If

Next Wave CNC determines that your SHARK LCD Pendant is

defective in material or workmanship, Next Wave CNC will at its

expense and upon proof of purchase send replacement parts to the

original retail purchaser necessary to cure the defect. Next Wave

CNC will repair the SHARK LCD Pendant provided it is returned to

Next Wave CNC, shipping prepaid, with proof of purchase and within

the warranty period.

Next Wave CNC disclaims all other express or implied warranties,

including fitness for a particular purpose. Next Wave CNC shall not be

liable for death, injuries to persons or property, or incidental,

consequential, contingent or special damages arising from the use of

the SHARK LCD Pendant.

Warranty

Safety

Read and follow all safety instructions that appear in the

SHARK CNC Owner’s Manual that came with your machine.

Copies of current owner’s manuals can be downloaded at

www.NextWaveCNC.com/support

Next Wave CNC warrants your new

SHARK LCD Pendant to be free from

defects in material and workmanship for

TWO YEARS from the date of purchase.

The warranty applies only to the original

retail purchaser of the SHARK LCD

Pendant when purchased from an

authorized Next Wave CNC distributor.

This warranty covers the parts and labor to

correct the defect. It does not cover the cost

of shipping the machine and/or parts to

Next Wave CNC for evaluation or repair.

5

v.12/2020

LCD Pendant System Requirements

The LCD is compatible with all current SHARK HD and SD

series CNC machines as well as past machines that use a

control box with a Pendant cable input port. Some (but not all)

older machines that lack the Pendant input port can be

upgraded by switching to the new style Control Box that has

the Pendant input port. For information on upgrading an older

Next Wave CNC machine contact Customer Service at

Support@NextWaveCNC.com

Serial Number and Software License Information

For easy reference and record keeping, enter your SHARK

Pendant and Controller information below. To locate the

information see the pages listed below.

Controller Box Serial Number

(see page 60)_______________________________________

LCD Pendant Serial Number

(see page 60)_______________________________________

LCD Pendant Unlock Code

(see page 10)_______________________________________

Technical Support

If you need technical assistance with your SHARK LCD Pendant,

please visit our Support webpage at:

NextWaveCNC.com/support or email Customer Support at:

Support@NextWaveCNC.com. Please include your product

model number, date of purchase, and other pertinent information

associated with the issue such as .tap files, VCarve files, screen

captures, or photos of your setup or the problem.

Support Email: support@nextwaveCNC.com

Available: 9am –5 pm Monday-Friday (Eastern time).

6Shark HD 500 Series User’s Manual

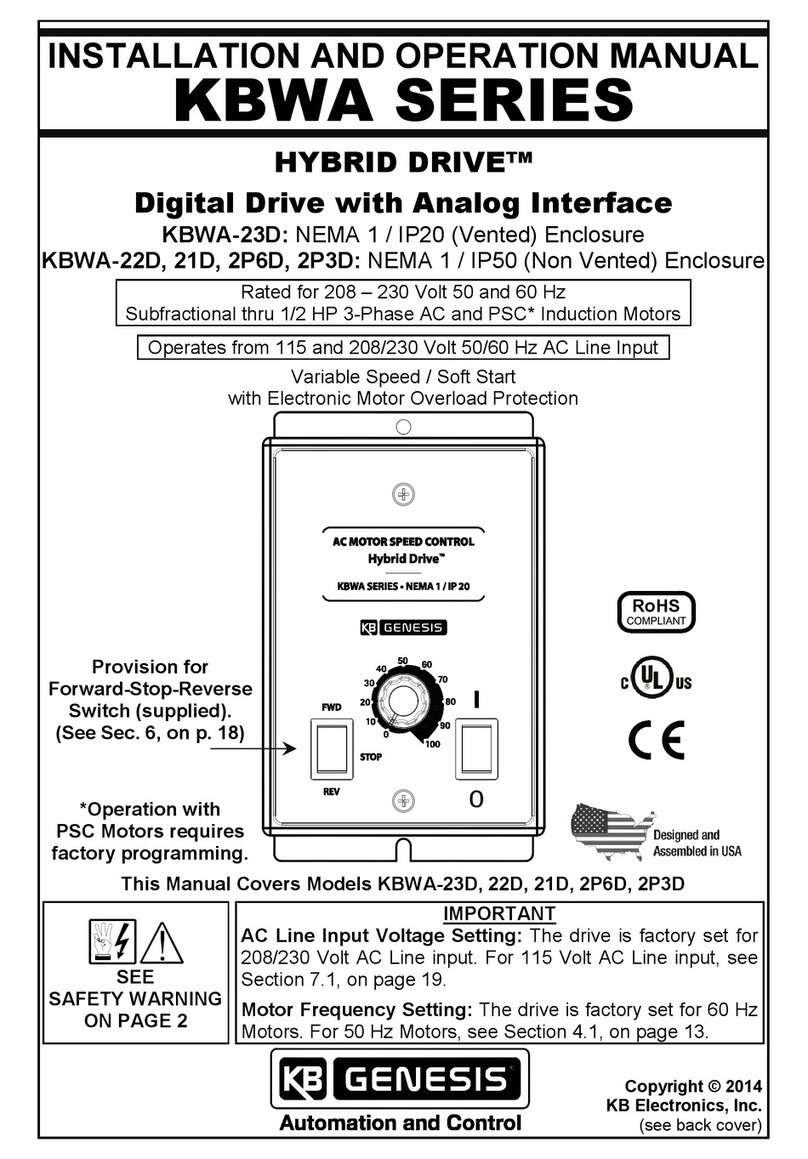

Basic parts

LCD touch screen

USB drive port

Special Pendant cable

Connects to

control box

Z Touch plate port

The touch screen buttons can be activated

using your fingertip, a pencil eraser or a

soft-tipped stylus (not included)

NOTE: The Pendant cable has a

special pin configuration. A

standard VGA cable can not be

substituted –it will not work.

7

v.12/2020

First attach the pendant cable between the Pendant and

the control box. Then plug power cord into a power

source. Using a switched power strip is highly

recommended. As well as providing surge protection for

your tool, it provides another method for shutting off the

machine in case of an emergency.

IMPORTANT –DO NOT plug in and turn on the

powerbeforeall the motor cables have been

attached. DO NOT attach or detach motor cables

when the control box is powered up as this can

damage the electronics and isnot covered by the

warranty.

Control Box

Pendant Cable Connection

8Shark HD 500 Series User’s Manual

Emergency Switch

Registering your SHARK HD CNC

Step 1

Power up your SHARK CNC control box.

•The HD machines two power switches on the control

box.

•The SD machines have only one power switch.

Step 2

Once you power up your SHARK CNC, an opening screen

appears on the pendant. Click Continue.

Main power Switch

IMPORTANT. Always turn off the power switch(s) when

connecting or disconnecting any of the cables. Failure to do so

can cause damage to electrical components and is not covered

by the warranty.

9

v.12/2020

Registration (cont.)

Step 4

Go to www.NextWaveCNC.com and click on the

Product Registration tab

XXXXX XXXXX

Controller Box

Serial Number

LCD

Pendant

Serial

Number

Step 3

The Registration screen appears next. It lists the serial numbers

for your LCD Pendant and Control Box. Record these numbers

on Page 5 of this manual.

10 Shark HD 500 Series User’s Manual

Step 5

Complete the Quick Unlock form, then click the Unlock your

CNC Machine button at the bottom of the form.

Registration (cont.)

Step 6

An Access Code appears on

your screen. This code will

also be sent to the email you

entered in the registration

form. Record your Unlock

(Access) Code on page 5 of

this manual.

4XXX0

XXXX2 XXXX2

Step 7

Use the number keys on the

Pendant to enter your Unlock

(Access) Code. Press

Submit. This unlocks the

Pendant.

4XXX0

11

v.12/2020

Step 9

The Main Screen appears at the end of calibration process.

Your SHARK LCD Pendant is now unlocked.

Registration (cont.)

Step 8

The Calibration Screen appears next. Follow the on-screen

directions to complete the calibration. Touch screen to

continue.

The Calibration Screen also appears after a firmware

updates. The screen can also be opened by holding your

finger on the screen while turning on the control box.

Contain dust and noise with a

SHARK machine encloser from Next Wave CNC.

Available from your local Next Wave CNC distributor

or online at www.NextWaveCNC.com

The SHARK CNC machine enclosure is designed to

help control dust, add safety and reduce machining

noise. The enclosure is made with an aluminum frame,

acrylic panels, and steel connectors. The hinged access

door with magnetic catch allows for easy material

removal or bit changes. There are pre-drilled 3” hole for

cords. The case to be placed on any flat surface. The

enclosure ships flat, assembly is required.

SHARK machine enclosure

13

v.12/2020

Main Control Screen

1

2

8

9

3456 7

10

11

1. Axis position fields –Shows the current location of axis.

Pressing one of these buttons to opens the Axis edit window

for that axis (see pages 15,16,17).

2. Axes Jog buttons –Press to jog an axis in the specified

direction. The jog speed can be change with the jog speed

toggle button (9).

3. Mv 0,0

•Short press / Single tap (Mv 0,0) - Moves the X and

Y axes to their zero positions.

•Long press / Double tap (Mv 0,0,0) –Moves the X, Y

and Z axes to their zero positions.

4. Zero xyz –Press to zero the XYZ axes. The axes position

fields (1) will all reset to 0.000.

5. Setup –Press to access the Setup submenu (see page 18).

6. Apps –Press to access the Apps submenu (see page 27).

7. USB –Glows blue when a USB drive is inserted into the

Pendant. Press to access the toolpath selection screen

(see page 38).

8. Refresh –Press this button if the numbers in the Position

fields freeze or appear inaccurate.

9. Slow (Med, Fast) –Press to toggle between jog speeds

(see page 19).

10. Wake –Press if LCD screen appears to freeze.

11. Plate –Press to start touchplate routine (see page 28)

14 Shark HD 500 Series User’s Manual

The Axis position fields show the current location of the

axis. Pressing a field button opens the edit window for that

axis.

Axes Position Fields

X and Y Position

fields See page 15 Z Position field

See page 16,17

This space intentionally left blank:

15

v.12/2020

X and Y Axis Edit screen

12

8

9

3

4

567

10 11

1. Active Axis –The label in upper left corner shows the axis

that is currently open for editing.

2. Position field –This field shows the current or edited

position of the axis. The field can be edited using the

keypad.

3. Exit screen–Press the X symbol in the upper right to exit

the edit screen and return to the main control screen.

4. Home –Pressing this button to move the axis to its current

zero position.

5. Set –After entering a new location in the position field,

press this button to apply (set) the new location. The

position also changes on the Main Control Screen.

6. Number keypad –Use these keys to enter a new location

in the position field.

7. C –Press to delete the information in the position field.

8. Location –Pressing this key to enter the current axis

location into the position field

9. MOVE –Press this button to move axis to the location

currently showing in the position field.

10. +/-button –Toggles the position field between a positive

and negative value.

11. Function keys –Similar to those on a typical math

calculator.

16 Shark HD 500 Series User’s Manual

Z-axis Edit screen

1

2

1. Active Axis –Toggles between Z and A with the use of the

“View” button (2)

2. View A –Press to toggle the Edit Screen and the Main

Control Screen to the A axis view. (see next page for info on

the A axis view).

The buttons on the Z edit screen function the same as on the X

and Y screens except as noted below.

This space intentionally left blank:

17

v.12/2020

A-axis Edit screen

1

2

3

1. Active Axis –Toggles between Z and A with the use of the

“View” button (2)

2. View Z –Press to toggle the Edit Screen and the Main

Control Screen to the Z axis view.

3. Position field – The A axis position field displays “degrees”

of rotation.

The other buttons function the same as those in the XYZ edit

screen.

The A-axis is used to set the rotational position on the Rotary

4th Axis accessory

4

4. A-axis controls also appear in the Main Control Screen.

The A-axis position field displays degrees of rotation.

18 Shark HD 500 Series User’s Manual

Setup Menu Screen

Press the Setup button to open the Setup submenu screen

(below).

See page 19

See page 20

See page 20

See page 21

See page 21

Scroll down arrow

See page 22

See page 23

See page 24

See page 25

The Setup submenu contains options for controlling how the

Pendant functions. Press a submenu item to open the settings

screen for that option. To return to the Main Control Screen,

press X Press in the upper right corner.

19

v.12/2020

Press on one of the Jog Speed menu items to open the jog

speed settings window. The current jog speed setting is shown

at the tope of the window. Press the current speed setting field

opens the keypad (shown below).

Jog Speed Settings

Current

Speed

setting

Maximum system speed

Use the keypad to change the Jog Speed setting. Press OK to

save the setting. Press Xto exit this window.

Exit button

NOTE: The maximum system jog speed is 200 inches/min.

20 Shark HD 500 Series User’s Manual

LCD Brightness

Press the Brightness setting to open the keypad. Use the

keypad to adjust the LCD Brightness. Press Xto exit the current

screen.

Beep Sound

Press the sound setting field at top right to open the keypad.

Use the keypad to adjust the volume of the Beep Sound. Press

Xto exit the current screen.

Table of contents

Popular Controllers manuals by other brands

Flycolor

Flycolor FlyDragon V4-80A WP user manual

American DJ

American DJ Light Copilot User instructions

Bartlett

Bartlett RTC 1000 manual

DIMLUX

DIMLUX MAXICONTROLLER user manual

Samson

Samson 2371-10 Mounting and operating instructions

Delta Electronics

Delta Electronics Programmable Logic Controller DVP04AD-H2 instruction sheet