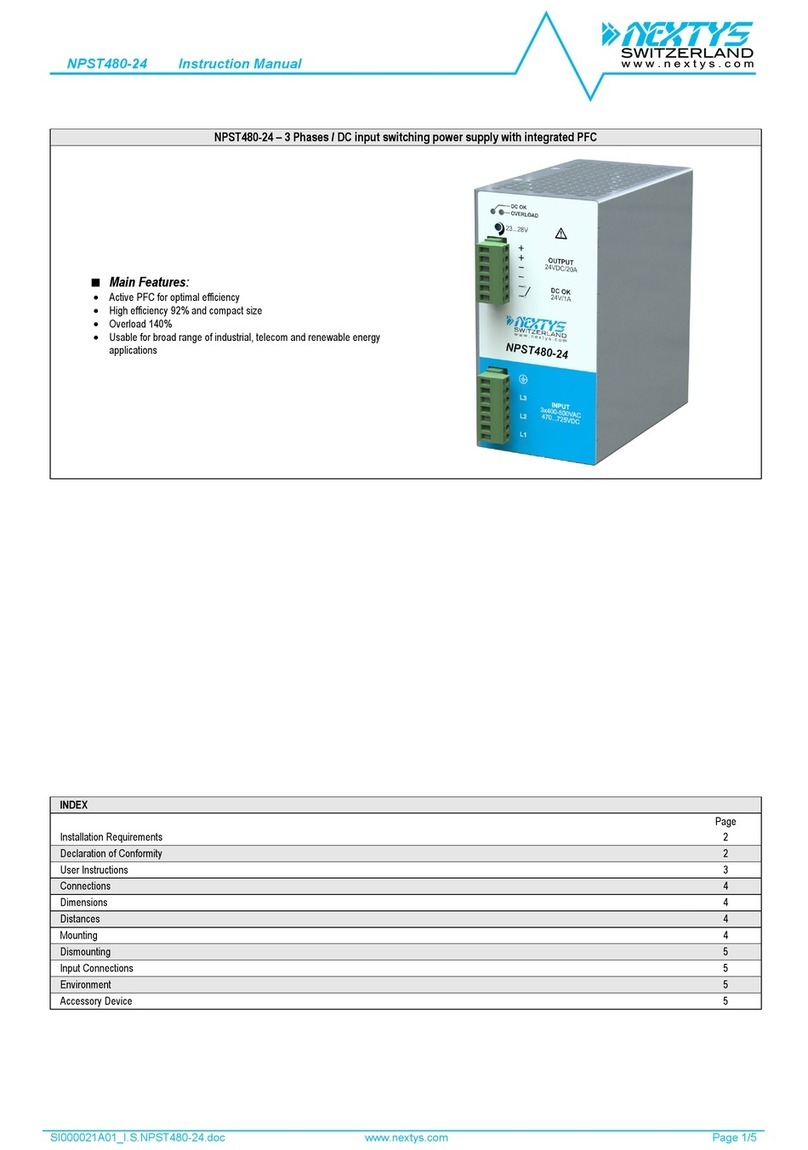

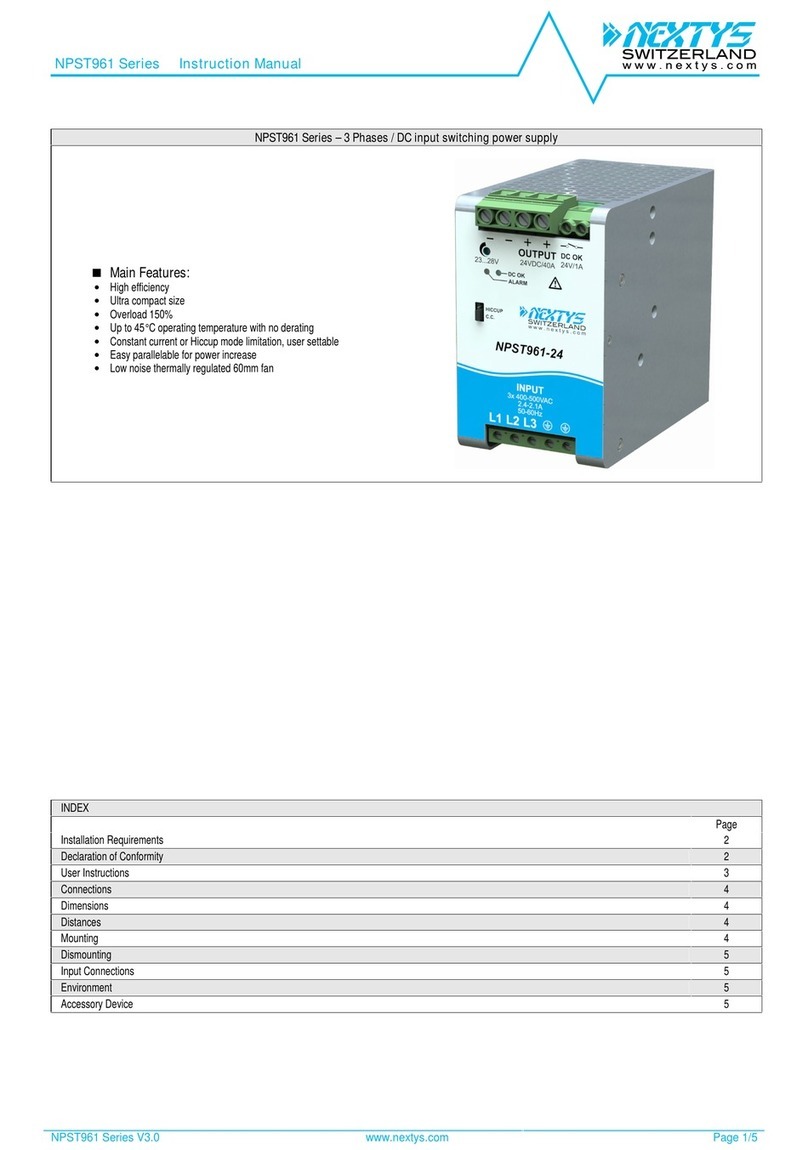

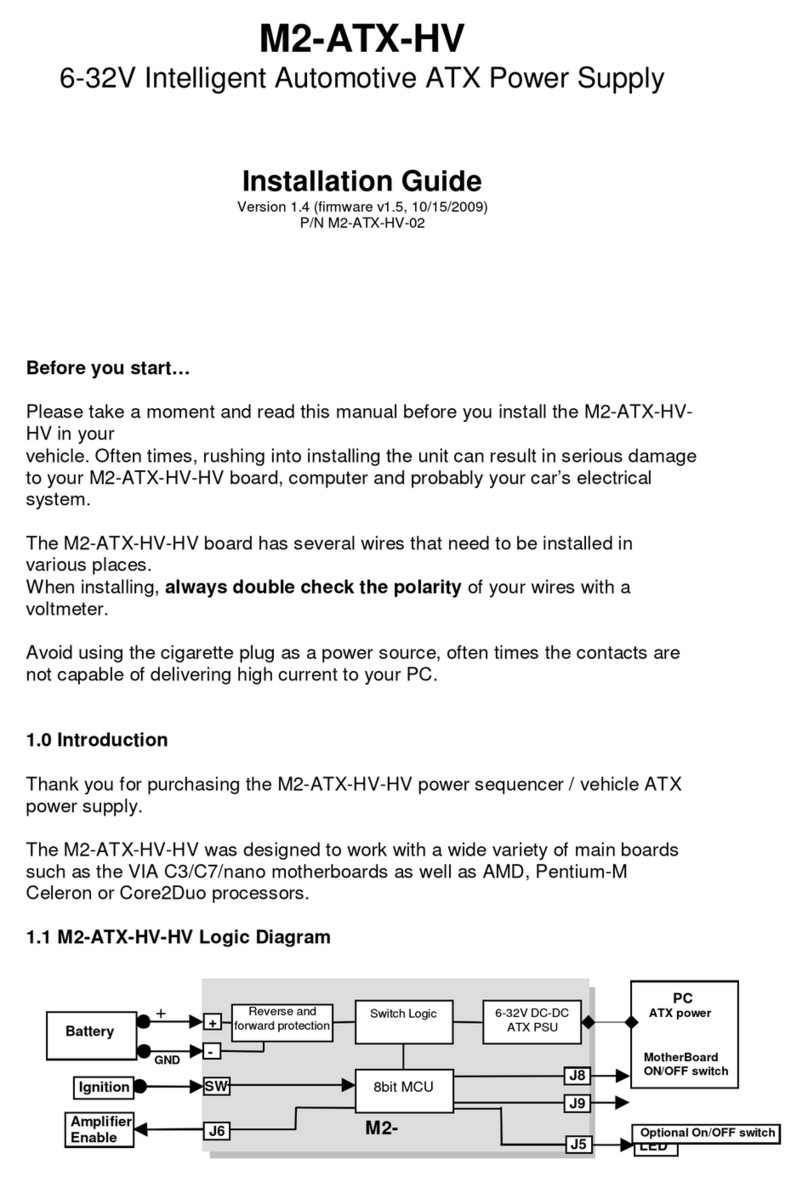

1) Description: DIN rail mountable primary switched-mode power supply with 90...264Vac (110…345Vdc) input, suitable for Single phase main line and DC line.

Functions:

Battery +: connection to batteryPLUS

Battery –: connection to battery MINUS

PS OK connector: connection to SPDT contact foroperating status/failure remote alarm (P.S. OK signal)

Load +/-: connection to load PLUS /MINUS

IN +/-: connection to power supply output PLUS /MINUS

Battery fuse: protects the battery and its cables against dangerous over currents. 15A Mini car Blade Fuse factory supplied is the max. allowed value, it

can be replaced witha lower value fuse for a better protection with small batteries.

Note: if the fuse blows and if the module isfed only by the battery and without any voltage connected to IN+, IN– terminals, all LEDs ofthe

module are turnedoff.

Charging circuitry: regulates and controlsbattery charging current. 2A or 4A charging current can be selected (see Fig.7).

It’s recommended to use 2A with battery capacity up to 20Ah and (if a faster charging time isnot required) and 4Acurrent with battery

capacity 20-45Ah max.

PS OK: green LED, when it lights indicates that power supply is OK and that it is feeding the load and keeping battery under charge too.

PS OK off: indicates either that the power supply is turned off for AC mains black-out, or is disconnected form the AC mains, or that its output is

overloaded and thus output is turned off for a short circuit - overload, or that the power supply failed.

LOAD OK: yellow LED, when it lights on indicates that the load receive power, either from the P.S. (PS OK LED On) or from battery (PS OK LED Off).

BATT. OK: green LED, with the power supply turned off or disconnected indicates that the battery is connected and charged.

Attention: with the power supply connected and active BATT. OK is always turned on even if thebattery is not connected.

BATT. LOW: red LED, indicates that the battery is charged, increasing current required by the load and/or increasing the battery discharge.

BATT. LOW LED lights on together with BATT OK, and its light intensity can vary depending on current required by the load, or blink if

loads are switched on / off, due tounavoidable battery voltage variations depending on applied load. When BATT. LOWLED is lit, itis

recommended to safely shut down the load, in order to avoid unexpected power loss.

Failure contact: at 1A/24V SPDT contact switches when the battery startsback-up feed of the load.The remote signal informsthat the system isno more

fed by the DC power supply e.g. fora fuse failure or fora power supply failure, thus giving awarning even if there isnot a general and

visible black-out but only a local failure.

NUPSxx restartafter a long duration black out with low battery. In such condition the module hasdisconnected the batteryfrom the load (to prevent total discharge and thus

battery damage). It can be started up only by feeding IN+, IN – with a 24Vdc source (e.g. the power supply or a battery). By connecting only the discharged battery to

BATT. +/- terminals the module cannotbe restarted. If the module isfeeding the load from the back-up battery and if a short circuit makes the batteryprotection fuse to

blow, the module can be re-started (after fuse replacement)only by first connecting a 24Vdc power source to IN+,IN – terminals.

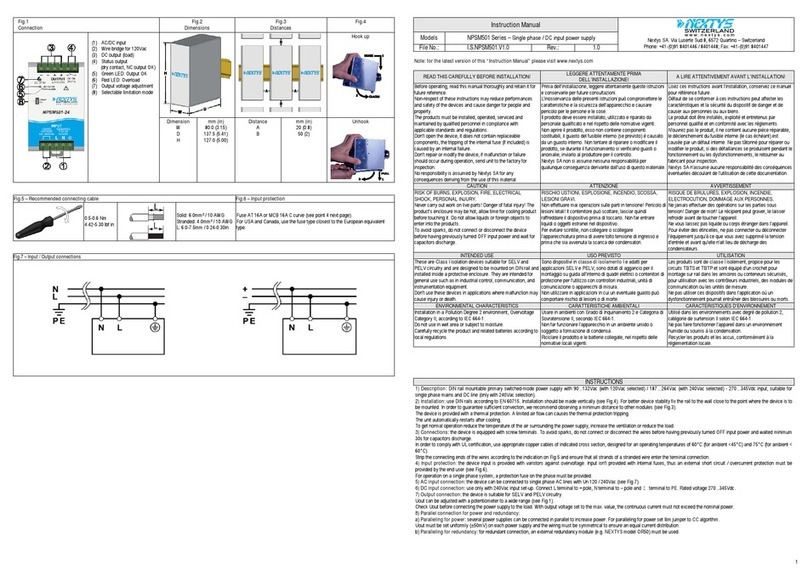

2) Installation: use DIN-rails according to EN60715. Installation should be made vertically (see Fig.4). Forbetter device stability fix the rail to the wall close to the point where

the device is to be mounted. Inorder to guarantee sufficient convection, we recommend observing a minimum distance to other modules (see Fig.3).

The device isprovided with a thermal protection; a limited air flow can cause the thermal protection tripping. The SMPSautomatically restartsafter cooling.

To get normal operation reduce the temperature ofthe air surrounding the power supply, increase the ventilation or reduce the load (see Fig.8)

3) Connections: the device is equipped with pluggable screw terminals. To avoid sparks, do not connect or disconnect the connectors before having previously turned-off input

power and waited for internal capacitorsdischarge (minimum1 minute).

In order to complywith UL certification, use appropriate copper cables of indicated crosssection, designed for an operating temperaturesof:

60°C for ambient up to 45°C

75°C for ambient up to 60°C

90°C for ambient up to 70°C

Strip the connecting ends of the wiresaccording to the indication and ensure that all strands of a stranded wire enter the terminal connection (see Fig.5)

4) Battery protection: protects the battery and its cables against dangerous over currents. 15A Mini car Blade Fuse factory supplied is the max. allowed value, it can be

replaced with a lower value fuse for abetter protection with small batteries (see Fig.6)

5) DC input connection: connect L terminal to (+) positive pole, N terminal to (-) negative pole and Iterminal toGND. Rated voltage 110...345Vdc.

The device isalso suitable for photovoltaic or wind turbine applications (seeFig.7).

6) Output connection: The device issuitable for SELV and PELV circuitry.

Check Uout before connecting the NUPSxx to the load. With output voltage set to the max. value, the continuous current must not exceed the nominal current 10A max.

7) Protection: the device is protected against

REVERSE battery connection: a red LED indicates that battery is connected with reversed polarity.

Protection diode: it avoids the voltage and current supplied by the battery to circulate through the power supply output circuitry and preventsfailures due to reverse

polarity connection.

Deep discharge battery protection circuit: this circuit disconnects the battery when its voltage drops under DDV voltage, to avoid battery damage.

8) GENERAL INFORMATION ON BATTERIES

Rated voltage: is the voltage thatthe battery can supplyin condition of full charge and rated current. Battery voltage without load is always higher of rated voltage.

Capacity: given inAh (Ampere / hour) measured at 25°C/ 77°F. (e.g. at 10Ah battery can supply 10Afor 1 hour or 1A for 10 hours).

Charging current: isthe current to be applied to charge the battery, usually indicated bythe manufacturer. A charging current higher than specified can damage the battery or

shorten its life, a too low charging current resultsin a too long charging timeand uncompleted or partial charge, thusreduced Ah capacity.

Charging current of sealed lead batteries would never exceed 20% of capacity of the battery. The battery limits by itself the charging current supplied by the battery charger,

depending on its charge status. Only when the battery is completely discharged it’s possible to apply the maximum charging current.

Note: when choosing the capacity of the battery, consider that real capacity indicated by manufacturers can vary compared with rated capacity depending quality and cost,

capacity is always given for new battery at 25°C/77°F, but during battery life it’s capacity decreases due to ageing, even if the battery is not used, so calculate battery capacity

and duration considering the worstoperating conditions.

Discharge voltage: the right charging voltage value is given by the manufacturer; generally the voltage/current source must be capable to supply a voltage 10-15% higher than

rated voltage of the battery. If charging voltage is lower than +10% of battery rated voltage, charging time increases and produce an uncompleted charge and thus a reduced

capacity. Charging voltages higher than +20% of rated voltage can damage the battery and shortens its life.

Charging time: variesaccording to charging current/voltage. Consider a minimumcharging time of 3-4 hours after abattery discharge.

Discharged battery: a battery is considered discharged when its voltage, measured applying a 50% load, is lower than -10% of rated voltage, or when voltage measured with

no load is lower than rated voltage.

Total discharge: when a batterygives a voltage between 0 - 60% of rated voltage, it’stotally discharged. Total or deep discharge reducesbattery life and mustbe avoided.

Disconnect the batteryfrom the load when voltage is lower than e.g. 18V/9V inat 24V/12V battery.

Operating temperature: for a long duration of the battery operating temperature must be kept within 10°C/+50°F…30°C/+ 86°F. Battery duration decreases outside this

range. At low temperatures the battery might not supply rated Ah, because electrochemical reaction are less efficient.

Overload–short circuit battery protection: battery and its connecting cables must be protected with overcurrent protection devices (fuses, circuit breakers, etc.) able to cut-

off dangerous currents.