Nexxt Solutions Professional Series User manual

ProfessionalSeries

Fully assembled

dual hinged wallmount enclosure

NPC-P12U65B

NPC-P15U65B

NPC-P18U65B

NPC-P6U65B

NPC-P9U65B

User manual

Warning: the wall structure must be capable of supporting the total weight, which

includes the cabinet plus its maximum static load. Otherwise, the wall structure must be

reinforced.

Caution: this product is heavy, at least two qualified people should perform the

assembly procedure. Personal injury and/or property damage can result from dropping

or mishandling the enclosure.

Do not exceed the recommended load capacity per rack, and the maximum weight

supported by the enclosure, as indicated by the manufacturer’s specifications. Failure

to comply will void the warranty of this product.

For safety, use proper equipment and tools during the assembly to prevent personal

injury and to avoid damaging its parts.

FALLING EQUIPMENT HAZARD: ensure that the cabinet is properly anchored to the

wall prior to loading equipment inside.

Carefully read and follow the safety

instructions included in this manual before

assembling and using the cabinet.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN LEAD TO

SERIOUS INJURY, DEATH, OR DAMAGE TO YOUR EQUIPMENT

IMPORTANT SAFETY INFORMATION

Main features

• No assembly required, the system ships ready to mount to a wall

• Hinged cabinet opens away from the wall for ease of equipment Installation

• Accessibility from both the front and rear for simplified diagnostic, maintenance and

service of devices housed inside the enclosure

• Pivoting frame with locking mechanism swings out 180 degrees

• Features a fully welded frame construction reinforced with heavy gauge steel, specially

designed to support heavy equipment

• 132lb (60kg) maximum static load capacity and 66lb (30kg) maximum dynamic load

capacity

Caution: for dynamic weight applications, do not open the door if the cabinet load

rating is equivalent to or greater than 132lb (60kg)

• Toolless, reversible glass door installation

• Solid and removable side panels

• Standard square-punched mounting rails for faster equipment loading

• The front door can turn 180 degrees

• U-rack units are numbered front and back for easy equipment installation

• Finished surface to prevent damage caused by rust and other external factors

• High-grade, cold-rolled steel structure with a 5-year warranty

For support and to find out more about our complete line of products and solutions,

we invite you to visit us at nexxtsolutions.com.

ELECTRICAL

SHOCK

HAZARD.

DANGER All parts of the unit must be properly grounded to the frame

of the enclosure and connected to the Common Bonding

Network (CBN) of your facility.

1. Introduction

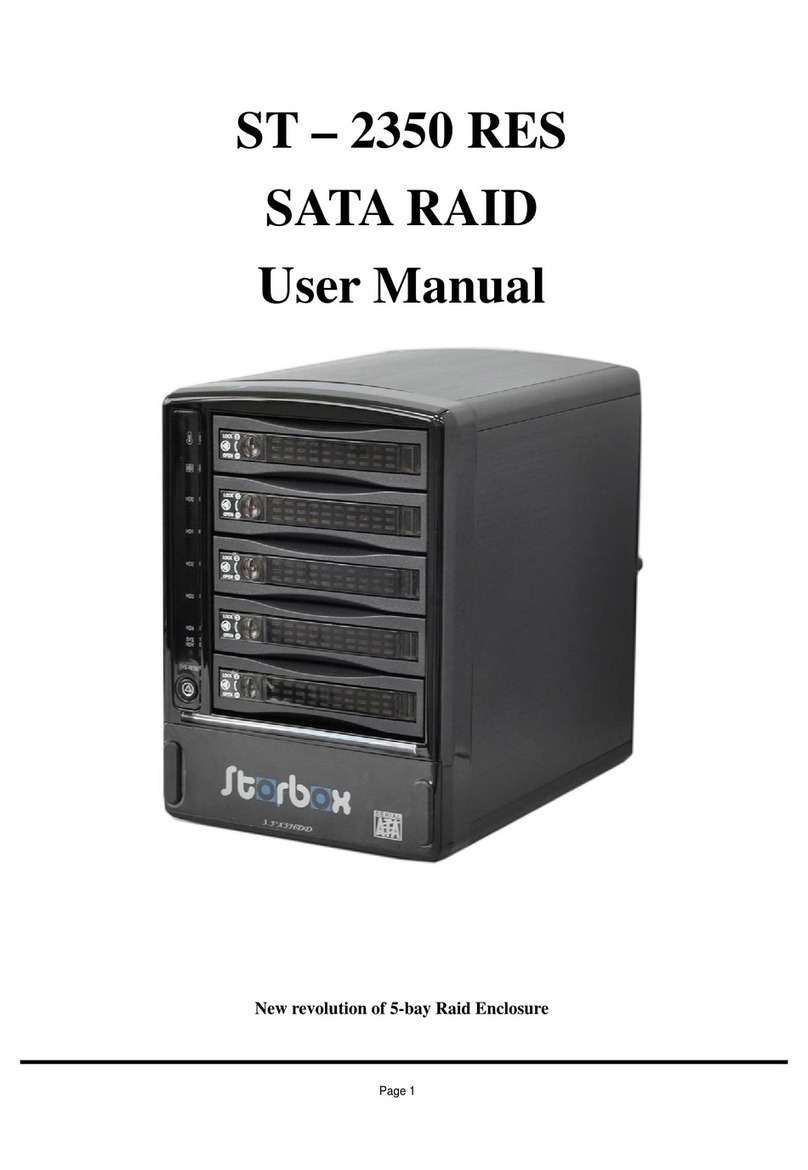

Thank you for purchasing the welded swing frame wallmount cabinet system from

Nexxt Solutions. This enclosure is made up of heavy-gauge steel and a sturdy mounting

frame. It also features a tempered-glass front door, with lockable access to keep

network gear and communication cabling safe and properly organized. Each enclosure

supports optional fans to ensure optimum ventilation inside the unit.

Available with 6, 9, 12, 15 and 18 rack spaces, these enclosures are designed for

housing patch panels, switches, PDUs and any standard 19in equipment where floor

space is at a premium. Flexible and versatile, our cabinets come fully assembled for

rapid deployment, offering a practical and cost-effective solution for applications

requiring protection, structural integrity and cable management capabilities.

1 2

2.Preliminary steps

• Prior to installing this product, you must read all instructions thoroughly.

• Keep these instructions handy in an easily accessible location for future reference.

• A clean, flat, level, protected floor area should be provided for the enclosure assembly

to prevent damage to parts.

• The installers may need to have the following items and tools available to assemble

and install the rack. They are not included in the box.

3. Product overview and components

Upon opening the box, inspect the contents to ensure that all the items listed

below are included:

1. Phillips screwdriver

2. Power drill with the following:

M6 bit

M8 hexagonal-head tip

3. Hex to square socket adaptor

4. Pair of gloves

5. Long-nose pliers

6. Cleaning towel

7. 3mx2m mat or padded surface

1 2 3 4 5 6

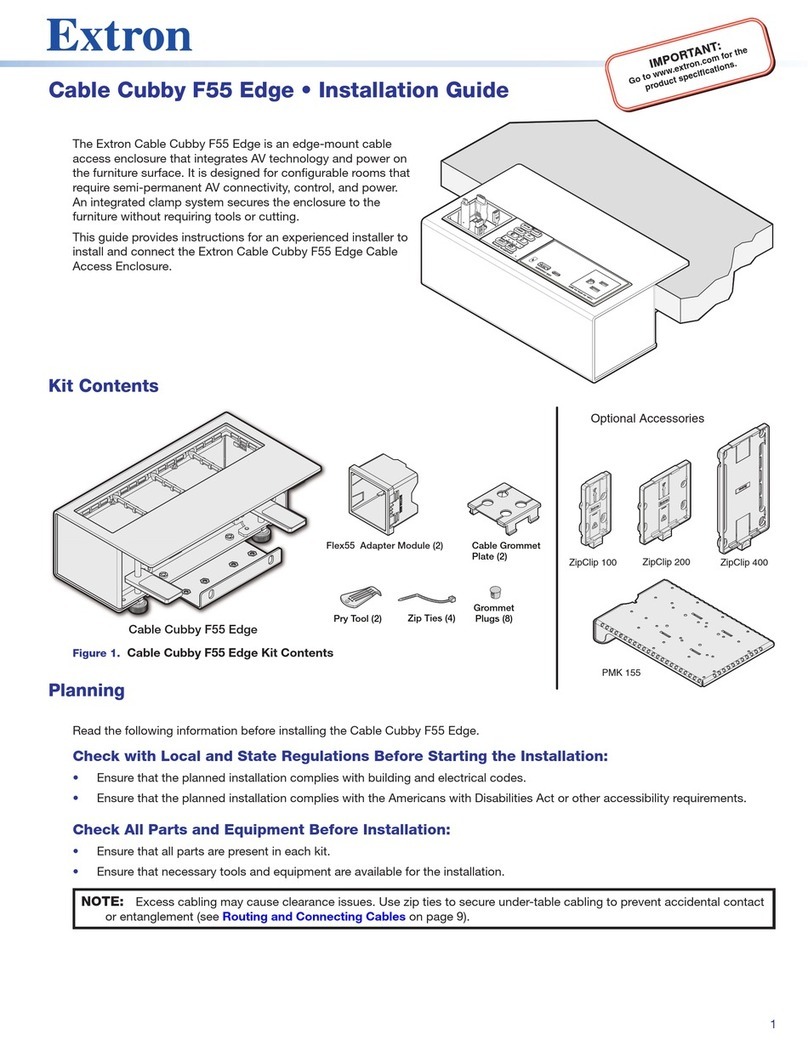

Part ID Item Quantity Image

Wallmount enclosure

Tempered glass front door

1

Pre-installed

White plastic bushing

M6 washer

M6x12mm phillips head screw

M6 cage nut

M6 wall anchor bolt

Set of keys

Drilling template

User manual

6U 9U 12U 15U 18U

6U 9U 12U 15U 18U

12

12

12

4

24

24

24

6

Pre-installed

Hardware mounting kit

1

3

4

5

6

7

8

9

10

2

3 4

1 set (door and

pivoting frame

mechanism)

1

1

4. Wall-mounting procedure

3

4

Preliminary steps

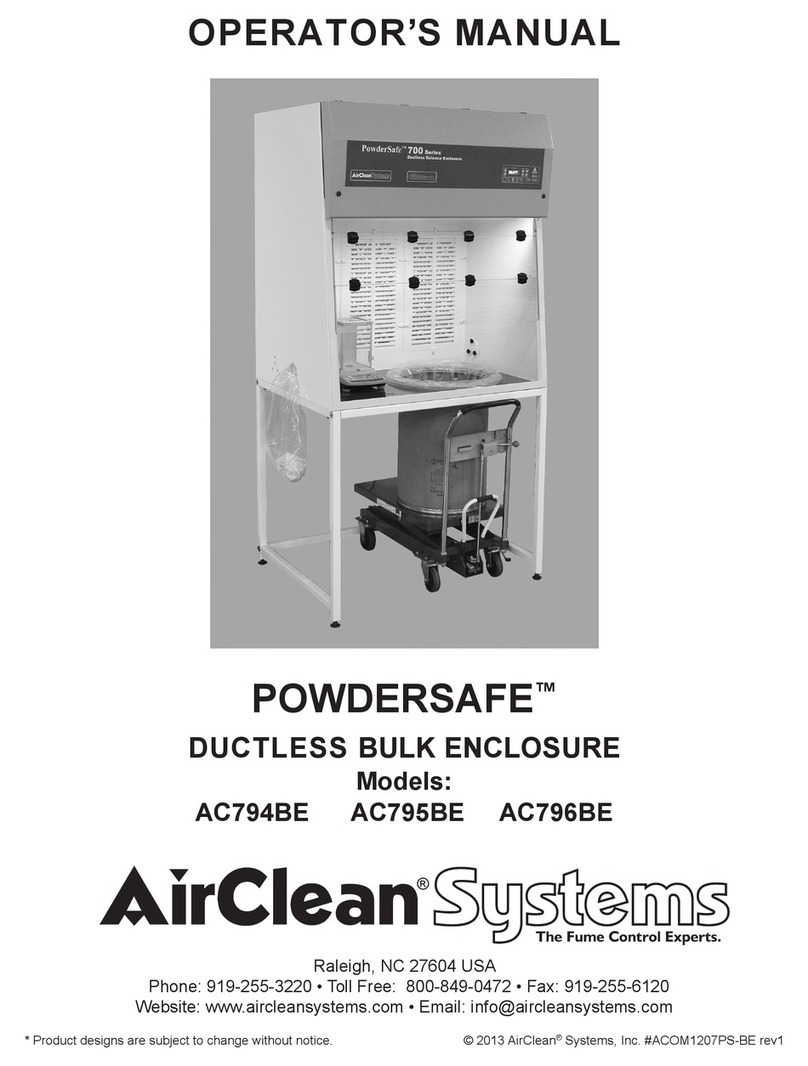

1. On the rear wall of the enclosure are 4 mounting holes.

2. Choose a mounting position and with the supplied template,

proceed to mark the locations of the holes on the wall surface.

3. Drill a pilot hole in the center of each mark using the hand-held

tool.

Note: prior to drilling the holes, confirm that the markings are

accurately leveled to avoid destabilizing the entire structure.

4. Drive the anchors and bolts into the predrilled holes on the wall.

Leave a small clearance (¼in) between the surface and the bolt

heads to allow hanging the enclosure into position.

1

2

Phase Image Mounting step

Warning

Confirm that the wall is strong enough to support the weight of the enclosure

with all the loads. Failure to follow these procedures may result in personal injury

damage to the equipment.

Mounting the enclosure to the wall

1. Once the bolts are properly secured, align the enclosure frame

with the anchor bolts installed.

2. Make sure that the pivoting frame is locked prior to hanging the

unit against the wall.

3. Carefully slide the enclosure into its final mounting position.

Securing the enclosure

1. Unlock the pivoting frame and swing the body of the enclosure out

to expose the back of the structure.

2. With the enclosure already installed in place, fully tighten the

mounting bolts from the inside to firmly secure the unit.

Ground connection

1. Connect the first grounding cable to the door using the provided

hardware.

2. Likewise, connect the second grounding cable to the side panel

using the hardware provided.

3. Using the self-tapping screw bind both grounding cables to the

closest mounting hole on the right side horizontal beam.

5 6

4. Then, connect the grounding cable to the left side panel on the

rear section of the cabinet.

5. Using the self-tapping screw, bind the grounding cable to the

closest mounting hole on the left side horizontal beam.

Note: fully-tighten the screws only after all the screws have been

inserted.

Notes

7 8

NotesNotes

9 10

Other manuals for Professional Series

3

This manual suits for next models

5

Table of contents