Your XTM Racing engine is equipped with a pull-starter. You should

use this to start the engine.

The following details the starting procedure for your engine.

❑1) If your fuel tank has a primer pump, press this pump several

times and watch the fuel as it is drawn up to the carburetor. When

the fuel reaches the carburetor, stop priming. Over-priming the

engine can cause the engine to "hydro-lock" or flood.

(See warning on page 2). Never try to start the engine

if it is hydro-locked. This could cause serious damage to both

the engine and the pull-start assembly.

☞If your fuel tank does not have a primer pump, open the throttle

completely, cover the tip of the tuned pipe with your finger, and pull

the pull-start cord several times to draw fuel into the carburetor.

❑2) The engine is started by connecting the power to the glow

plug then pulling on the pull-start cord. To do this properly you should

pull the cord in short, quick, successive pulls until the engine starts.

Once the engine has started, release the pull-start cord.

IMPORTANT Never pull the pull-start cord out to its maximum

length. This may damage the pull-start assembly. Always use

short, rapid pulls. When the engine is new, it can sometimes be

difficult to turn over using the pull-starter. You may find you need

to pull the pull-starter harder than you expect. A trick to help this is

to loosen the glow plug slightly, start the engine, then remove the

glow starter and retighten the glow plug.

STARTING PROCEDURE

BREAK-IN PROCEDURE

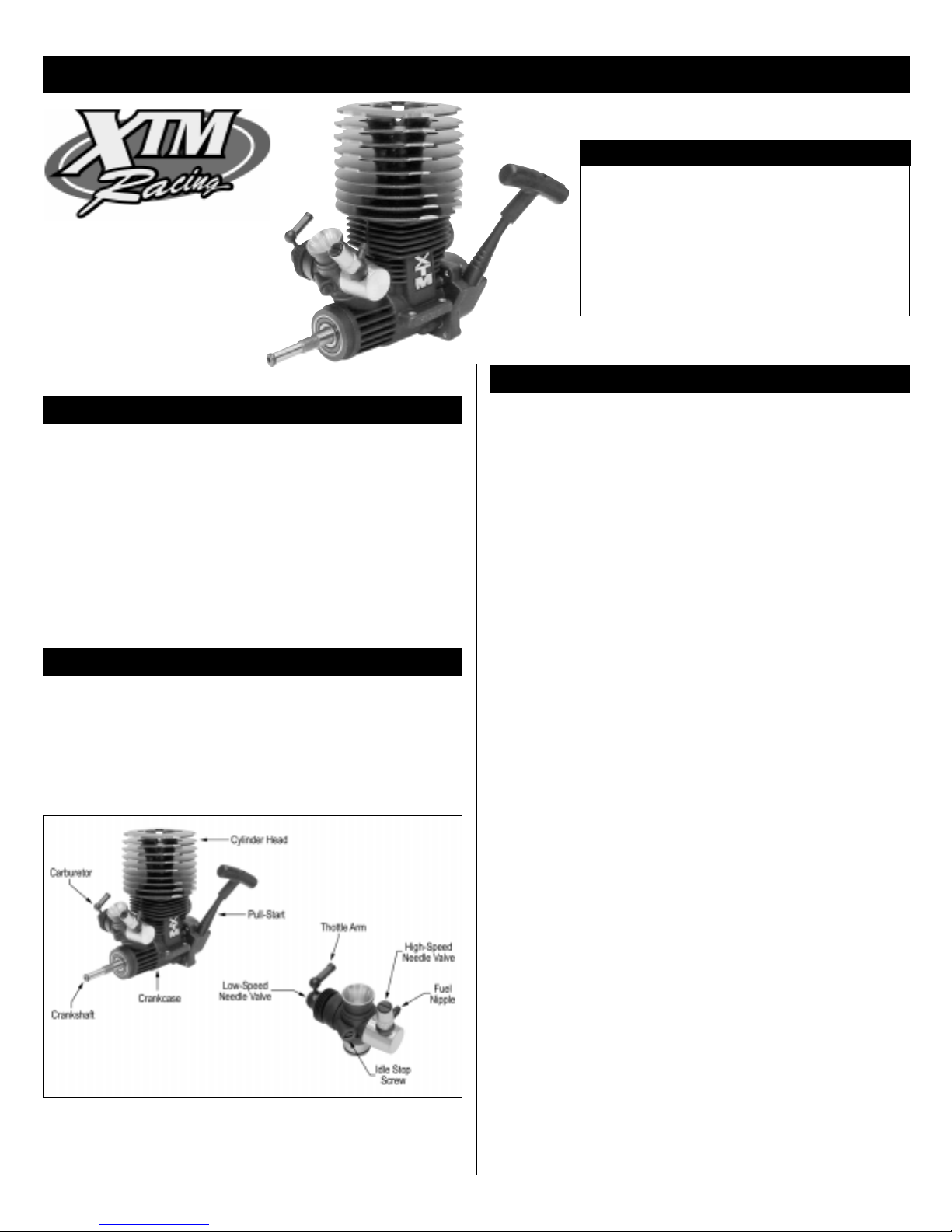

Your XTM Racing engine is an ABC engine. The cylinder sleeve is

tapered at the top, causing resistance when the piston moves through

the top of the stroke. This is normal. When the engine heats up to

operating temperature, this resistance will decrease and the proper

clearance will be achieved. The break-in procedure will guide you

through the steps necessary to properly break in your new engine.

Please follow the steps closely.

☞The break-in process allows the engine parts to perfectly fit to

each other and properly protect each part from premature wear. The

engine should be broken in using a good quality R/C

car fuel that contains no more than 20% nitromethane.

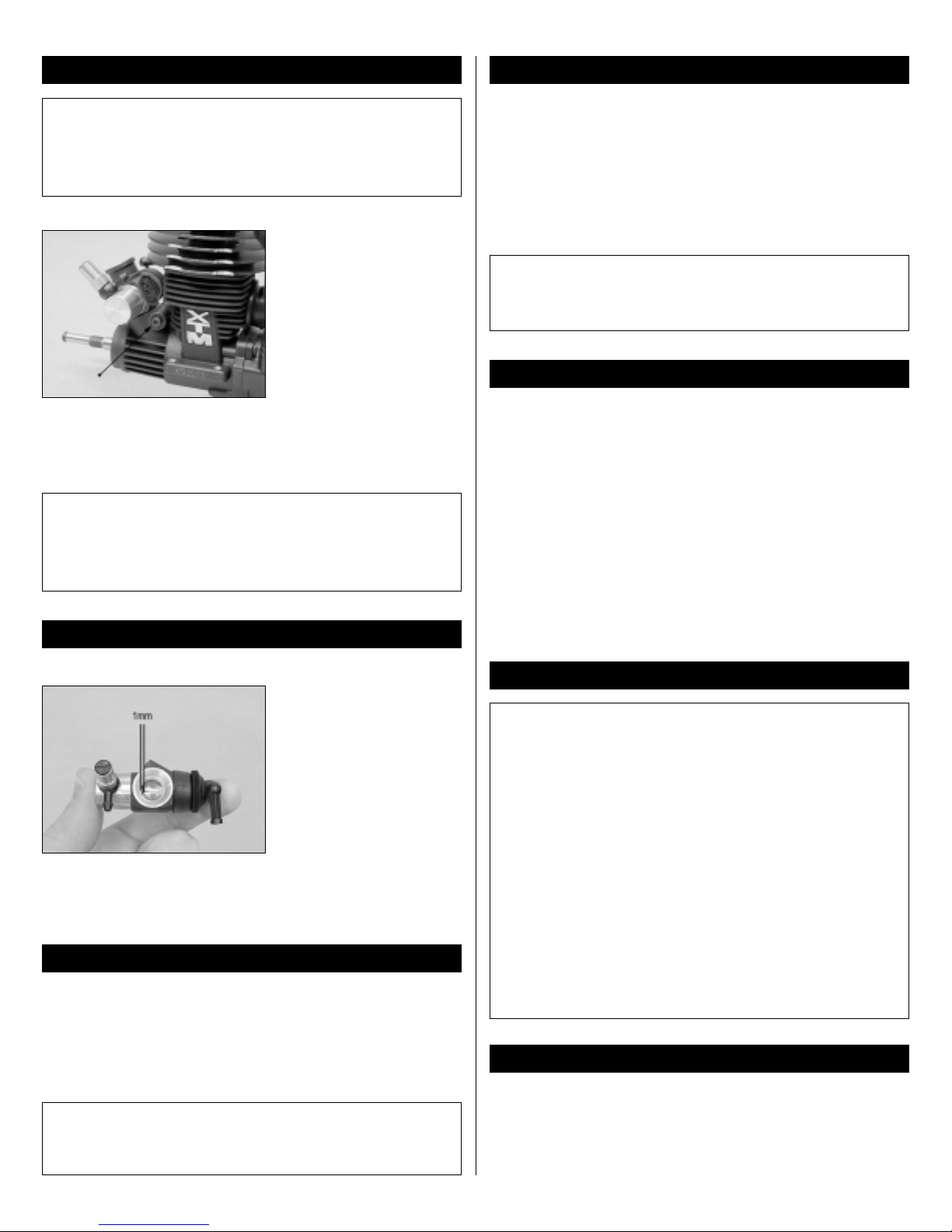

❑1) Turn the high speed needle valve out 3.5 turns from the fully

closed position and follow the starting procedure in the previous

section to prime and prepare the engine for starting. Do not adjust

the low speed needle valve.

❑2) Open the throttle barrel just above the idle position and

attach a glow starter to the glow plug. Start the engine following the

guidelines in step 2 in the previous procedure.

❑3) Once the engine starts, allow it to run for about 10 seconds

without giving it throttle. This will allow the engine to warm up. At

this point the engine should be running very "rich" and the engine will

also sound like it's running rough.

❑4) After the engine has been running for about 10 seconds,

remove the glow starter from the glow plug. Advance the throttle in

short, quick bursts and drive the car around for about 2-3 minutes. If

the engine is running rich enough, you should notice smoke coming

from the tuned pipe and the engine should sound like it’s running

very rough. Also, the car will barely be moving. This is what you

want for now. If there is not smoke coming from the tuned pipe,

richen the high speed needle valve. After 2-3 minutes stop the

engine by pinching the fuel line to the carburetor.

❑5) Let the engine cool for apximately 10 minutes, then restart it.

Set the high speed needle valve mixture to a slightly leaner setting,

about 1/8 turn more in. Repeat step 4 above, then stop the engine

and let it cool for approximately 10 minutes.

❑6) Repeat step 5, while leaning the high speed needle valve slightly

more each time. In all, you should run the engine a total of about 45

minutes. After 45 minutes of run-time the engine will be broken in.

Run the engine with the high speed needle valve set slightly rich,

but lean enough to power the car. At this point the engine should

hold a good setting on the high speed needle valve and you can

begin to fine tune the needle valve settings to increase performance.

IMPORTANT It is of the utmost importance that the engine never

be leaned out too much. When running the engine, you should

always be able to see a trail of smoke coming from the tuned pipe.

If you can’t, stop the engine immediately and richen the high speed

needle valve. You should also make sure there is plenty of air

flowing over the cylinder head to keep the engine from overheating.

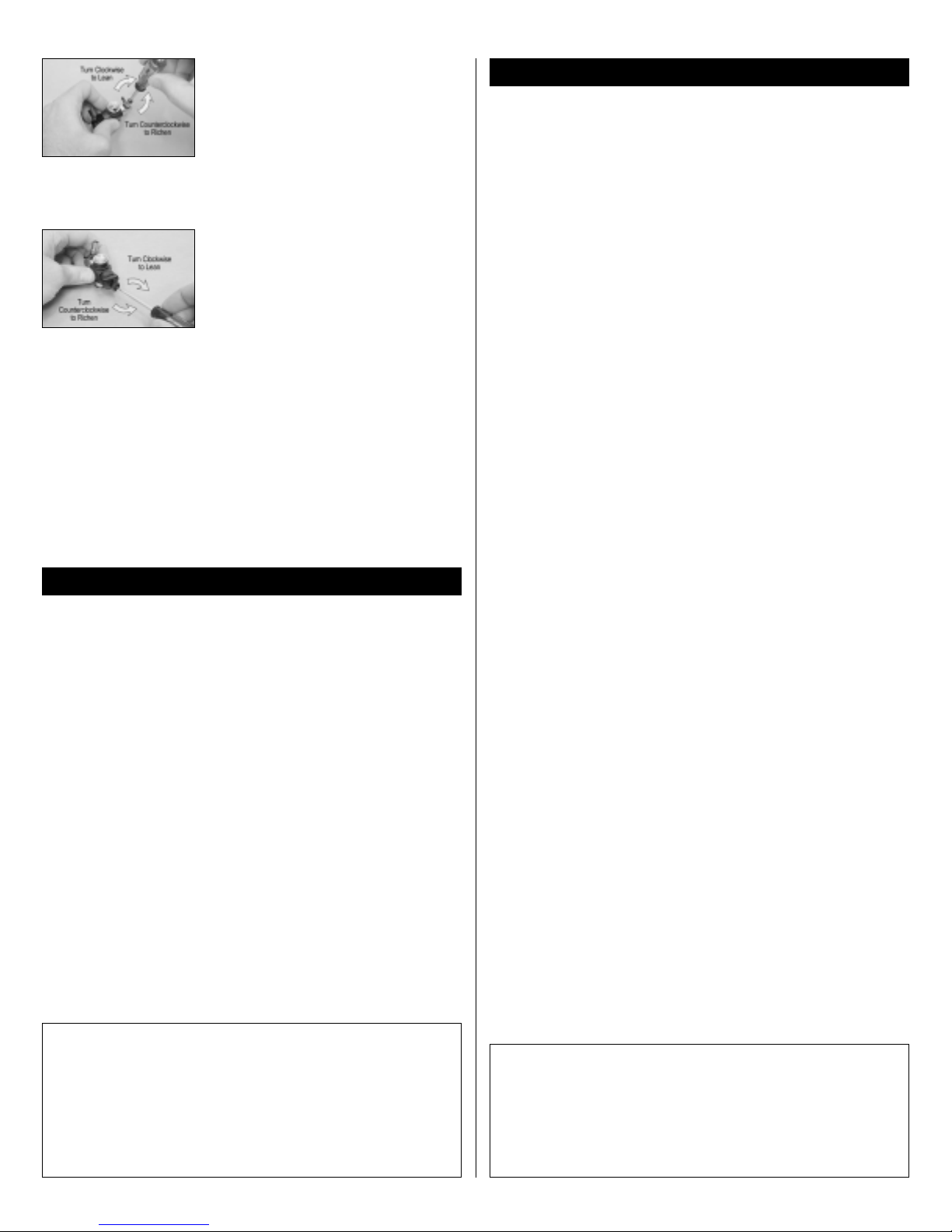

the mixture. When you start the engine

for the very first time, the needle valve

should be turned in completely, then

backed out 3.5 turns. This is the factor y

break-in setting.

LOW SPEED NEEDLE VALVE:

The low speed needle valve meters the air/fuel mixture at idle and

during transition from idle to full throttle.

Turn the low speed needle clockwise to

lean the mixture. Turn it counter-clockwise

to richen the mixture. The low speed

needle valve is preset from the factory, but

minor adjustments may need to be made to suit your application:

fuel used, glow plug and environment all contribute to the setting.

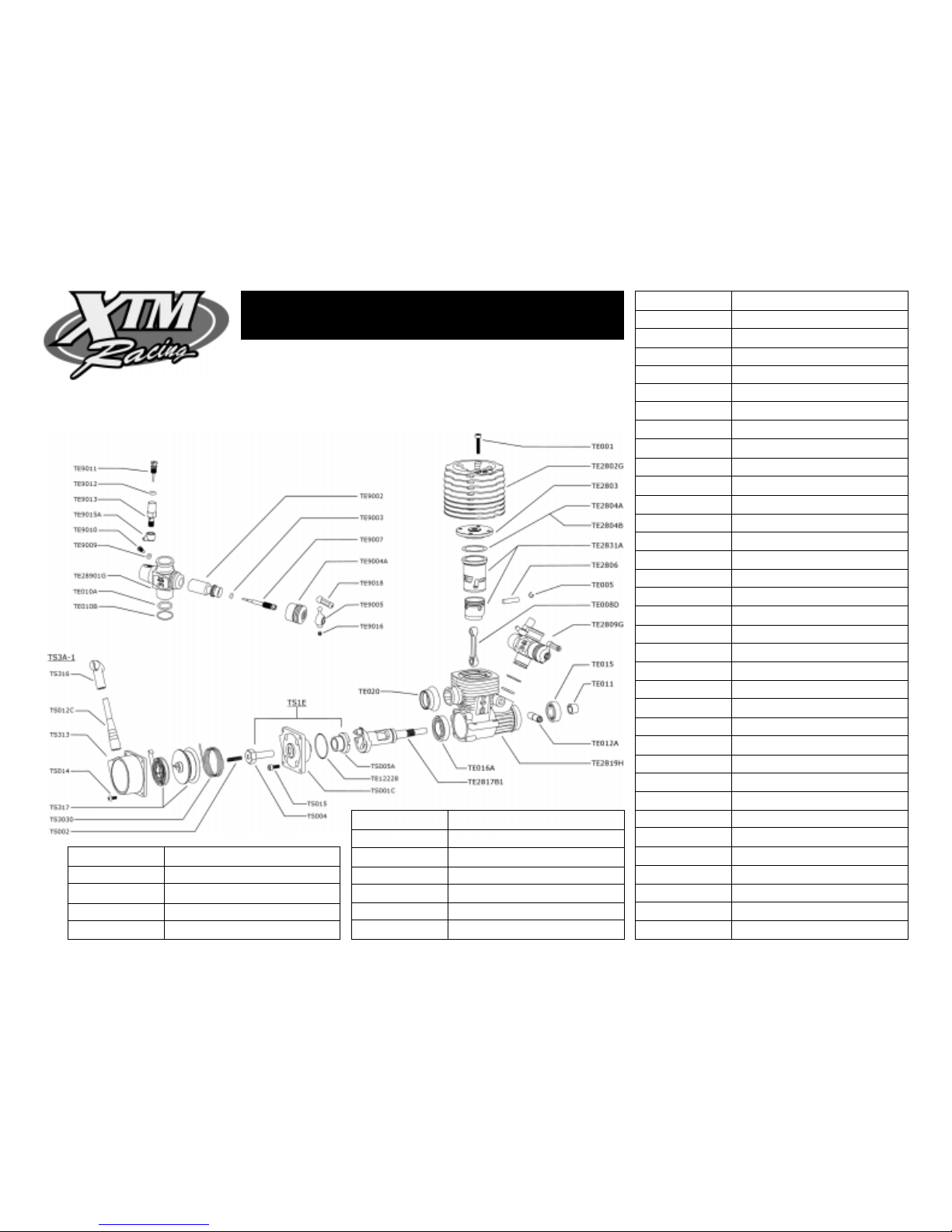

To reset the low speed needle valve back to the factory

setting, follow these simple steps:

●Open the carburetor barrel completely.

●While holding the barrel open with your finger, use a flat blade

screwdriver to turn the low speed needle valve clockwise until it stops.

From this point, turn the low speed needle valve counter-clockwise

3 full turns. This is the factory break-in setting.

3