GETTING STARTED

NI 7330/7340/7350 Motion Controllers and

P7000 Series Stepper Drives

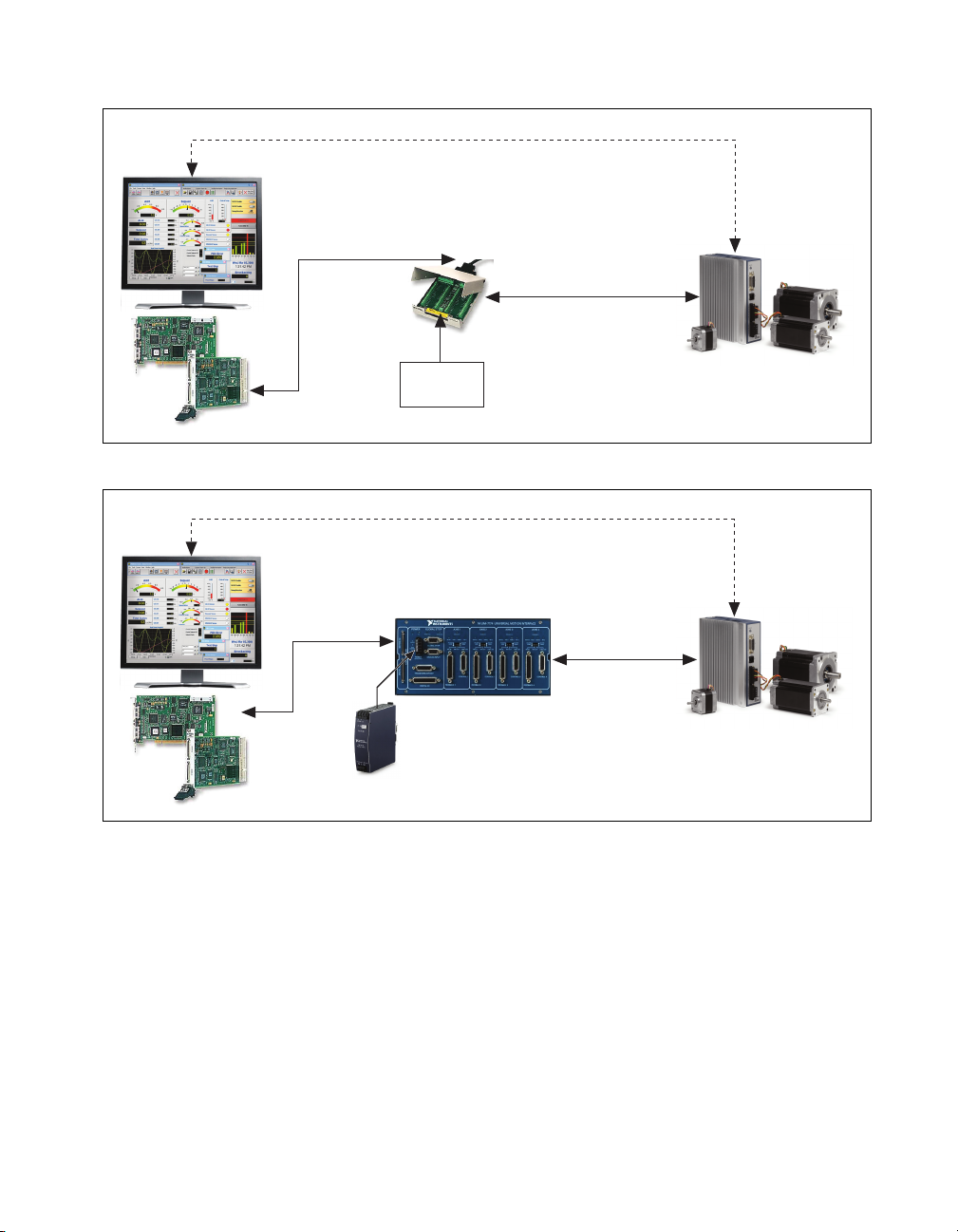

This manual helps you quickly install and configure the P7000 series stepper drives and stepper motors

for use with NI 7330, NI 7340, and NI 7350 motion controllers. It assumes you have already installed

your National Instruments motion controller and driver software. The driver CD installs the

NI Measurement & Automation Explorer (MAX) configuration files and documents referenced in this

manual. You can find all the software, files, and documents at ni.com/motion/stepper.

Additionally, this manual assumes you are using either the NI Universal Motion Interface (UMI)-7764

or NI UMI-7774/7772 and have the appropriate 68-pin cable for connecting to your NI motion

controller. Refer to the NI Stepper Motion System Selection Guide at ni.com/motion/stepper for

assistance. For specifications or installation questions about your NI motion controller or NI UMI, refer

to the appropriate user manual.

Contents

What You Need to Get Started ............................................................................................................ 1

Hardware...................................................................................................................................... 1

Software ....................................................................................................................................... 2

Related Documentation................................................................................................................ 3

Configuration and Installation ............................................................................................................. 4

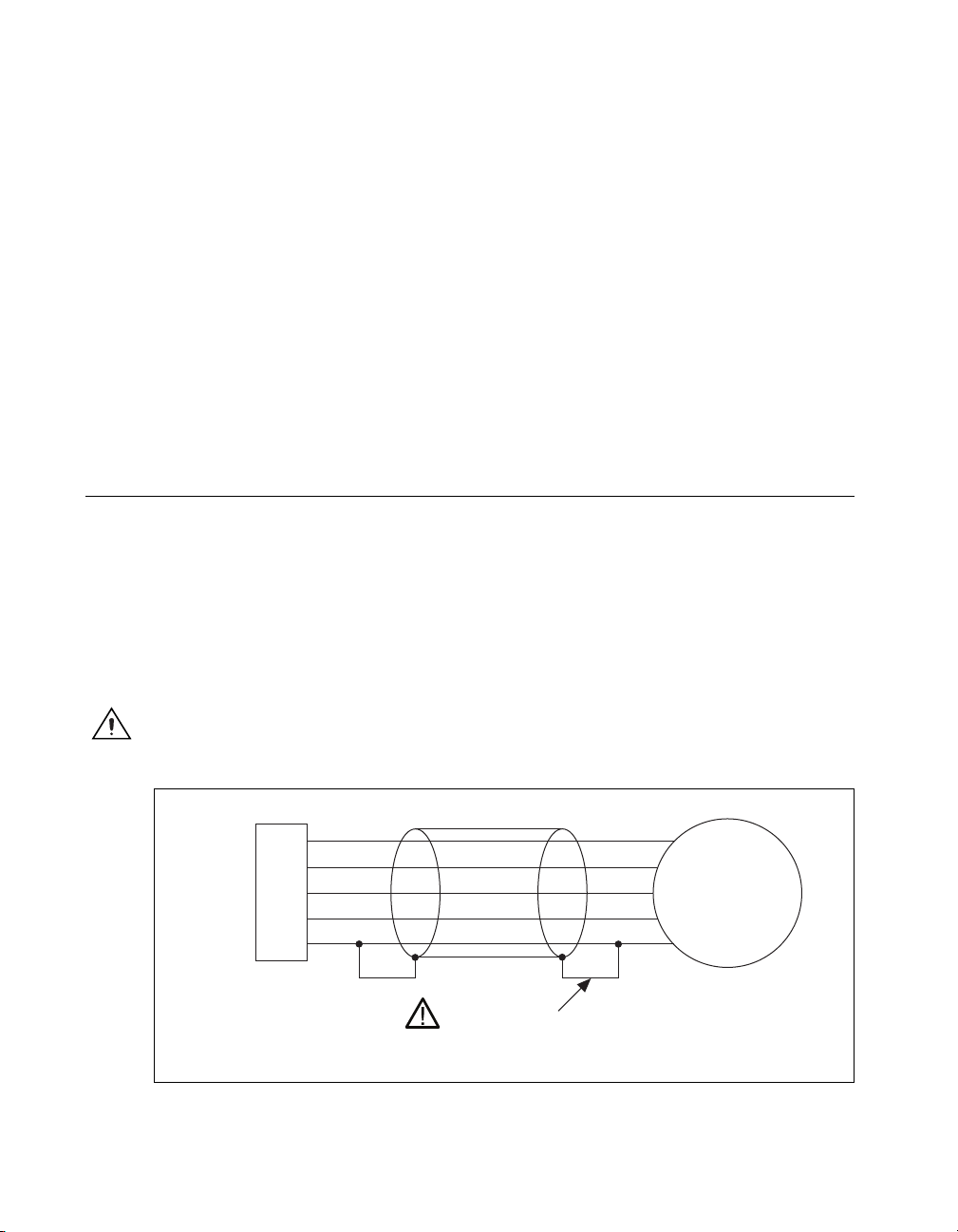

Step 1: Connecting the Stepper Motor to the Drive..................................................................... 4

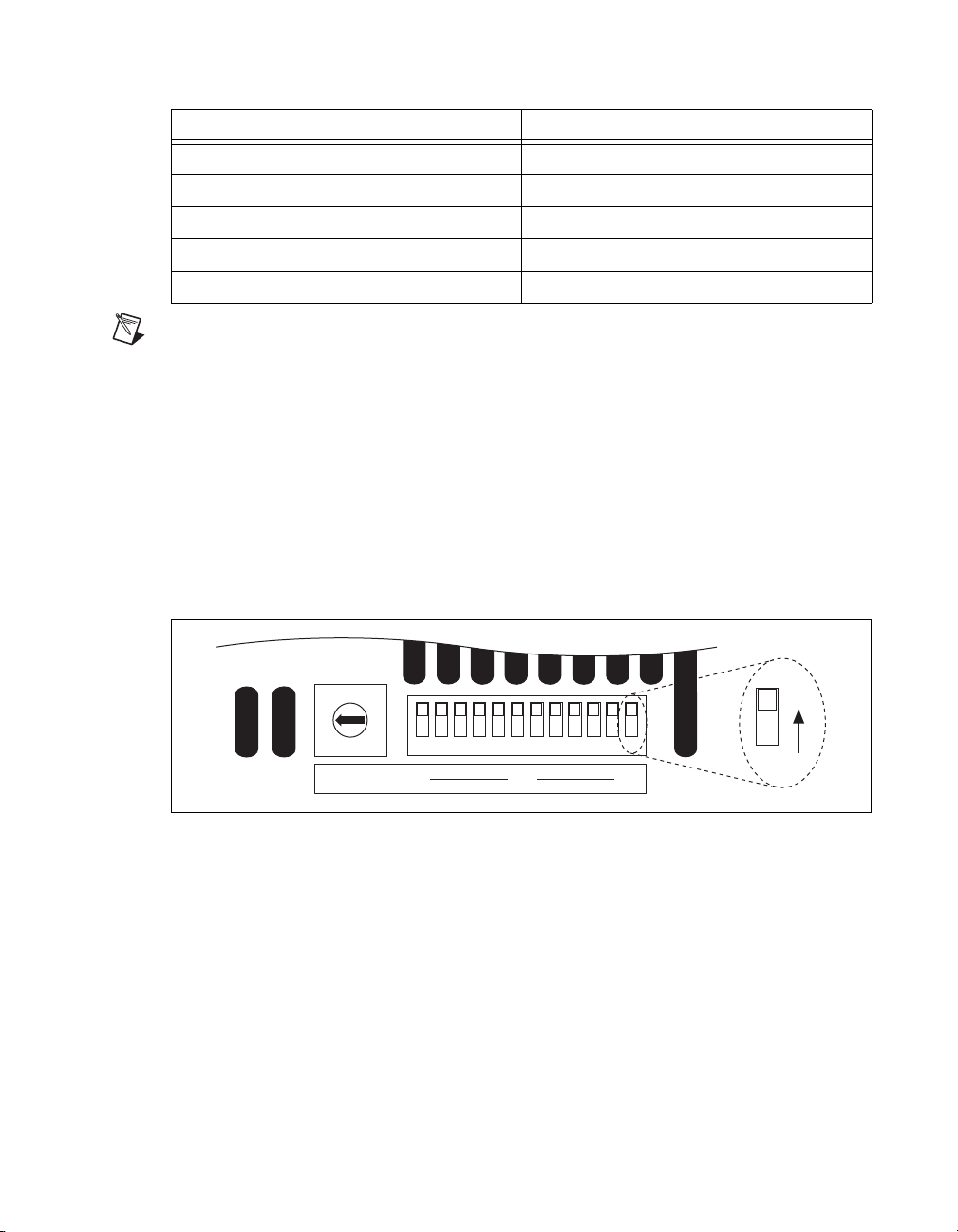

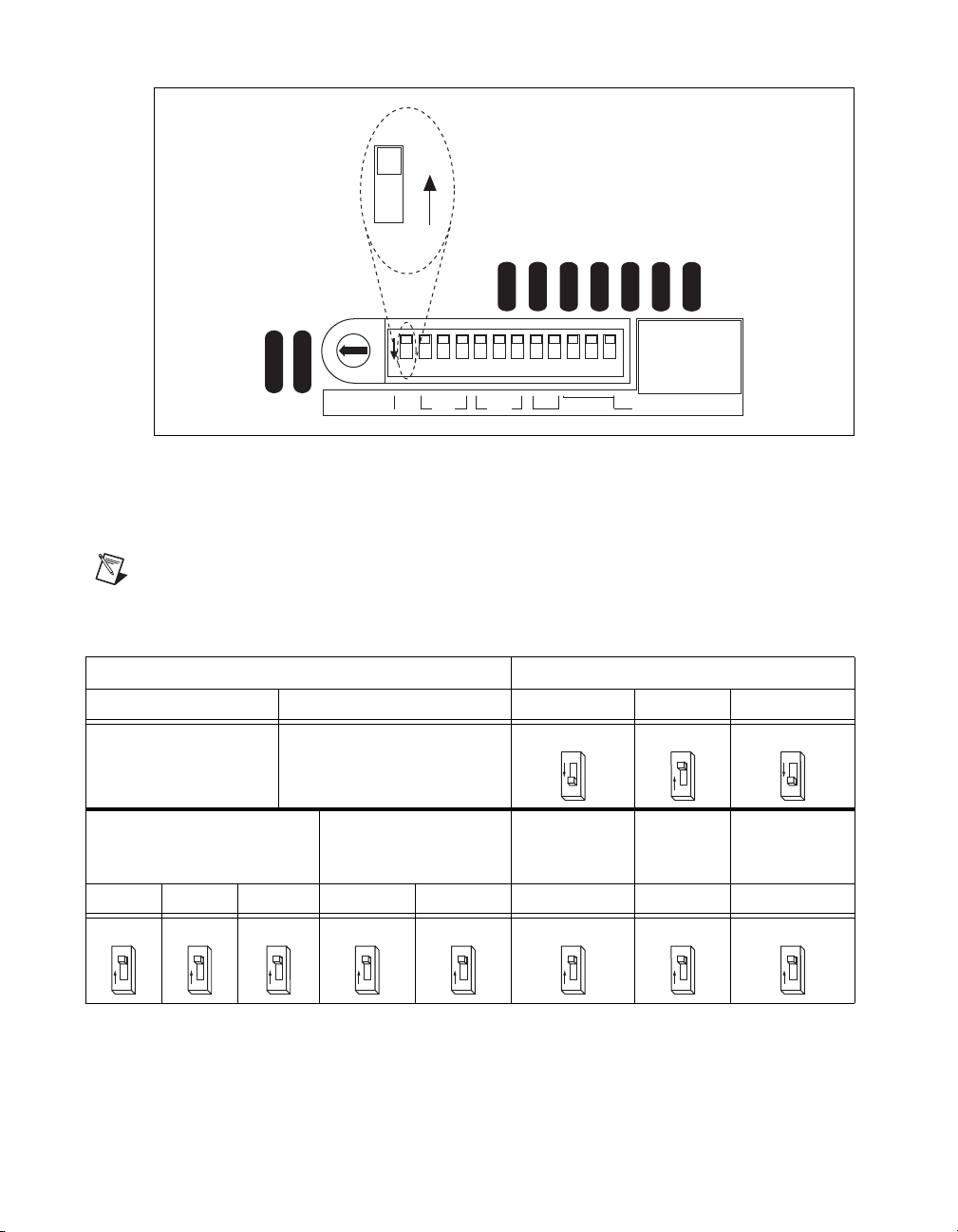

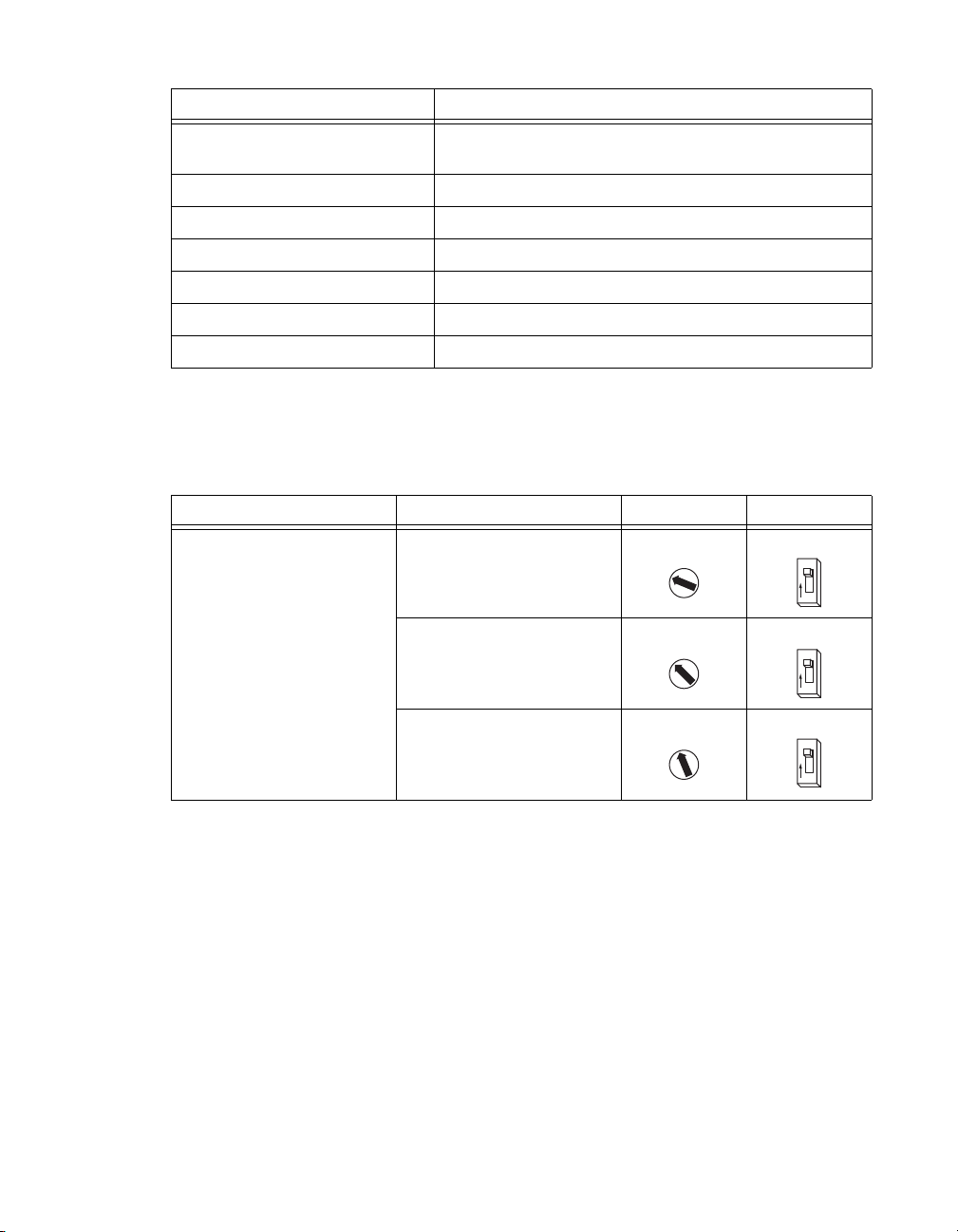

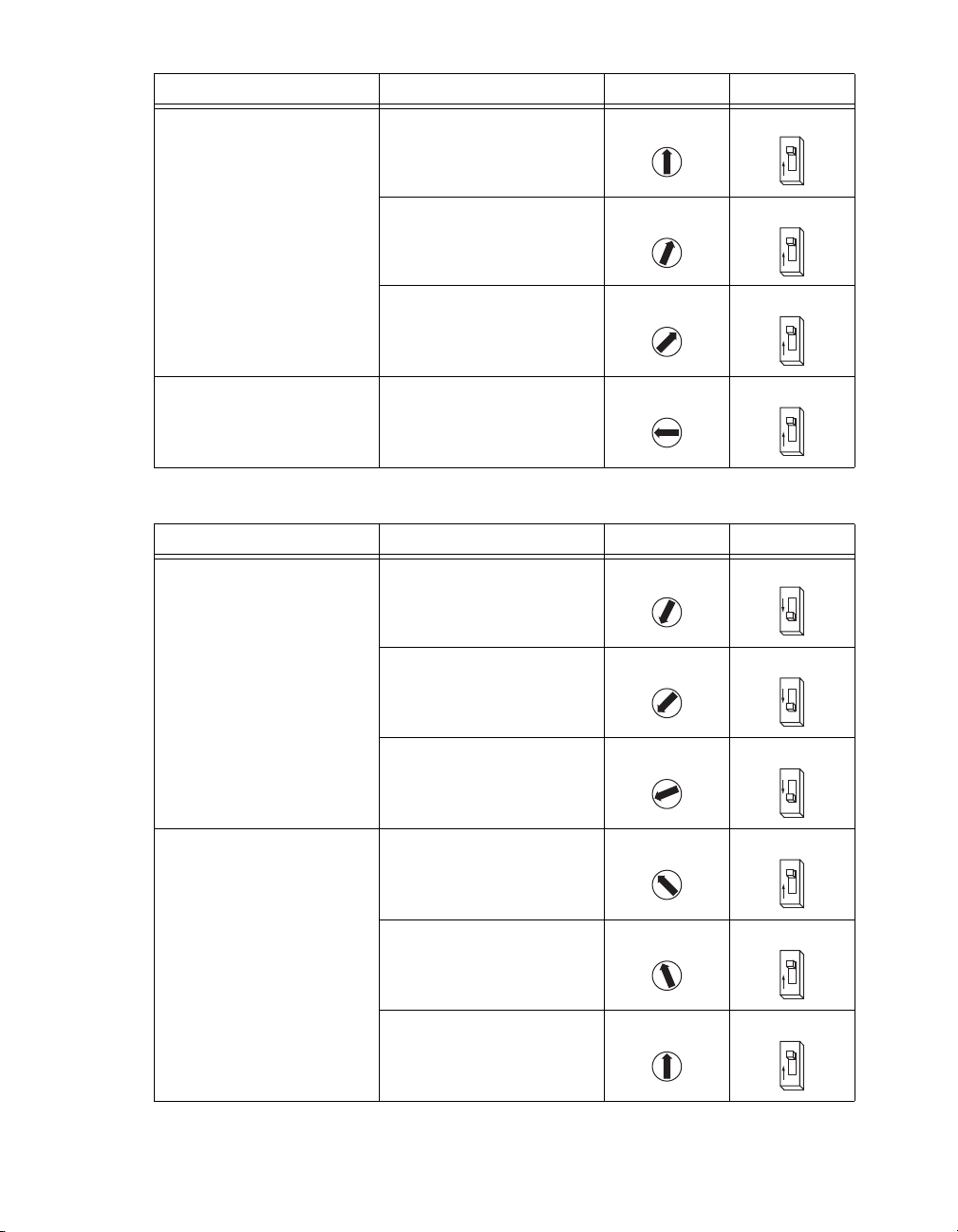

Step 2: Configuring the DIP Switches......................................................................................... 5

Step 3: Connecting Power to the P7000 Drive ............................................................................ 13

Step 4: Configuring the P7000 Drive with the Serial Port (Optional)......................................... 15

Step 5: Installing the P7000 Tools (Optional) ............................................................................. 16

Step 6: Testing the Motor With the P7000 Tools (Optional) ...................................................... 20

Step 7: Configuring the NI UMI..................................................................................................20

Step 8: Configuring Your NI Motion Controller Using Measurement & Automation

Explorer (MAX) ....................................................................................................................... 22

Step 9: Testing the Motor Using MAX ....................................................................................... 26

Configuring Moves with NI Motion Assistant (Optional)................................................................... 26

Exporting to LabVIEW................................................................................................................ 27

Troubleshooting the P7000 Series Stepper Drive................................................................................ 28

Where to Go for Support ..................................................................................................................... 28

What You Need to Get Started

You need the following items to get started.

Hardware

❑NI 7330/7340/7350 motion controller

❑NI UMI-7764 or NI UMI-7774/7772