www.ReadyLIFT.com - Phone: (877) 759-9991

244-3060/44-3080IM-AC

READ INSTRUCTIONS THOROUGHLY AND COMPLETELY BEFORE BEGINNING INSTALLATION.

INSTALLATION BY A CERTIFIED PROFESSIONAL MECHANIC IS HIGHLY RECOMMENDED.

READYLIFT® IS NOT RESPONSIBLE FOR ANY DAMAGE OR FAILURE RESULTING FROM IMPROPER INSTALLATION.

Safety Warning

MISUSE OF THIS PRODUCT COULD LEAD TO INJURY OR DEATH.

Suspension systems or components that enhance the on and off-road performance of your vehicle may cause

it to handle differently than it did from the factory. Extreme care must be used to prevent loss of control or

vehicle rollover during abrupt maneuvers.

Always operate your vehicle at reduced speeds to ensure your ability to control your vehicle under all driving

conditions. Failure to drive safely may result in serious injury or death to driver and passengers.

Driver and passengers must ALWAYS wear your seat belts, avoid quick sharp turns and other sudden maneu-

vers. ReadyLIFT Suspension does not recommend the combined use of suspension lifts, body lifts, or other

lifting devices.

You should never operate your vehicle under the influence of alcohol or drugs.

Constant maintenance is required to keep your vehicle safe. Thoroughly inspect your vehicle before and after

every off-road use.

It is the responsibility of the retailer and/or the installer to review all state and local laws, with the end user

of this product, related to bumper height laws and the lifting of their vehicle before the purchase and installa-

tion of any ReadyLIFT products.

It is the responsibility of the driver/s to check their surrounding area for obstructions, people, and animals

before moving the vehicle.

All raised vehicles have increased blind spots; damage, injury and/or death can occur if these instructions are

not followed.

.

Installation Warning

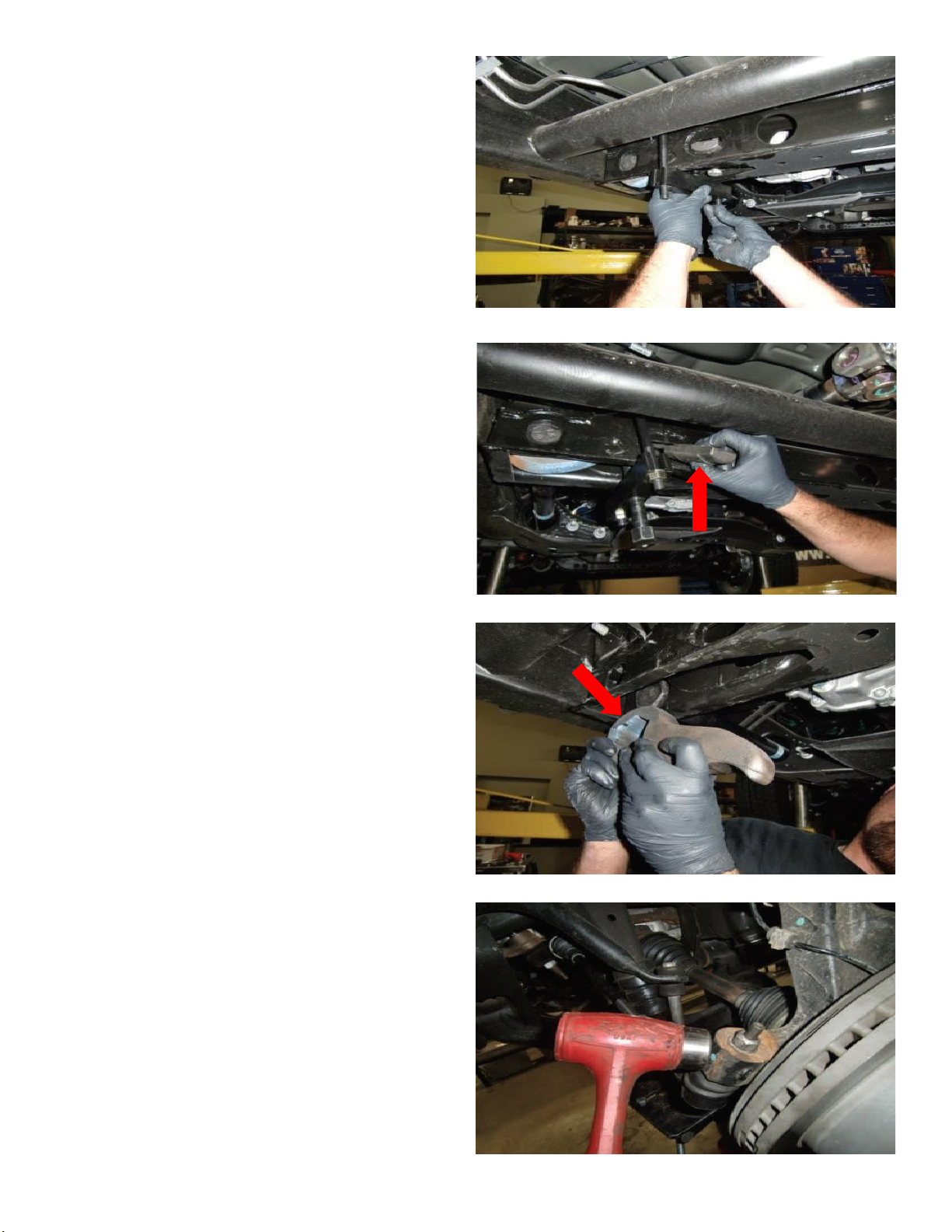

All steps and procedures described in these instructions were performed while the vehicle was properly sup-

ported on a two post vehicle lift with safety jacks.

Use caution during all disassembly and assembly steps to insure suspension components are not over extend-

ed causing damage to any vehicle components and parts included in this kit.

Included instructions are guidelines only for recommended procedures and are not meant to be definitive.

Installer is responsible to insure a safe and controllable vehicle after performing modifications.

ReadyLIFT Suspension recommends the use of an OE Service Manual for model/year of vehicle when disas-

sembly and assembly of factory and related components.

Unless otherwise specified, tighten all bolts and fasteners to standard torque specifications listed within the

OE Service Manual.

Suspension components that use rubber or urethane bushings should be tightened with the vehicle at normal

ride height. This will prevent premature wear or failure of the bushing and maintain ride comfort.

Larger tire and wheel combinations may increase leverage on suspension, steering, and related components.

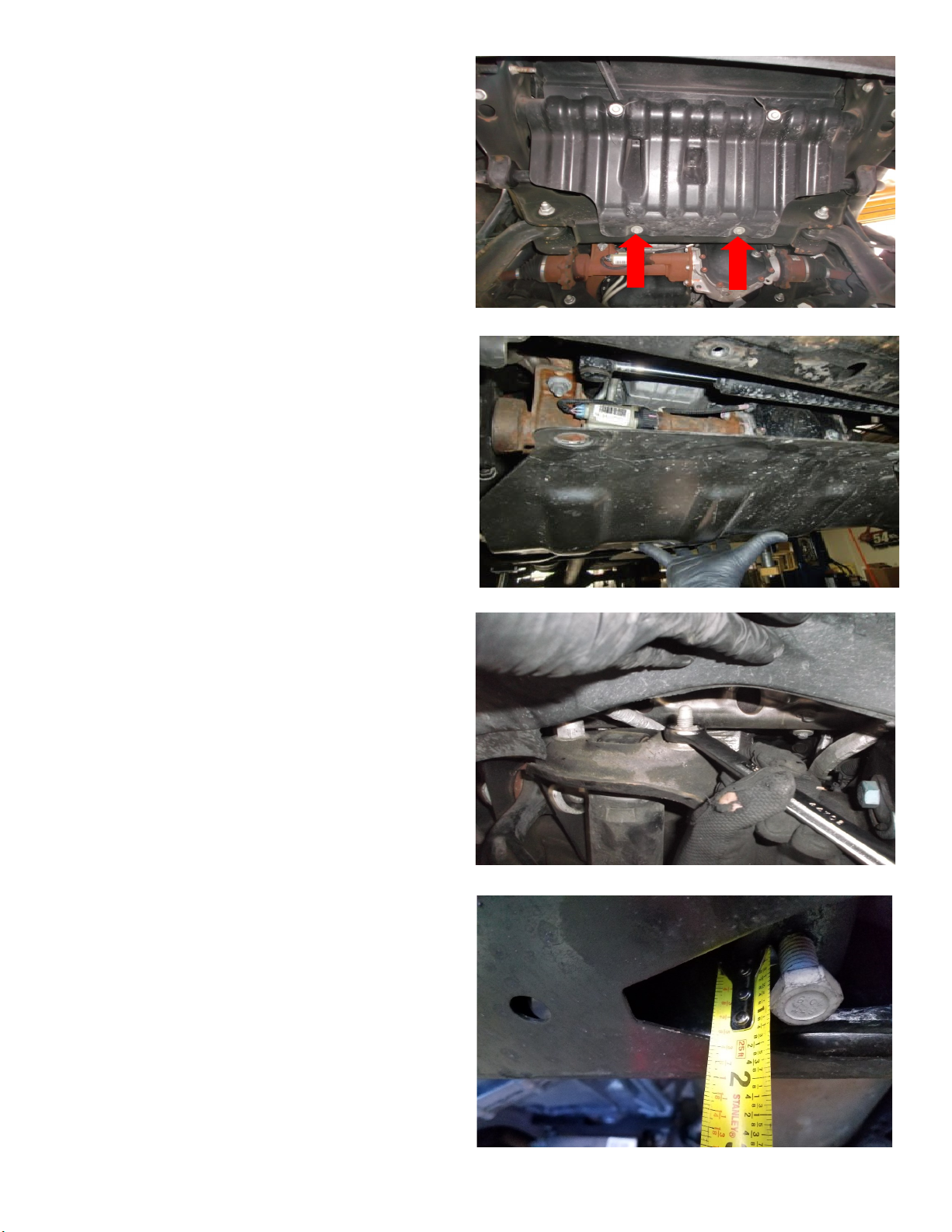

Due to payload options and initial ride height variances, the amount of lift is a base figure. Final ride height

dimensions may vary in accordance to original vehicle ride height. Always measure the vehicle ride height

prior to beginning installation.