VMB TL-A450 User manual

TL - A450

EELEVADOR LINE ARRAY

MANUAL DE INSTRUCCIONES

LINE ARRAY LIFT

INSTRUCTIONMANUAL

QuickOperation Guide

GB

V 11.03

DTRAVERSENLIFT

BEDIENUNGSANLEITUNG

Fabricante - Manufacturer - Hersteller - Fabricant

TORRE ELEVADORA

TOWERLIFT

TRAVERSENLIFT

PIED ÉLÉVATEUR

TL-A450

Este manual de usuario y catálogo anexo de piezas de repuesto es propiedad de PRO LIFTS S.L. Queda

prohibida su reproduccion total o parcial por cualquier medio que la tecnología actual permita.

Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Calle 7 - Pol. Ind. Picassent

E-46220 Picassent

www.prolifts.es - info@prolifts.es

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

CONTENTS

1. Introduction.

2. Technical Data.

3. Security.

4. Instructions.

5. Maintenance.

6. Warranty.

7. Certifications.

1. INTRODUCTION

Thank you for choosing VMB Towerlifts.

You have acquired a first class, quality product

used by professionals around the world.

To be able to work with this tower, lifting and

flying PA and Line Array, please pay special

attention to this manual. Please observe the

technical data and follow all instructions fully

for a correct and safe use.This manual should

also be made available and remain with the

towerlift.

All VMB towerlifts undergo a strict quality con-

trol to guarantee the maximum safety and

durability.

The TL-A450 has been especially designed and

engineered to hang Line Array to a maximum

height of 6m and a load of 450kg. This lift is

capable of situating the PA50cm fromthe body

of the lift. The benefit of placing the load at a

distance enables the user to achievethe perfect

curve and coverage for the Line array flown.

The TL-A450, incorporates the ALS system

(Auto-Lock-Security) and ILS system (Inertia-

Lock-Security),both exclusive to VMB and which

guarantee the load will not fall and provide com-

plete security.

ATTENTION: Do not use this towerlift if you

have not read and understood the instructions.

2. TECHNICAL IINFORMATION

2.1 – Towerlift mod. TL-A450

2.2 – Especially designed for lifting and flying

Line array directly from the floor to a height of

6m (19.7’).Able to hang at 50cm (1.6’) from the

main body of the lift.

2.3 – Maximum load : 450Kg (992lb) . at 50cm

(1.6’) from lift body..

2.4 – Minimum Load : Can lift or lower without

load.

2.5 – Maximum Height : 6m (19.7’).

2.6 – Folded Height : 1.98m (6.5’).

2.7 – Base Surface : 2.2 x 2.1m (7 x 7’).

2.8 – Transport Weight : 196Kg (432lb).

2.9 – Construction Material : 6082-T6

aluminium for the main body comprised of 4

profiles and lifting carriage. DIN 2394 steel for

the base and outriggers. ST-37 steel for the

ALS security system and pulleys.

2.10 – Security Systems: ALS (Auto-Lock-

Security), ILS (Inertia-Lock-Security) which

guarantee complete security at all times.

During the life of this towerlift, it may need spare

parts for maintenance. In this case please

contact your distributor.

Only original spare parts must be used. The user

loses all rights towarranty ifany spareparts other

than originals are used or carries out any

modification or alteration to the towerlift.

For any questions relating to this towerlift

please indicate serial number and year of

production.

Quick Operation Guide ENGLISH

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Quick Operation Guide ENGLISH

2.11 – 1200kg Manual winch with automatic

disc brake.

2.12 – Cable : DIN 3060 steel. 180 Kg/mm2

quality antitorsion. 6 mm diametre.

2.13 – Adjustable stabilisers on the outriggers

with anti-slip injected rubber base.

2.14 – Outriggers fixed with security locks.

2.15 – Spirit level to adjust vertical positioning.

2.16 – All lift elements are finished in polyester

satin black.

2.17 – 360º Wheels for ease of transport to

work place.

3. SAFETY PRECAUTIONS.

3.1 – The TL-A450 is designed for lifing Line

Array and should never be used for elevating

persons.

3.2 – Onlysituate the lift on hard,flat surfaces

checking that it is in a vertical position with

the spirit level (F) included. If necessary,

adjust with support stabilisers(Q) by turning

the handle (H). Do not use any other

materials to balance the lift.

3.3 – Check all outriggers are inserted

correctly and locked with security locks.

!

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Quick Operation Guide ENGLISH

3.5 – Never exceed the maximum weight

indicated on the towerlift and in this ma-

nual.

3.4 – Never elevate the Line Array before

checking it is correctly attached to the lift.

Kgs

3.6 – If there is excessive wind, place the

lift on firm ground and attach slings to add

stability. Never attach a sling to a vehicle

or any other element than can move.

3.8 – Be carfeful of any high, obstructions

such as balconies, signs etc. It is important

to avoid the presence of cables beneath

the working position of the lift.

3.7 – Do not use a ladder on the lift.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Quick Operation Guide ENGLISH

3.11 – Never use the lift on a mobile surface

or on any vehicle.

3.10 – Never try to move the lift once the

load is raised.

3.9 – Never stand below the raised mate-

rial and do not allow others to stand

beneath or around the working area of the

lift.

3.12 – Before using the lift check the

condition of the cable. The cable should

not be broken or torn. NEVER use defect

cables and if in doubt change the cable.

Only use DIN 3060 steel cable 180 Kg/mm2

quality torsion resistant cable.

3.13 – Never remove the handle from the

winch if the lift is elevated with load.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

3.16 – All profiles must be lowered before

the lift is transported.

3.15 – Do not grease or lubricate the break

mechanism in the winch. The break discs

have been especially greased with a

special anti heat, pressure material.

Other products must not be used so as to

avoid the break not working effectively.

3.14 – The minimum load for the brake

functioning in the winch is 25kg. Without

this weight the brake will not function.

3.17 – Only original spares must be used.

ORIG INAL

-25

Quick Operation Guide ENGLISH

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

4. INSTRUCTIONS.

4.1– Situate the lift on its transport wheels (T)

upon a flat and stable surface.

When erecting the lift in open air, the risk of

wind is prevalent.

Where wind speeds exceed 30 Km/h it is

essential to tie the lift. 2 lateral fixing points (X)

are situated at the top of profile 2, where

tensors should be attached and fixed on secure

and firm ground (NEVER ON A VEHICULE OR

ANYTHING THAT CAN MOVE).

4.2 – Remove the outriggers from their

transport compartments (S) and place them in

the working position (V) ensuring they are fixed

with the security locks (R). The long outriggers

are placed and the front beneath the load. The

short outriggers are placed at the back.

4.3 – Remove the front support bars (BA) from

their transport compartment (S) and place them

in their corresponding fixed position (D) on each

front outrigger and at the top of the first profile

(E) ensuring they are fixed with the pins

provided BU/P1.

To correctly fix the front support bars (BA),

adjust the support of the front outrigger by

turning the stabiliser handel in the necessary

direction.

Insert clips (BU) and security pins (P1).

Adjust the vertical position of the lift with the

stabilisers (Q) turning the handels so that the

spirit level is centred (F).

4.4 – Let go of transport security B, remove

the forks and place them horizontally.

Place the lifting carriage at the required height

so that the Line Array buffer can be attached.

The careful positioning of the front outriggers

enables the LineArray to fit between them and

ease assembley on to the forks.

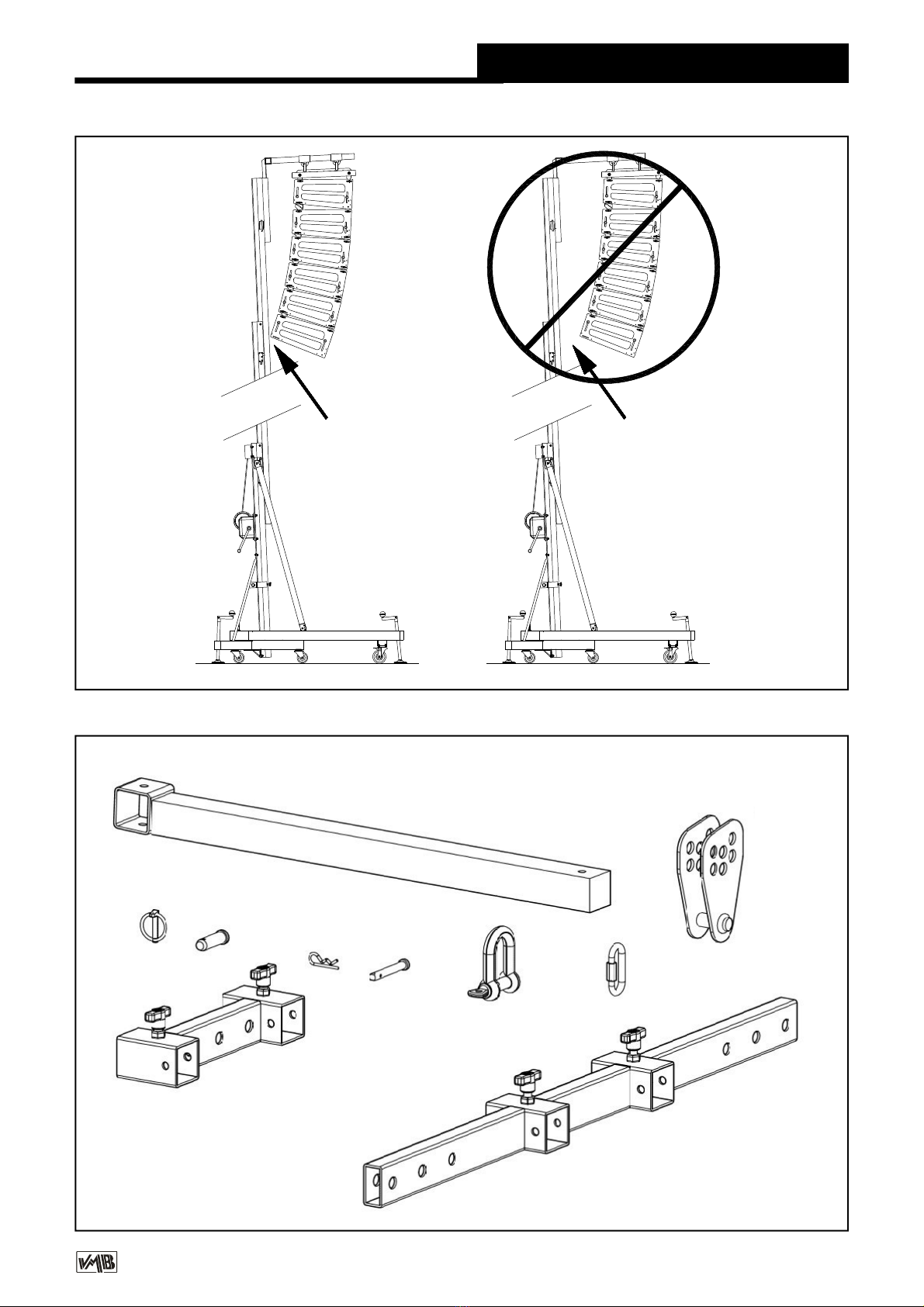

Support FAS-01 is to be fixed to the forks by

either 1 or 2 points. See fig. 1.

If the Line Array Buffer has 4 link points use

the FAS-02 support which enables the Line

Array to be flown from 4 points, see fig. 2.

Both supports FAS-01 and FAS-02 are inserted

on the forks as follows:

The Line Array cabinets will be attached to their

buffer with the angles calculated according to

the acoustic coverage required.

This ensures the Line Array cabinets can be

curved in function with the necessary degrees

required between them.

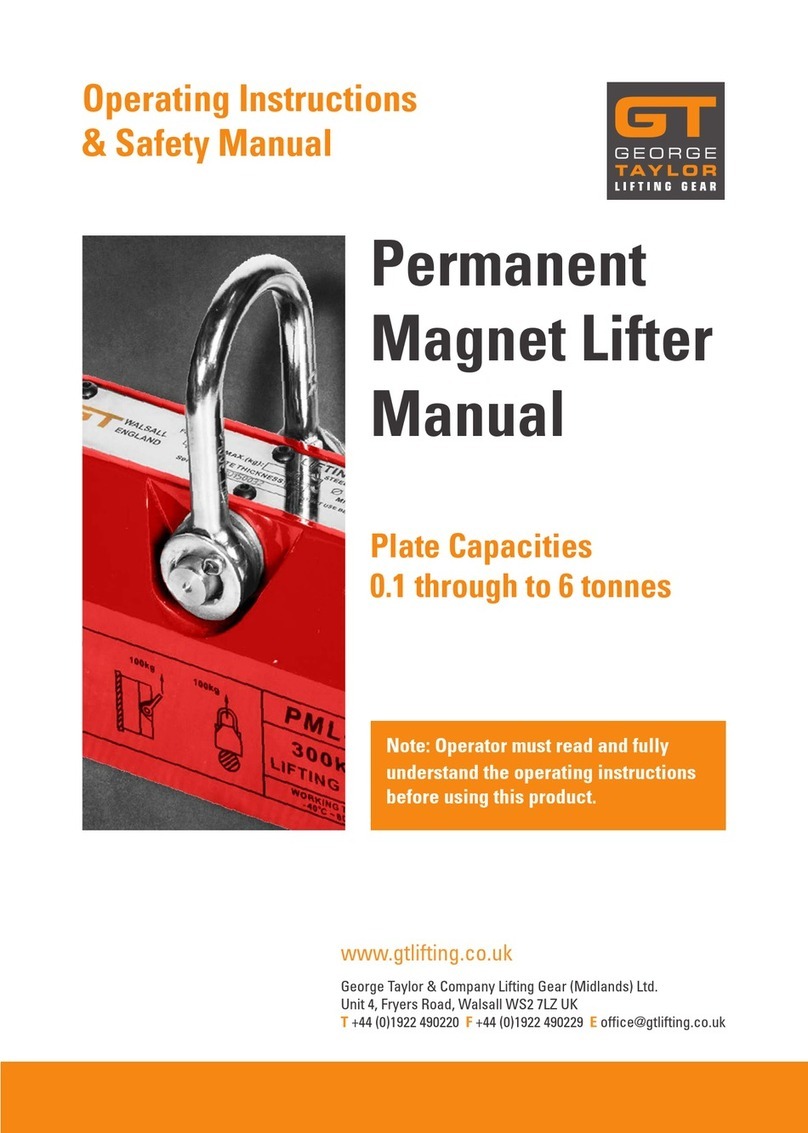

The system should be attached at the

necessary distance to achieve the required

curve. The last cabinet should not hit the body

of the lift. See fig. 3.

To ensure the maximum security margin it is

necessarry to always attach the Line Array at

the minimum distance possible from the body

of the lift. This will mean that the bottom cabinet

is as close as possible to the body of the lift.

See fig. 3A.

To avoid overloading do not seperate

uneccessarily the Line Array from the body of

the lift. See fig. 3B.

Quick Operation Guide ENGLISH

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Quick Operation Guide ENGLISH

Fig. 2

Fig. 1

FAS-01

FAS-02 PR-01

PR-01

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Quick Operation Guide ENGLISH

Fig. 3

TL-A450TL-A450

BA

FAS-01

BC-075L

FAS-02

MR-PAS

MO-30

GS-500

PAT-01

PR-01

MR-SPI PAS-SPI

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Quick Operation Guide ENGLISH

4.5 – The maximum load of the TL-A450 is 450

Kg with the load point at 50 cm from the lift’s

body.

The loading point capacity can be found on the

vertical line which marks the centre of gravity

of the Line Array wich is to be flow.

The situation of the centre of gravity depends

upon the chosen Line Array and is necessary

to calculate before use. Never the less, it is

usually situated at the centre of the LineArray.

Fig. 4

50 cm

TL-A450

P.A. (450 Kg)

Never overload the liftabove the stated maximum

weight of 450 Kg.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

4.6 – The TL-A450, can also be used as a

conventional towerlift.

If you are using it as a conventional towerlift

always place the load as close to the body as

possible. In all frontal load towerlifts the

maximum load is reduced the further away from

the body the load is placed.

4.7 – Elevating the lift:

Once the LineArray is attached to its buffer and

in the desired position on the forks it is ready to

be lifted to the required height. Turn the winch

handle in a clockwise direction to elevate the

lift.

First, the lifting carriage with the attached Line

Array will raise. When it has reached the top

then the first profile will start to rise. When this

has reached the top the second profile will raise

followed by the third.

The ILS and ALS enable the lift to rise and

automatically block the carriage and profiles

whilst rises ensuring that it will never fall. The

lift, with the Line array attached will remain fixed

at all times.

Once the systemis elevatedto itsrequired height

gently turn the handle in a clockwise direction.

The security systems will ensure that the load

stays fixed and blocked. The red ALS locks will

be blocked. This enables the cable to be without

any force and means it is only used for the

elevation and descent of the lift. The following

instructions will help you to bring the system

down.

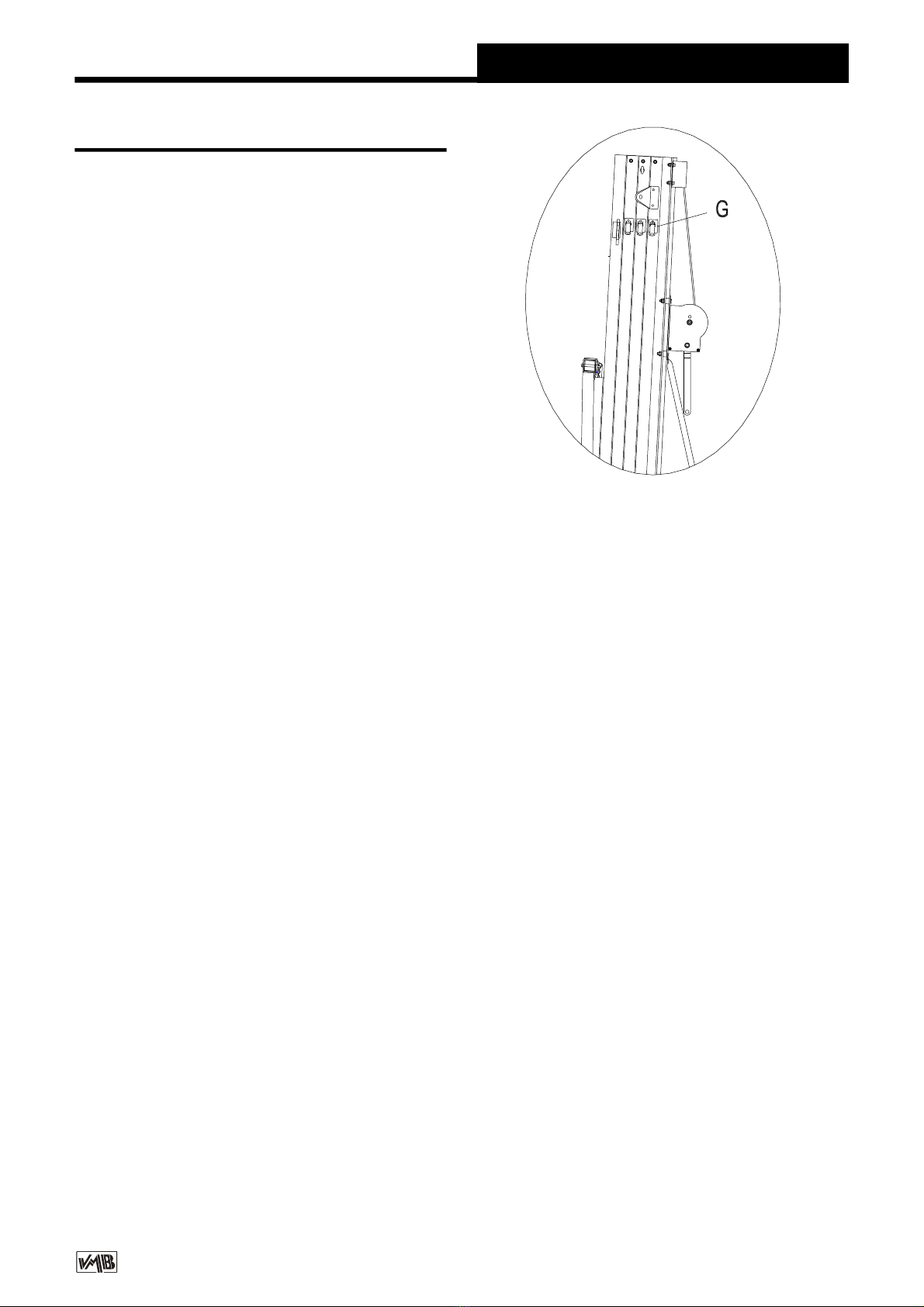

4.8 – Descending the lift:

To bring the lift down you need to first turn the

winch handle slightly clockwise and at the same

time push the red ALS lock in (G). (Fig. 7)

This releases the blocking systems. Then turn

the handle anti clockwise, whilst maintaining

theALS lock pushed in until the profile has been

completely lowered.

All red ALS locks should be held in one by one

whilst the handle is turned anti clockwise and

the profiles are brought down, one by one. If

you release your finger from the ALS lock it

will automatically block. In this case, repeat the

first operation by turning slightly clockwise and

then anti clockwise whilst always pushing the

red ALS lock in.

It is necessary to completely lower each profile

before starting to lower the next. If you push

another red ALS lock without having completely

lowered the previous profile the first profile will

remain blocked by the security system and you

will not be able to lower it later.

If this happens, elevate the towerlift to the

locked position and free the lock so that you

can commence the descent again until it is

completely lowered.

Finally, release the carriage lock following the

same principle as before and lower it to the

required level to be able to dismount the Line

Array from the lift.

Quick Operation Guide ENGLISH

4.9 – Transport

Once all the profiles are completely lowered

remove the FAS-01 or FAS-02 support and the

forks placing them in their horizontal position

facing down. Lower the carriage so that right

fork can be fixed and blocked for transport (B).

Remove the front support bars ( BA) by taking

out the pins (BU). Replace the pins in the top

support ( E ) of the lift’s base profile and also

at the top of each front support bar.

Fig. 7

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

5. MAINTENANCE.

5.1 – Periodically check the condition of the

cable. If a cable is torn or broken it should be

replaced immediately. Do not use the lift if the

cable is not perfect. Only use torsion resistant

steel cable DIN 3060.

5.2 – The lift is supplied completely greased

from the factory. Never the less, we

recommend you periodicallygrease (depending

on amount used) the teeth of the winch (CD),

end point of the handle (RM), bar (EB) (Fig. 8)

and the profile nylon drums.

ATTENTION: Do not grease or lubricate the

break mechanism.

The brake discs have been greased with a

special heat and pressure resistant grease. Do

not use other products.

Quick Operation Guide ENGLISH

7. CERTIFICATIONS

-

EC Machinery Directive

89/392/ECC and 98/37/ECC

- BGV C1 (GUV-VC1) / BGG 912 (GUV-G912)

6. GUARANTEE.

The warranty period for this lift is 3 years from

the date of purchase.

PRO LIFTS S.L. promises, that from the date of

purchase and during the warranty period to

resolve any faults that may occur produced

through defect material or fabrication.

Damage caused by inproper use, product

modification, terciary manipulation or acciden-

tal fire are not covered by this warranty.

5.3 – All lifts should undergoan annual technical

inspection carried out by an authorized VMB

dealer to check the certifications and general

condition of all the lift’s elements and security

systems involved in the lift’s use.

5.4 – Only use original spare parts to guarantee

a continued security level.

The user loses all rights to warranty if any spare

parts other than originals are used or carries

out any modification or alteration to the towerlift.

5.5 – To request a spare part please indicate

the corresponding code which can be found in

this manual.

VMB Tecnical Assistance

info@prolifts.es

Place the bars in their transport compartment.

Remove the outriggers, releasing the locks and

place in their transport position (S). Turn and

tighten the fixing screws (J). The lift can be

transported horizontally by adding the RH-4 kit.

Figura 8

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Manual de instrucciones ESPAÑOL

CONTENIDO

1. Introducción

2. Datos técnicos

3. Normas de seguridad

4. Instrucciones de uso

5. Mantenimiento

6. Garantía

7. Certificaciones

1. INTRODUCCION

Estimado usuario:

Agradecemos su confianza al adquirir las

torres elevadoras VMB.

Tiene en sus manos un producto de calidad

y fiabilidad contrastadas por la dilatada

experiencia de los usuarios profesionales

en todo el mundo.

Para poder trabajar con este elevador

volando todo tipo de equipos de sonido sin

peligro y de forma segura, lea atentamente este

manual, observe los datos técnicos y siga

íntegramente todas las instrucciones de

utilización y seguridad.

Este manual de instrucciones, deberá estar dis-

ponible permanentemente junto al elevador.

Todos los elevadores VMB son sometidos a

un constante control de calidad y durísimas

pruebas de verificación, para garantizar la

máxima fiabilidad y resistencia.

El elevador TL-A450, ha sido proyectado

especialmente para levantar hasta 6 metros

de altura, equipos de sonido tipo line array con

un peso de 450 Kg desplazados 50 cm. en

avance respecto al cuerpo de la torre.

Este desplazamiento, es necesario para po-

der angular los recintos acústicos los gra-

dos precisos para lograr una perfecta co-

bertura de sonorización.

2. DATOS TECNICOS

2.1 - Torre elevadora modelo TL-A450.

2.2 - Diseñada especialmente para levantar

equipos de sonido tipo line array desde el

mismo suelo en sentido vertical a cualquier

altura hasta 6 m., con un avance respecto al

cuerpo de la torre de 50 cm.

2.3 - Carga máxima elevable: 450 Kg. despla-

zada 50 cm del cuerpo del elevador.

2.4 - Carga mínima elevable: Puede subir o

bajar sin carga alguna.

2.5 - Altura máxima: 6 m.

2.6 - Altura plegada: 1,98 m. Altura mínima de

carga : 0,05 m.

2.7 - Superficie de la base : 2,2 x 2,1 m.

El elevador, TL-A450, incorpora los sistemas

de seguridad ILS (Inertia-Lock-Securyty) yALS

(Automatic-Lock-Security), exclusivos de VMB,

que garantizan la imposibilidad de caida de

la carga y una total seguridad de utilización.

ATENCION:

No utilice este elevador sin haber leído y

seguir estas instrucciones. En caso contrario,

podría llegar a provocar un grave accidente.

Durante la vida útil del elevador, puede

necesitar piezas de repuesto. Diríjase en este

caso a su distribuidor habitual.

Solamente deben utilizarse piezas de repuesto

originales. El usuario perderá todos sus

derechos de garantía si incorpora cualquier

repuesto que no sea original o realiza

cualquier modificación en el elevador.

Para cualquier consulta sobre el elevador,

deberá indicar el número de serie y año de

construcción.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

2.8 - Peso de transporte : 196 Kg.

2.9 - Material de construcción: Cuerpo principal

de cuatro tramos más carro elevador, en perfil

de aluminio extrusionado 6082-T6. Base,

patas y soportes varios, en perfileria de acero

según DIN 2394. Gatillos de seguridad y

poleas acanaladas en acero ST-37.

2.10 - Sistemas de fijación, seguridad ALS

(Automatic-Lock-Security), ILS (Inertia-Lock-

Securyty) que fijan e imposibilitan la caida de

la carga en todo momento.

2.11 - Cabrestante de acción manual de

1.200Kg de capacidad de carga máxima con

freno de discos automático.

Manual de instrucciones ESPAÑOL

2.12 - Cable : Acero según DIN 3060. Calidad

180 Kg/mm2antitorsión. Diámetro 6 mm.

2.13 - Platillos estabilizadores ajustables en las

patas, con apoyos antideslizantes de caucho

inyectado.

2.14 - Fijación de las patas con gatillos de

seguridad.

2.15 - Nivel de burbuja para ajustar la posición

vertical de la torre.

2.16 - Todos los elementos del elevador es-

tán acabados en poliéster negro satinado.

2.17 - Ruedas direccionables para facilitar el

transporte de la torre en posición vertical y

plegada hasta su emplazamiento de trabajo.

3. NORMAS DE SEGURIDAD.

3.1 - El elevador TL-A450 es una máquina

diseñada para la elevación de cargas en

sentido vertical, NUNCA se debe utilizar

como plataforma elevadora de personas.

3.2 - Colocarelelevadorsóloensuperficies

duras y planas, verificando que está en

posición vertical, mediante el nivel de

burbuja (F) situado en el tramo base.

Ajustar si fuera necesario con los platillos

de apoyo (Q), girando la manivela (H) en

el sentido adecuado. Nunca utilice cuñas

ni elementos extraños para equilibrar el

elevador.

!

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Manual de instrucciones ESPAÑOL

3.5 - No se debe sobrepasar la capacidad

de carga máxima indicada en la etiqueta

de características del elevador y en este

manual de instrucciones.

3.4 - Nunca se debe elevar una carga

sin antes verificar que está correctamente

apoyada y centrada en los soportes

elevadores adecuados, de forma que el

peso de la carga sólo actúe en sentido

vertical.

3.3 - Comprobar que las patas están

correctamente montadas y sujetas por sus

pasadores retenedores de seguridad.

Kgs

3.6 - Si existe posibilidad de viento fuerte o

en ráfagas, coloque el elevador en suelo

firme y asegúrelo con la ayuda de tirantes.

Nunca fije un tirante sobre un vehículo

o cualquier otro elemento que pueda

desplazarse.

3.7 - No use escaleras encima del elevador

ni las apoye en él para realizar ningún tipo

de trabajo.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

Manual de instrucciones ESPAÑOL

3.11 - No utilice nunca el elevador sobre

una superficie móvil o vehículo.

3.10 - No desplace nunca el elevador si se

encuentra con la carga elevada. No es

aconsejable realizar ningún tipo de

movimiento, ni tan siquiera pequeños

ajustes de posicionamiento.

3.9 - Nunca se ponga debajo de la carga ni

permita la presencia de otras personas en

la zona de trabajo del elevador.

3.8 - Tenga cuidado con todo tipo de

salientes por encima del elevador como

cornisas, balcones, letreros luminosos,

etc...

Es muy importante evitar la presencia de

cables por debajo de la altura de trabajodel

elevador.

3.12 - Antesdeutilizarelelevador,verifique

el estado del cable. El cable no debe

presentar rotura de hilos o aplastamiento.

NUNCA use cables defectuosos yen caso

de duda cambie el cable. Sólo utilice cable

de acero según DIN 3060. Calidad 180 Kg/

mm2resistente a la torsión.

v11.03- Depósito legal y Copyright 2011. Todos los derechos reservados.

PRO LIFTS S.L.

3.16 - Para el transporte del elevador hay

que bajar todos los tramos.

3.15 - Noengrase ni lubriqueel mecanismo

de freno del cabrestante. Los discos de

freno, han sido engrasados con una grasa

especial resistente al calor y la presión.

No deben ser utilizados otros productos

para evitar influir negativamente en el

funcionamiento del freno.

3.14 - La carga mínima para el funciona-

miento del freno del cabrestante sin proble-

mas, es de 25Kg. Sin esta carga mínima el

freno podría no actuar.

3.13 - Nunca desmonte la manivela del

cabrestante si el elevador está con carga y

elevado.

3.17 - Solamente deben utilizarse piezas

de repuesto originales.

Manual de instrucciones ESPAÑOL

-25

ORIG INAL

Other manuals for TL-A450

1

Table of contents

Languages:

Other VMB Lifting System manuals