Nice HySecurity SlideSmart DC Series Assembly instructions

Installation and Programming Manual

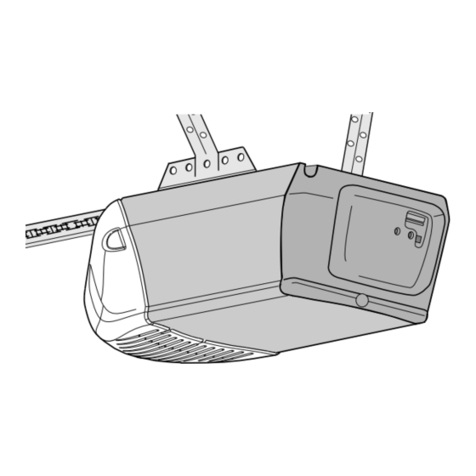

SlideSmart™DC

DC10F, DCS10F, DC15, DCS15

Vehicular slide gate operator with Smart DC Controller

(This page intentionally blank)

MX4505 Rev. E ©2020

2 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

TABLE OF CONTENTS

SlideSmart DC

TABLE OF CONTENTS.................................... 4

INTRODUCING SLIDESMART DC ................... 5

Intelligent Features: Smart DC ControllerTM ............................5

Technical Support.......................................................5

Installer's Check List......................................................6

Installer’s Check List ..................................................6

SlideSmart DC Components ......................................... 7

Safety Requirements.....................................................8

INSTALLATION ............................................. 19

Pad Condition...........................................................20

Using an Existing Pad ..............................................21

Front Installation.......................................................22

Rear Installation .......................................................23

Unpacking the Operator ...........................................24

Concrete Pad Mount ................................................25

Gate Bracket and Chain Installation.........................26

Aligning the Chain ....................................................27

Connecting Battery and Turning DC Power On .......28

Programming the Initial Setup Menu........................28

Establishing the Open & Close Limits ......................30

Installing the Target Magnet .....................................31

Installing The Earth Ground .....................................33

POWER ......................................................... 33

Wiring AC Power ...................................................... 34

Wiring 115VAC Power ..............................................35

Wiring 208/230VAC Power....................................... 36

Using A Solar Powered Operator .............................37

Design Requirements & Considerations ..................37

Connecting the SlideSmart DCS to Solar Power .....38

Connecting Peripherals to Solar Operators .............40

Understanding Gate Activity based on Solar Zones. 41

Considerations For DC-Powered Operators ............42

Installing the Extended Battery Backup Kit ..............43

Initial Setup .............................................................. 45

Turning Both Power Switches On ............................ 45

DISPLAY AND MENU OPTIONS .................... 45

Using Smart DC Controller Buttons In Menu Mode .47

Run Mode.................................................................48

Using Smart DC Controller Buttons in RUN Mode...48

Viewing Operator Status Displays............................49

User Menu................................................................50

Adjusting the Close Timer ........................................ 50

Setting the Time and Date........................................ 51

Setting AC Power Loss Gate Function.....................51

Adjusting the Display Contrast ................................. 53

Installer Menu...........................................................57

Resetting the OPEN and CLOSE Limits ..................58

Adjusting Gate Speed ..............................................59

Adjusting the IES Sensitivity ....................................60

Reinstating Factory Defaults .................................... 62

Enabling the Fire Department Override ...................63

SMART DC CONTROLLER ............................ 74

Overview Of The Smart DC Controller.....................75

Vehicle Detector Installation Options .......................78

Connecting Hy5B Vehicle Detectors ........................ 79

Install Standard 11-Pin Box Type Vehicle Detectors 81

Connecting Accessory Devices................................82

Entrapment Sensor Connections ..........................82

Manual Push Button Station.....................................83

User Relays - Programming Procedure ...................84

Power Requirements................................................87

BI-PARTING GATE SYSTEMS ....................... 87

Primary And Secondary Wiring Connections ........... 88

Primary and Secondary Menu Setup .......................89

ACCESSORY CONNECTIONS ....................... 90

Connecting A Radio Receiver For Remote Open.....90

Installing A Maglock Or Solenoid Lock ..................... 90

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 3

TABLE OF CONTENTS

Installing a Lock for 12VDC or 24VDC Systems ...... 91

Installing a Lock for High Voltage Systems ..............91

Installing Vehicle Detectors and Loops .................... 92

Monitored External Entrapment Sensors .................95

External Entrapment Protection ...............................97

Photo Eye Installation Tips .......................................97

Photo Eye Function:..............................................98

Edge Sensor Installation Tips................................. 100

Smart DC Controller Troubleshooting .................... 101

Vehicle Detector and Loop Fault Diagnostics ........ 111

SCHEMATICS.............................................. 114

MAINTENANCE........................................... 116

GENERAL MAINTENANCE ................................... 116

Smart Touch Analyze and Retrieve Tool ............. 116

What You Need ................................................... 116

Installing Start Software ...................................... 116

Setting User Account Controls ............................ 117

Electrical Controls .................................................. 117

Mechanical Maintenance ....................................... 117

Software Maintenance ........................................... 117

Drive Belt Tension And Alignment .......................... 118

DC Battery Replacement ....................................... 119

Clock Battery Replacement....................................120

APPENDIX A - INSTALL CONFIGURATIONS 121

APPENDIX B - FRENCH TRANSLATIONS ... 131

PARTS & LIMITED WARRANTY.................. 135

Slidesmart Parts.....................................................135

Slidesmart Parts List ..............................................136

WARRANTY ................................................ 137

SLIDESMART DC SPECIFICATIONS ........... 138

NOTICE

Visit https://hysecurity.com/technical-support/ for installation manuals, replacement part instructions, part

diagrams and more.

MX4505 Rev. E ©2020

4 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

INTRODUCING SLIDESMART DC

Thank you for purchasing our premium SlideSmart DC™ slide gate operator. At HySecurity® Gate, Inc.,

we pride ourselves on quality. Our new line of electromechanical gate operators include a number of

unparalleled user benefits:

Robust - An especially low flex, corrosion resistant, steel chassis combines with an attractive, key-locked,

fade resistant, roto-molded cover. The components on the Smart DC Controller™ are protected by

opto-isolators which shield them from power surges and lightning strikes.

Power - The Smart DC Controller provides variable speed control to a powerful, continuous duty

24V DC motor which drives the gearbox. The electronics, motor and gear box are rated to operate in

temperatures that range from -13°F to 158°F (-25°C to 70°C). SlideSmart DC 15 is rated for gates up

to 40 feet long and 1,500 pounds (12m and 682kg). SlideSmart DC 10F is rate for gates up to 40ft and

1,000lbs. (12m and 454kg). Solar options are available for both models.

Finesse - A variable rate of gate acceleration and deceleration, dependent upon gate weight and length,

assures very smooth handling.

UPS backup and Solar ready - Two 12V, 8 amp hour (Ah) batteries will provide a fully functional gate

operator (up to 4000ft/1219m of gate travel) when AC power is unavailable. Four user-selectable UPS

modes are available. 12VDC and 24VDC are available to power accessory controls. An optional base

extension is available that provides space for the optional 50Ah batteries which support solar applications

or usage during extended power outages.

INTELLIGENT FEATURES: SMART DC CONTROLLERTM

Menus and User relays - The Smart DC Controller has over 55 menu items to allow installer configuration

of gate function and two user relays, which can be configured for over 30 different functions.

Independent adjustment for open and close gate speeds - An easy-to-use menu on the Smart DC

Controller allows the installer to vary the open and close speed settings.

Intelligent Inherent Entrapment Sensor (IES) - Any impediment to gate travel is sensed by the system,

stopping gate movement per UL 325 Safety Standards. The intelligent system monitors gate power then

adapts the IES to trip at an adjustable threshold above normal power.

Improved Liquid Crystal Display (LCD) - A 32-character LCD provides increased readability for

programming and troubleshooting.

USB communications port - A direct connect provides accessibility to download system diagnostics

and upload system configurations using the Smart Touch Analyze and Retrieve Tool (START) software.

START software and diagnostics - With START software loaded on a laptop computer, you can get

the latest software upgrade and have an invaluable troubleshooting tool for all HySecurity operators.

To download this free software, visit the HySecurity website at www.hysecurity.com.

TECHNICAL SUPPORT

For technical support, call your installer or authorized HySecurity distributor. Obtain the serial number

of your operator before calling. Refer to SlideSmart Components on the front page. For the name of a

distributor near you, call HySecurity at 800-321-9947.

For information about HySecurity training for installers, maintenance personnel and end users, refer to

the company website at www.hysecurity.com or call 800-321-9947.

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 5

INSTALLER'S CHECK LIST

INSTALLER’S CHECK LIST

The following list provides a high level overview of the tasks involved in installing the SlideSmart DC

gate operator. Take a moment to review the list and check off the items as you complete the install.

Site Prep - concrete pad location/dimensions, distance from gate, chain height, and

mounting considerations: post or base extension, front or rear installation.

Make sure gate installation complies with ASTM F2200 Standard Specification for

Automated Vehicular Gate Construction. And, install the supplied WARNING signs

on both sides of the gate.

Check for compliance with local codes, site conditions, and NEC standards.

Install operator - (on concrete pad use four ½ - 13 x 3.5in long concrete wedge anchors.)

Attach chain end bracket to gate at proper height.

Attach chain to end brackets and feed under SlideSmart idlers and over chain sprocket.

Tighten chain using tensioning bolts.

Verify chain is level with idlers and parallel to operator and gate.

Connect red wire to DC Power Switch.

Turn DC Power ON.

Complete Initial Setup Menu programming.

Install the target magnet and make sure it is in line with and passes by the target sensor

so it can be recognized by the software programming.

Connect AC Power.

Connect all accessory devices.

Set the Close Timer (through the User Menu).

Set gate speed, if applicable (through Installer Menu). Refer to START ("Smart Touch

Analyze and Retrieve Tool" on page 113 in the "Reference" on page 87.

Adjust IES sensitivity, if needed (through Installer Menu).

Check the Smart DC Controller software version. If needed, upload the latest version

from www.hysecurity.com. See "Smart Touch Analyze and Retrieve Tool" on page 113.

Program changes through the Installer Menu depending on the accessory devices

that you have installed.

Give a copy of the operator instructions to the end user. Show the end user how to:

Remove the operator cover. Turn the power off and on to demonstrate learn

limits after DC/AC cycles.

Turn the DC power switch off, which disengages the motor, and manually push

the gate.

Test the red Emergency Stop Button located on the side of the control box. It

can be accessed through a hole in the cover. See illustration on page XXX.

Take photographs of the completed installation site and save it in your business files.

Install external entrapment sensors as needed.

Refer to "Parts & Limited Warranty" on page 132 for SlideSmart parts list.

MX4505 Rev. E ©2020

6 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

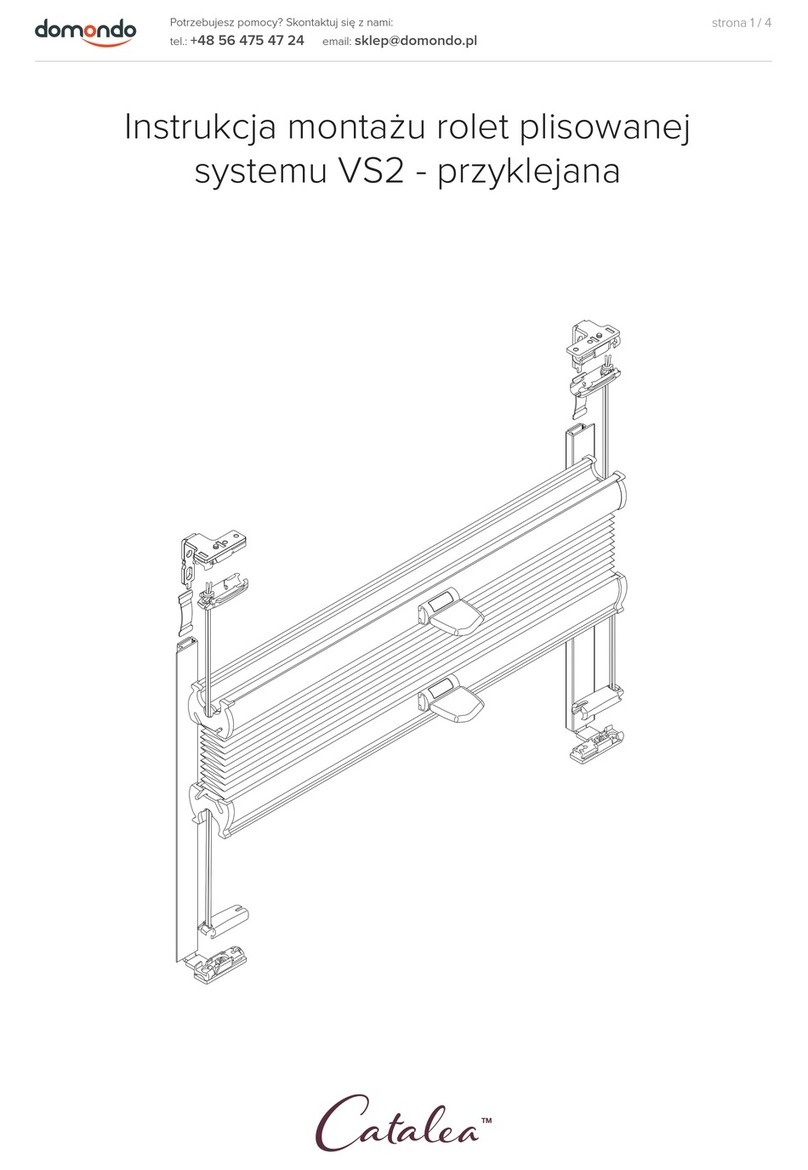

SLIDESMART DC COMPONENTS

Service Outlet

115VAC, 15A

O

DC

POW

OF

O

AC

POW

OF

COVER, LATCH

COVER

WARNING

LABEL

PULLEY,

MOTOR

PROTECTION

PLATE

& COVER

PULLEY, GEARBOX

BELT DRIVE, 2 ft/s

PULLEY, GEARBOX

BELT DRIVE, 1 ft/s

GEARBOX

BRUSH

KIT

TRANSFORMER

BATTERY KIT,

8 Ah

SPROCKET

IDLER (x2)

BASE

PLATE

30 ft OF #40 CHAIN,

BRACKET & HARDWARE

BOARD, POWER SUPPLY

TARGET SENSOR (x2)

SERIAL # LOCATION

AC SWITCH,

ON/OFF

115VAC

SERVICE

OUTLET

MOTOR

DC SWITCH,

ON/OFF

SWITCH, RESET

EMERGENCY

STOP BUTTON

BUZZER

CONTROL BOX

BOARD, SMART

DC CONTROLLER

CIRCUIT

BREAKER

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 7

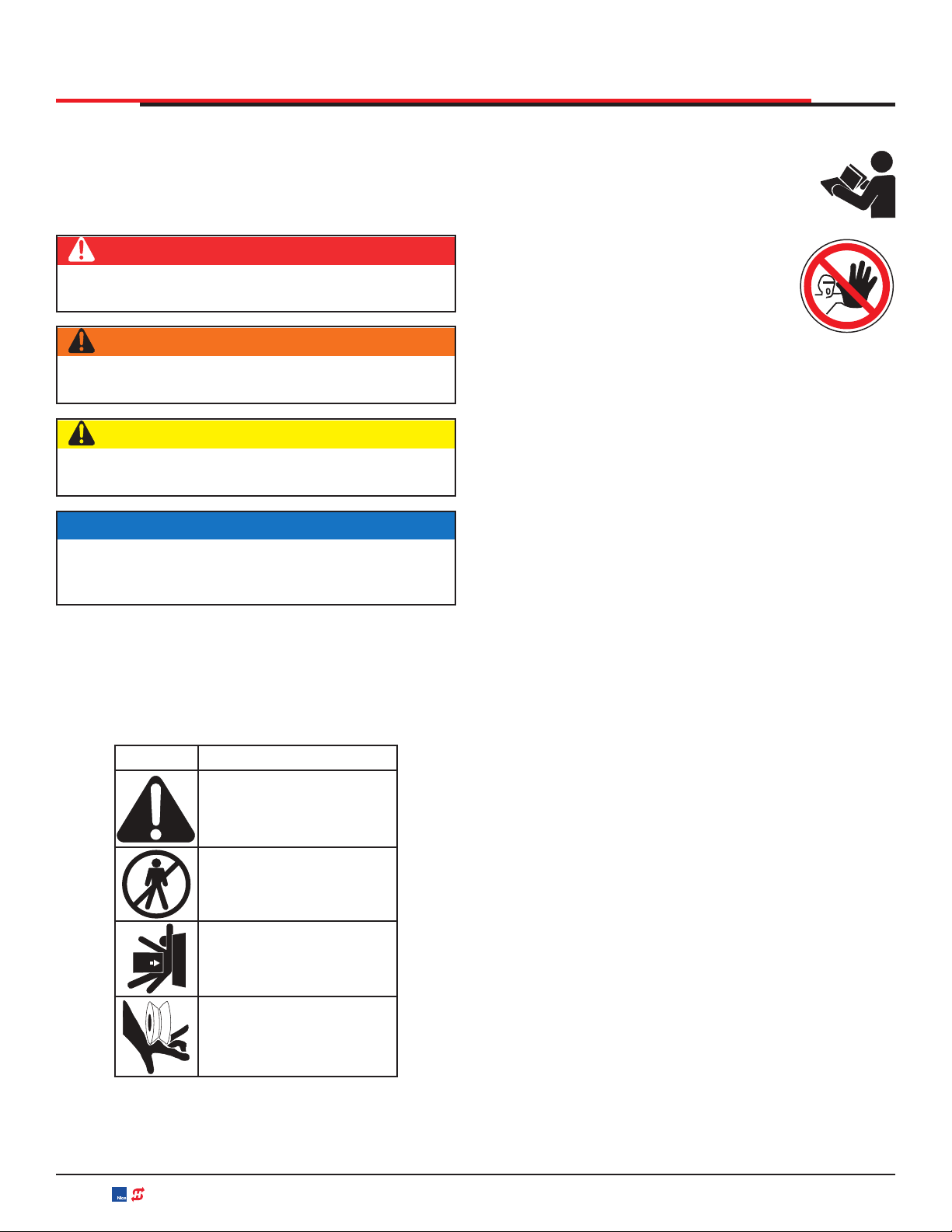

SAFETY REQUIREMENTS

SAFETY MESSAGES

The safety messages below inform you about potential

hazards that can result in injury. Safety messages specifically

address level of exposure to operator and are preceded by

one of four words: DANGER, WARNING, CAUTION or

NOTICE.

COMMON INDUSTRIAL SYMBOLS

These international safety symbols may appear on product

or in its literature to alert of potential personal injury hazards.

Obey all safety messages that follow these symbols to avoid

possible injury or death.

Symbol Safety Hazard

Attention -

Take Notice

Danger -

Keep Away

Entrapment Zone

Possible Pinch Point

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

Indicates damage to equipment is probable if the

hazardous situation is not avoided.

IMPORTANT SAFETY INSTRUCTIONS

Hazards, associated with automatic gates, can

be reduced with proper site design, installation,

and use. Installers, maintenance crews, and

owners/users must read and follow the safety

requirements found in HySecurity® product

manuals.

It is important that only qualified installers

handle installation of HySecurity Gate

vehicular gate operators. A “qualified”

installer has one of the following:

1. A minimum of three years experience installing simila

r

equipment.

2. Proof of attending a HySecurity Technical Training

seminar within the past three years.

3. Significant manufacturer endorsements of technical

aptitude in gate operator installation and operation.

Underwriter Laboratories (UL) and the American Society fo

r

Testing and Materials (ASTM) are responsible for current

safety standards and regulations regarding gate operators

and automated gates. All aspects of gate installation must

comply with the appropriate safety standard. For the most

up-to-date ASTM F2200 Gate and Fence Standards, refe

r

to www.astm.org. For UL 325 Safety Standard, refer to

www.ul.com. Consult local government agencies for up-to-

date rules and regulations as certain municipalities have

established licensing, codes or regulations that regulate

automated gate system design and installation.

GENERAL SAFETY INFORMATION

A gate operator is only a component in a gate system.

The other parts of the gate system can include the

gate, the external safety sensors, access controls, and

vehicle detectors. To have a gate system that provides

for safety, security, and reliable operation it is essential

these components operate together as a system. It is

the responsibility of the system designer and/or installe

r

to ensure any safety or operational issues have been

addressed.

MX4505 Rev. E ©2020

8 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

SAFETY REQUIREMENTS

WARNING

To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING

GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object

activates the non-contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to

adjust and retest the gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the user’s manual. Have a qualified service person make repairs to

gate hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS.

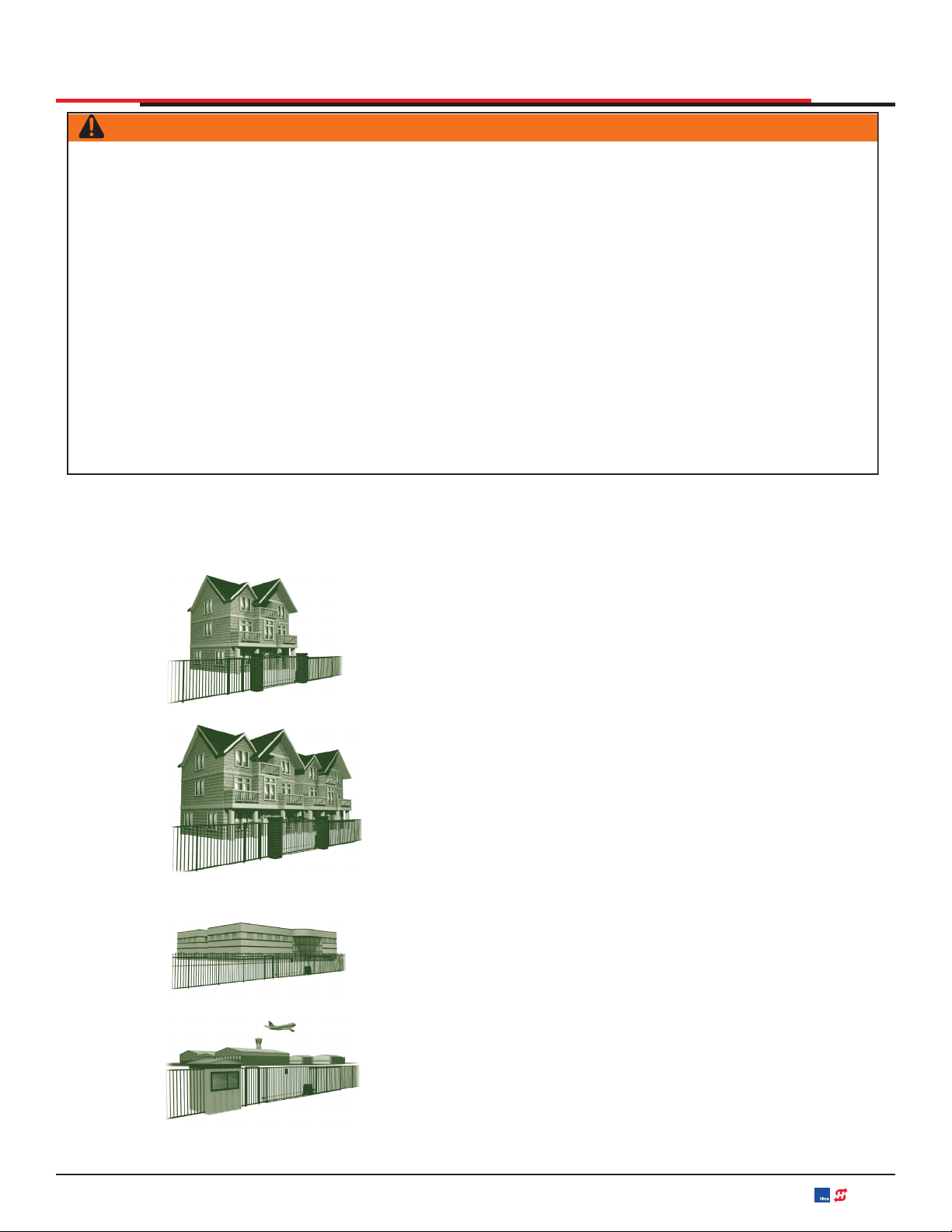

IDENTIFYING GATE OPERATOR CATEGORY AND UL 325 USAGE CLASS

The UL 325 standard covers gate operators. Within this safety standard several Usage Classes are described that defin

e

different types of installations where gate operators can be applied. Some operators are restricted in their usage application

.

Appropriate Usage Classes are shown in the Specifications.

Class I Class I: Intended for use in a location of one to four single family dwellings

or a parking area associated with one to four single family dwellings.

Class II

Class II: Intended for use in a commercial location or building such as a multi-

family housing units (five or more single family units) hotels, garages, retail

stores or other buildings servicing general public.

Class III Class III: Intended for use in an industrial location or building such as factories

or loading docks or other locations not accessible by the general public.

Class IV

Class IV: Intended for use in guarded industrial locations or buildings such as

an airport security area or other restricted access location, not servicing general

public, in which access is monitored by security personnel or via closed circuitry.

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 9

SAFETY REQUIREMENTS

VEHICULAR TRAFFIC ONLY

WARNING

This automatic gate operator is not designed nor is it intended for pedestrian traffic. Vehicular gate operators must by

their nature be powerful to function reliably. This power can cause injury or death. Accordingly, direct all pedestrian traffic

to a separate walk-through gate.

Install this gate operator only when:

The operator is appropriate for the construction of the

gate and the usage Class of the gate.

All openings of a horizontal slide gate are guarded or

screened from the bottom of the gate to a minimum of

1.83 m (6 ft) above the ground to prevent a 57.2 mm (2-1/4

in) diameter sphere from passing through the openings

anywhere in the gate, and in that portion of the adjacent

fence that the gate covers in the open position.

All exposed pinch points are eliminated or guarded.

Guarding is supplied for exposed rollers.

The operator is intended for installation only on gates used for

vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to

promote pedestrian usage. Locate the gate such that persons

will not come in contact with the vehicular gate during the entire

path of travel of the vehicular gate.

The gate must be installed in a location so that enough

clearance is supplied between the gate and adjacent structures

when opening and closing to reduce the risk of entrapment.

Swinging gates shall not open into public access areas.

The gate must be properly installed and work freely in both

directions prior to the installation of the gate operator. Do

not over-tighten the operator clutch or pressure relief valve

to compensate for an improperly installed, improperly

functioning, or damaged gate.

Permanently mounted controls intended for user activation

must be located at least 1.83 m (6 ft) away from any moving

part of the gate and where the user is prevented from

reaching over, under, around or through the gate to operate

the controls.

Exception: Emergency access controls only accessible

by authorized personnel (e.g. fire, police, EMS) may be

placed at any location in the line-of-sight of the gate.

The Stop and/or Reset button must be located in the line-

of-sight of the gate. Activation of the reset control shall not

cause the operator to start.

A

minimum of two (2) WARNING SIGNS shall be installed,

in the area of the gate. Each placard is to be visible by

persons located on the side of the gate on which the placard

is installed.

For gate operators utilizing a non-contact sensor (Photo

Eye):

See instructions on the placement of non-contact

sensors for each type of application.

Care shall be exercised to reduce the risk of nuisance

tripping, such as when a vehicle trips the sensor while

the gate is still moving.

One or more non-contact sensors shall be located where

the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

For a gate operator utilizing a contact sensor (Edge):

One or more contact sensors shall be located where

the risk of entrapment or obstruction exists, such as at

the leading edge, trailing edge, and postmounted both

inside and outside of a vehicular horizontal slide gate.

A hardwired contact sensor shall be located and its

wiring arranged so that the communication between

the sensor and the gate operator is not subjected to

mechanical damage.

A wireless device such as one that transmits radio

frequency (RF) signals to the gate operator fo

r

entrapment protection functions shall be located where

the transmission of the signals are not obstructed o

r

impeded by building structures, natural landscaping

or similar obstruction. A wireless device shall function

under the intended end-use conditions.

One or more contact sensors shall be located on

the inside and outside leading edge of a swing gate.

Additionally, if the bottom edge of a swing gate is greate

r

than 152 mm (6 in) but less than 406 mm (16 in) above

the ground at any point in its arc of travel, one or more

contact sensors shall be located on the bottom edge.

USE OF VEHICLE DETECTORS

Use of vehicle detectors (loop detectors) is strongly

encouraged to prevent damage to vehicles caused by gates

closing on them. This is not considered to be a safety item as

vehicle detectors cannot provide protection to pedestrians.

In some situations, photoelectric devices may be used as

vehicle detectors, but should be wired accordingly.

GATE CONSTRUCTION AND SAFETY

Gate construction plays a very important role in ensuring

the safety of any automated gate system. The standard fo

r

gate construction is ASTM F2200. Below are key areas to

address in gate design for safety. For complete information

consult the standard. Copies of the standard are available at:

https://www.astm.org/Standards/F2200.htm.

MX4505 Rev. E ©2020

10 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

SAFETY REQUIREMENTS

A

nother source of information is available from DASMA, the

Door and Access System Manufacturer’s Association. The

A

ssociation publishes Technical Data Sheets, one of which

concerns ASTM F2200. For more information, see:

http://www.dasma.com/PDF/Publications/TechDataSheets/

OperatorElectronics/TDS370.pdf.

General Requirements for gate construction:

Gates shall be constructed in accordance with the

provisions given for the appropriate gate type listed.

Refer to ASTM F2200 for additional gate types.

Gates shall be designed, constructed and installed to not fall

over more than 45 degrees from the vertical plane, when a

gate is detached from the supporting hardware.

Gates shall have smooth bottom edges, with vertical bottom

edged protrusions not exceeding 0.50 in (12.7 mm) other

than the Exceptions listed ASTM F2200.

The minimum height for barbed wire shall not be less than 6

ft (1.83 m) above grade. The minimum height for barbed tape

shall not be less than 8 ft (2.44 m) above grade.

An existing gate latch shall be disabled when a manually

operated gate is retrofitted with a powered gate operator.

A gate latch shall not be installed on an automatically

operated gate.

Protrusions shall not be permitted on any gate. Consult

ASTM F2200 for exceptions.

Gates shall be designed, constructed and installed such

that their movement shall not be initiated by gravity when

an automatic operator is disconnected.

For pedestrian access in the vicinity of an automated

vehicular gate, a separate pedestrian gate shall be

provided. The pedestrian gate shall be installed in a

location such that a pedestrian shall not come in contact

with a moving vehicular access gate. A pedestrian gate

shall not be incorporated into an automated vehicular

gate panel.

Any non-automated gate that is to be automated shall be

upgraded to conform to the provisions of this specification.

This specification shall not apply to gates generally

used for pedestrian access and to vehicular gates not

to be automated.

Any existing automated gate, when the operator requires

replacement, shall be upgraded to conform to the

provisions of this specification in effect at that time.

The following provisions shall apply to Class I, Class II,

Class III, and Class IV vehicular horizontal slide gates:

All weight bearing exposed rollers 8 ft (2.44 m), or less, above

grade shall be guarded or covered.

All openings shall be designed, guarded, or screened from

the bottom of the gate to the top of the gate or a minimum o

f

72 inch (1.83 m) above grade, whichever is less, to prevent

a 2-1/4 inch (57 mm) diameter sphere from passing through

the openings anywhere in the gate, and in that portion o

f

the adjacent fence that the gate covers in the open position.

The gate panel shall include the entire section of the moving

gate, including any back frame or counterbalance portion o

f

the gate.

A gap, measured in the horizontal plane parallel to the

roadway, between a fixed stationary object nearest the

roadway (such as a gate support post) and the gate frame

when the gate is in either the fully open position or the fully

closed position, shall not exceed 2-1/4 inches (57 mm).

Exception: All other fixed stationary objects greater than 16

inches (406 mm) from the gate frame shall not be required

to comply with this section.

Positive stops shall be required to limit travel to the designed

fully open and fully closed positions. These stops shall be

installed at either the top of the gate, or at the bottom of the

gate where such stops shall horizontally or vertically project

no more than is required to perform their intended function.

All gates shall be designed with sufficient lateral stability to

assure that the gate will enter a receiver guide. Consult ASTM

F2200 for details on various gate panel types.

SECONDARY ENTRAPMENT PROTECTION

SENSORS

Most HySecurity gate operators are equipped with a Type

A, Inherent Entrapment Sensor (IES). UL 325 Safety Standard

compliance requires installation of external entrapment

protection sensors, the number of which, depends on

entrapment hazards that exist at each particular installation.

To comply with UL 325, the following external sensors may

be used:

Contact sensors, such as edge sensors

Non-contact sensors, such as photo eyes

Site designer or installer can choose either photo eyes,

edge sensors, or a combination of these devices. Whatever

devices are used, protection in both opening and closing

directions of gate travel must be provided.

UL 325 Safety Standard for automatic sliding gates

specifically requires that edge sensors, photo eyes, or a

combination of both devices be installed to protect against

pedestrian entrapment in BOTH directions of gate travel

and wherever entrapment hazards exist.

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 11

SAFETY REQUIREMENTS

PHOTO EYES: One or more non-contact sensor

(photo eyes) shall be located where entrapment risk

or obstruction exists, such as perimeter reachable by a

moving gate.

Care shall be exercised to reduce the risk of nuisance

tripping, such as when a vehicle trips the sensor while the

gate is moving.

EDGE SENSORS: One or more contact sensors (edge

sensors) shall be located at leading edge, trailing edge,

and post-mounted, both inside and outside of a sliding

gate.

One or more contact sensors shall be located on the inside

and outside leading edge of a swing gate. Additionally, if

the bottom edge of a swing gate is greater than 6"(152mm)

but less than 16"(406mm) above the ground at any point in

its arc of travel, one or more contact sensors shall be located

on the bottom edge.

SENSOR SECURITY: A hard-wired contact sensor shall

CAUTION

A contact or non-contact sensor is also required to

protect against possible entrapment if gate opens to

a position less than 16 inches from any object, such as

a post or wall.

be located and its wiring arranged so that communication

between sensor and gate is not subjected to mechanical

damage.

SENSOR FUNCTION and COMMUNICATION: A sensor

that transmits its signal to gate operator must be located

so its signal is not impeded by building structures or other

obstructions. All sensors must be installed so that they

function as intended for end-use conditions.

UL 325 LISTING: Edge sensors and photo eyes must

be tested and labeled as “Recognized Components” or

otherwise certified to UL 325 requirements in order to

be deemed acceptable for use in a gate operator. Study

Important Safety Instructions and consider your specific

installation to determine where greatest entrapment

risks exist. Locate edge sensors and/or photo sensors

accordingly. Be certain that a sufficient number of sensors

are used so that pedestrians are protected from entrapment

in both directions of gate travel and all hazard areas are

fully protected. Most HySecurity gate operators require

external entrapment sensors that utilize Normally Closed

(NC) contact means of monitoring. HySecurity gate

operators utilizing the SmartCNX Controller require external

entrapment sensors that have a 10k Ohm or 4-wire pulsed

monitoring scheme. Refer to UL website at www.ul.com for

most up-to-date list of gate operator safety standards (UL

325). Refer to www.astm.org for a complete list of ASTM

F2200 Gate and Fence Standards.

Gate operator will not automatically cycle the gate unless an indication that the appropriate

number of external entrapment protection sensors are connected and operational.

The normally closed (NC) entrapment protection sensors wired to the Controller’s SENSOR

inputs are monitored using HySecurity software. Prompts appear on the display requesting

specific configurations based on the gate operator type.

Use of Approved External Entrapment

Protection Sensors is REQUIRED

325

Effective August 1st, 2018, the UL 325 Standard has changed:

• The operator shall monitor for the presence of every device at least once during each open and close cycle (32.1.8)

• It shall not be possible to make simple modifications in the field by adding, suppressing or changing, either on the operator or

external entrapment protection device(s), to bypass, interfere with, or otherwise defeat the monitoring function. (32.1.10)

• Entrapment zones are now defined for each gate type (4.23, 4.24, 4.29, 4.34)

SLIDE GATES: To enable fully automatic operation, all SLIDE gate operators will require a minimum of TWO monitored external

entrapment protection sensors (one for each direction) to protect entrapment zones in both the open and close direction of travel.

Preferred solution for slide gates: A photo eye for the close direction and a hard-wired edge sensor for the open direction

that is mounted to the face of the leading post of the fence behind the gate. (Reach through injuries are the most common

hazard associated with automatic sliding gates)

SWING GATES: To enable fully automatic operation, all SWING gate operators will require a minimum of ONE monitored external

entrapment protection sensor to protect entrapment zones in either the open or close direction of travel. However, an additional

monitored sensor is required if there is a risk of entrapment in both directions of gate travel.

Preferred solution for swing gates: A photo eye for the close direction and/or a hard-wired wraparound edge sensor on the

leading edge of the gate, which protects for both directions of gate travel.

MX4505 Rev. E ©2020

12 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

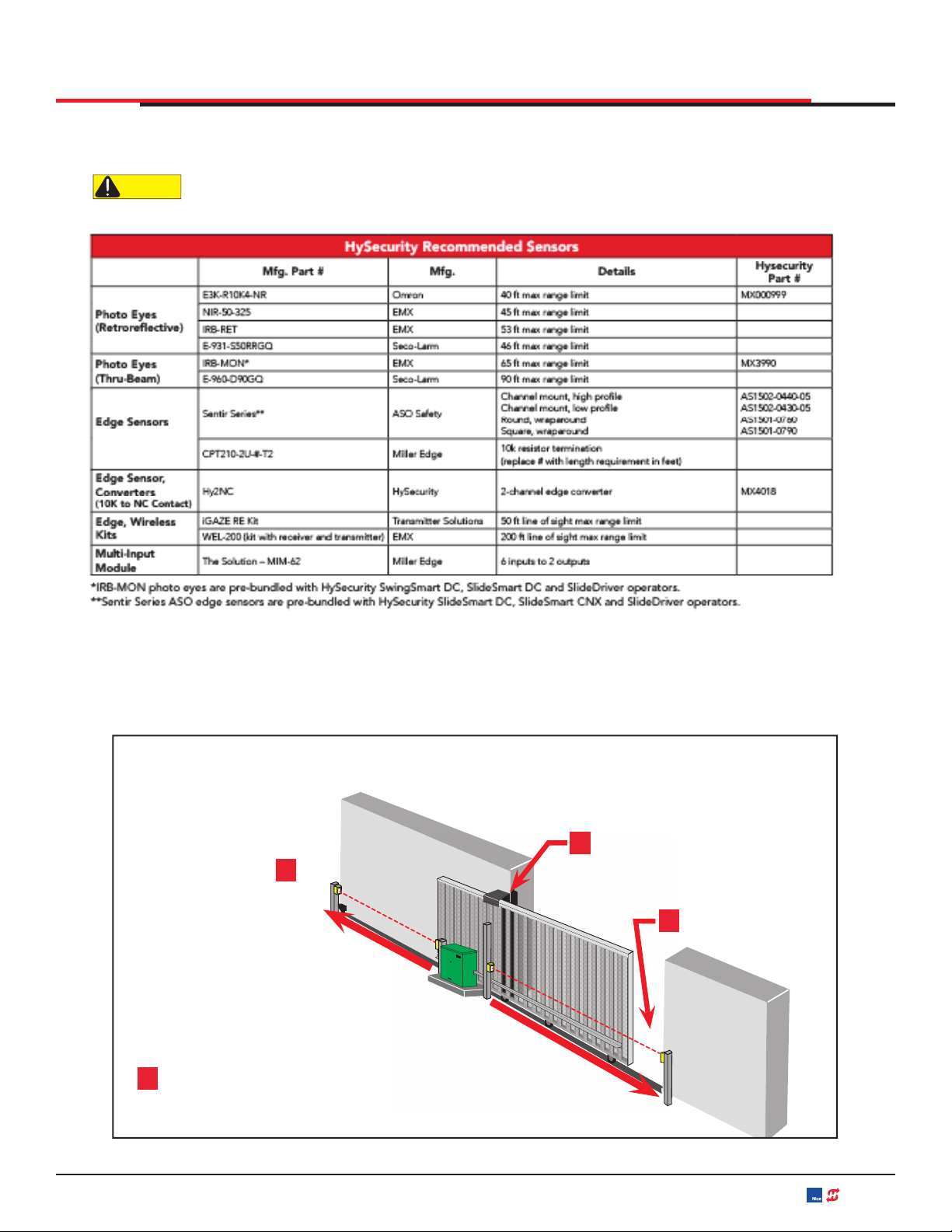

SAFETY REQUIREMENTS

T

h

e

f

o

ll

owing sensors

h

ave

b

een teste

d

wit

h

HySecurity gate operators

b

y an in

d

epen

d

ent

l

a

b

oratory an

d

certi

fi

e

d

to

comply with UL 325 7th Edition. Select sensors from this list for UL compliant gate automation solutions. Contact the

sensor manufacturer for specific recommendations for use.

CAUTION All external entrapment protection sensors must have NC sensor outputs and be wired to the SENSOR COM

terminal for monitoring and powering purposes. Depending on software version, the sensor becomes powered

when the gate operator’s motor runs or is always powered when the operator is connected to AC power.

Installers must assess each specic site and

install sensors that protect all potential entrapment zones.

For more information visit Gate Safety at www.hysecurity.com/gatesafety or

see latest operator manual at www.hysecurity.com/contact-us/technical-support/installation-manuals

Protects open direction

(EDGE OPEN)

1

A

Install Edge for

Draw-in Zone

Trailing End

Leading End

PUBLIC

SECURE

2

Install Photo eye

Protects Leading End

(EYE CLOSE)

Slide Gate

Common

Entrapment

Zones

Indicates Additional Potential Entrapment Zone

A

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 13

SAFETY REQUIREMENTS

ELECTRICAL SAFETY

Turn gate operator and all circuit

breakers OFF before performing

maintenance on the gate operator

or making contact with output

receptacles.

Never insert any objects into output

receptacles during operation. The

possibility exists of electrical shock,

electrocution, or death.

Never let power wires lay in water.

Never use damaged or worn wire when connecting

equipment. Inspect for cuts in the insulation.

Never grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

Always make certain that proper

power has been selected for the job.

See Cable Selection Chart in this

manual.

GROUNDING SAFETY

Always make sure that electrical

circuits are properly grounded to a

suitable earth ground (ground rod)

per the National Electrical Code

(NEC) and local codes. Severe

injury or death by electrocution

can result from operating an

ungrounded operator.

Never use gas piping as an electrical ground.

BATTERY SAFETY

HySecurity operators use sealed Absorbed Glass Mat (AGM)

batteries and HySecurity highly recommends replacing used

batteries with new AGM-type batteries.

CAUTION

Batteries used with HySecurity gate operator contain

materials considered hazardous to environment.

Proper battery disposal is required by federal law.

Refer to Hazardous Waste Regulations federal

guidelines.

To reduce risk o

f

fi

re or injury to persons:

Observe polarity between batteries and charging circuit.

Never mix battery sizes, types, or brands. Charging circuit

on HySecurity DC operators is designed for AGM-type

batteries, not flooded lead acid-type batteries.

Exercise care in handling batteries. Be

aware metal found in rings, bracelets, and

keys can conduct electricity, short

batteries, and cause potential injury.

Do not open or mutilate batteries. Battery cells

contain corrosive materials which may cause

burns and other injuries. Material within

batteries is toxic.

Always dispose of batteries properly. Do not

place batteries in fire. Battery cells may

explode. Follow federal guidelines for proper

disposal of hazardous waste.

Always keep battery cables in good working

condition. Repair or replace all worn cables.

Replace batteries according to instructions

found in DC Battery Replacement.

Do not charge frozen battery. Battery can

explode. If frozen, warm the battery to at

least 61°F (16°C).

ENVIRONMENTAL SAFETY/

HAZARDOUS MATERIALS AND PROPER

DISPOSAL

Decommissioning is a controlled process used to safely

retire a piece of equipment that is no longer

serviceable. If the equipment poses an

unacceptable and unrepairable safety risk due to

wear or damage or is no longer cost effective to

maintain (beyond life-cycle reliability) and is to be

decommissioned (demolition and dismantlement), be sure to

follow rules below.

Do not pour waste or oil directly onto the ground, down a

drain or into any water source.

Contact your country's Department of Public Works o

r

recycling agency in your area and arrange for prope

r

disposal of any electrical components, waste or oil

associated with this equipment.

When the life cycle of this equipment is over, remove battery

and bring to appropriate facility for lead reclamation. Use

safety precautions when handling batteries that contain

sulfuric acid.

When the life cycle of this equipment is over, it is

recommended that the frame and all other metal and plastic

parts be sent to a recycling center.

Metal and plastic recycling involves the collection of metal and

plastic from discarded products and its transformation into raw

materials to use in manufacturing a new product.

MX4505 Rev. E ©2020

14 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

SAFETY REQUIREMENTS

Recyclers and manufacturers alike promote the process

of recycling metal and plastic. Using a metal and plastic

recycling center promotes energy cost savings.

WIND LOAD FACTORS & SITE PREP

Wind load is always a factor when

considering the appropriate gate for a

particular site. Solid gate panels produce

a larger wind load than gates with slats

or open decorative features. If you are

installing a gate operator in a high wind

area, gate design will affect the load on

the gate operator because wind load acts

the same as an obstruction. Good gate

panel design presents a low surface area

to reduce the wind load.

If gate is heavy and near weight capacity of what the gate

operator can handle (see specifications), make sure it has

an open design that allows wind to flow through it. A solid or

semi-solid gate design under certain wind load conditions

may cause damage to gate operator and is not covered by

the HySecurity Limited Warranty.

Several factors play into calculations of wind load on a gate

panel. To find out maximum wind speed in areas around

the United States, search for US government wind speed

maps on the internet. If you don’t know how to calculate for

wind load, ask a mechanical engineer or site architect for

assistance prior to installing gate operator and gate panels.

When the IES trips, it sends a signal to gate operator to stop

and reverse direction. This feature may be falsely triggered

in excessively windy conditions because wind itself, acting

over surface area of gate panel, can provide necessary

force to trigger IES.

CAUTION

Do not adjust IES sensitivity to accommodate for

inappropriately designed gate panels. Loss of IES

sensitivity increases mechanical wear on gate

hardware and gate operator. It may also pose a safety

hazard. Compensating for wind loads by adjusting

IES may set IES sensitivity to a level which, when

encountering an obstruction, ignores obstruction and

fails to reverse direction. For more information, refer to

Adjusting the IES Sensitivity.

MAINTENANCE

OF

GATE

SYSTEMS

To keep your automated gate system performing both safely

and reliably it is important to ensure that the components o

f

that system are functioning properly.

At least monthly:

Disconnect the gate operator and manually move the

gate through its range of travel. Note any squeaks from

rollers or hinges or areas of binding. The gate should

travel smoothly and quietly throughout its range. If it

does not, contact a gate professional to correct the

problem.

Reconnect the gate operator and perform the following

tests:

• With the gate opening, block any photo eyes and/

or depress any safety edges used to protect the

open direction. The gate should stop and/or reverse.

• With the gate closing, block any photo eyes and/o

r

depress any safety edges used to protect the close

direction. The gate should stop and/or reverse.

• Using a suitable obstruction in the path of the gate

(a solid, immovable object), run the gate in the open

direction until it contacts the obstruction. The gate

should stop and reverse.

• Using a suitable obstruction in the path of the gate

(a solid, immovable object), run the gate in the close

direction until it contacts the obstruction. The gate

should stop and reverse.

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 15

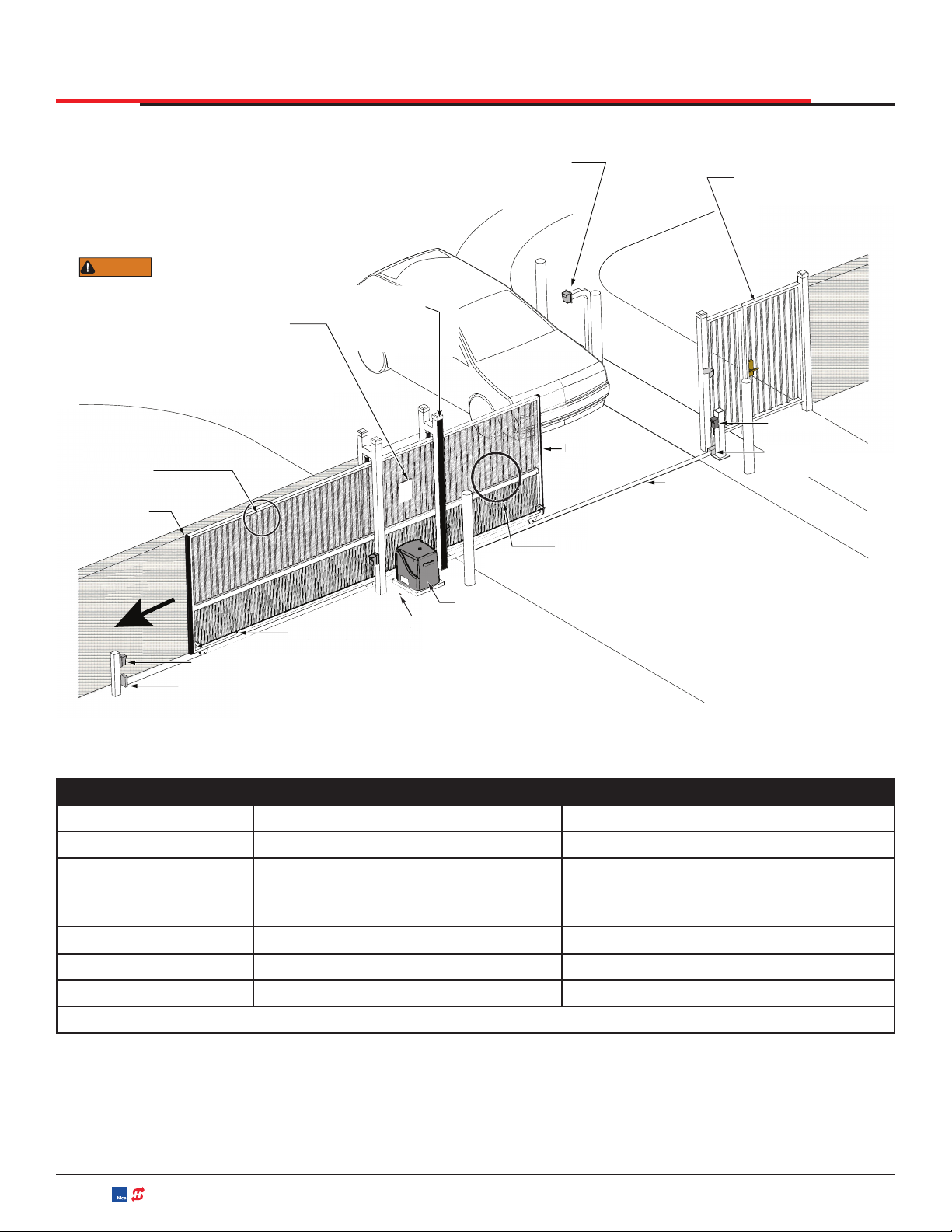

INSTALLATION

Site Overview & Planning

Figure 1. Site Overview and Planning

Table 1. SlideSmart Specifications

Operator SlideSmart DC 15 SlideSmart DC 10F

Duty Cycle Continuous Continuous

Power, 1Ø

Switch Selectable

115 volts, 3 amps, 50/60 Hertz

208-230 volts, 1.5 amps, 50/60 Hertz

Switch Selectable

115 volts, 3 amps, 50/60 Hertz

208-230 volts, 1.5 amps, 50/60 Hertz

Motor ½ hp ½ hp

Gate Speed 0.75, 1 ft/s (23, 30, 38 m/s) 1.75, 2 , or 2.25 ft/s (53, 61, or, 69 cm/s)

Gate Weight Maximum 1500 lbs (675 kg) Maximum 1000 lbs (450 kg)

Note: For SlideSmart DC Solar operators, refer to www.hysecurity.com

Secure Side

Public Side

Attach WARNING Signs

Be sure to place the

WARNING signs on both

sides of the gate. For your records, take a

ƉŚŽƚŽŐƌĂƉŚŽĨƚŚĞĐŽŵƉůĞƚĞĚŝŶƐƚĂůůĂƟŽŶƐŝƚĞ

WARNING

Maximum 2¼" (57mm)

width between

ǀĞƌƟĐĂůďĂƌƐ

>ĞŌ,ĂŶĚ'ĂƚĞ

opening

Physical stop - weld stops at both ends of V track

WŚŽƚŽĞLJĞ;ĞŶƚƌĂƉŵĞŶƚƉƌŽƚĞĐƟŽŶƐŚŽǁŶŝŶĨŽƵƌůŽĐĂƟŽŶƐͿ

Pedestrian gate.

Key or Card reader

Mount access control

ĚĞǀŝĐĞƐĂƚůĞĂƐƚϲŌ

(183cm) beyond the gate.

Make sure a separate walk-

through entrance is available

and its pedestrian path is

clearly designated.

Target magnet on chain

SlideSmart

To comply with ASTM F2200, a screened wire

mesh extends to the top of the gate or to a mimimum

ŚĞŝŐŚƚŽĨϲŌ;ϭϴϯĐŵͿŝĨĂϮЬΗ;ϱϳŵŵͿŽƌůĂƌŐĞƌŐĂƉĞdžŝƐƚƐ

ďĞƚǁĞĞŶƚŚĞǀĞƌƟĐĂůďĂƌƐ

Site Overview

Edge sensor on

leading edge

V track

Physical

stop

Earth ground

Photo eye

2¼"

(

57mm

)

ween

ƌƐ

ŶĚ'ĂƚĞ

g

Target magnet on chain

h

T

o co

m

Edge

l

ead

Edge sensor

on trailing

edge

Edge sensor

MX4505 Rev. E ©2020

16 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

PAD CONDITION

1. Follow the local building codes to identify the

frost line and determine the required depth of

the concrete pad. HySecurity recommends a

minimum 16-inch depth with a minimum 2-inch

extension Refer to Figure 2.

2. Before pouring the pad, consider conduit

placement so it fits within the confines of the

6.9 x 12-inch cutout in the SlideSmart as shown

in Figure 2. Run separate conduits for:

high voltage wiring (115/230V supply power)

including equipment ground

INSTALLATION

Low voltage wiring (12V and 24V accessory

power)

• vehicle loop control wiring

• primary/secondary connections

Earth ground (NEC/NFPA)

3. Extend conduit height 2-inches (5cm) above

the pad (4-inches (9cm) above ground level).

Make sure the concrete forms are square with

the gate and the pad is level. The operator

footprint, with covers, is approximately an

18-inch square (4.7cm). See Figure 2 for the

minimum pad dimensions.

Figure 2. Conduit View

Grounding rod depth at

10(3m) or per local code

Vehicle loop

control wires

Extra conduit

(Dual Gate wiring)

(Conduit may be shared with low voltage wires)

Low

voltage/Communicaon wires

20.7"

(52.6cm)

Conduit runs

2" (5cm) above

concrete pad

Minimum pad

height is 2" (5cm)

above grade level.

High voltage wires

Main AC power

Cut-away

view

Concrete pad

(depth set per

local codes)

Consult local

codes for

proper depth

3 max.

(91.4cm)

Ground

lug

Chain

SlideSmart HD

operator

Grade level

Ground

wire & rod

19" minimum

(48.3cm)

Area

cut out

for

conduit

6.9 x 12"

(17.5 x 30.5cm)

GateChain,

#40 Roller

Sloed holes (4x) for

concrete anchors:

½ - 13 x 3½"

21"

(53.3cm)

10.5"

(26.7cm)

1.6"

(4.1cm)

6.4"

(16.3cm)

10.4"

(26.4cm)

Concrete

pad

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 17

USING AN EXISTING PAD

In many applications, SlideSmart may be a

replacement operator for an existing gate system.

Make sure the pad is level and inspect the pad for:

Compliance with local building codes.

Appropriate distance from the gate. See Figure

3.

Appropriate dimensions (See Figure 3) for

SlideSmart installation.

Durability.

INSTALLATION

To use an existing pad, take the following steps:

1. Remove any existing equipment from the pad.

2. Measure the pad to ensure it is sized properly

for SlideSmart.

3. Check the mounting hole locations and re-drill,

if necessary.

4. Follow the steps in "Concrete Pad Mount" on

page 22.

CAUTION

Consider positioning the operator so existing

conduit enters the cutout in the SlideSmart

base plate. Cutting small holes in the plastic

base plate and cover for pre-existing conduit

is permissible. Two 0.875-inch (22mm) diameter

holes for running conduit are also provided on

both sides of the chassis. See Figure 4.

Figure 3. Conduit Side View

Side View

7¾"

(19.7cm)

Gate

Chain to Gate

Ideal distance = 3-1/4" (8.25cm)

Min. distance = 2-1/2" (6.4cm)

Chain

height

Grade

level

Concrete pad

Cut out

if rear

install

Conduit cut outs

Figure 4. Conduit Cut Out Views

MX4505 Rev. E ©2020

18 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

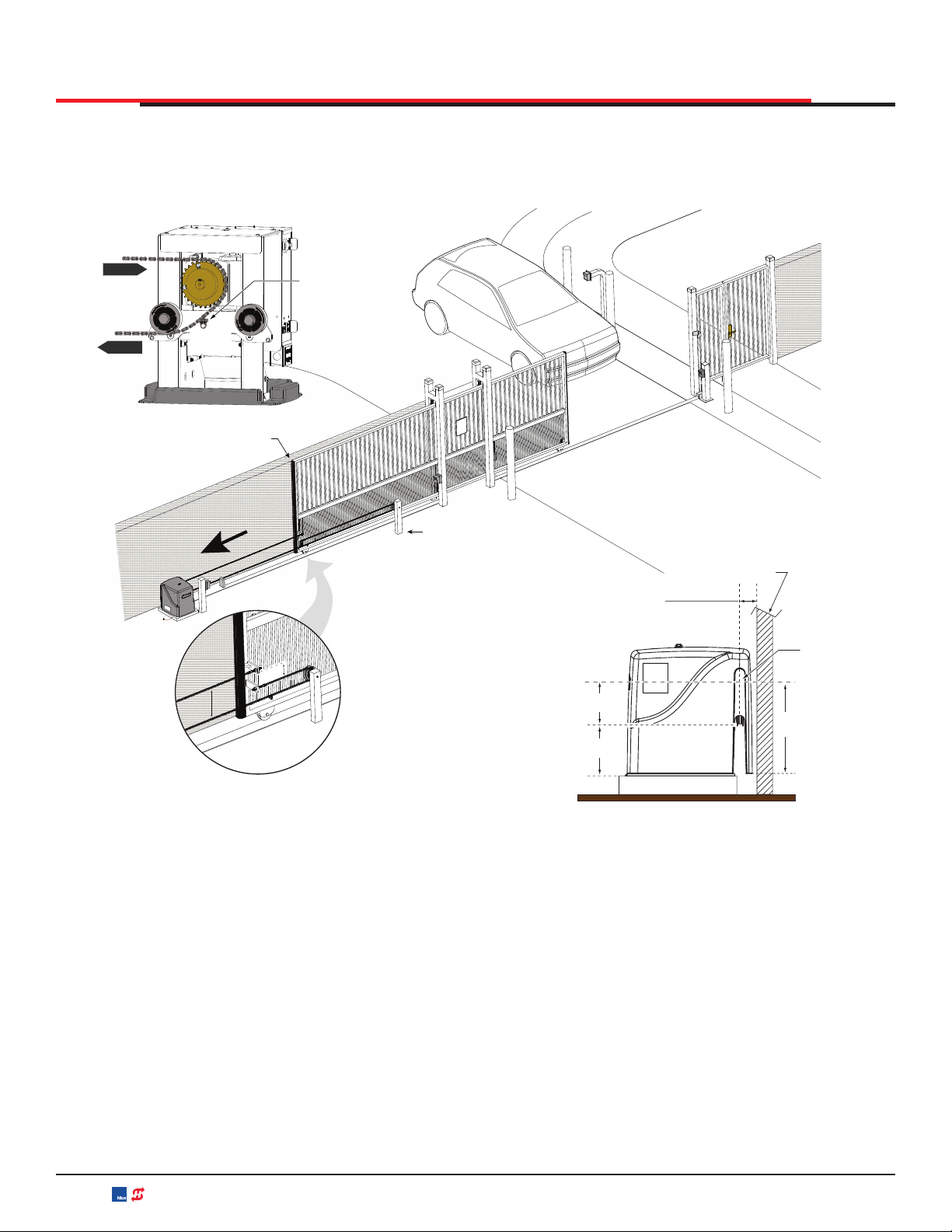

FRONT INSTALLATION

The most common and cost efficient type of installation is the front installation. See Figure 5 and Figure 6.

Figure 5. Front Installation

Figure 6. Base Extension Mount

Secure Side

Public Side

P

ublic

S

id

e

Chain bracket (x2)

Chain

Physical Stop (x2)

NOTICE

Several different ways to mount the SlideSmart operator exists. A few are shown here. For more

detailed drawings, refer to the "Appendix A - Installation Configurations" on page 118.

OPTIONAL

50Ah

batteries

BASE EXTENSION

MOUNT

POST MOUNTED POST MOUNTED WITH

BASE EXTENSION

CHAIN

INSTALLATION

MX4505 Rev. E ©2020 SlideSmart DC Programming and Operations hysecurity.com | 800-321-9947 19

REAR INSTALLATION

A rear installation requires additional idler wheels and gate brackets, but it provides aesthetics as the

chain is not visible along the gate. See Figure 7.

Figure 7. Rear Installation

>ĞŌ,ĂŶĚ'ĂƚĞ

ŽƉĞŶŝŶŐ

8"

5"

/ĚůĞƌWŽƐƚ

WŽƐŝƟŽŶƉŽƐƚƚŽŵĂŝŶƚĂŝŶĂŵŝŶŝŵƵŵ

ĚŝƐƚĂŶĐĞŽĨϭĨŽŽƚ;ϯϭĐŵͿĨƌŽŵƚŚĞĞŶĚ

ŽĨƚŚĞŐĂƚĞǁŚĞŶŐĂƚĞŝƐĨƵůůLJĐůŽƐĞĚ

ŶĚŽĨƚŚĞŐĂƚĞ

ŚĂŝŶΘďƌĂĐŬĞƚƉŽƐŝƟŽŶ

ϴ;ϮϬĐŵͿĂŶĚϱ;ϭϯĐŵͿ

'ĂƚĞ

Side View

ŽŶĐƌĞƚĞƉĂĚ

Chain to Gate

/ĚĞĂůĚŝƐƚĂŶĐĞсϯвΗ;ϵϱĐŵͿ

DŝŶĚŝƐƚĂŶĐĞсϮЪΗ;ϲϰĐŵͿ

7вΗ

;ϭϵϳĐŵͿ

8"

;ϮϬϯĐŵͿ

ŚĂŝŶ

ŚĞŝŐŚƚ

>ĞŶŐƚŚĞŶƚŚĞ

ĐŚĂŝŶĂĐĐĞƐƐƐůŽƚďLJ

ĐƵƫŶŐƚŚĞĐŽǀĞƌŽŶ

ƚŚĞĐŚĂŝŶƐŝĚĞŽŶůLJ

ϭϳЪΗ

;ϰϰϱĐŵͿ

^WZK<d

,/E

/>Zt,>

dZ'd

D'Ed

dĂƌŐĞƚŵĂŐŶĞƚƉŽƐŝƟŽŶ

ďĞƚǁĞĞŶŝĚůĞƌǁŚĞĞůĂŶĚ

ƐƉƌŽĐŬĞƚǁŚĞŶŐĂƚĞŝƐ

ĨƵůůLJĐůŽƐĞĚ

sŝĞǁƐŚŽǁƐŚŽǁƚŽ

ĚĞĞĚĐŚĂŝŶŽǀĞƌ

ƐƉƌŽĐŬĞƚĂŶĚŝĚůĞƌǁŚĞĞů

ĨŽƌĂƌĞĂƌŝŶƐƚĂůůĂƟŽŶ

KWE

KWE

INSTALLATION

MX4505 Rev. E ©2020

20 hysecurity.com | 800-321-9947 SlideSmart DC Programming and Operations

This manual suits for next models

4

Table of contents

Popular Garage Door Opener manuals by other brands

Automatic Technology

Automatic Technology ATS Series instruction manual

Decko

Decko 24000-DKO owner's manual

Chamberlain

Chamberlain 7710CB manual

Cardin Elettronica

Cardin Elettronica 311/GL124EBSS instruction manual

APRITECH

APRITECH ANTES 24 GUIDE FOR THE INSTALLER

Chamberlain

Chamberlain D2101 installation manual

Roger Technology

Roger Technology R41 Series INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

Raynor

Raynor Navigator 2245RGD owner's manual

SAMT

SAMT RGD350 Installation instructions and user guide

Chamberlain

Chamberlain 8500 manual

DOORWORKS

DOORWORKS GDC6 Installation instructions & owner's manual

GRITAL

GRITAL GR30 manual