Chamberlain D2101 User manual

Other Chamberlain Garage Door Opener manuals

Chamberlain

Chamberlain RollerLift Plus CR855MYQ User manual

Chamberlain

Chamberlain LiftMaster Security+ 2500 User manual

Chamberlain

Chamberlain door opener User manual

Chamberlain

Chamberlain PREMIUM series User manual

Chamberlain

Chamberlain 4400E User manual

Chamberlain

Chamberlain 710CR4 User manual

Chamberlain

Chamberlain LiftMaster ATS 2113X User manual

Chamberlain

Chamberlain 970CF User manual

Chamberlain

Chamberlain Merlin MT800 User manual

Chamberlain

Chamberlain PD432DM 1/2 HP Owners User manual

Chamberlain

Chamberlain Merlin MGS300 User manual

Chamberlain

Chamberlain RJO20C User manual

Chamberlain

Chamberlain 2580 1/2 HP User manual

Chamberlain

Chamberlain C205 User manual

Chamberlain

Chamberlain merlin MT5580P User manual

Chamberlain

Chamberlain 821LM User manual

Chamberlain

Chamberlain LiftMaster Professional RDO800-series User manual

Chamberlain

Chamberlain Merlin Professional MT230 User manual

Chamberlain

Chamberlain 8360W User manual

Chamberlain

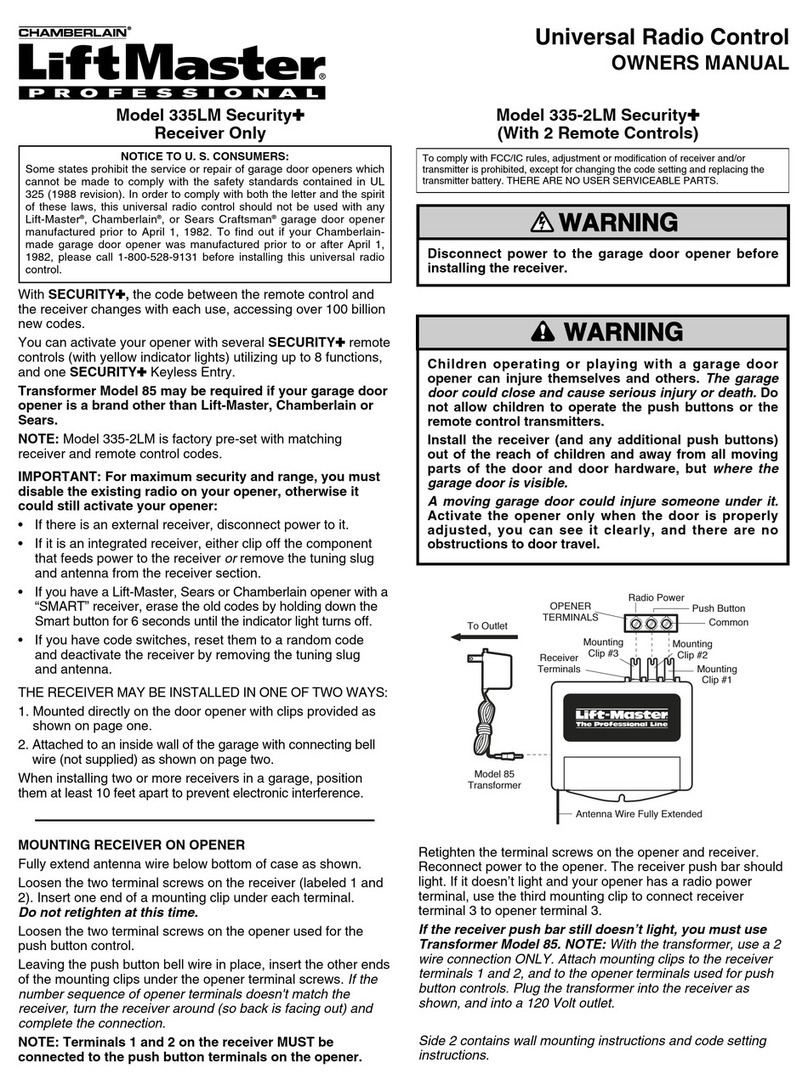

Chamberlain LiftMaster 335LM Security+ User manual

Popular Garage Door Opener manuals by other brands

Westfalia

Westfalia 19 36 07 instruction manual

Cardin

Cardin BL Series instruction manual

Craftsman

Craftsman 139.53997D owner's manual

Bauer

Bauer CROSS18 Application. Installation and Maintenance Manual

Wayne-Dalton

Wayne-Dalton 8124 Installation instructions and owner's manual

Craftsman

Craftsman 139.18867 owner's manual