2 – ENGLISH

ENGLISH

Complete instructions translated from Italian

CONTENTS

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS . . . . . 2

1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2 PRODUCT DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 List of parts making up the kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

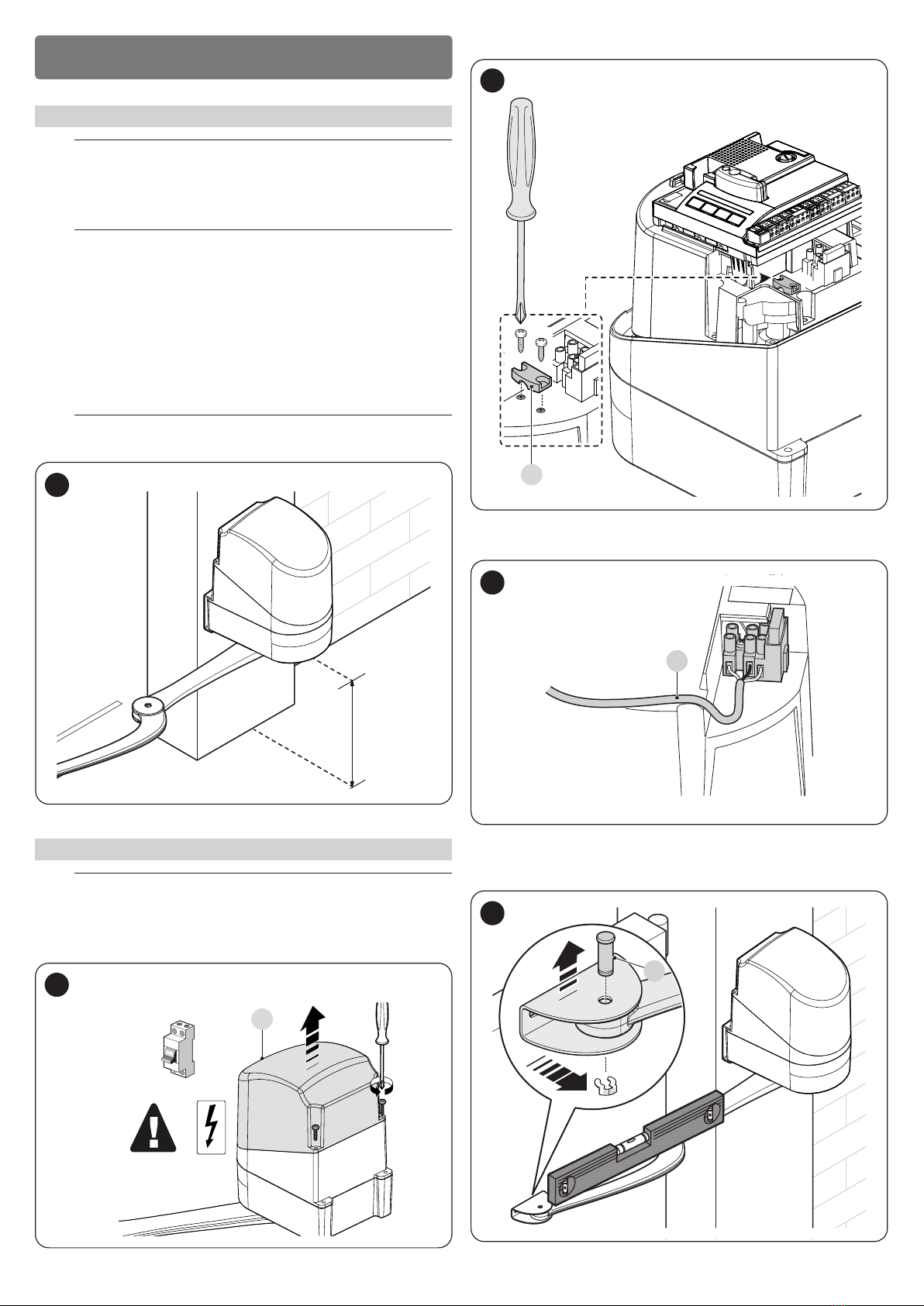

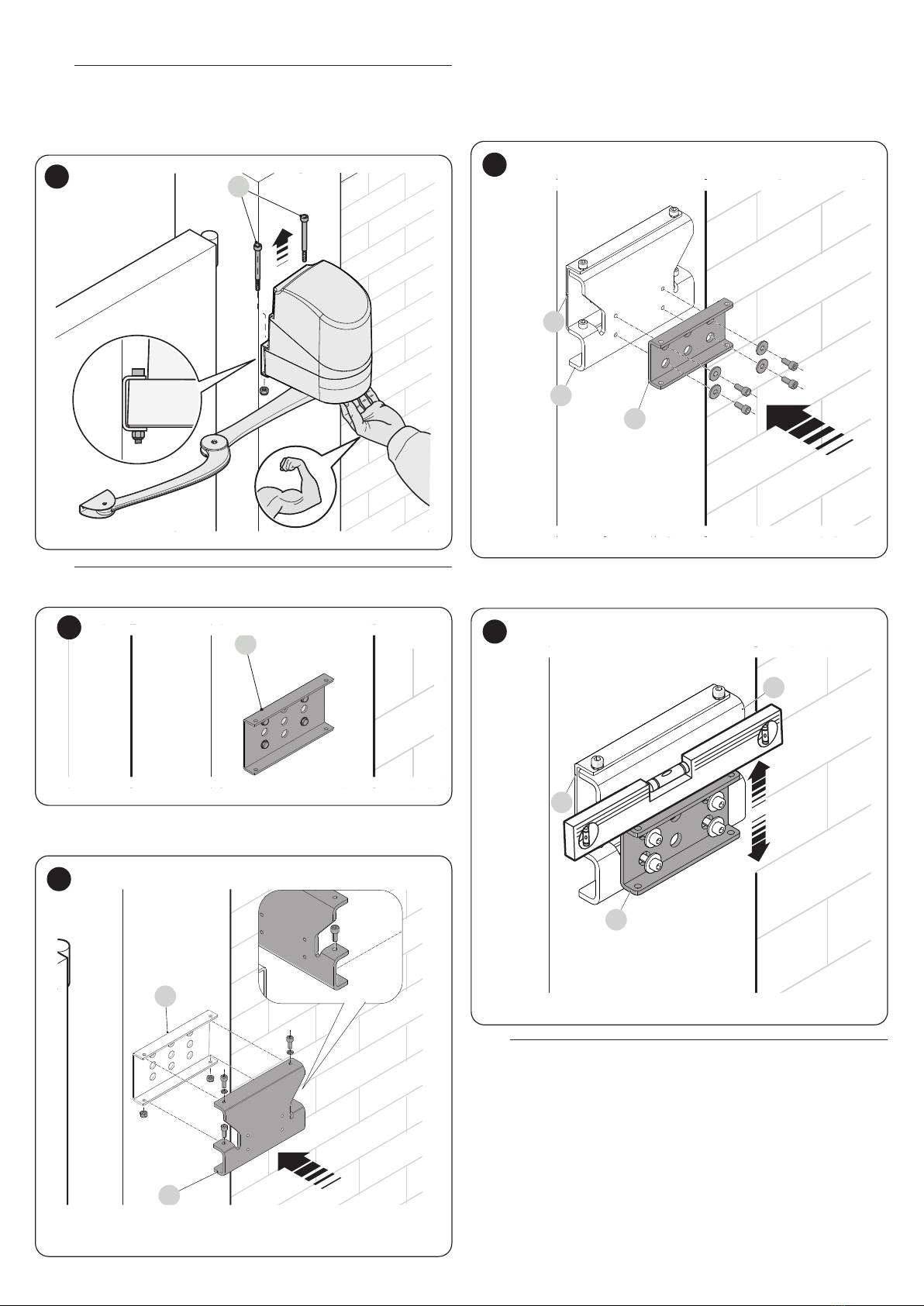

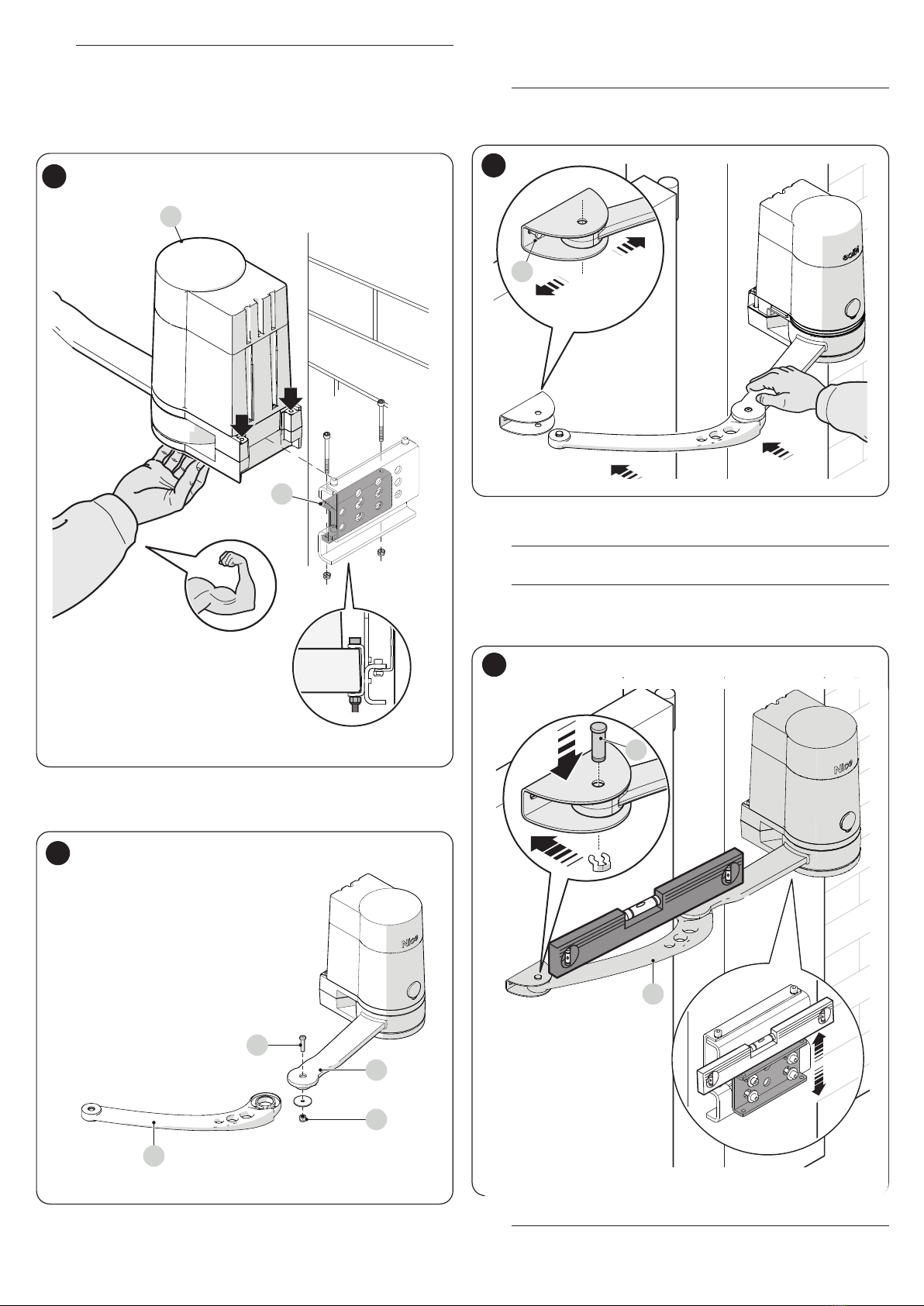

3 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Pre-installation checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.2 Installing the kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4 PRODUCT DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GENERAL SAFETY WARNINGS AND

PRECAUTIONS

1

1 GENERALSAFETYWARNINGSANDPRECAUTIONS

1.1 GENERAL WARNINGS

a

WARNING! Important safety instructions. Observe all the

instructions as improper installation may cause serious

damages.

a

WARNING! Important safety instructions. It is important

to comply with these instructions to ensure personal

safety. Store these instructions carefully.

a

According to the most recent European legislation, the

implementation of an automation system must comply

with the harmonised standards set forth in the Machinery

Directive in force, which allow for declaring the presumed

conformity of the automation. On account of this, all op-

erations regarding connection to the mains electricity,

as well as product testing, commissioning and mainte-

nance, must be performed exclusively by a qualied and

skilled technician.

–Before proceeding with the product’s installation, check that all

the materials are in good working order and suited to the intend-

ed applications.

–The product is not intended for use by persons (including chil-

dren) with reduced physical, sensory or mental capacities, nor

by anyone lacking sufcient experience or familiarity with the

product.

–Handle the product with care during installation, taking care to

avoid crushing, knocks, falls or contact with liquids of any kind.

Keep the product away from sources of heat and open ames.

Failure to observe the above can damage the product and in-

crease the risk of danger or malfunctions. Should this happen,

stop installation immediately and contact Customer Service.

–The manufacturer assumes no liability for damage to proper-

ty, items or persons resulting from non-compliance with the

assembly instructions. In such cases, the warranty for material

defects is excluded.

–Cleaning and maintenance reserved for the user must not be

carried out by unsupervised children.

–The packing materials of the product must be disposed of in

compliance with local regulations.