Nichiryo Nichipet Premium User manual

Autoclavable &UV resistant

Digital micro pipette for liquid handling

User’s Manual

In Vitro Medical Diagnostic Devices (98/79/EC)

Annex III self-declared

ISO 8655 STANDARD

CERTIFIED ISO9001

●Thank you very much for purchasing Nichipet Premium.

●Please read this manual carefully before using.

Always Pursuing Originality

Since 1944

Autoclavable &UV resistant

Digital micro pipette for liquid handling

Features

●Nichipet Premium is fully autoclavable at the condition of 121°C for 20 minutes.

●Nichipet Premium is made of UV resistant material which can be used in clean bench.

(If UV is applied to Nichipet Premium for a considerably long time, it may become discolored

but nothing affects its performance.)

●New round shape improves friendly handling capability, and mitigates operator’s fatigue from

long time use.

●Sample volume can easily be set by simply rotating the push button.

●Setting of sample volume can easily be locked with one touch (one-touch lock mechanism).

●A wide range of sampling volume can be covered by eight models from 0.1ul to 10,000ul.

●Patented body construction avoids permeating hand temperature through the body that

prevents inaccuracy of volume measurement.

●Since PTFE (Fluoroplastic) is used in an airtight chamber, this combination keeps airtight and

precise reproducibility for long hours.

●A thin nozzle corn can be easily inserted and reached to a bottom of many tubes for

dispensing/aspiration. (110mm in depth, 2ul – 1000ul)

●Tip can be removed without touching by using the tip ejector.

●The Easy-Calibration function provides smooth and easy calibration with an attached

adjustment tool.

Standard accessories

●Three tips (one tip for NPP-5000/10000)

●Three nozzle filters (NPP-1000/5000/10000)

●Nozzle O-ring (NPP-5000/10000)

●A nozzle filter remover (NPP-1000/5000/10000)

●An adjustment tool

●User’s Manual

When unpacking package, check to make sure that the above-mentioned items are included.

Precautions on safety

●For using your Nichipet Premium properly and safely, carefully read “Precautions on safety” in

this paragraph and “CAUTION” on the next page before starting work with it.

●Contents of “CAUTION” are matters that require user’s attention, not only for using Nichipet

Premium properly but for preventing user from accidents and physical damage.

●After reading this manual, please keep it in a convenient place for referring to at any time.

-1-

Please read following prior to use for your safety and correct usage.

CAUTION

Be sure to observe the following instructions for using Nichipet

Premium properly and safely.

If user misuses “Nichipet Premium”, or disregards the following instructions, it may result in

injury to the user or/and other persons or physical damage to pipette or/and other equipment.

1. Do not use pipette for any purpose except pipetting/dispensing liquid.

2. Do not modify pipette, because modification may cause an accident.

3. Do not use pipette for pipetting any liquid to be injected into human body.

4. Do not expel dispensed liquid towards anybody.

5. Do not eject tip towards anybody.

6. Do not eject tip with liquid inside.

7. Carefully handle pipette and tip because tip is sharply pointed.

8. If pipette is contaminated with liquid harmful to human, immediately take appropriate

disposal to clean it safely before continuing to work.

9. Do not use pipette for stirring liquid and so on, otherwise not only tip may be loose and

fall off but the pipette may be soiled with scattered liquid.

10. Do not touch filters which may be contaminated by harmful substances.

11. Take extreme care for sharpness of Nozzle filter remover when filters for 5000 ul or

10000ul types are taken off.

12. Do not touch pipette directly right after drying, because it will have got very hot during

drying. Touching hot pipette directly may cause injury.

13. Components of water used for autoclave may cause pipette malfunction or performance.

14. If pipette can not be fixed after examining and conducting in accordance with designated

procedure, immediately stop using the pipette and ask us or our agent to repair it.

15. For organic solvents, Nichipet EX Plus (NPLO) will be recommended to use.

16. Although this pipette has good chemical-resistance in general, it may be damaged by

some kinds of chemicals, please contact to our company.

17. Pipette can be used between +4°C and +40°C, but the specifications may vary.

18. Depending on frequency of use, pipette should be cleaned in a soap solution and airtight

chamber should be maintained according to this manual.

-2-

Note

Users are required to strictly observe the followings in order for the

pipette to keep its excellent precision, reproducibility and original

performance for a long time.

1. Do not expose pipette directly to the sun when working with it or for 2 hours before

starting work, otherwise the pipette may lose accuracy. Avoid working with pipettes in a

humid and hot place.

2. Just before starting work with pipette, avoid touching tip and nozzle cylinder as far as

conditions are allowed. If nozzle cylinder is warmed by your hand, accuracy may vary.

3. For pipetting, follow the forward method (the way explained in this manual). If it is

performed in a different way, it may result in inaccurate pipetting.

4. Operate push button very gently. If it is quickly released, it may result not only inaccurate

pipetting but also deteriorated the pipette because sample liquid may be permeated into

the main body. To prevent the pipette from malfunction, inaccuracy and contamination, a

filter is attached to models NPP-1000, -5000, and -10000. (A filter is supplied at time of

purchase.)

5. Do not reuse tip that has been used once, and carefully dispose used tip. If tip is used

repeatedly, it may cause inaccurate and impure pipetting and cross contamination (*)

among samples.

* For example, if previous sample liquid is left inside tip, it is mixed with new sample liquid

and the new sample is contaminated by the previous one. Therefore, pipetting of the

next sample results wrong. This phenomenon is called mutual contamination of samples.

6. Do not hold pipette horizontally or upside down when there is liquid inside tip, otherwise

the liquid gets into the main body and the pipette may be contaminated.

7. When autoclaving, do not pile pipettes on others in the autoclave or lean pipettes with a

nozzle top facing down so that self-load is applied on the nozzle. This pipette is made of an

autoclave compatible material, but because of high temperature in the sterilizer, there is a

risk that parts subject to load will be deformed.

8. After autoclaving and drying pipette, leave it until it gets completely cool before using

again. If the pipette is used when warm, the accuracy may not come up to the standard

level.

9. After autoclaving and drying pipette, assemble the pipette after it is completely cooled, if it

is assembled when it is still hot, it may cause deterioration in the pipette such as breakage

of the screw threads.

10. When rotating push button, do not exceed the specified sample volume limit, otherwise

pipette may be damaged or deteriorated.

11. Do not perform pipetting with less liquid than set volume. If the quantity of liquid is less

than the set volume, it may cause the liquid to scatter into the main body and the pipette

may deteriorate in quality.

-3-

-4-

Contents

Operating procedure ······················································· P5

Disassembling/Reassembling the airtight chamber ··················· P9

Autoclaving/Drying the pipette ··········································· P17

Specification ································································· P18

Calibration procedure······················································· P19

Troubleshooting ····························································· P21

Parts list······································································· P23

Warranty······································································ P26

Operating procedure

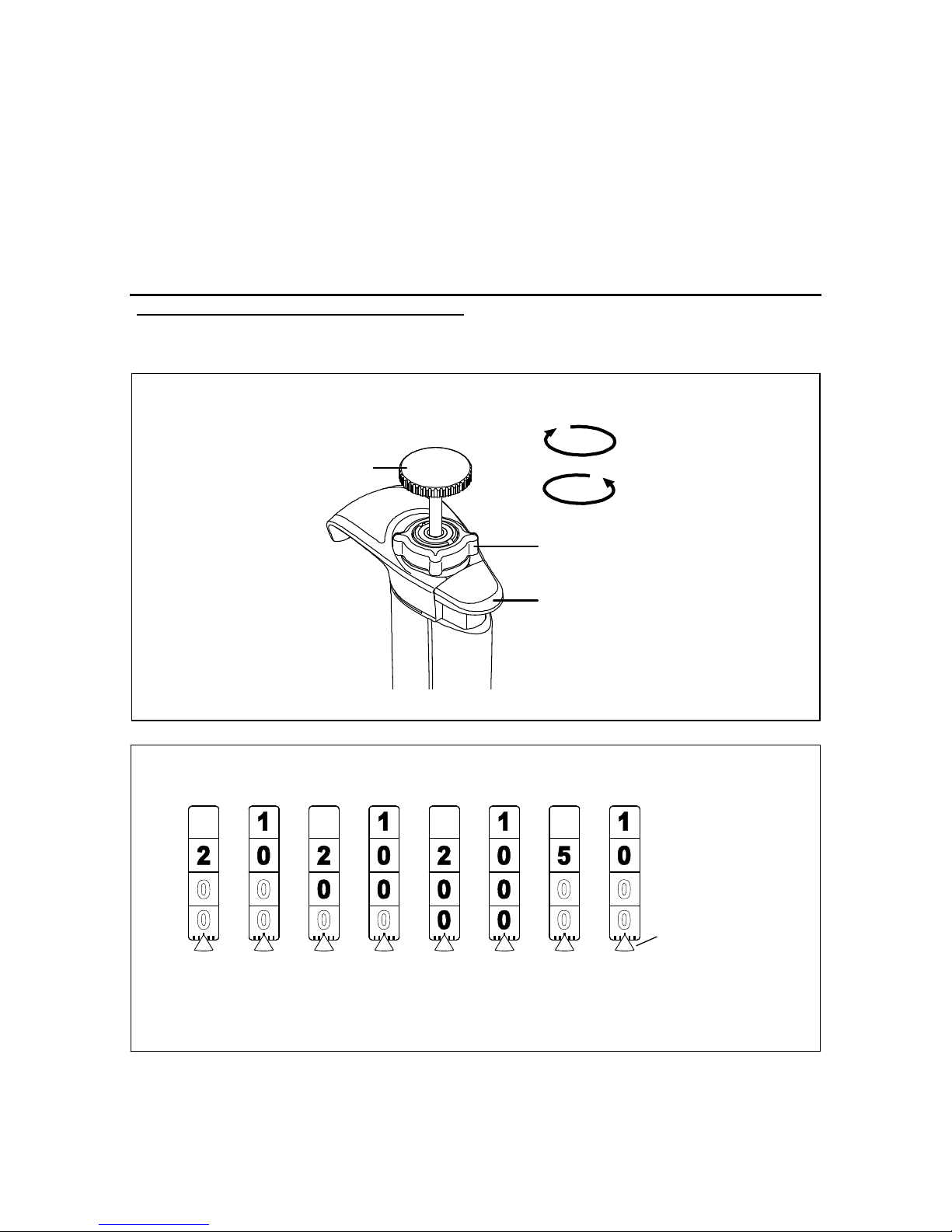

1.Volume setting

1) Turn the lock lever to unlocking direction to loosen it (Fig. A)

2) Turn the push button to set the digital counter to a desired liquid volume. To increase

volume setting, turn the push button until passing designated volume setting by half of the

scale, and then set the designated volume. To decrease volume setting, simply turn to

designated volume. When setting the liquid volume, set the counter’s graduation at point

mark (red) appearing in the lower part of counter window. (Fig. B)

3) After setting the liquid volume, turn the lock handle to locking direction to lock it. (Fig. A)

Note: Don’t exceed the specified liquid volume limit, otherwise pipette may be

damaged or deteriorated in the quality.

Fig. A

Ejector button

Lock lever

Push button

Increase

Decrease

NPP-2

2μl 10μl 20μl 100μl 200μl 1000μl 5000μl

10m l

(0 .002) (0.01) (0.02) (0.1) (0.2) (1.0) (10.0) (10.0)

N P P -10 N P P -20 N P P -100 N P P -200 N P P -1000 N P P -5000 N P P -10000

Point mark

Minimum scale:ul

Volume indicator

Fig. B

-5-

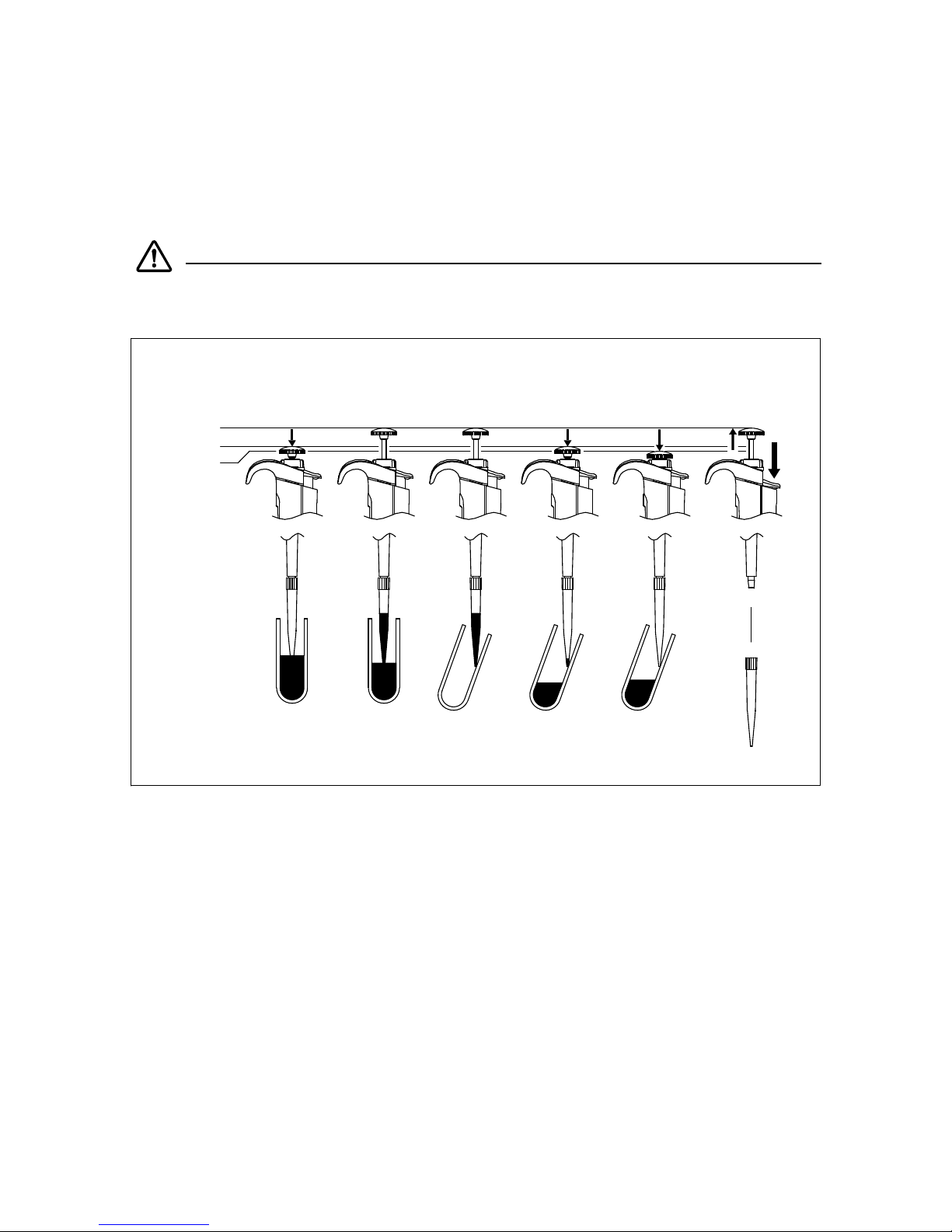

2. Aspiration liquid

1) Attach a new tip to the nozzle end. (We recommend that you attach it from rack)

Note: It would be recommended that tips are directly picked up from rack. And do

not twist pipette when fixing tip.

2) Press down push button to first stop position “b”. (Fig. C)

* Don’t aspirate the liquid with the push button pressed at the second stop “c”.

3) Hold the pipette vertically and immerse the tip 2mm to 3mm below the surface of the liquid.

(Fig. D-)

4) Release the push button slowly and smoothly to aspirate the set volume of the liquid.

(Fig. D-)

5) Wait 1 to 2 seconds, then withdraw the pipette vertically and carefully from the surface of

the liquid. (Fig. D-)

6) Wipe any droplets away from the outside of the tip using a medical wipe and avoid

touching the tip’s orifice.

Note: Do not aspirate when push button position is at “c”.

Note: The push button has to be pushed and released slowly. Otherwise it may

cause wrong accuracy.

①②③④

Fig. C

a

b

c

Ejector button

-6-

3. Dispensing liquid

1) Gently place the end of tip against inside wall of recipient vessel just above liquid surface

10 degrees to 45 degrees in angle.

2) Press down the push button slowly and smoothly to the first stop “b”. Wait for a few

seconds then press down the push button to the second stop to expel the last drop of the

liquid from the tip. (Fig. D-,)

3) Release the push button slowly.

4) Press the ejector button to remove the tip and dispose of it. (Fig. D-)

CAUTION

When using any toxic or harmful liquid to human, do not touch any used tips.

①②③④⑤⑥

a

Fig. D

b

c

-7-

4. Recommendation for accurate pipetting

In addition to the above mentioned operations of pipetting, the following procedure maximizes

performance of pipette.

1) Make sure that tip is firmly attached to nozzle end.

2) Before pipetting, pre-rinse the tip by filling and expelling the tip for three to five times. It

gives good precision of pipetting, especially with a viscosity or a vaporous liquid.

a

b

c

Fig. E

3) Especially with volumes under 50ul, the operation should be done very slowly and

smoothly and the air humidity should be as high as possible to reduce the effect of

evaporation loss.

4) Sampling high density liquids and viscous solutions.

When aspirating, once the liquid has entered the tip, wait 2 to 3 seconds before removing

the tip from the surface of the liquid. When dispensing, wait 2 to 3 seconds at the first

stop position before pushing to the second stop position.

-8-

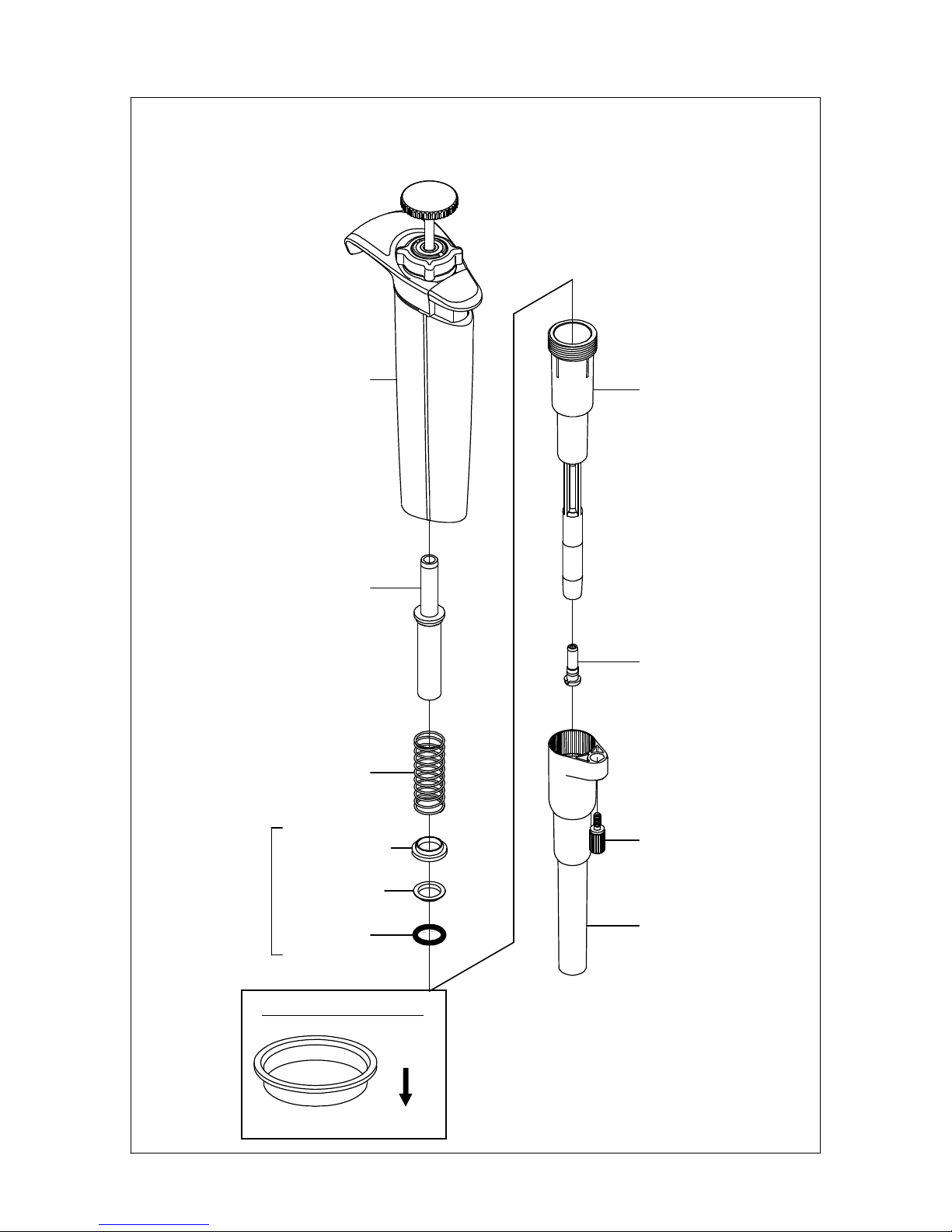

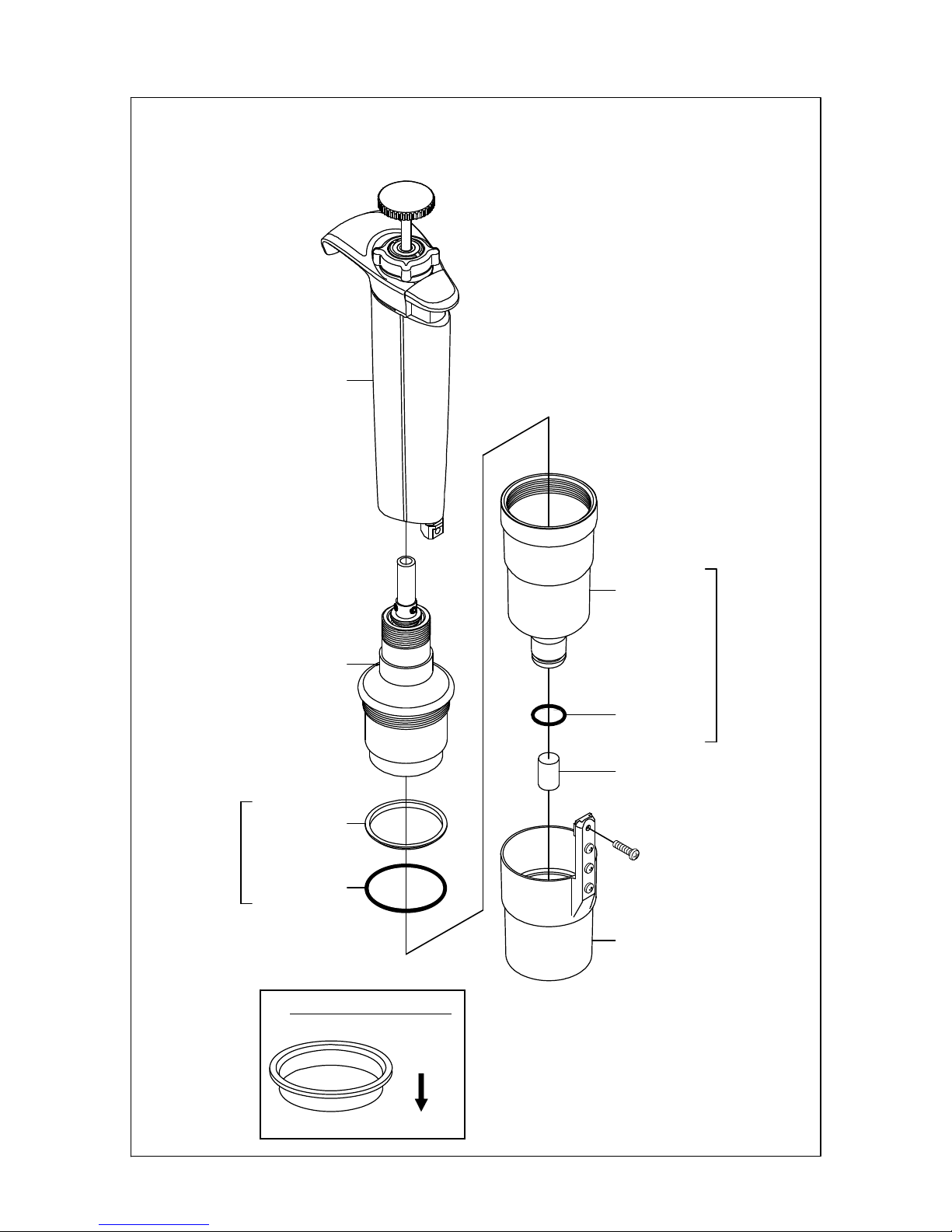

Disassembling/Reassembling the airtight chamber

If such symptoms as mentioned in “Troubleshooting” (page 21) occur, disassemble and inspect

pipette according to the following procedures.

1. Disassembling

Remove an ejector setting screw.

- 2ul – 200 ul : Figure F–

Turn the ejector setting screw in the direction of the arrow to remove it, and then pull out

ejector pipe in the direction of arrow.

- 5000ul : Figure F-

Remove the three ejector setting screws with a Phillips head (+) screwdriver, and then pull

out the ejector pipe in the direction of arrow.

③

②

①

Fig. F

Ejector setting

screw

Turn the nozzle cylinder counterclockwise to remove it, as it is screwed into the main body.

Note: When removing the nozzle cylinder, take care with the internal parts as some

of them occasionally spring out of the body (for types of 2ul to 1000ul volume).

Remove internal parts one after another.

, O-ring retainer, O-ring, and seal ring from the nozzle cylinder.

rom the nozzle cylinder.

N Shapes of the O-ring retainer are different by types of pipette.

- 2ul-1000ul : Fig.F1 to F3

Remove the plunger, 1st spring

* The shape of the O-ring retainer differs depending on the type of the pipette.

- For the 20ul type, remove the fluoroplastic (PTFE) spacer that is inside.

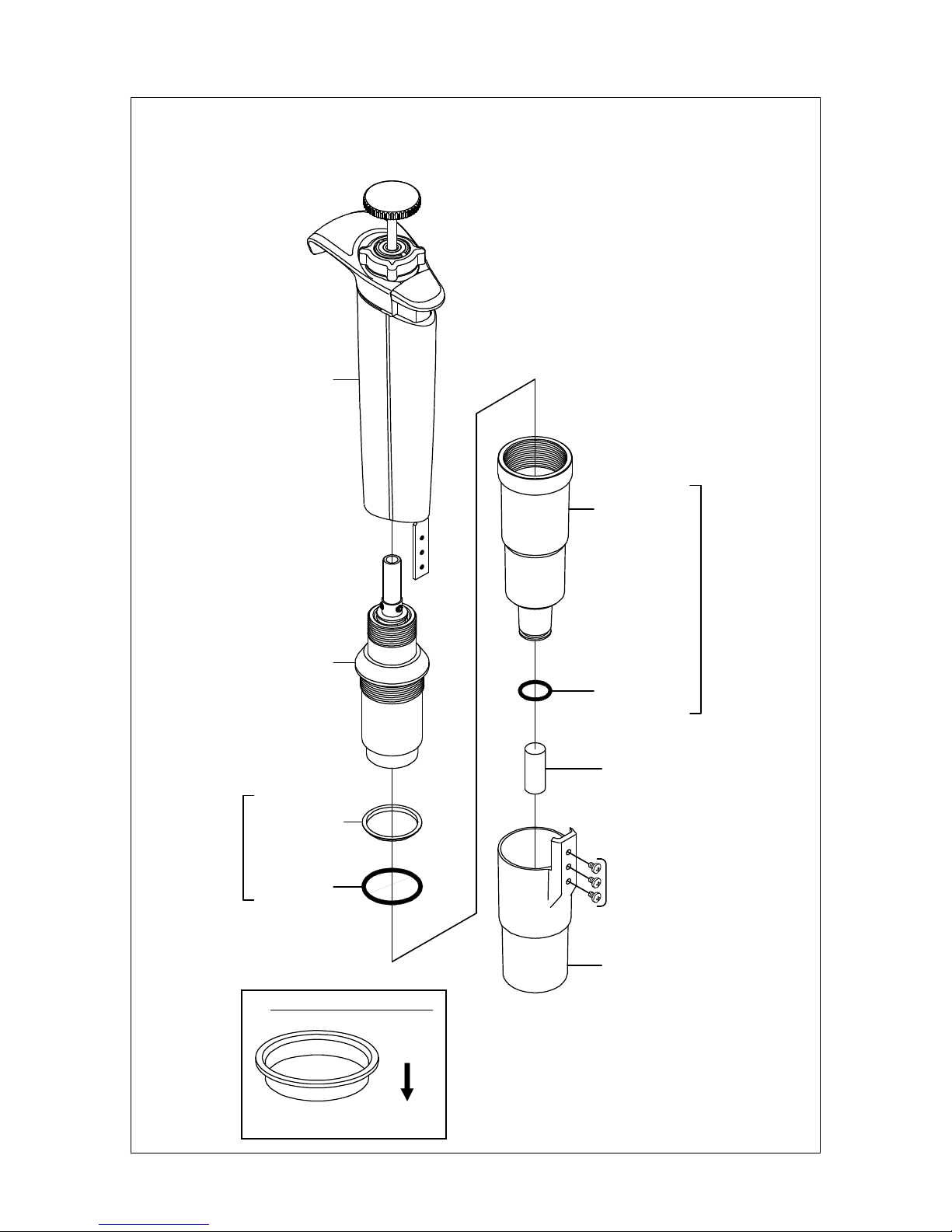

- 5000ul, 10000ul : Fig.F4, F5

Remove the O-ring and seal ring f

ote: mbling.Note: Pay attention to small parts for not loosing them during disasse

-9-

- 10 -

2. Reassembling

Reassemble nozzle cylinder.

- 2, 10, 20ul : Fig. G1, 100, 200ul : Fig G2, 1000ul : Fig G3

Firstly, set 1st spring on plunger, next set O-ring retainer, seal ring and O-ring in this order.

Then, insert assembled plunger into nozzle cylinder and screw it into the body.

Note: For 1000ul, make sure a seal ring and an O-ring are securely assembled.

Strained or distorted seal ring or O-ring may cause leakage.

- 5000ul: Fig. G4, 10000ul : Fig. G5

Set the seal ring, O-ring on the plunger in this order, and then insert the assembled plunger

into the nozzle cylinder with paying attention to the O-ring not to come off. After inserting,

screw the nozzle cylinder into the body.

Note: When screwing into the body, make sure that the nozzle cylinder and the

body are in vertical direction, and screw the nozzle cylinder into the body very

gently. If not, it may cause leakage.

Note: When reassembling, be careful not to put the seal ring and O-ring in the

wrong order. If the order is wrong, it may cause not only leakage but also

uracy, failure in extracting liquid, etc.inacc

②Fit the ejector pipe to the body.

- 2, 10, 20ul : Fig G1, 100,200ul : Fig. G2 1000ul: Fig. G3

While pressing down the ejector button with your finger so that the metal stay sticks out from

just under the grip, insert the ejector pipe into the body and fasten it with the ejector setting

screw.

- 5000ul : Fig. G4, 10000ul : Fig.G4, G5

While pressing down the ejector button with your finger, insert the ejector pipe into the body

so that its hole meets the tapped hole on the metal stay and fasten the ejector pipe with the

ejector setting screw(s).

Note: After reassembling, repeat trial operation several times and inspect that

there is nothing wrong with the pipette.

-11-

NPP-2/NPP-10/NPP-20

⑥Ejector pipe

Body

①Plunger set

②1st spring

O-ring retainer

⑦Ejector setting screw

Seal ring

O-ring

Nozzle cylinder

③Nozzle

cylinder set

Enlar

g

ement of seal rin

g

To nozzle c

y

linder

Fig. G1

NPP-100/NPP-200

Fig. G2

Seal ring

O-ring

③Nozzle cylinder

⑤O-ring

seal ring set

Enlargement of seal ring

To nozzle c

y

linder

⑦Ejector setting screw

⑥Ejector pipe

O-ring retainer

②1st spring

①Plunger set

Body

- 12 -

- 13 -

NPP-1000

Body ③Nozzle cylinder

①Plunger set

⑧Nozzle Filter

②1st spring

O-ring retainer ⑦Ejector setting screw

⑤O-ring

seal ring set Seal ring

⑥Ejector pipe

O-ring

Enlargement of seal ring

To nozzle c

y

linder

Fig. G3

- 14 -

NPP-5000

⑧Nozzle Filter

⑥Ejector pipe

⑦Ejector setting screw

Nozzle

cylinder

Seal ring

O-ring

O-ring

④Nozzle

Body

①Plunger set

③Nozzle

cylinder

⑤O-ring

seal ring set

Enlargement of seal ring

To nozzle c

y

linder

Fig. G4

NPP-10000

③Nozzle

cylinder

⑧Nozzle Filter

Fig. G5

⑥Ejector pipe

⑦Ejector setting screw

Enlargement of seal ring

To nozzle c

y

linder

⑤O-ring

seal ring set

Nozzle

cylinder

O-ring

Seal ring

O-ring

④Nozzle

①Plunger set

Body

- 15 -

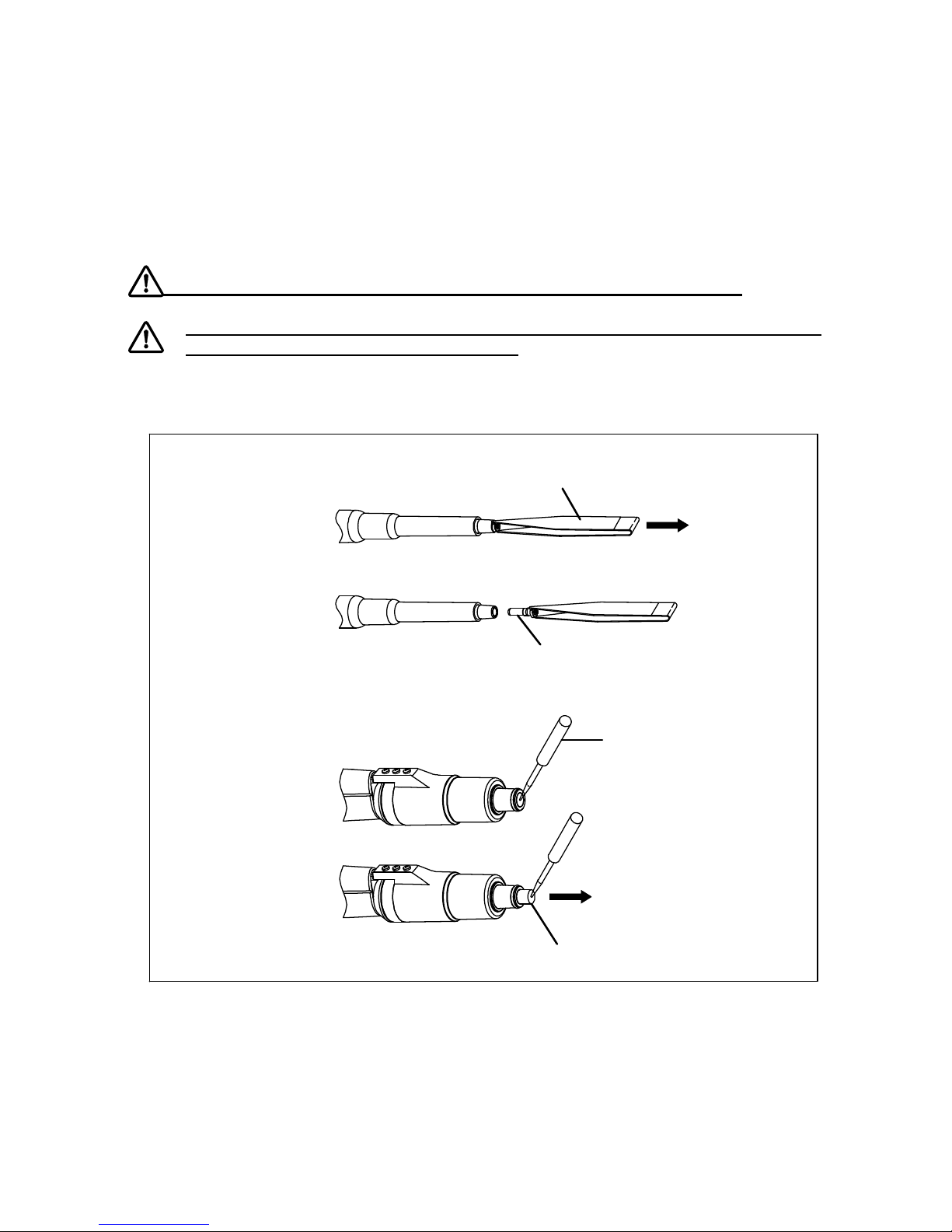

Filter replacement procedure

1000ul: Fig. H-,

Insert the tips of filter remover into two notches on the sides of a filter, and pull out the

filter in the direction of the arrow.

Set the projection of a new filter in the internal groove of the nozzle, and then press the

filter into the nozzle.

5000 ul, 10000ul: Fig.L-,

Insert the filter remover into the filter and pull in the direction of the arrow.

Insert a new filter into the nozzle.

- 16 -

Do not touch filters which may be contaminated by harmful substances.

CAUTION

Take extreme care for sharpness of Nozzle filter remover when filters for

5000 ul or 10000ul types are taken off.

CAUTION

①

②

③

④

1000μl

5000μl、10ml

⑩Nozzle filter remover

⑨Nozzle filter

⑨Nozzle filter

⑩Nozzle filter remover

Fig. H

Autoclaving

This pipette is autoclavable. When autoclaving, carry it out at 121°C for 20 mimutes following

the procedure mentioned below.

①For the 1000 ul, 5000 ul and 10000 ul types, remove the filter referring to the “Filter

replacement procedure” mentioned on P16.

②Release the lock lever from the locked position and set the counter graduation to the

allowable limit of the liquid volume.

③After autoclaving is complete, dry the pipette completely.

Note: When autoclaving, don’t pile pipettes on others in the autoclave or lean

pipettes with a nozzle top facing down so that self-load is applied on the nozzle.

This pipette is made of an autoclave compatible material, but because of high

temperature in the sterilizer, there is a risk that parts subject to load will be

deformed.

Drying the pipette

Dry the pipette immediately after autoclaving is complete. It is necessary to dry the pipette with

a constant temperature air-drier at 60°C for 60 minutes or longer.

①Pull out the ejector pipe, referring to “Disassembling” on page 7.

②Turn the nozzle cylinder counterclockwise by two and a half turns to loosen it.

③Put the pipette in a constant temperatures air-drier for drying.

④After the pipette is dry, wait until it returns room temperature and then fasten the nozzle

cylinder and reassemble the ejector pipe into the body.

Note: If the pipette is reassembled when it is still warm, it may cause breakdown or

deterioration of the pipette such as breakage of the screw threads, etc. Be sure to

reassemble the pipette after it has completely cooled down.

If the pipette is used when it is warm, accurate liquid handling can not be

carried out.

: Don’t touch the pipette directly right after drying, because it will have got

CAUTION very hot during drying. Touching the hot pipette directly may cause injury.

Components of water used for autoclave may cause pipette malfunction or

performance.

- 17 -

- 18 -

Specifications

Nichipet Premium is a high quality pipette. The technical figures given in the Table-1 “Nichipet

Premium Maximum Permissible Errors” were obtained using genuine Nichiryo BMT Tips.

Nichiryo declares that pipettes comply with the requirement of the ISO 8655 Standard, by type

testing. The adjustment is carried out under strictly defined and monitored conditions (ISO

8655-6):

●The basis of adjustment, EX

●Reference temperature, 20°C

●Relative humidity, 50%

●Barometric pressure, 101KPa,

●Use of distilled water grade 3 (ISO 3696)

●Ten measurements for each test volume at three points, nominal volume, 50% of

nominal volume and the minimum or 10% of nominal volume.

Table-1:Nichipet Premium Maximum Permissible Errors

Pipette types

(Code)

Volume range

(ul)

Volume

(ul)

Accuracy

(systematic

error) AC (%)

Precision

(random error)

CV(%)

NPP-2 0.1-2 (ul)

0.2 ±12.0 ≤6.0

1 ±5.0 ≤2.5

2 ±3.0 ≤1.0

NPP-10 0.5-10 (ul)

1 ±4.0 ≤3.0

5 ±1.0 ≤1.0

10 ±1.0 ≤0.5

NPP-20 2-20 (ul)

2 ±5.0 ≤3.0

10 ±1.0 ≤1.0

20 ±1.0 ≤0.4

NPP-100 10-100 (ul)

10 ±2.0 ≤1.0

50 ±1.0 ≤0.3

100 ±0.8 ≤0.3

NPP-200 20-200 (ul)

20 ±1.0 ≤0.5

100 ±0.8 ≤0.3

200 ±0.8 ≤0.2

NPP-1000 100-1000 (ul)

100 ±1.0 ≤0.5

500 ±0.8 ≤0.3

1000 ±0.7 ≤0.2

NPP-5000 1000-5000 (ul)

1000 ±1.0 ≤0.3

2500 ±0.8 ≤0.3

5000 ±0.6 ≤0.2

NPP-10000 1000-10000 (ul)

1000 ±2.0 ≤0.4

5000 ±0.8 ≤0.3

10000 ±0.4 ≤0.2

* The data given in the table conform to the ISO 8655-2 standard.

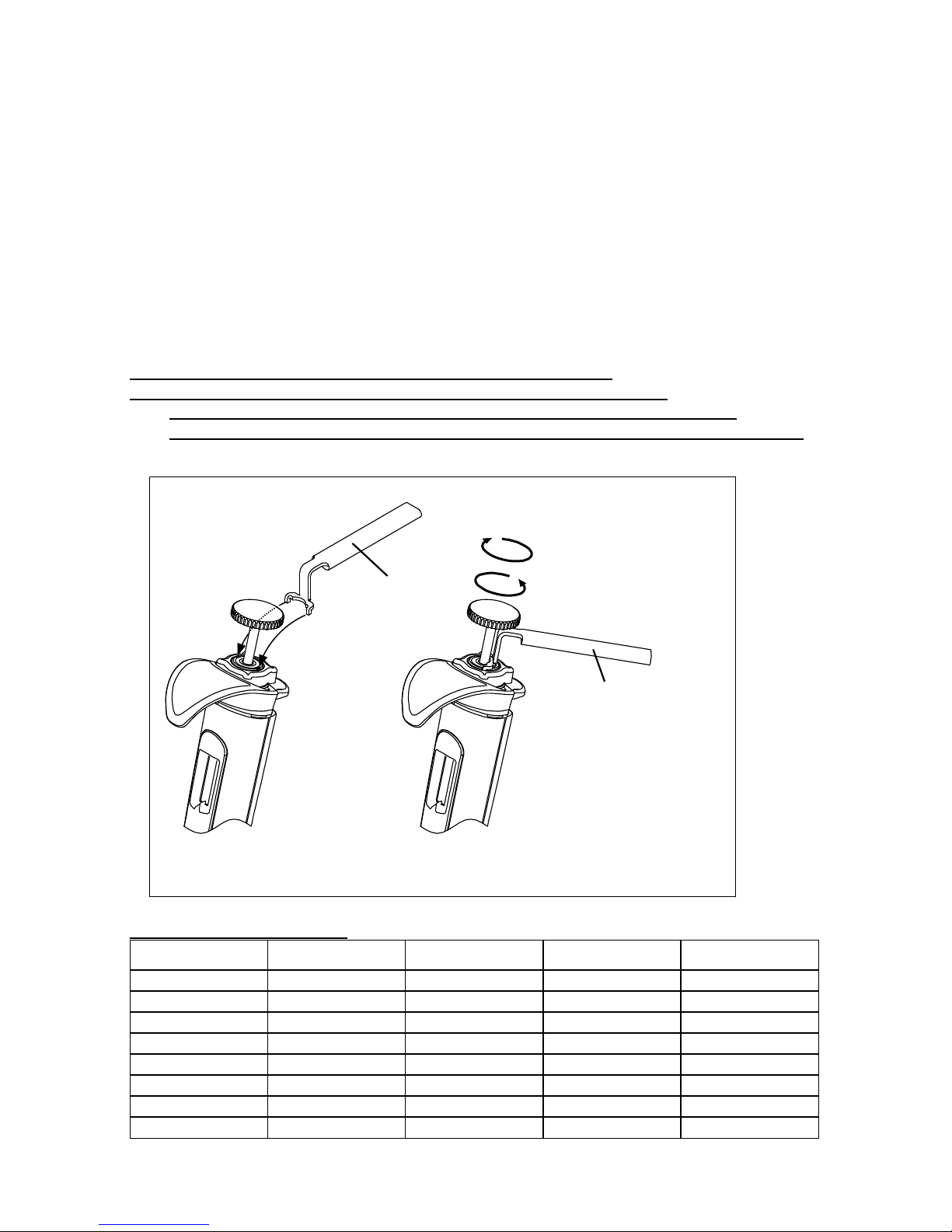

Calibration procedure

* For good volume setting (calibration), Volume adjustment should be conducted minimum

volume setting first and then followed by maximum volume setting for each size of pipettes.

①Loosen the lock lever freely.

②Insert the adjustment tool’s tabs into the two grooves on the adjustment head. (Fig. J①)

③Hold the unit in one hand and secure the adjustment tool not to turn. (Fig. J②)

④Rotate the push button clockwise for dispensing volume increase (the counter display

turns to lower.), and counter-clockwise for dispensing volume decrease (the counter

display turns to raise.).

⑤Please refer to the “Table-Calibration guideline” below for approximate rotating scale on

the display.

Note: Be sure the lock lever is loosened before adjusting.

Note: Rotating directions for volume adjustment are as follows,

Dispensing volume increase (counter display turns to lower) : clockwise

Dispensing volume decrease (counter display turns to raise) : counter-clockwise

①②

Adjustment tool

Adjustment tool

Clockwise:

dispensing volume increase

Counter-clockwise:

dispensing volume decrease

Fig. J

Table-2 Calibration guideline(Unit: ul)

1scale mark 2 scale marks 5 scale marks 10 scale marks

NPP-2 0.0015 0.0029 0.0073 0.0145

NPP-10 0.0077 0.0154 0.0385 0.0769

NPP-20 0.012 0.025 0.062 0.125

NPP-100 0.078 0.156 0.390 0.780

NPP-200 0.13 0.25 0.63 1.26

NPP-1000 0.79 1.58 3.96 7.91

NPP-5000 8.0 16.0 40.0 79.9

NPP-10000 8.0 16.1 40.2 80.3

The numerical values (volume) above are for reference only. For actual measurement, please

- 19 -

Other manuals for Nichipet Premium

1

Table of contents

Other Nichiryo Laboratory Equipment manuals