Nichiryo Nichipet ECO User manual

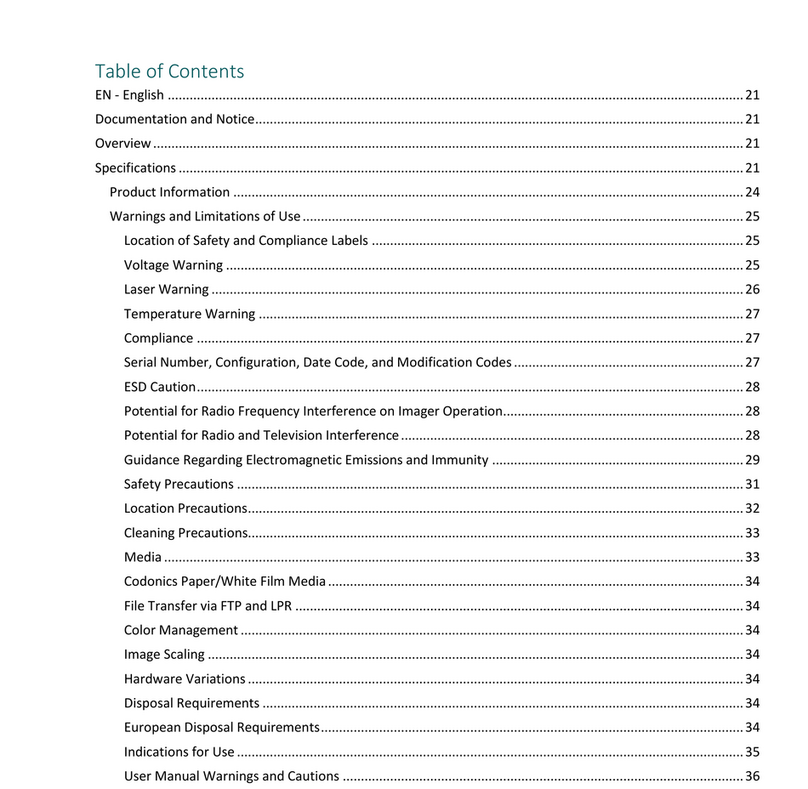

Table of contents

Other Nichiryo Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies QuickSwap G3185B Installation and setup

Radiometer Analytical

Radiometer Analytical TitraLab TIM960 user guide

Spinner II

Spinner II 600 HD installation instructions

Bartscher

Bartscher 823HO instruction manual

Hach

Hach AS950 AWRS Basic Installation and Maintenance

Holland Green Science

Holland Green Science 10301001 user manual

Judo

Judo JUV 20 G Installation and operating instructions

Ampronix

Ampronix Horizon XL manual

Xylem

Xylem WTW OxiTop Box operating manual

Metrohm

Metrohm OMNIS 2.1006.00X0 product manual

Agilent Technologies

Agilent Technologies 5100 ICP-OES Site preparation guide

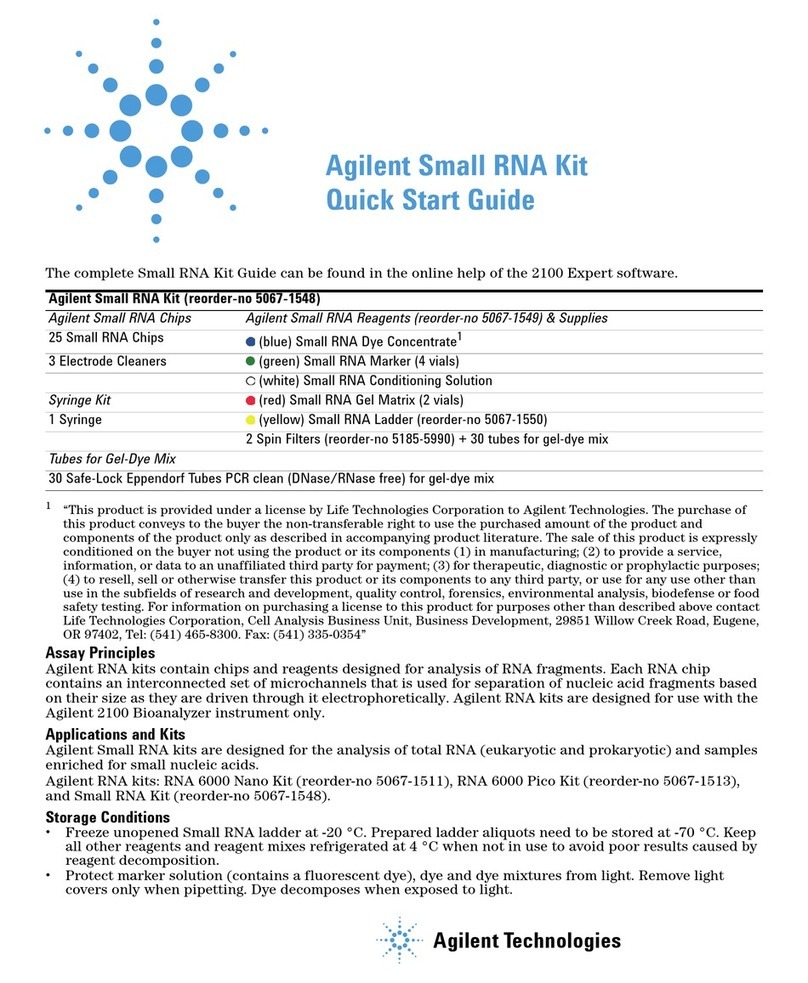

Agilent Technologies

Agilent Technologies Small RNA Kit quick start guide

Thermo Savant

Thermo Savant SPEEDVAC SPD Series instruction manual

PlexBio

PlexBio IntelliPlex 1000 user manual

Helmer Scientific

Helmer Scientific i Series Service manual

Julabo

Julabo ME-4 operating manual

Thermo Scientific

Thermo Scientific Heraeus Multifuge X3 F Instructions for use

EnGenius

EnGenius EPE-4818G Installation guides