Nichiryo Nichipet Premium User manual

Autoclavable & UV Resistant

Digital micro pipette for liquid handling

User’s Manual

-1-

*SB-NPP002ER 2022/6/10

SB-NPP001ER 2022/4/15

Thank you very much for purchasing Nichipet Premium.

Please read this manual carefully before using this device.

Danger Levels

Will lead to serious injuries or death.

May lead to severe injuries or death.

May lead to light to moderate injuries, and/or cause

property damage.

User information

Caution on disposal of this product

When disposing the pipette body and tips (including adhering liquid), please

comply with the laws and regulations of each country related to disposal, or local

ordinance or regulation.

Please read this manual carefully and have sufficient understanding of the

contents and instructions, especially concerning matters of safety, prior to

use.

The notes stated here is for the safety of the user, and for the correct

usage of the product.

Contents marked with “Danger Level Symbols” are matters that

require the user’s utmost attention, not only for using Nichipet Premium

properly, but also to prevent users from injuries or death, harm to others,

and/or property damage.

After reading this manual, please keep it in a noticeable and accessible

place for ‘users of the device’ to refer to at any time.

Any serious incidents that has occurred in relation to the equipment shall

be reported to the manufacturer and to the competent authority of the

Member State in which the user and/or the patient is established.

Safety Precautions

WARNING

CAUTION

DANGER

-2-

Autoclavable & UV resistant

Digital micro pipette for liquid handling

Table of Contents

1. Product overview 3

1.1 Features 3

1.2 Standard Accessories (Included) 3

1.3 Main illustration 3

2. Information on safety 4

2.1 Intended Use 4

2.2 Warnings for Intended Use 4

2.3 Material information 5

3. Operation/Operating procedure 6

3.1 Volume setting 6

3.2 Aspiration of liquid (Forward technique) 7

3.3 Dispensing the liquid 9

3.4 Recommendation for accurate pipetting (Technique) 10

4. Maintenance 11

4.1 Cleaning 11

4.2 Disassembling 11

4.3 Reassembling 12

4.4 Changing the Nozzle Filter 20

4.5 Autoclaving 21

4.6 Drying the pipette 21

5. Specifications (Accuracy/Precision) 22

6. Calibration (Adjustments) 23

6.1 Volume adjustment method 23

6.2 Volume measurement/Inspection procedure 24

7. Troubleshooting 26

8. Replacement Parts List 27

8.1 Consumables 27

8.2 Spare parts list

28

-3-

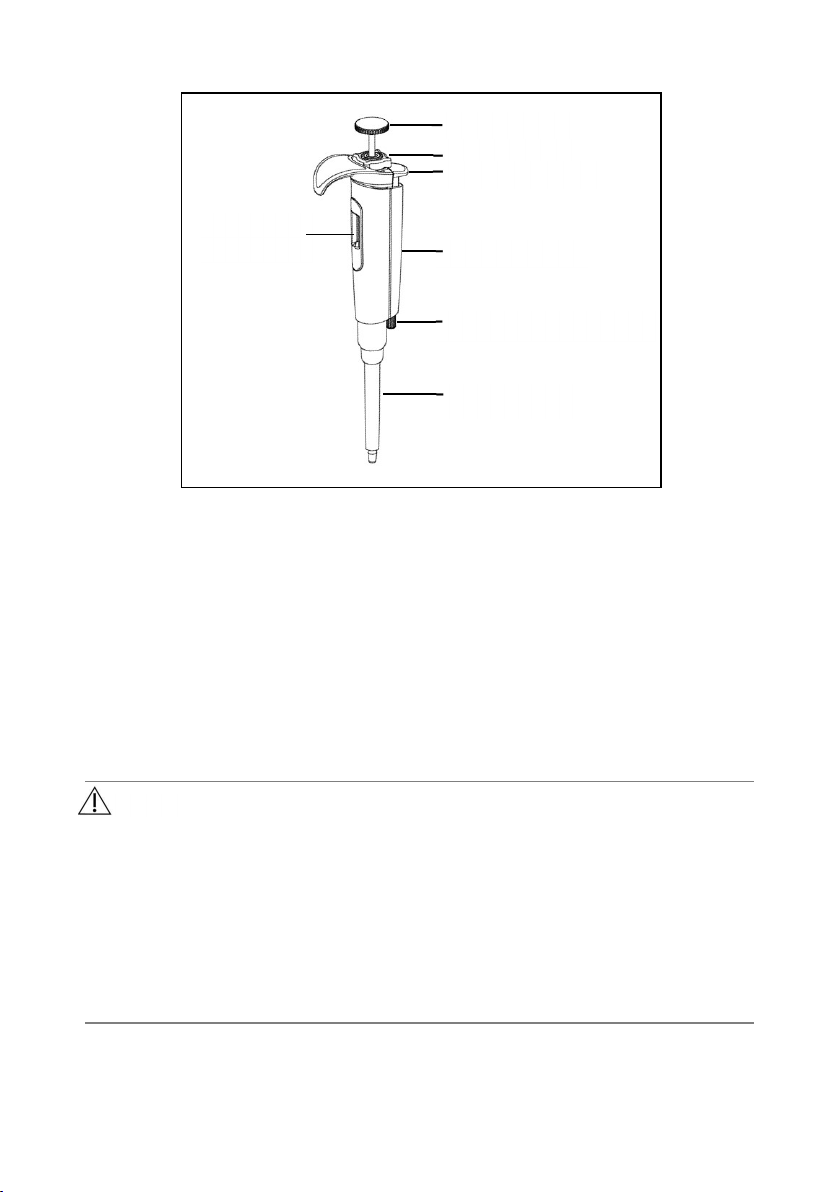

1. Product overview

1.1 Features

● Nichipet Premium is fully autoclavable at the condition of 121°C for 20 minutes.

● Nichipet Premium is made of UV resistant materials, thus it can be used in a clean

bench environment.

● Enhance UV resistance has been applied, but the surface of the pipette body might be

deteriorated by long time UV irradiation. It does not affect the accuracy and precision.

● The newly designed curvature and roundness in shape is ergonomic, and mitigates the

user’s fatigue and stress levels from long periods of use.

● Easy to read digital indicator.

● The sample volume can easily be set by simply rotating the push button.

● Setting the sample volume can easily be locked on with the one-touch lock mechanism.

● A wide range of sampling volume can be covered by eight models, from 0.1μL to

10,000μL.

● Patented body construction shields the hand temperature permeating through the body

and inner workings of the device, which increases the accuracy of the volume measurements.

● Since highly durable PTFE (Fluoroplastic) is used in the product, long lasting accuracy

and precision is maintained.

● A thin nozzle tip can be easily inserted, and can reach the bottom of universal test tubes

(110mm in depth) for aspiration and dispensing of liquid. (2μL – 1000μL)

● The tip can be removed without direct contact, by simply pressing the tip ejector.

● The Easy-Calibration function provides smooth and easy adjustment with the included

adjustment tool.

1.2 Standard accessories (Included)

Accessories QTY

Tip(2μL/10μL/20μL/100μL/200μL/1000μL) 3

Tip(5000μL/10000μL) 1

N

ozzle filter

(

1000

μL

/

5000

μL

/

10000

μL

)

3

N

ozzle filter remover

(1000μL

/

5000μL

/

10000μL)

1

A

djustment tool

1

User’

s Manual

1

When unboxing the package, check that all of the items above are included for

the respective model.

-4-

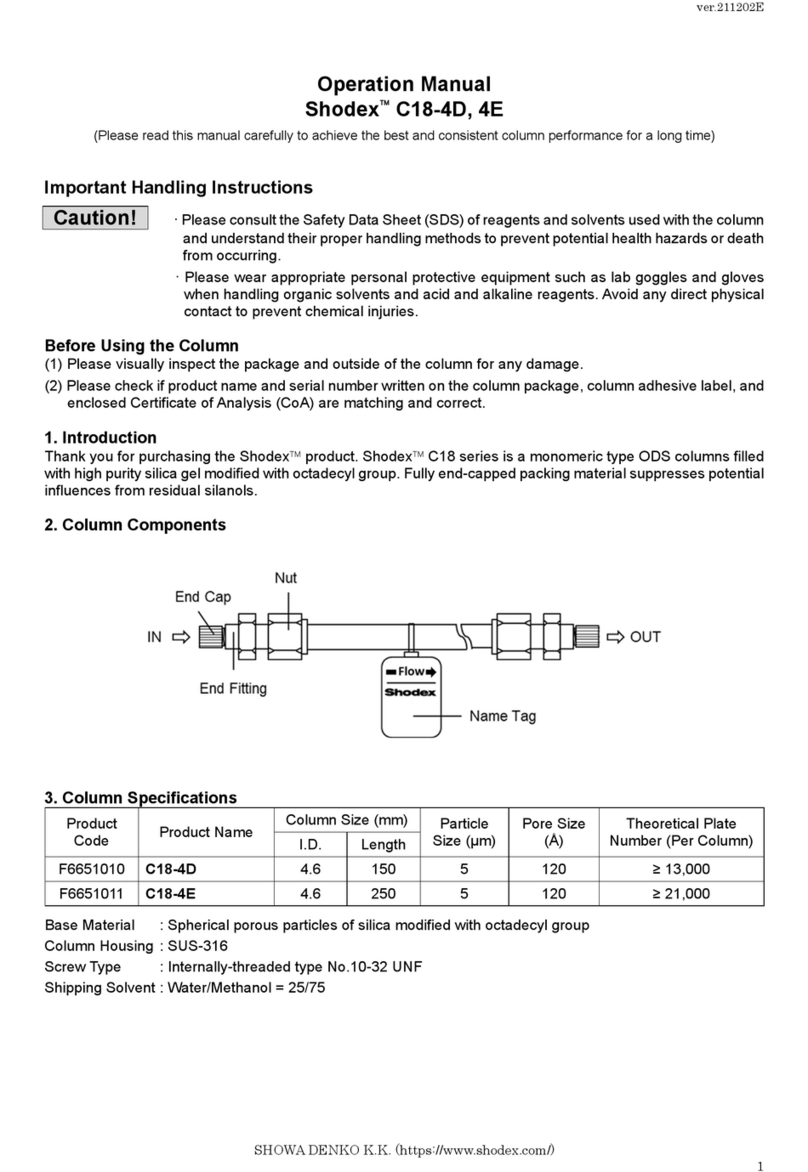

1.3 Main illustration

2. Information on Safety

2.1 Intended Use

Nichipet Premium, used in conjunction with pipette tips recommended by Nichiryo,

are designed and constructed for low-contamination transfer of liquids, especially for

samples from the human body and for reagents within the scope of an in-vitro diagnostic

application in order to allow the in-vitro diagnostic medical device to be used as intended.

Therefore, Nichipet Premium is subjected to the accessories of in-vitro diagnostic medical

devices under Regulation (EU) 2017/746. The accessories is treated as in vitro diagnostic

medical devices in their own right under Regulation (EU) 2017/746.

Nichipet Premium are intended for operation by qualified staff.

2.2 Warnings for intended use

When handling radioactive substances or infectious substances, always check and

confirm the information first, and follow guidelines on their safety procedures.

When using harmful liquids to the human body, be very careful in the handling of the

substances.

Never touch or come into direct contact with the used chips.

Never touch filters directly that are contaminated by harmful or toxic substances.

When liquids that are harmful to the human body adheres and/or contamination occurs,

use appropriate measures to clean and decontaminate the device before continuing

its use.

This product is not intended for use on living organisms.

Ejector setting screw

Push button

Lock lever

Ejector button

Ejector pipe

Main body

Volume

indicator

DANGER

-5-

Do not eject the tip with liquid inside of it.

Do not eject the tip towards anybody.

Do not expel or dispense any liquids towards anybody.

Depending on the splashed liquid, there is danger of causing injuries to the human

body.

Please protect yourself in accordance with the general procedure of danger prevention,

such as wearing protective clothing, protective glasses and gloves.

Do not use the pipette for any other purpose, use only for pipetting and liquid dispensing.

Do not modify the pipette, modification can lead to accidents.

Do not stab the tip into the human body, or eject the tip towards anyone. The tip is

very sharp and extremely dangerous.

The filter replacement tool tip is very sharp and can be dangerous. Please handle it

with caution.

Since the main body of the pipette becomes extremely hot right after autoclaving and

drying. In this state, please do not touch it directly with your hands. It can lead to

accidents and burn injury.

Do not use the pipette for any purpose other than pipetting and liquid dispensing,

such as stirring liquid with this product. It can lead to loosening of the tip, the tip

dropping off, liquid adhesion and contamination to the main unit of the device and

accidents and/or injury.

During operation and maintenance, if any worn, missing or broken parts are detected,

discontinue use immediately. Order and replace the part or parts, before use.

2.3 Material information

The use of highly reactive chemicals may damage the device. Please acknowledge

the following materials that are used, and do not use liquids that will violate them.

Material of external parts

Polypropylene (PP)

Polyetherimide (PEI)

modified- Polyphenyleneether (m-PPE)

Polyetheretherketone (PEEK)

Fluororubber (FKM)

Stainless steel

Aluminum alloy

Alumina

WARNING

CAUTION

CAUTION

-6-

3. Operation/Operating procedure

Users of the device are required to strictly observe the following in order

for the pipette to keep its excellent accuracy, precision and original

performance.

Do not expose pipette to direct sunlight when using it, or for 2 hours prior to use,

otherwise the pipette may lose its accuracy. Avoid working with pipettes in a high

temperature, low temperature, low humidity environment, or when the

temperature difference between the environment including the main body of the

device and the liquid is large, accuracy and precision may not be guaranteed.

This Pipette can be used in a stable environment between +4°C and +40°C, but

the specifications may vary.

Just prior to use, avoid touching the tip or nozzle cylinder as much as possible. If

they are warmed up, accuracy may not be obtained.

Original Nichiryo tips are recommended. Nichipet Premium is calibrated with the

original Nichiryo tip (Premium Tip), if you use other tips, deviations in original fac-

tory settings may occur, and accuracy will not be guaranteed.

Depending on the frequency of use, the pipette should be cleaned and the airtight

chamber should be maintained according to the manual.

3.1 Volume setting

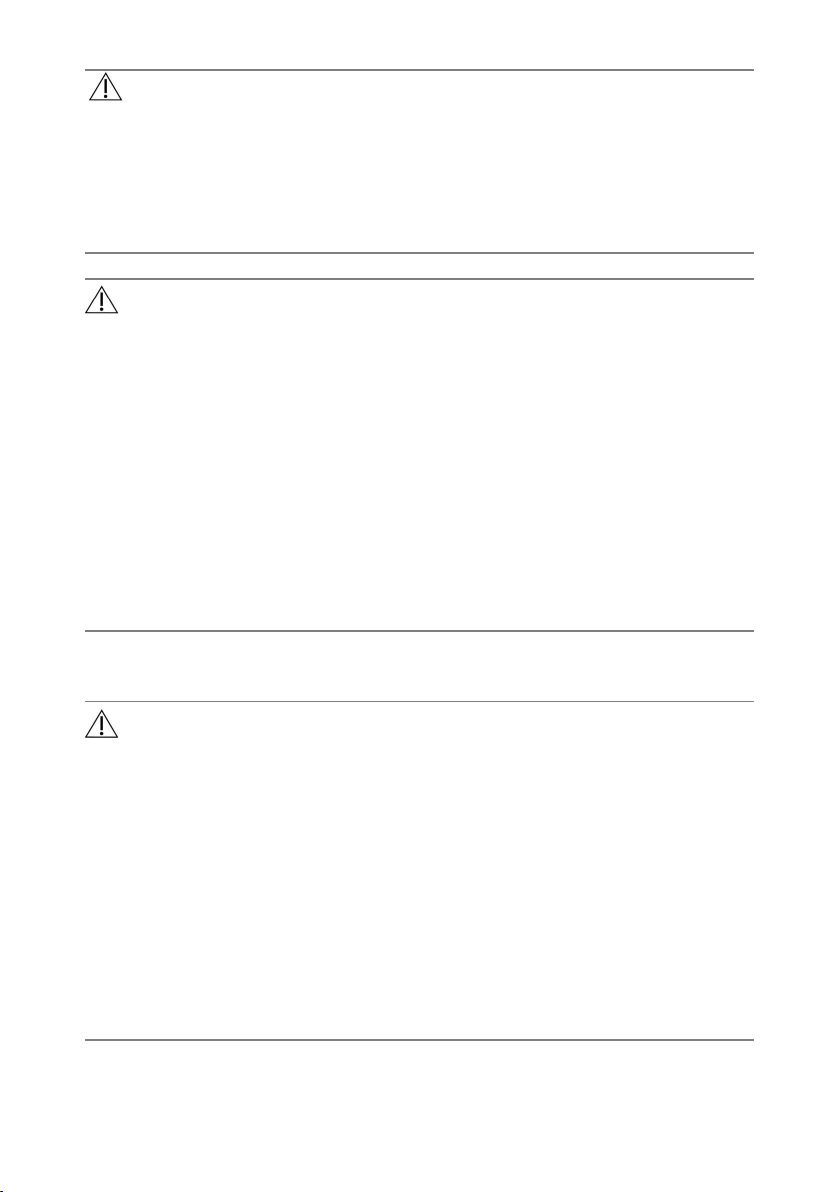

1) Turn the lock lever to the unlocking direction to loosen it (Fig. A).

2) Turn the push button to set the volume indicator to a desired liquid volume.

When setting the liquid volume, set the indicator’s minimum graduation scale to the

triangle point marker in the lower part of the volume indicator (Fig. B). Please refer

to the volume indicator and the minimum graduation unit for each model to set the measurement

volume accordingly. The volume indicator numbers are colored in black, or in red, to indi-

cate the position of the decimal point. Black indicates the integer, red indicates the

decimal. For models 2uL, 10uL, 20uL, 100uL, 200uL, 1000uL scale units are in (μL),

for models 5000uL, 10000uL scale units are in (mL).

3) To increase the volume setting, turn the push button till it passes the designated

volume setting by at least half a rotation of the push button dial, and then dial back to set

the designated volume.

4) To decrease the volume setting, simply turn it to the designated volume directly.

5) After setting the liquid volume, turn the lock lever to the locking position to lock it

(Fig. A).

Do not exceed the specified liquid volume limit, otherwise the pipette may be

damaged or deteriorate in its quality.

CAUTION

*

-7-

3.2 Aspiration of liquid (Forward technique)

1) Attach a new tip to the nozzle end.

It is recommended that tips are directly picked up from the rack. Do not twist the

pipette when fixing tip on.

Please be sure to mount the tip on the main nozzle securely. Failure to do so

may cause the tip to drop off and liquid to splash.

Do not perform pipetting with less liquid than the set volume. If the quantity of liquid is

less than the set volume, it may cause the liquid to spray into the main body, and the

pipette may be damaged or deteriorate in its quality.

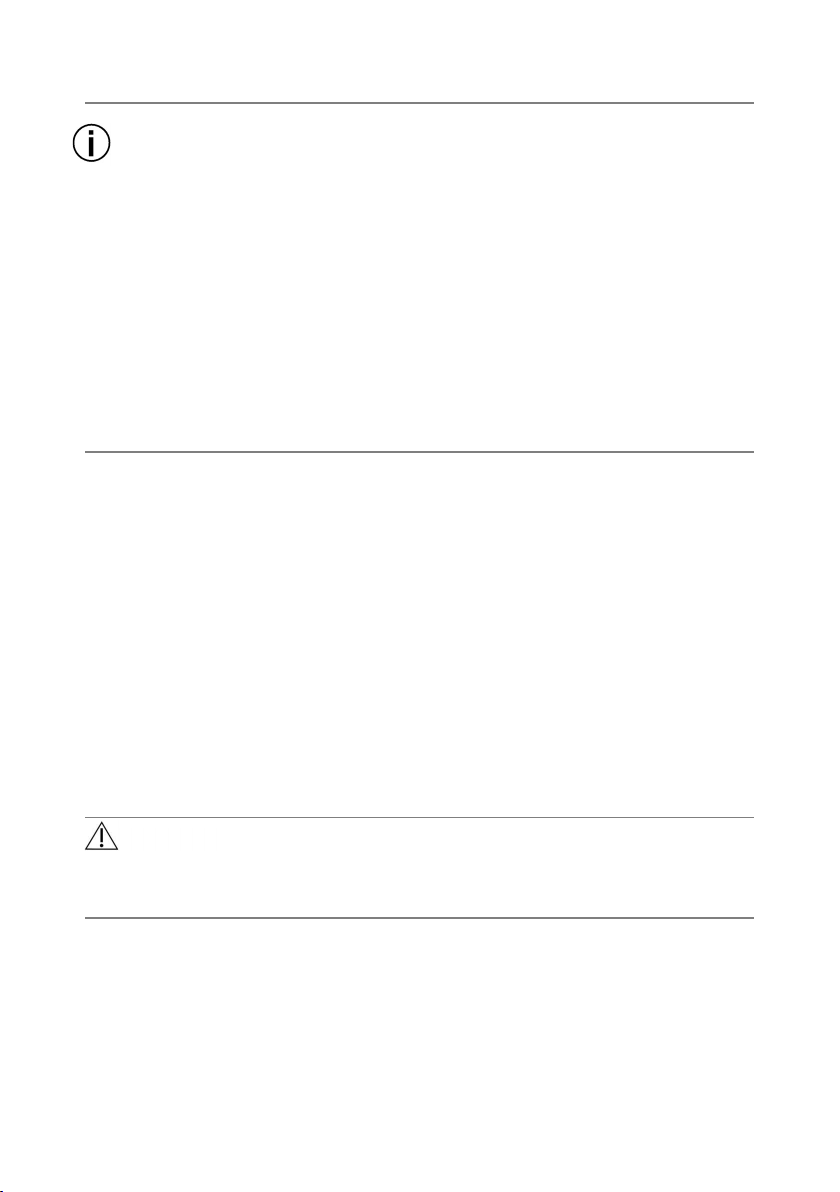

2) Press down the push button fully to the first stop position “b” (Fig. C) – ①.

NPP-2

2μl 10μl 20μl 100μl 200μl 1000μl 5000μl

10000

μl

(0.002) (0.01) (0.02) (0.1) (0.2) (1.0) (10.0) (10.0)

NPP-10 NPP-20 NPP-100 NPP-200 NPP-1000 NPP-5000 NPP-10000

CAUTION

Lock

Unlock

Push button

Lock lever

Ejector button

Fig. A

Fig. B

Point marker

Minimum

graduation unit

Volume indicator

2uL 10uL 20uL 100uL 200uL 1000uL

5

mL 10mL

2μL

10μL

20μL

100μL

200μL

1000μL

5000μL

10000μL

Model:

-8-

3) Hold the pipette vertically and immerse the tip 2mm. to 3mm. below the surface of

the liquid (Fig. D) - ①.

4) To aspirate the set volume of liquid into the tip, release the push button slowly and

let the push button go back to the initial position naturally. It takes 1 second (up to 3

seconds for a volume of 5000μL, 10000μL) to aspirate the liquid. During this operation,

stop to wait for the suction process of the liquid to be totally completed, making sure

that the liquid is drawn up into the tip with certainty (Fig. D) -②.

5) Draw the tip of the pipette carefully vertically upward and away from the liquid

surface, then touch the tip to the side of the tube to remove excess droplet adhering

to the outside of the tip (Fig. D) - ③.

Do not aspirate when the push button is at ‘position ④’ (Fig. C).

We recommend using the forward technique as the operation method of this

device for pipetting. Nichipet Premium has been calibrated with the forward

method, and precision may not be obtained when dispensing by any other

means.

Always change the tip when using different liquids to avoid cross-contamination.

Please operate the push button slowly and gently.

Sudden release of the push button, can lead to the aspiration of the liquid into the nozzle

cylinder; not only precise accuracy will not be obtained, but also the quality of the device

will be impaired. Due to the larger base volume measurements of models, 1000μL,

5000μL and 10000μL, there is a higher chance of the above to occur. To eliminate this

possible situation that leads to inaccuracy, precision failure or contamination, filters

(Sold separately.) are included in the package.

We highly recommend that the ‘Filter’ is used and regularly replaced in due intervals.

(Please order and replace the filters of the respective models when needed.)

When using the pipette, be sure to always attach and use a tip. Failure to do so, will

lead to liquid entering the inside of the device’s nozzle cylinder and cause serious

malfunctions.

Never turn the device sideways or upside down with liquid in the tip. Liquid can enter

inside the device’s nozzle cylinder, which can cause ※contamination and breakdown.

CAUTION

① ② ③ ④

Fig. C

a

b

c

Ejector button

-9-

※Cross-contamination with the entered liquid remaining inside the main body and/or nozzle

cylinder of the device can also occur, when switching liquids thereafter.

3.3 Dispensing the liquid

1) Touch the end of the tip against the inside wall of the recipient tube at a slight angle.

2) Press the push button down slowly and smoothly to the first stop “position b”.

Wait for a second, then press the push button down to the second stop “position c” to

expel the last droplet of liquid from the tip (Fig. D) - 4 and 5.

3) Keep the push button compressed. Remove the last droplet by slightly touching and

running the end of the tip up against the inner wall of the tube, then move the tip of the

pipette vertically straight up and out of the tube.

4) Press the ejector button to detach the tip to dispose (Fig. D) – 6.

We recommend the tip to be disposed of after each use.

Repeated use may lead to and result in; loss of accuracy, precision, and may

lead to contamination/cross-contamination due to adhesion and deposits from

prior use.

① ② ③ ④ ⑤ ⑥

Fig. D

b

c

a

-10-

3.4 Recommendation for accurate pipetting (Technique)

In addition to the previously mentioned operations of pipetting, the following

technique maximizes the performance of the pipette.

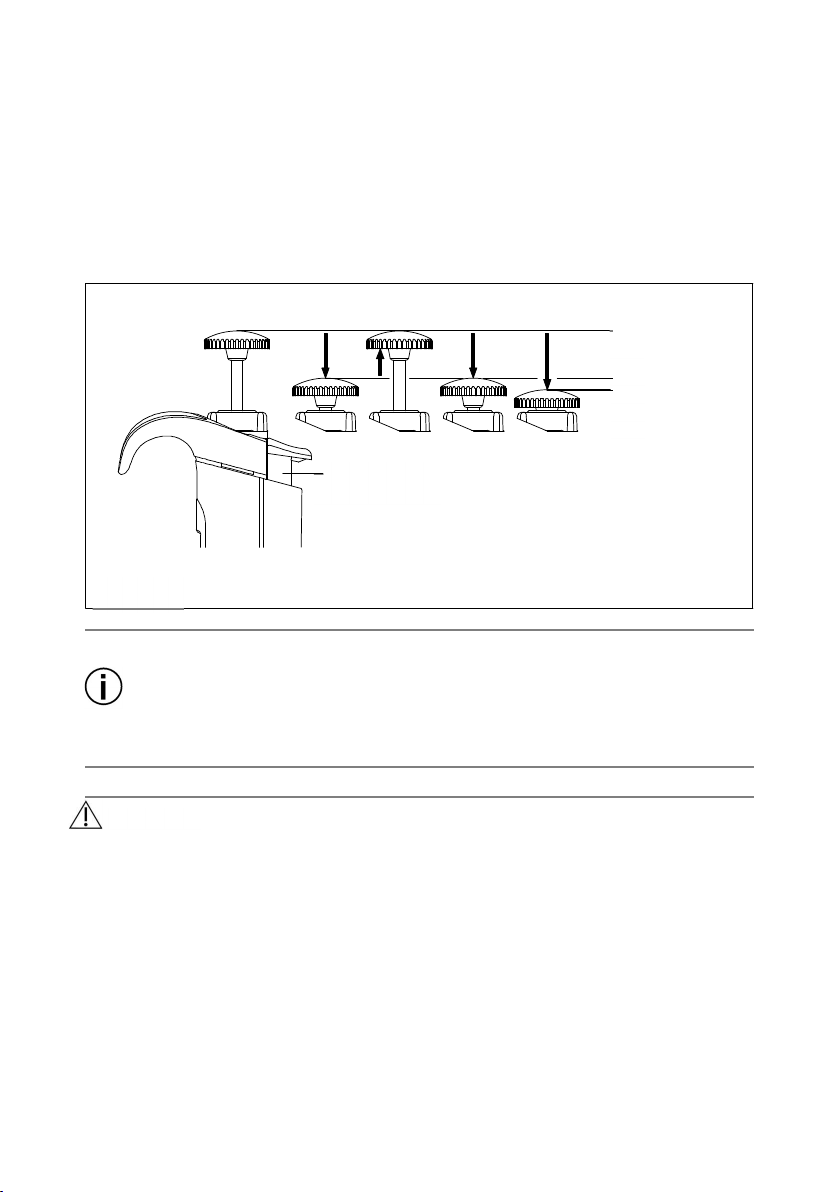

1) Pre-Rinsing the tip

Higher precision can be obtained by performing the pre-rinsing of the tip. When using a

fresh pipette tip for the first time and before sampling, it is important to pre-rinse the tip

at least two to three times with the target solution before pipetting. Repeat the aspiration

and discharge to the position of the 1st stop consecutively for two to three times

(Fig. E) – b.

When strict precision is required, this method is recommended for all kinds of liquid

handling. Pre-rinsing is a fast and easy way to increase the accuracy.

2) Handling of High Density Solutions / Viscous Solutions

After aspirating the liquid into the tip, wait for 2 to 3 seconds before removing the tip slowly

from the surface of the liquid. When dispensing, wait 2 to 3 seconds at the first stop

position before pushing into the second stop position (Fig. E) – c.

3) Small volume dispensing

Especially for volumes less than 50μL, please operate the pipette slowly and smoothly.

Also, please pay close attention to the effect of evaporation loss, due to temperature and

humidity.

Fig. E

a

b

c

-11-

4. Maintenance

4.1 Cleaning

When Nichipet Premium’s exterior is soiled, please use 70% ethanol on a clean soft cloth to

wipe it off.

Also, if any symptom that is described in the "7. Troubleshooting" section occurs, disassemble

and inspect the device (each part), and then check and follow the procedures in the

‘Troubleshooting Table’ to identify and isolate, correct and/or fix the situation or problem.

Use of highly reactive liquids, may damage the device.

After using a highly reactive liquid or/and if contamination occurs, perform the disassembly

and cleaning of the device, accordingly to the following method in this manual.

In order to keep and use Nichipet Premium in its best condition, we recommend

the user carries out; periodic checks and maintenance, and volume

inspection/calibration of the device.

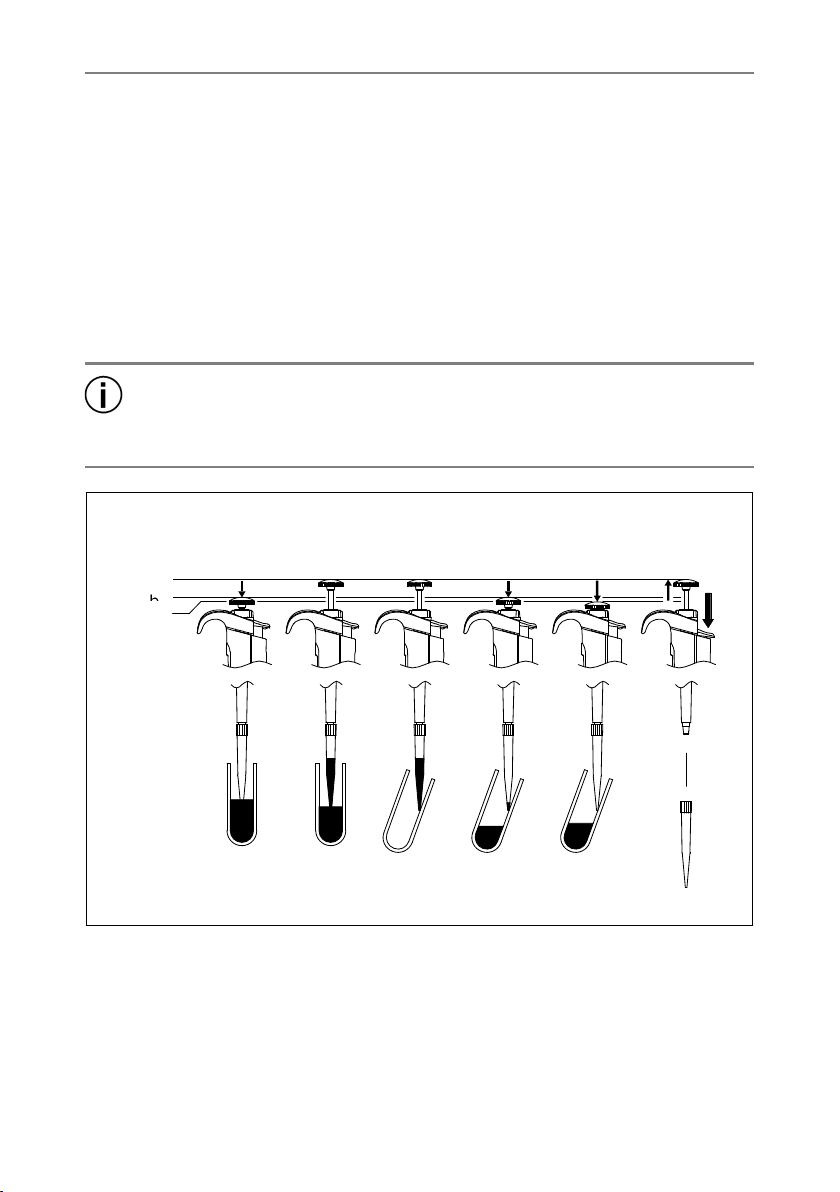

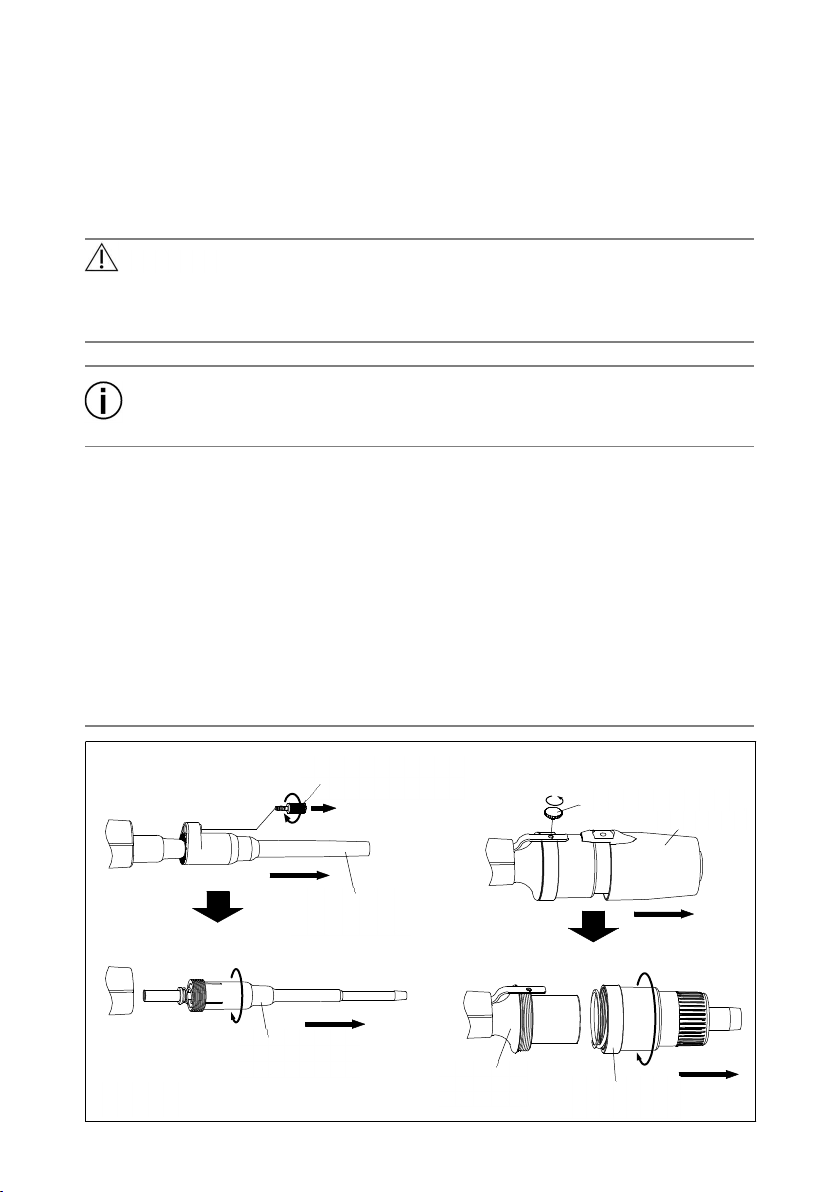

4.2 Disassembling

1) Turn counterclockwise to loosen and remove the ejector setting screw.

(6 Models) - 2μL to 1000μL (Fig. F) - (1-1)

Turn the ejector setting screw counterclockwise to remove it, and then carefully pull

out the ejector pipe, straight in the direction of the horizontal arrow.

(2 Models) - 5000μL and 10000μL (Fig. F) - (2-1)

2) ・6 Models ranging from 2μL to 1000μL (Fig. F) - (1-2)

The nozzle cylinder (Outer threading) screws into the main body.

・For the 2 models: 5000μL and 10000μL (Fig. F) - (2-2)

The nozzle cylinder is threaded onto the lower body. (Inner

threading.)

Note the differences in design; turn counterclockwise to remove the nozzle cylinder.

CAUTION

Fig. F

(2-2)

(2-1)

(1-2)

(1-1)

⑥Ejector pipe

⑥Ejector pipe

③Nozzle cylinder

⑦Ejector setting screw

⑦Ejector setting screw

③

Nozzle cylinder

Lower body

Circled Numbers in (Fig. F) corresponds to Parts

Numbers in the

replacement parts list

.

-12-

When removing the nozzle cylinder, the internal parts may spring out and apart from

the reaction of the loaded spring inside, be mindful of this point, and take precautions

when unscrewing and taking apart the nozzle cylinder.

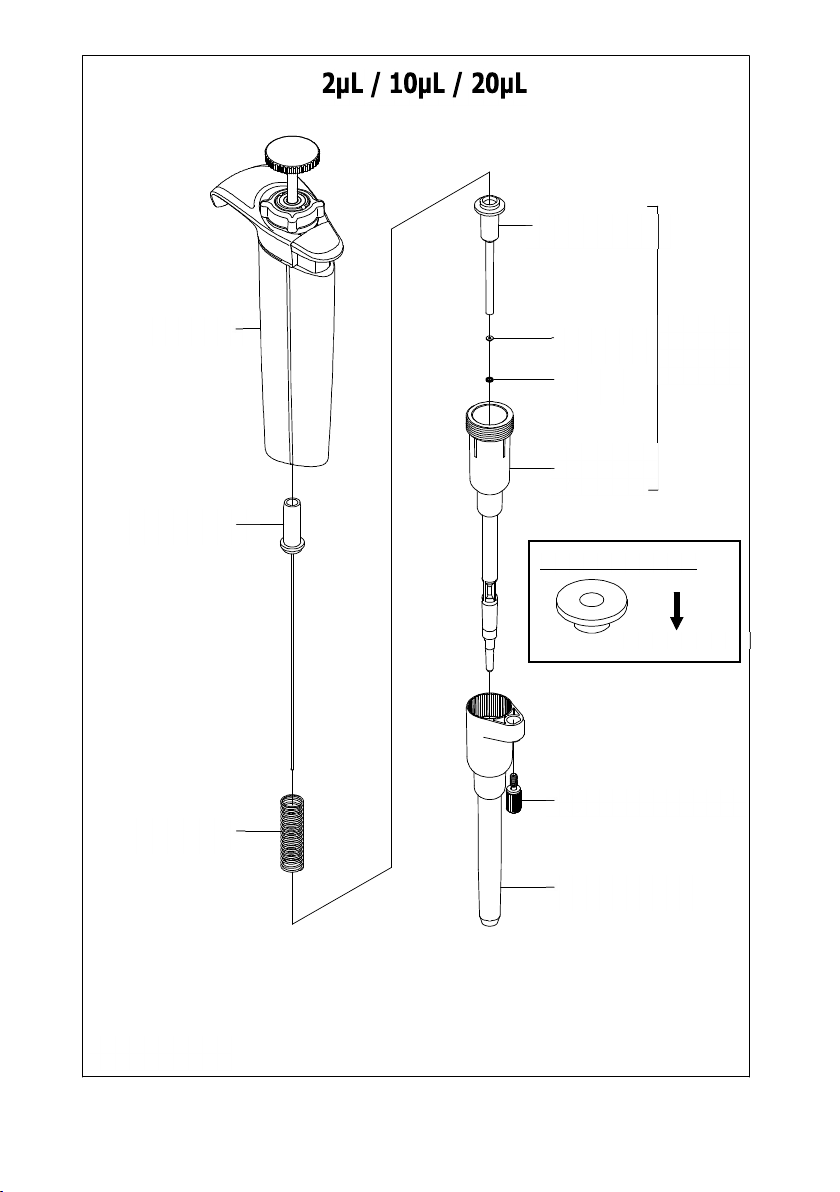

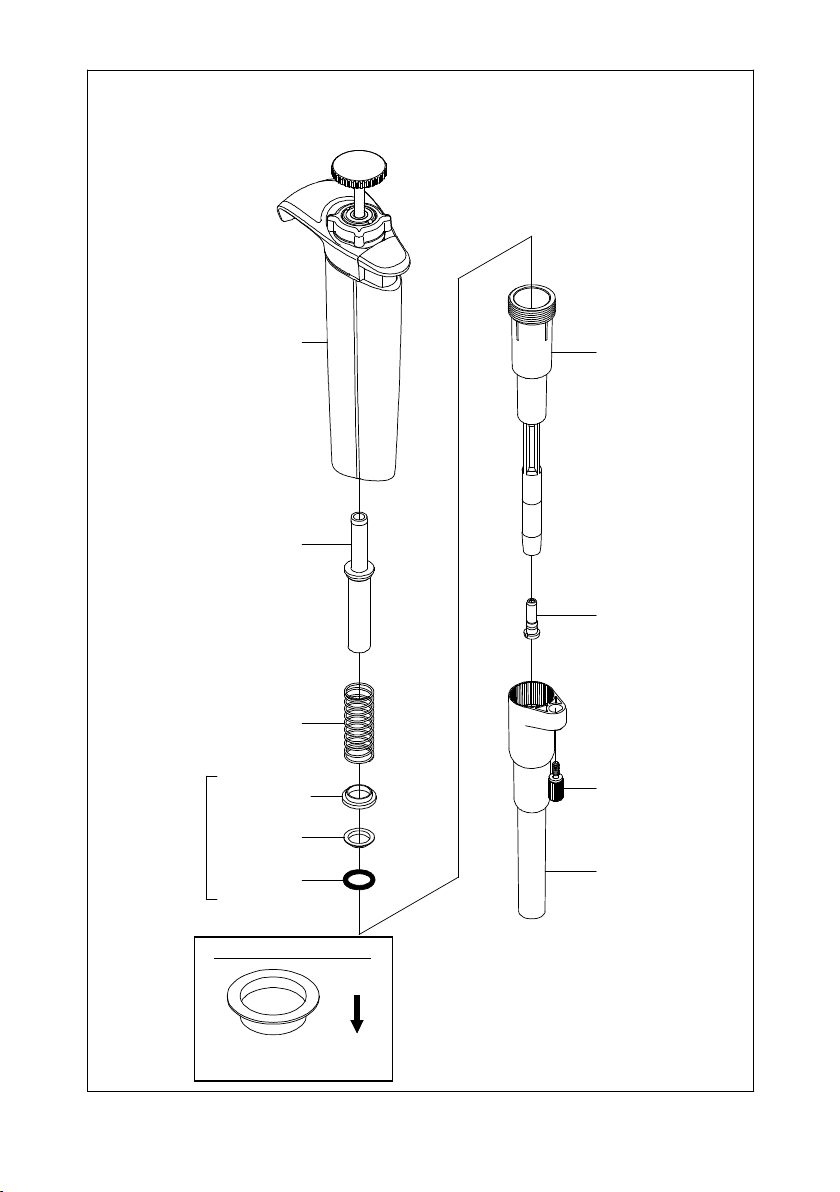

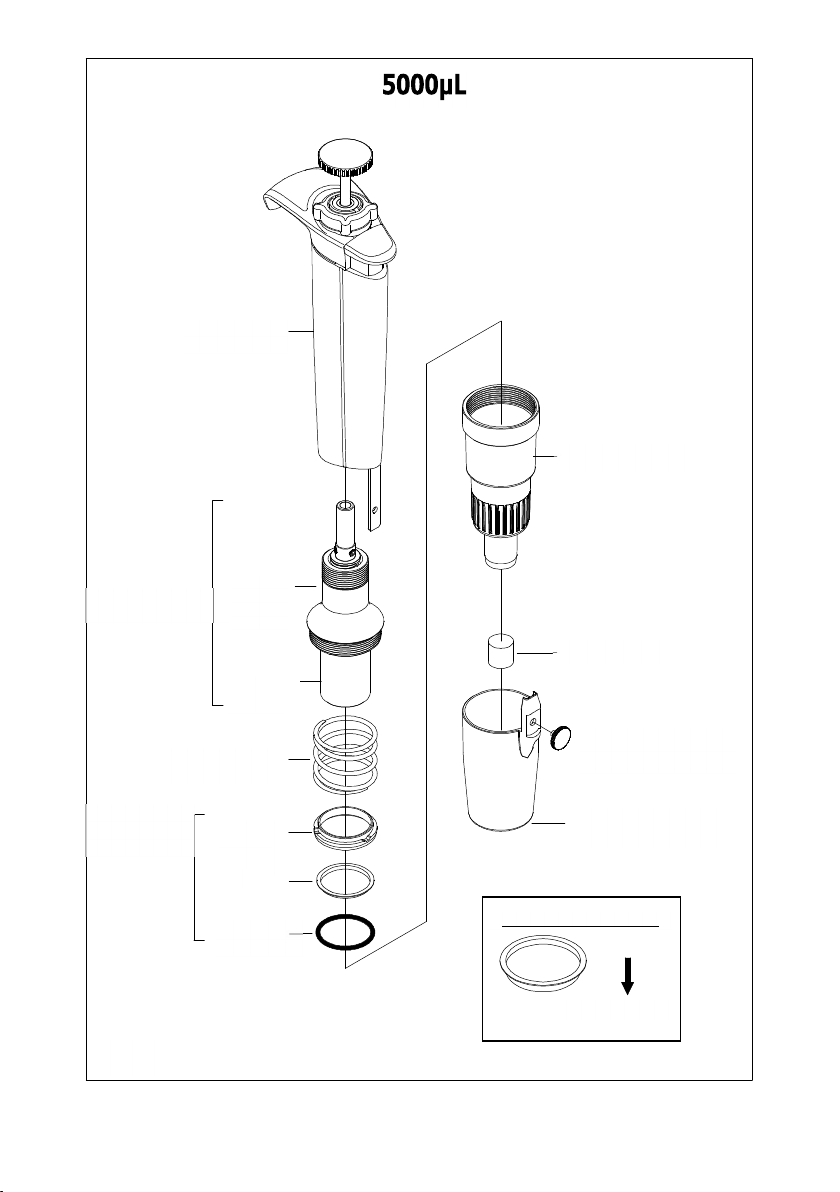

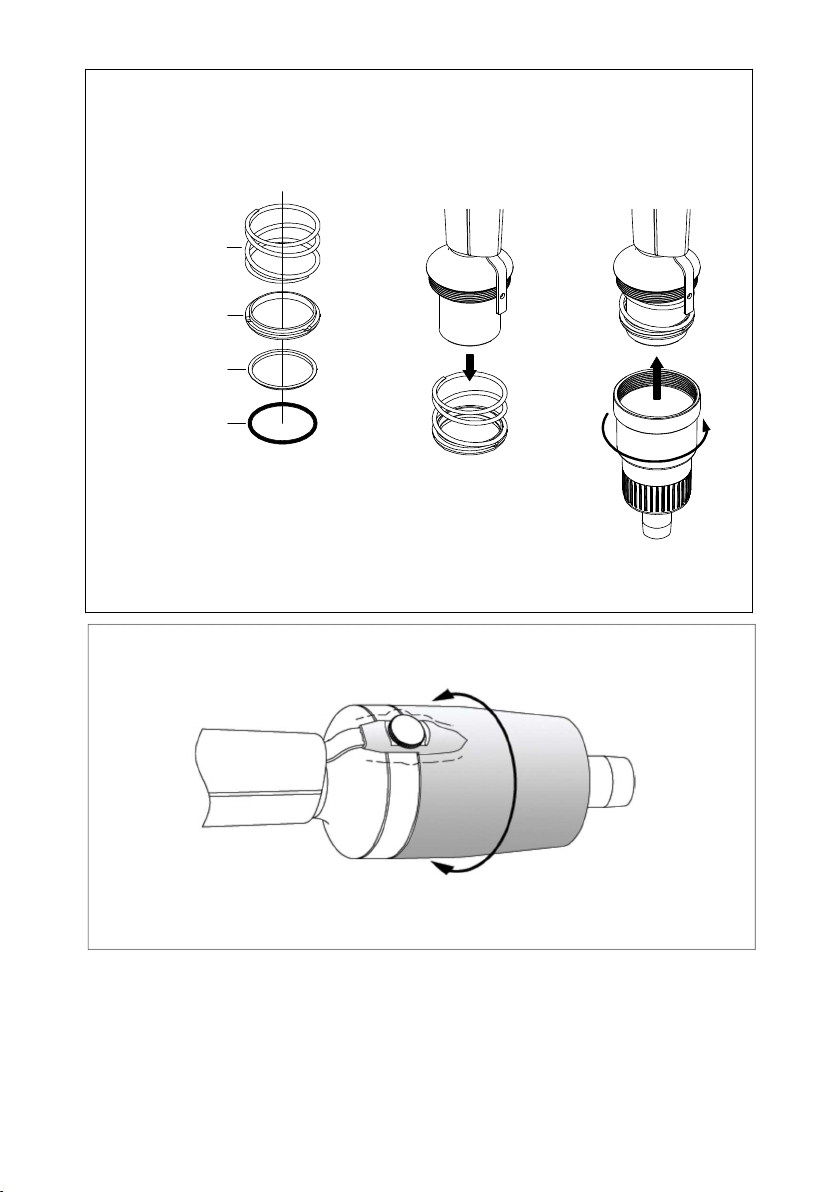

3) Disassemble the internal parts as shown in; (Fig. G1) for Models: 2μL,10μL and 20μL,

(Fig. G2) for Models: 100μL and 200μL, and (Fig. G3) for the Model: 1000μL.

・ For Models: 2μL and 10μL, remove the plunger, 1st spring, O-ring retainer in the

correct and stated order. The O-ring and the seal ring cannot be detached.

They are press-fitted and built into the structure as an integral part of the nozzle

cylinder. Please take out only the 1st spring and the O-ring retainer.

・ For Models: 20, 100, 200 and 1000μL, remove the plunger, 1st spring, O-ring retainer,

O-ring, and the seal ring in the nozzle cylinder in the correct and stated order.

・ For Models: 5000μL: (Fig. G4) and 10000μL (Fig. G5), remove the seal spring,

O-ring retainer, O-ring and seal ring in the nozzle cylinder.

Please be careful not to lose any small parts during disassembly.

Depending on the Model, the specification of the O-ring retainer will be different.

4.3 Reassembling

1) Reassembling the nozzle cylinder

・For models: 2μL, 10μL, 20μL (Fig. G1), 100μL and 200μL (Fig. G2), 1000μL (Fig. G3)

First, attach the 1st spring onto the plunger, set the O-ring retainer, seal ring and

O-ring in order and correctly intact. Then, insert the assembly into the nozzle cylinder

and screw it clockwise into the upper body.

However, for Models: 2μL and 10μL, the O-ring and seal ring cannot be detached.

They are press-fitted and built into the structure as an integral part of the nozzle

cylinder. Please reassemble with; only the 1st spring and O-ring retainer.

・For Models: 5000μL (Fig. G4) and 10000μL (Fig. G5)

Set the volume setting below 30% of the maximum volume. (This moves the plunger

forward/out.)

Assemble together the seal ring, the O-ring and the O-ring retainer, and place the

seal spring on top (Fig. H) - (1).

Place the assembly and seal spring up on a flat surface, and insert the plunger into

the seal spring until the O-ring is fully inserted.

Take extreme caution not to deform or damage the seal ring, when inserting the

assembly into and onto the plunger (Fig. H-(2)).

Put the nozzle cylinder over the plunger with the seal spring, the seal ring, the O-ring

retainer and O-ring in order and correctly intact, and screw the nozzle cylinder

clockwise onto the lower body securely (Fig. H-(3)).

CAUTION

-13-

For Models: 1000μL, 5000μL, 10000μL, securely set the seal ring and O-ring to

the O-ring retainer. If set in an uneven and unseated state, liquid leakage will

occur.

When screwing the nozzle cylinder into/onto the main body, hold the parts

vertically as a visual reference, and slowly turn to let the threads bite together

correctly. If screwed in an offset way or with force, the O-ring will be unseated,

stripping of the threads and/or damage to the casing can occur, all of which, will

cause leakage.

When reassembling, be careful not to assemble the seal ring and O-ring in the

wrong order or direction. Failure to do so, may cause not only air and/or liquid

leakage, but also inaccuracy, failure in extracting liquid and/or contamination.

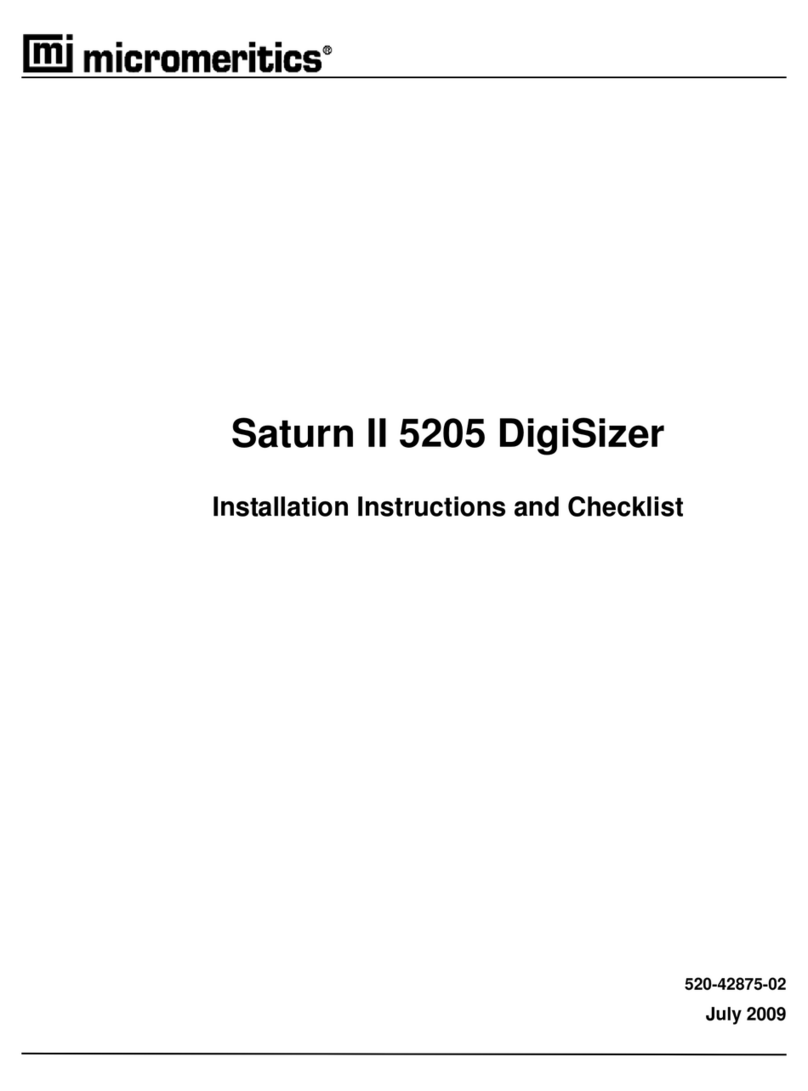

2) Fitting the ejector pipe to the main body.

・Models: 2μL, 10μL, 20μL (Fig G1), 100μL and 200μL (Fig. G2), 1000μL (Fig. G3)

Press the ejector button down with your thumb to help meet and align with the

position to secure, insert the ejector pipe onto the body and secure it with the ejector

setting screw. If resistance is felt when ejecting, jiggle the ejector pipe back and

forth very slightly, to give it better alignment, response and action (Fig. J).

After reassembling, perform several tests to inspect the pipette’s function/reliability.

Main body

①Plunger set

②1st spring

O-ring retainer

Seal ring

O-ring

Nozzle

cylinder

③Nozzle

cylinder

set

Enlargement of seal ring

To nozzle cylinder

⑦Ejector setting screw

⑥Ejector pipe

Fig. G1

-14-

Circled Numbers in (Fig.

G1

) corresponds to Parts Numbers in the

replacement parts list

.

-15-

Fig.G2

Main body

①Plunger set

Seal ring

③

Nozzle cylinder

Enlargement of seal ring

⑥Ejector pipe

⑦

Ejector setting screw

To nozzle cylinder

⑤O-ring

seal ring

set

②1st spring

Circled Numbers in (Fig.

G2

) corresponds to Parts Numbers in the

replacement parts list

.

O-ring

O

-

ring

retainer

100μL / 200μL

-16-

Main body

①Plunger set

②1st spring

O

-

ring

retainer

Seal ring

O-ring

③Nozzle cylinder

⑤O-ring

seal ring set

Enlargement of seal ring

To nozzle

cylinder

⑦Ejector setting

screw

⑥Ejector pipe

Fig. G3

⑧Nozzle filter

Circled Numbers in (Fig.

G3

) corresponds to Parts Numbers in the

replacement parts list

.

1000μL

-17-

Lower

body

O-ring

retainer

Seal ring

Main body

①Plunger set

④Seal spring

O-ring

⑤O-ring

seal ring set

To nozzle cylinder

⑦Ejector setting

screw

⑥Ejector pipe

Fig. G4

⑧Nozzle filter

③Nozzle cylinder

Enlargement of seal ring

Plunger

Circled Numbers in (Fig.

G4

) corresponds to Parts

Numbers in the

replacement parts list

.

-18-

Circled Numbers in (Fig.

G5

) corresponds to Parts Numbers in the

replacement parts list

.

Main body

①Plunger set

Seal ring

O-ring

⑤O-ring

seal ring set

Enlargement of seal ring

To nozzle cylinder

⑦Ejector setting

screw

⑥Ejector pipe

Fig. G5

③Nozzle

cylinder

⑧Nozzle filter

Lower

body

Plunger

O-ring

retainer

④Seal spring

10000

μL

-19-

O

-

ring retainer

Seal ring

O-ring

(3)(1)

(2)

Fig. H

Seal Spring

Fig.

J

Other manuals for Nichipet Premium

1

Table of contents

Other Nichiryo Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Metrohm

Metrohm 6.5330.210 manual

Amsco

Amsco Century Series Routine Maintenance

Micromeritics

Micromeritics Saturn II 5205 DigiSizer Installation Instructions and Checklist

ASEG GALLONI

ASEG GALLONI MODULAR 6 Operating and maintenance manual

ibidi

ibidi m–Slide VI 0.4 Series instructions

Philips

Philips UVCC200 80W instructions