2019.02 / j

10

Electric Power Generation Installation and maintenance

LSA 50.2

Low Voltage Alternator - 4 pole

4099 en -

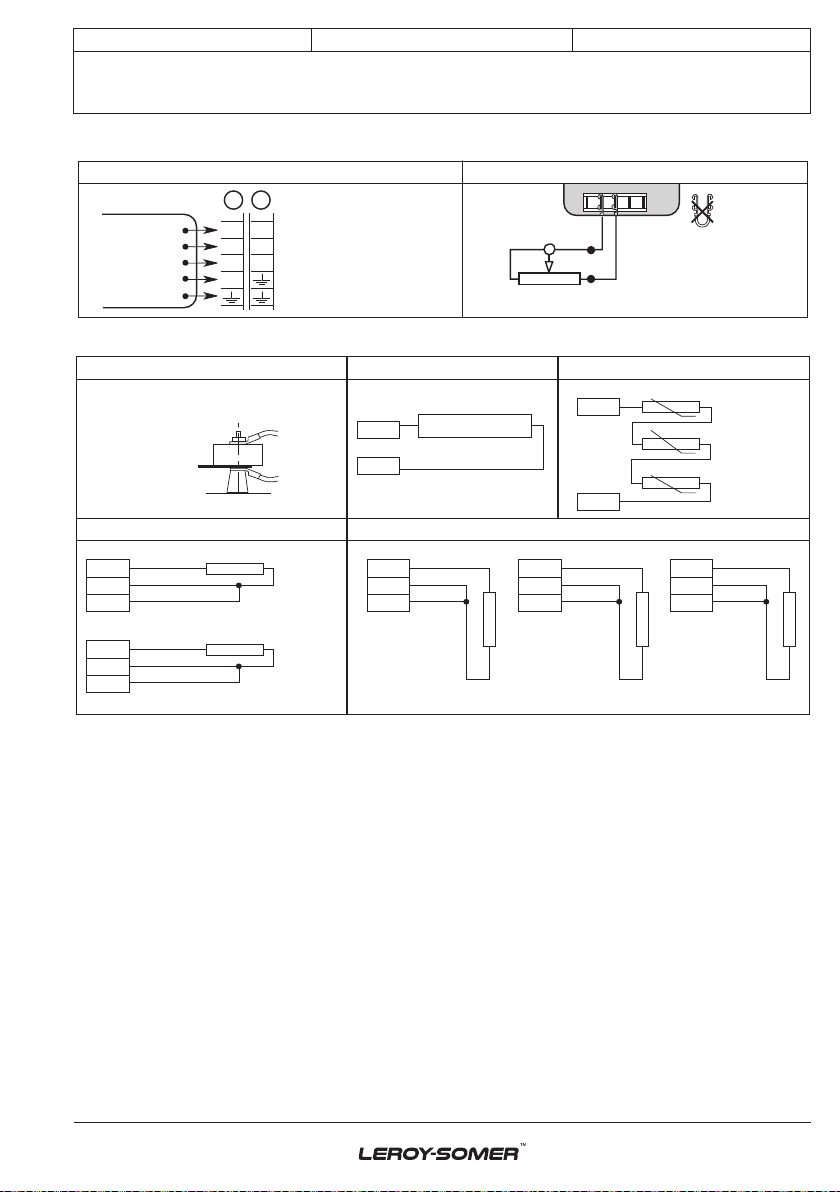

• Connection checks

Electrical installations must comply with

the current legislation in force in the

country of use.

Check that:

- The residual circuit-breaker conforms to

legislation on protection of personnel, in

force in the country of use, and has been

correctly installed on the alternator power

output as close as possible to the alternator.

(In this case, disconnect the wire of the

interference suppression module linking the

neutral).

- Any protection devices in place have not

been tripped.

- If there is an external AVR, the connections

between the alternator and the cabinet are

made in accordance with the connection

diagram.

- There is no short-circuit phase-phase or

phase-neutral between the alternator output

terminals and the generator set control

cabinet (part of the circuit not protected by

circuitbreakers or relays in the cabinet).

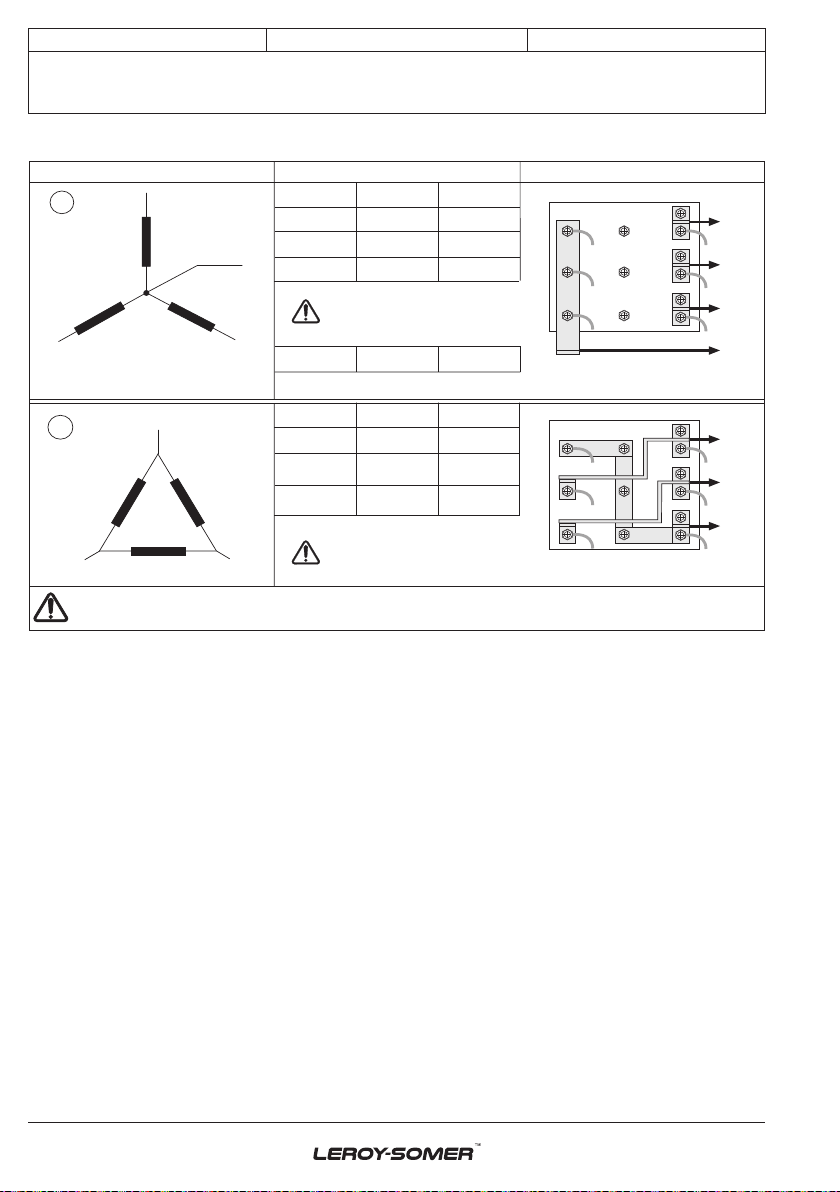

- The machine should be connected with the

busbar separating the terminals as shown in

the terminal connection diagram.

- The alternator earth terminal inside the

terminal box is connected to the electrical

earth circuit

- The earth terminal is connected to the

frame.

The connections inside the terminal box

must never be subjected to stress due to

cables connected by the user.

Diameter M6 M8 M10 M12

Torque 4 Nm 10 Nm 20 Nm 35 Nm

Tolerance ± 15%

3.4 - Commissioning

The machine can only be started up and

used if the installation is in accordance

with the regulations and instructions

dened in this manual.

The machine is tested and set up at the

factory. When rst used with no load, make

sure that the drive speed is correct and

stable (see the nameplate). With the

regreasable bearing option, we recommend

greasing the bearings at the time of

commissioning (see section 4.3).

On application of the load, the machine

should achieve its rated speed and voltage;

however, in the event of abnormal operation,

the machine setting can be altered (follow

the adjustment procedure in section 3.5). If

the machine still operates incorrectly, the

cause of the malfunction must be located

(see section 4.5).

3.5 - Setting up

The various adjustments during tests

must be made by a qualied engineer.

Ensure that the drive speed specied on

the nameplate is reached before

commencing adjustment.

After operational testing, replace all

access panels or covers.

TheAVR is used to make any adjustments

to the machine.