Nietz NZ2000 Series User manual

IW

IETZ

NII:TZ

ELECTRICCO.,LTD

•

Thank

you

very

much

for

your

buying

NZ2000

series

High-

performance Vector Control Inverter.

• Before use, please read this manual thoroughly to ensure proper

usage. Keep this manual at an easily accessible place so that can

refer anytime as necessary.

Safely

Precautions

Please read this operation manual carefully before installation,

operation, maintenance

or

inspection In this manual, the

safety

precautions were sorted

to

'WARNING" or "CAUTION".

A

wARNING

,A

cAUTION

Indicates a potentially dangerous situation which,

if

can

not

avoid will result in death

or

serious

injury.

Indicates a potentially dangerous

si'b..Jation

which,

if

can

not

avoid will

cause

minor

or

moderate

injury and damage the device.

This

Symbol is

also used forwarning any un-safaty operation.

In

some cases, even the contents

of

NCAUTION"

still can cause serious accident. Please

follow

these important precautions in any situation.

In some cases, even the contents

of

"CAUTION" still can cause

serious

accident

Please follow these important precautions

in

any

situation.

In some cases, even the contents

of

"CAUTION" still can cause

serious accident. Please follow these important precautions

in

any

situation.

*NOTE indicate the necessary operation

to

ensure the device run

properly.

Warning Marks are placed on the front cover

of

the inverter.

Please follow these indications when using the inverter.

WARNING

• May cause injury

or

electric shock.

• Please follow the instructions in the manual before installation

or

operation.

• Disconnect all power line before opening front cover

of

unit. Wait

at

least 10 minutes until DC Buscapacitors discharge.

• Use proper grounding techniques.

• NeveroonnectAC power

to

output UVWterminals.

Instruction

of

NZ2000 Series Inverter

Contents

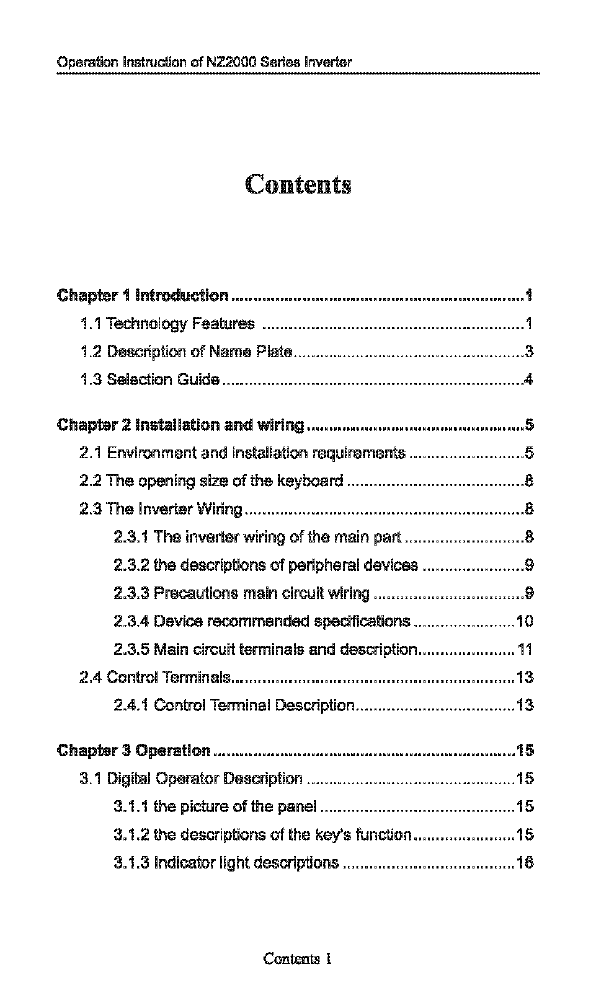

Chapter1 Introduction..........•................•......................•...............1

1.1

Technology Features ...........................................................1

1.2

Description

of

Name

Plate..................................................3

1.3 Selection Guide....................................................................4

Chapter2 lnalallation and wiring.................................................5

2.1

Environment

and

Installation requirements ..........................5

2.2 The opening size ofthe keyboard ........................................8

2.3 The InverterWiring ...............................................................8

2.3.1

The inverterwiring

of

the main part...........................8

2.3.2 the descriptions

of

peripheral devices..... ......9

2.3.3 Precautions

main

circuit wiring ..................................9

2.3.4 Device recommended specifications....... .

...

10

2.3.5

Main

circuit terminals

and

description......................

11

2.4 Control Terminals................................................................13

2.4.1

Control

Terminal

Descriptlon....................................13

Chapter3 Operation..............•................•......................•.............15

3.1

Digiml

Operator Doscliption .............................................15

3.1.1 the picture

of

the

panel

............................................15

3.1.2 the descriptions a!

the

key's function.......................15

3.1.3 Indicator light descliptlons.......................................16

Contents 1

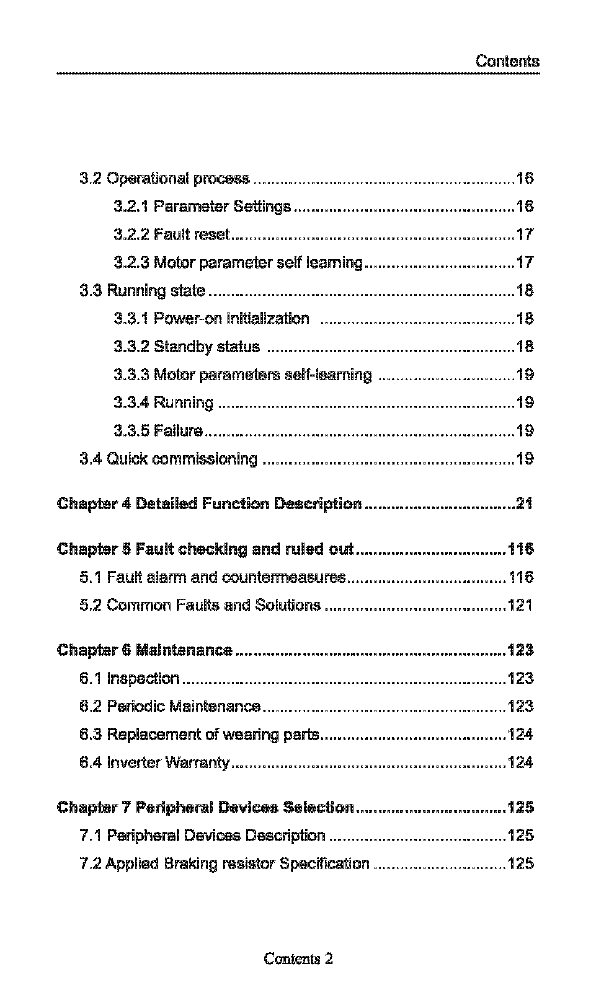

Contents

3.2

Operational process .........................................................16

3.2.1

Parameter Settings..................................................16

3.2.2 Fault reset................................................................17

3.2.3 Motor parameter self leaming..................................17

3.3

Running

slate .....................................................................18

3.3.1

Power-on initialization ............................................18

3.3.2 Standby status ........................................................18

3.3.3 Motor paramelers sell-learning ..............................19

3.3.4 Running ...................................................................19

3.3.5 Failure....................................................................19

3.4 Quick commissioning .........................................................19

Chapter4 Detailed Function Description....................•.............

21

Chapter5 Faullchocking and ruled out......................•...........116

5.1

Fault alarm

and

oounterrneasures....................................

116

5.2

Common

Faults

and

Solutions ....

,,

........

,,

.......

,,

.......

,,

121

Chapter6 lllalntonanco.........•................•......................•...........123

6.1

Inspection.........................................................................123

6.2

Periodic Maintenance.......................................................123

6.3 Replacement ofwearing par!s..........................................

124

6.4 Inverter

Wanrsnty

..............................................................

124

Chapter7 Peripheral Devices Selection..................................125

7.1

Peripheral Devices Description .....................................

,,

125

7.2

Applied Braking resistor Specification ..............................125

Contents

2

Instruction

of

NZ2000

Series

Inverter

AppendixA

list

of

Function Parametsrs................................127

Appendix B Communication Protocol..•......................•...........166

Contents

3

Chapter 1 Introduction

Chapter 1 Introduction

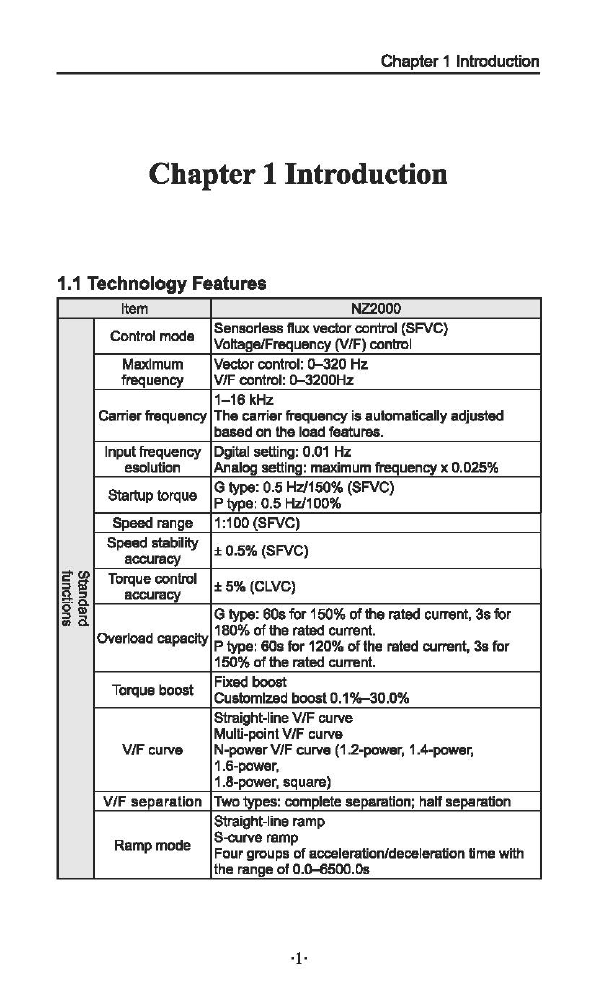

1.1 Technology Features

Item NZ2000

Control mode Sensorless

nux

vectorcontrol (SFVC}

Voltage/Frequency (V/F) control

Maximum Vectorcontrol: 0--320

Hz

frequency V/F control:

0-3200Hz

1-16kHz

Carrierfrequency

The

carrier frequency is aulomaticallyadjusted

based

on

the load features.

Inputfrequency Dgital setting: 0.01

Hz

esolution Analog setting: maximum frequencyx 0.025%

Startup lorque G type: 0.5 Hz/150% (SFVC}

P type: 0.5

Hz/1

00%

Speed range 1

:1

00(SFVC)

Speed stability ± 0.5% (SFVC}

accuracy

~~

Torque control

±5%(CLVC)

!l.:>

accuracy

~-~

G type:

60s

for

150%

oftherated current, 3s

for

Overload capacity 1

BO%

of

the

rated current.

P type: 60s

for

120%

of

the rated current,

3s

for

150% of

the

rated current.

Torque boost Fixed

boost

Cuslomlzed

boost

0.1%-30.0%

straight-lineVJF curve

Multi-point

VJF

curve

VJF curve N-power

VJF

curve (1.2-power, 1.4-power,

1.6-power,

1.8-power, square}

V/F

separation

Twotypes: complete separation; halfseparation

Straight-line ramp

Ramp

mode S-o...rve ramp

Four groupsofacceleration/deceleration time with

the range

of

0.0-6500.08

·1·

Operation Instruction

of

NZ2000 Series Inverter

Item

NZ2000

DC

braking

frequency:

0.00

Hz

to

maximum

frequency

DC

braking Braking

Ume:

O.Q-100.0s

Braking action currentvalue: 0.0%-100.0%

JOG control

JOG

frequencyrange: 0.00-50.00 Hz

JOG

acceleration/deceleration time: 0.0-6500.0s

Onboard

multiple It implements

up

to

16

speedsviathe simple

PLC

preset

speeds

function orcombination

of

Xterminal states

Onboard

PID

Itrealizes process-controlled

closed

loop

control

system

easily.

Auto voltage It

can

keep

constant outputvoltage automatically

regulation

(AVR)

when

the

mains

voltage

changes.

Overvoltagal The current

and

voltage

ara

limited

automatically

Overcurrent stall during the running process so

as

to

avoid

fnsquent

control tripping

due

to

overvoltage/overcurrent.

Torque

limit

and

It

can

limit

the

torque

autDmatically

and

prevent

frequent

control

ovar

cull'llnt

tripping

during

the

running

procass.

;:-en

The

load

feedback energycompensates the voltage

~S'

Instantaneous

g&

stop

doesn't stop reduction

so

that

the

AC

drive

can continue to run

...

! fora shorttime.

Rapid

current Ithelps to avoid frequent overcurrent faults

af

the

limit

AC

drive.

Control

of

asynchronous motor is implemented

High

performance through the high-performance current vector

control

technology.

Timing

control

Time

range:

0.0-6500.0 minutes

Communication

RS485

methods

Running

Givan

by

the

panel,

control

terminals,

command

Serial communication port,can

be

switched by

many

channel ways

10 kinds

of

frequency source,given by

Frequencysource Digital analog voltage, analog current,Pulse,

ser1al

port.

can

be

switched

by

manyways

Auxiliary 10 kinds

of

Frequencysource,can easily realize

frequency source Micro adjustment,frequencySynthesizer

6 digitalinput terminals,

one

ofwhich supports

up

to

1

00

kHz high-speed

pulse

input.

S' Input terminals 2 analog input terminal,

one

af

which only supports

Js

Q-10

Vvoltage inputand the othersupports

Q-10

V

voltage input or

4-20

mA

current input

.,

Ill

1digital output terminal

_,

0.

Outputterminal 1relay output terminal

1analog output terminal :that supports

Q-20

mA

current output or

Q-10

vvoltage output

·2·

Chapter 1 Introduction

Item NZ2000

LED

display Itdisplaysthe parameters.

ii

Key locking and Itcan lock

the

keys partially

or

completely

end

define

the

function range

of

somekeys

so

as

to

iii iii

function selection prevent mis..function.

""8'

g:::J

Motor

short-circuit detection

at

power-on, output

~~

Protection

mode

phase loss protecUon. over-current protection,

over-voltage protection,

under

voltageprotection,

overheatprotection

and

overload protection.

Installation Indoor, avoid

direct

sunlight, dust, corrosive gas,

location combustible gas, oil smoke, vapour, drip

or

salt.

m Altitude

Lower

than 1000m (Lower the grades

when

using

~-

higher

then 1

OOOm)

a

Ambient

-1

o·c

-<IO"C

(lower

lhe

grades iflheambient

:I

temperature temperatura Is

~

40"C

and

&rC)

3

Cl>

Humidity

Less

than 95%RH, withoutcondensing

::1.

Vibration

Lass

than

5.9

mls

2 (0.6

g)

Storage

-20"c-60"C

temperature

1.2 Description

of

Name

Plate

MODEL:

NZ2400-3R7G/5RSP-o

INPUT:

3PH

380V

50Hz/60Hz

OUTPUT:

3PH

380V

9.0113.0

FREQ

RANGE:

0.1-320Hz

3.7/S.SkW

ri

ii

Ulmllill[IJ[)

]]

JI CE

(14011311111)

MODE:

NZ-

2 -

400

-3R7G/5R5P- o

~

T specific symbol

L____=

(Blank fur normal product)

3R7:

3.7KW

G: Constanttorque

P: Variable torque

'--------

200: 1PH

AC220V

400:

3PH

AC380V

600:

3PH

AC660V

L....--------

2:

NZ2000 series inverter

8:

NZBOOO

series inverter

.__

__________

NZ: Trade

Mark

·3·

Operation Instruction

of

NZ2000 Series Inverter

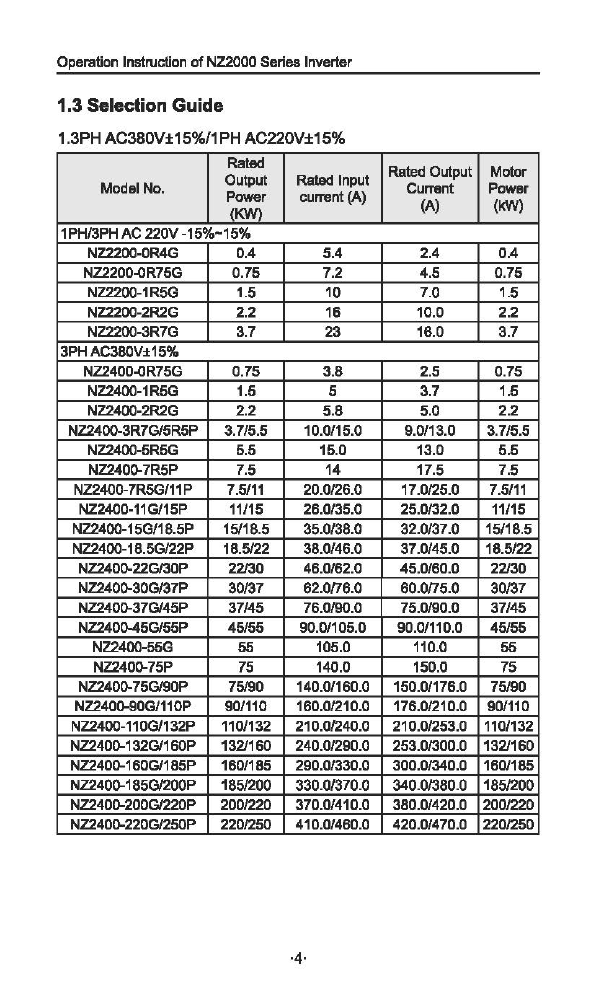

1.3 Selection Guide

1.3PHAC380V±15%/1PHAC220V±15%

Rated

Rated Output Motor

Model No. Output

Rated

Input

CuiTIIn

t

POWIIr

Power current

(A)

(A) (kW)

(KW)

1PH/3PH

AC

220V -15%-15%

NZ2200-0R4G

0.4

5.4

2.4

OA

NZ2200.()R75G 0.75

7.2

4.5 0.75

NZ2200-1R5G 1.5

10

7.0 1.5

NZ2200-2R2G 2.2

16

10.0

2.2

NZ2200-3R7G

3.7

23 16.0

3.7

3PH

AC380V±15%

NZ2400.()R75G 0.75 3.8 2.5 0.75

NZ2400-1R5G 1.5 5 3.7 1.5

NZ2400-2R2G 2.2 5.8 5.0

2.2

NZ2400-3R7G/5R5P 3.7/5.5 10.0/15.0 9.0/13.0 3.7/5.5

NZ2400-5R5G

5.5

15.0 13.0

5.5

NZ240Q-7R5P

7.5

14

17.5

7.5

NZ2400-7R5G/11

P

7.5111

20.0126.0

17.0125.0

7.5111

NZ2400-11G/15P

11/15

26.0135.0

25.0132.0

11/15

NZ2400-15G/18.5P

15118.5

35.0/38.0

32.0137.0

15118.5

NZ2400-18.5G/22P

18.5122

38.0/46.0 37.0/45.0

18.5122

NZ240Q-22GI30P

22130

46.0162.0

45.0/60.0

22130

NZ240Q-30G137P

30137

62.0/76.0 60.0/75.0

30137

NZ240Q-37G/45P

37/45

76.0190.0

75.0190.0

37/45

NZ240Q-45G/55P

45155

90.0/105.0 90.0/110.0

45155

NZ2400-55G 55 105.0

110.0

55

NZ240Q-75P

75

140.0

150.0

75

NZ240Q-75G/90P

75190

140.0/160.0 150.0/176.0

75190

NZ240Q-90GJ110P

901110

160.01210.0

176.0121

0.0 90/110

NZ2400-110GI132P

110/132

210.01240.0

21

0.01253.0

110/132

NZ240Q-132G/160P

132/160

240.01290.0

253.01300.0

132/160

NZ240Q-160G/185P

160/185 290.0/330.0

300.01340.0

160/185

NZ240Q-185G/200P

1851200

330.0/370.0

340.01380.0

1851200

NZ240Q-200G/220P

2001220

370.0/410.0 380.0/420.0

2001220

NZ240Q-220G/250P

2201250

410.0/460.0 420.0/470.0

2201250

·4·

Installation and

Chapter

2 Installation

and

wiring

2.1

Environmentand Installation requirements

Inverter's installation environment on the service life

of

inverter, and

has direct influence on the normal function, Inverter can't satisfy the

specification

of

environment , protection

or

fault could lead

to

the

Inverter.

NZ2000 series inverter

of

wall hung inverter, please use the vertical

installation so that the air convection and the heat dissipation effect

can

be

better.

Inverter's installation environment, please make sure must comply

with

(01) - 1O'C to +

40'C

ambient temperature

(02) Environment humidity 0 - 95% and no condensation

(03) Avoid direct sunlight

(04) Environment does not contain corrosive gasand liquid

(05) Environment without dust, floating fiber, cotton and metal

particles

(06) Away from the radioactive material and fuel

(07)

Away

from

electromagnetic

interference

source

(such

as

electric welding machine, big power machine)

(08) Installed planar solid, no vibration,

if

it cannot avoid vibration,

please add antivibration pads

to

reduce the vibration

(09) Please install the inverter in the well ventilated place,

easy

to

check

and maintain, and install on the solid non-combustible

material,

away

from

the

heating

element

(such

as

braking

resistance, etc.)

(10) Inverter installation please reserve enough space, especially

many inverters' installation, please pay attention

to

the placement

of

the frequency Inverter, and configure cooling fans, make the

environment temperature lowerthan 45"C.

(11) Inverter can output the rated power when installed with altitude

of

lower than 1

OOOm.

It will be derated when the altitude is higher

Operation Inalruction

of

NZ2000

SaliBI

Inverter

than 1000m.

(1

)singleInverterInstallation

Morc1boD

SOmm

I-

(2)Mullipleinvertersinstalled in

one

control cabinet.

Please

pay

attetion:

J

CDwhen

encasing

tile

multiple inverters,install tham

in

paralled

as

a

cooling measure.

®If

multiple Inverters

are

Installed In

one

control cablnet,please

leaveenoughclearances andtakecooling measure.

·6·

Chapter2 Installation

and

wiring

j

/

theInverter's outside shape

and

theInstallation dimensions

(1)0.4-22kW

w

D I"

(2)30-160kW

~g\,

==

I

=F!

D

==

~~

§~

g~

o=

g>~

o=

[§]g~

o=

0~--~-

I I 1

D

·7·

Operation Instruction

of

NZ2000Series Inverter

(3}185--220kW

w D

x m

E2.

Model Outline dlmenslon(mm) lnslalation size(mm)

w H

H1

D A B

8d

NZ2200-0R4G-

72 142 -152 62.7 132.7 5

NZ2200-1R5G

NZ2200-2R2G-

100 183 -

143

90 173 5

NZ2200-3R7G

NZ2200-5R5G-

130 260 -184 120 250 5

NZ2200-7R5G

NZ2400-0R4G-

72 142 -152 62.7 132.7 5

NZ2400-2R2G

NZ2400-3R7G/5R5P- 100 183 -

143

90 173 5

NZ2400-5R5G

NZ2400-7R5P-

130 260 -184 120 250 5

NZ2400-11G/15P

NZ2400-15G/16.5P-- 195 280 -

179

162.5 266 7

NZ2400-22G/30P

NZ2400-30G/37P- 245 390

425

193

180 410 7

NZ2400-37G/45P

NZ2400-45G/55P- 300 500 540 252 200 522 9

NZ2400-55G/75P

NZ2400-75G/90P 338 546 576 256.5 270 560 9

NZ2400-90G/110P- 338 550

580

300 270 584 9

NZ2400-110P/132P

NZ2400-132G/160P- 400 675 715 310 320 695

11

NZ2400-160G/185P

NZ2400-132G/160PZ- 400 871.5 915 310 320 895

11

NZ2400-160G/185PZ A1: 240

A2: 150

NZ2400-185G/200P- 300 1035 1080 500

E1:220

NZ2400-220G/250P

E2:450

W:13

·8·

Chapter2Installation

and

wiring

2.2Theopening

size

of

the

keyboard

68.5mmlC39mm

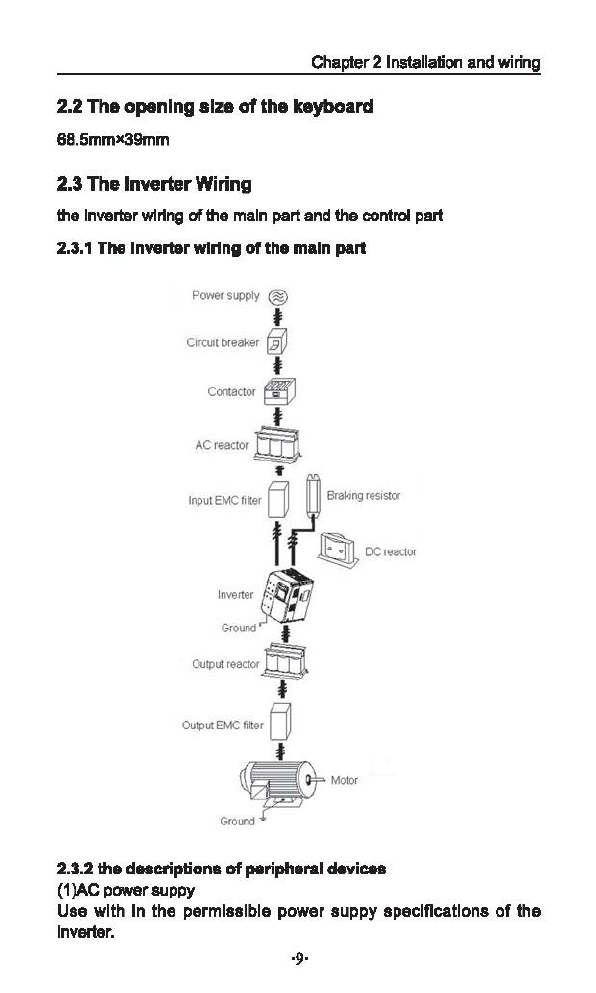

2.3TheInverterWiring

the Inverter

wlrfng

af

the

main

part

and

thecontrol part

2.3.1

The Inverterwiring

of

themain part

Powersupply ®

t

C~rcuot

br

eaker

~

t

Co.-.actor

~

t

ACreactor@

"

lnpu

l

EMC

file<

B

~

Braking

resostor

f(Q

0C••~LV

1

'=

f!P

Output

reactor

m

•

Mo

tor

2.3.2thedaacriptiona

of

paripbaraldaviC88

(1)AC powersuppy

Use with In the permissible power suppy speciOcatlons

of

the

In

verier.

Instruction

of

NZ2000 Series Inverter

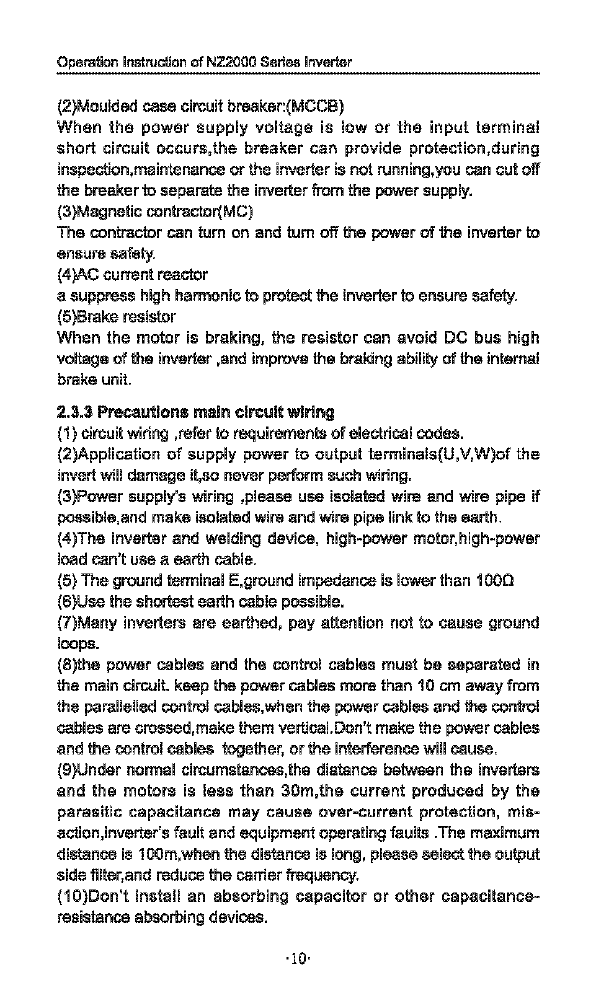

(2)Moulded case circuit broaker:(MCCB)

When

the

power

supply

voltage

is

low

or

the

input

terminal

short

circuit

occurs,the

breaker

can

provide

protection,during

inspection,maintenance

or

the inverter is

not

running,you can cut

off

the breakerto separate the inverterfrom the power supply.

(3)Magnetic contractor{MC)

The contractor can tum on and tum offthe power

of

the inverter

to

ensure safety.

(4)AC current reactor

a suppress high harmonicto protect the inverter to ensure safety.

(5)Brake resistor

When

the

motor

is braking, the resistor can avoid DC

bus

high

voltage

of

the inverter ,and improve the braking ability

of

the internal

brake

unit

2.3.3 Precautions main

circuit

wiring

(1) circuit wiring ,refer to requirements

of

electrical codes.

(2)Application

of

supply

power

to

output

terminals(U,V,W)of

the

invert will damage it,so never perform such wiring.

(3)Power supply's wiring ,please use isolated wire and wire pipe

if

possible,and make isolated wire and wire pipe link to the earth.

(4)The inverter and welding device, high-power motor,high-power

load can't use a earth cable.

(5) The ground terminal E,ground impedance is lower than

1000

(6)Use

the

shortest earth cable possible.

(?)Many inverters are earthed, pay attention

not

to cause ground

loops.

(8)the power cables and the control cables

must

be separated

in

the main circuit. keep the power cables more than 10

em

awayfrom

the

paral!elled control cables,

when

the power cables

and

1he

control

cables are crossed,make them verticai.Don't make the power cables

and the control cables together,

or

the interference will cause.

(9}Under nonnal circumstances,the diatance between the inverters

and

the

motors

is

less

than

30m,the

current

produced

by

the

parasitic

capacitance

may

cause

over-current

protection,

mis-

action,inverter's fault and equipment operating faults .The maximum

distance is 100m,when the distance is long, please selectthe output

side filter,and reduce the carrierfrequency.

(10)Don't

install

an

absorbing

capacitor

or

other

capacitance-

resistance absorbing devices.

Chapter2 Installation and wiring

(11}Ensure

the

terminals

are

all

locked

tightly,the

cables

are

connected well with the terminals,present the looseness due

to

an

action

of

shaking,causesparks and the shortcircuit

To

minimize the interference,it is recommended that the contactor

and relayshould be connected

to

the surge absorber.

• Noisefilter installed at the input side

of

inverter;

• Install noise isolation for other equipment

by

means

of

isolation

transformer

or

powerfilter.

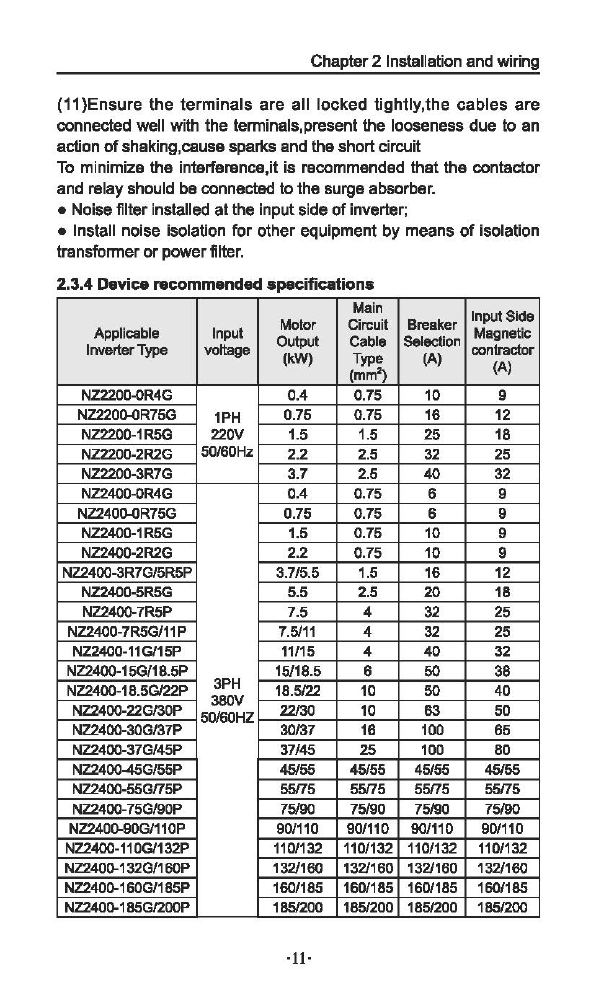

2.3.4 Deviceracommandad specifications

Main

Input Side

Motor Circuit Breaker

Applicable Input Output Cable Selection

Magne

tic

Inverter

Type

voltage (kW) Type (A) contractor

(mm")

{A)

NZ2200-0R4G 0.4 0.75

10

9

NZ220().()R75G

1PH

0.75 0.75

16

12

NZ2200-1R5G 220V 1.5 1.5 25 18

NZ2200-2R2G 50/60Hz 2.2 2.5

32

25

NZ2200-3R7G 3.7 2.5

40

32

NZ2400-0R4G 0.4 0.75 6 9

NZ240().()R75G

0.75 0.75 6 9

NZ2400-1R5G 1.5 0.75

10

9

NZ2400-2R2G 2.2 0.75

10

9

NZ2400-3R7G/5R5P 3.7/5.5 1.5

16

12

NZ2400-5R5G 5.5 2.5 20 18

NZ240Q-7R5P

7.5 4

32

25

NZ2400-7R5G/11P

7.5111

4

32

25

NZ2400-11G/15P

11/15

4 40

32

NZ2400-15G/18.5P

15118.5

6 50

38

NZ2400-18.5G/22P

3PH

18.5122

10

50

40

NZ2400-22GI30P 380V

22130

10

63

50

50/60HZ

NZ2400-30GI37P

30137

16

100

65

NZ2400-37G/45P 37/45

25

100

80

NZ2400-45G/55P

45155

45155

45155 45155

NZ2400-55G/75P

55175

55175

55175 55175

NZ2400-75GI90P

75190 75190

75190 75190

NZ240()..90GJ110P

901110

901110

901110

901110

NZ2400-11

OG/132P

1101132

1101132

110/132 110/132

NZ240Q-132G/160P

1321160

132/160 132/160

1321160

NZ240Q-160G/185P

160/185

1601185

1601185

160/185

NZ240Q-185GI200P

1851200 1851200

1851200

1851200

·11·

Operation Instruction

of

NZ2000 Series Inverter

Main

Input Side

Motor Circuit Breaker

Applicable Input Output Cable Selection

Magne

tic

Inverter

Type

voltage

(kW)

Type (A) contractor

(mm2) (A)

NZ2400-200GI220P

3PH

2001220

2001220

2001220

2001220

NZ2400-220G/250P 380V 220/250

2201250

2201250

220/250

50/60HZ

"The

above data are

for

reference only.

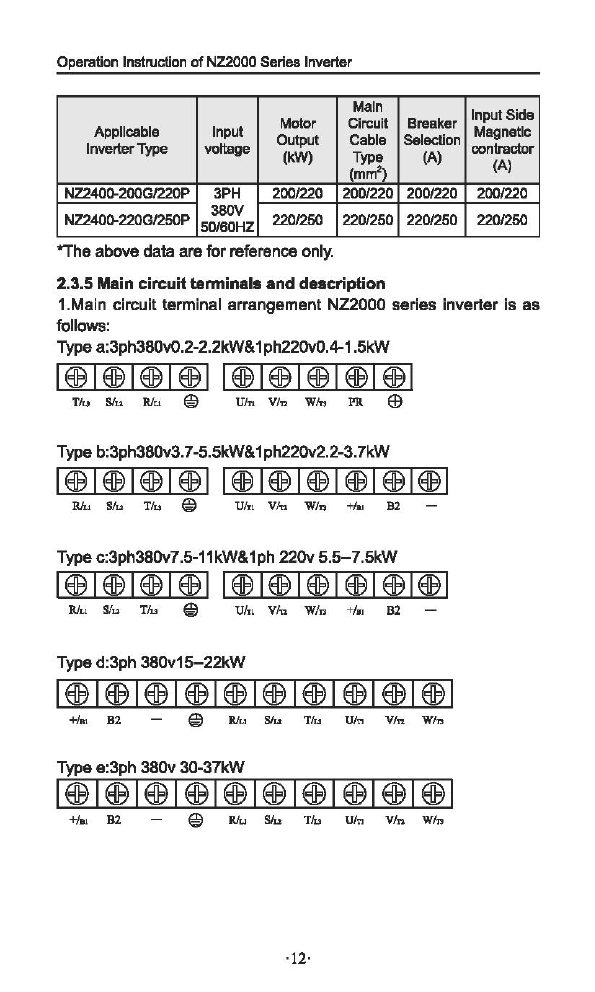

2.3.5 Main circuitterminals anddescription

1.Main circuit terminal arrangement

NZ2000

series

inverter

is

as

follows:

Typea:3ph380V0.2-2.2kW&1ph220V0.4-1 .5kW

1®1®1®1®11®1®1®1®1®1

Tiu

stu

Rlu @ Uin Vi.,

Wm

PR

ffi

Type b:3ph380v3.7-5.5kW&1ph220v2.2-3.

7kW

1®1®1®1®1

1®1®1®1®1®1®1

Rlu

SJu

Tlu

@

UIT1

Vm

Win

+/o1

B2

Typec:3ph380v7.5-11kW&1ph

220v

5.5-7.5kW

1®1®1®1®1

1®1®1®1®1®1®1

Rlu

S/u

Tlu @

U/T,

Vln

W/n +/.,

82

-

Typed:3ph

380v15-22kW

+J.,

82

@ Rlu

stu

Tlu

Uin

Vln

Win

Typee:3ph

380v

30-37kW

e Rlu Sfu

T/u

Uin

V/n

Win

·12·

Chapter

2 Installation

and

wiring

Typef:3ph

380v

45-75kW

1@1@1@1@1@1@1@1@1@1@1

R S

Te-+!.nB2U

VW

POWER MOTOR

Type

g:3ph

380v

90-110kW

R S T -

~

B2 U V W

POWER

M01UR

eo

Type h:3ph

380v

132-160kW

1@1@1@1@1@1

R S T

~

B2

POWER

-+1..82

u v w

M01UR

2.Description

of

main circuit terminals

Terminal Name

D~

lon

RIL

1,

S/l..2, T/L3 Connect to the commercial powersupply.

U/T1, U/T2,

UIT3

Inverteroutputterminals, connect a three-phase

motor.

+/B1, -Positive and negative

DC

inverter, brakeunit can

beconnected.

+/61,

B2

Connectbrake resistor.

+,

PR

@ Earth (ground)

3.Wiring Example

+/s1

B2

~

Rlu

Slu

Th,

U/n Vfn W/,

1~1~1!1'.!J~Ej'

1

1ml

·13·

Instruction

of

NZ2000 Series Inverter

4.The basicwiring diagram

Braking

resistor

{optional)

;---c::J---;

! !

>---<

RILl

+/Ill B1 u

owertmpply

:::

S/L2 v

w

T/L3 QlE

RA

r

RB

RC

Forwud/Ston -

''

FWD

"""""""""

' '

·----------~S:

Exccpti.onlllevcne ; '

REV

'

M-ulti-speed

eornn:wad

1o

Sl

Iligb-spced

puJ_::e

fugut

: S2 !

1Q:Q]

o n :MCM

S3 : V Fov I

Multi-speed

cciinn:iiuid

3i

iVhllll&'lli!ld!.1llre!l!:

S4

l-~-~-----l

FOV

' ' (0-10V/0-20mA}

Input signal

oomiiWU.'

'

GND

j_

E@

GND

-

~Q

"

Frequ.ency setting

JXlWer

!.

2 f

~

+lOV

lOmA(MAX)

RS-

I L

____

\_J

__

FIV{O-lOV)

FIC(0-10V/0-20m.A) RS-

GND

··--j_

!1rnO-J;----:

GND

!VFICI

!

i

Vbltap~wmmt

i

:.c.umt~-----~

2.4 Control Terminals

Control terminal arrangement

M)

""""

'"l,

Relay output

-

VDC/3A

250VAC/30

Multi-function

-

48VIX:f

SOmA

~Analog

<mtput

~

: tennlllill

' '

' '

...:....:--

j_

,-,

~

++Terminal

' '

Cmnnnmicetion

7-

Please Ulle shielded cable

1®1®1®1®1®1®1®1®1®1®1®1®1®1~®1®1

FWD

REV

Sl

S2

83

S4

lOV

FIV

FIC

GND

FOV

MCM

MOl

@.'D

RS-

RS1

1®1®1®1

RA

RB RC

This manual suits for next models

30

Table of contents