Niezgodka 21 User manual

Niezgodka GmbH www.niezgodka.de

Relief-Valve, springloaded

for steam, gases and liquids in closed completion

GB

Typ 21

Typ 21-E

04 / 2014

G 3/4 - G 1

Technical documentation

Englisch

Niezgodka GmbH www.niezgodka.de

Armaturen

Niezgodka GmbH

Bargkoppelweg 73

22145 Hamburg

Germany

copyright © 2014 by Niezgodka GmbH Germany

+49 (0) 40 679 469-0

Armaturen

Niezgodka GmbH www.niezgodka.de

Relief-Valve, springloaded

for steam, gases and liquids in closed completion

GB

Typ 21

IN 21-E

04 / 2014

Technical Data

Discharge capacities

Datasheet position

Datasheet

Approvals, certificates

Declaration of conformity

Terms of delivery and sale

General Terms and Conditions of Sale and Delivery

Headquarters and missions abroad

General Take-back conditions

Assembly, care and maintenance

Storage, transport and commissioning

Mounting Instructions

Contents

Maintenance Instructions

Troubleshooting operating problems

Niezgodka GmbH www.niezgodka.de

GB

General Take-back conditions 2

RB

04 / 2014

Attention!

Niezgodka GmbH reserves the right to decide on taking back its products on a process-related and situation-dependent basis.

Basically, only such products will be taken back, as remain unused and are not older than two years (date of delivery).

The costs of the assembly services rendered as well as expenses incurred in connection with the take-back will be deducted.

Custom-made products will basically, not be taken back.

In cases of custom-made products, order cancellations after the start of production shall not be free-of-charge. Production

expenses that have already been incurred shall be invoiced on the basis of the status of production.

Spare parts and wearing parts shall be excluded from these conditions and will generally not be taken back irrespective of the

condition they are in.

Niezgodka GmbH www.niezgodka.de

t

d

S

A

E

Hl

d

o

SW

A

S

E

¾

100

100

80 4,2

100

65 60 18 2901

600

1100

250

600

19

0,08

0,08

0,08

0,08

32 16 14

1 39 18 18

50

8

6

12,5

8

0,05

0,05

0,05

0,05

275

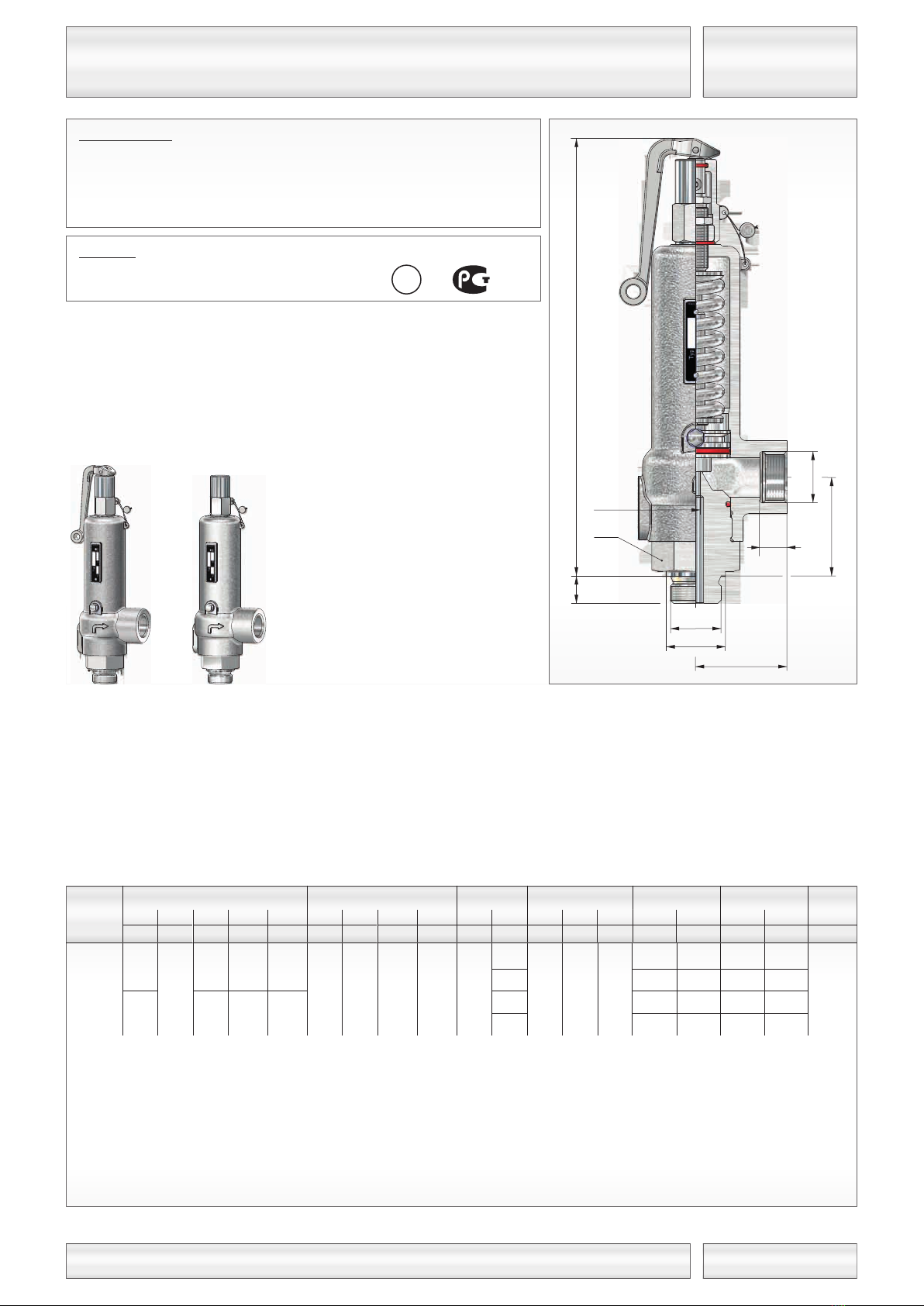

Relief-Valve, springloaded

for steam, gases and liquids in closed completion

GB

Typ 21

K 21-E

04 / 2014

Inlet Outlet Set pressure Weight

E SE

[mm]

p min.

[bar(g)]

p max.

[bar(g)] ~ [kg]

Height ´H´

for

head

A

[mm]

[mm]

d

[mm]

l (G)

[mm]

l (NPT)

[mm]

SA

[mm] [mm]

At (G) t (NPT)

Dimensions

[mm][mm]

doSW

C

[mm]

Coefficient

D/G

α

w max.

F

α

w

Size

other design on request

Connections:

Screwed connection: DIN ISO 228 / ASME B1.20.1

Typ 21.2:

soft seated

see techn. appendix: KWD-1

-60°C to 280°C

head Chead A

1.4571 / 1.4581

PED

S

P

Standard version:

Material:

Temperature ranges

metal seated

Inlet body / Spring bonnet

Pressure Equipment Directive: 97/23/EG

Declaration of Conformity

Approvals:

Niezgodka GmbH www.niezgodka.de

100

120

140

160

180

200

230

260

290

320

360

400

440

480

520

560

600

650

700

750

800

850

900

950

1000

754

826

896

954

1011

1066

1143

1216

1284

1349

1431

1508

1582

1652

1719

1784

1847

1922

1995

2065

2133

2198

2262

2324

2384

569

690

815

952

1100

1261

767

925

1086

1250

1415

1583

1840

862

972

1085

1241

1403

1571

1745

1927

2117

2316

3273

3585

3873

4156

4341

4629

4964

2161

2283

2398

2543

2681

2812

2937

3057

3172

3284

131

159

187

219

253

290

176

213

250

288

326

365

424

484

547

610

698

789

883

982

1084

1191

1302

1450

1607

1775

1956

2152

2366

2601

2862

1100 2501 3486

p

e [bar(g)]

0,08

α

w max.

α

w

0,05 0,08

α

w max.

α

w

0,05

6 8

0,08

α

w max.

α

w

0,05

12,5

Relief-Valve, springloaded

for steam, gases and liquids in closed completion

GB

Typ 21

V 21-E-1

04 / 2014

Water

20°C

[kg/h]

3

n

Air

0°C

[m /h]

Steam

[kg/h]

Water

20°C

[kg/h]

3

n

Air

0°C

[m /h]

Steam

[kg/h]

Water

20°C

[kg/h]

3

n

Air

0°C

[m /h]

Steam

[kg/h]

Size

d

o [mm]

Fluid

Coefficient of

discharge

Discharge capacities

Niezgodka GmbH www.niezgodka.de

005*

001

121

132

122

131*

133

125

081

082

097

130*

080

030

086

085

100*

089

101*

060*

084

112

092

057

059*

056

120

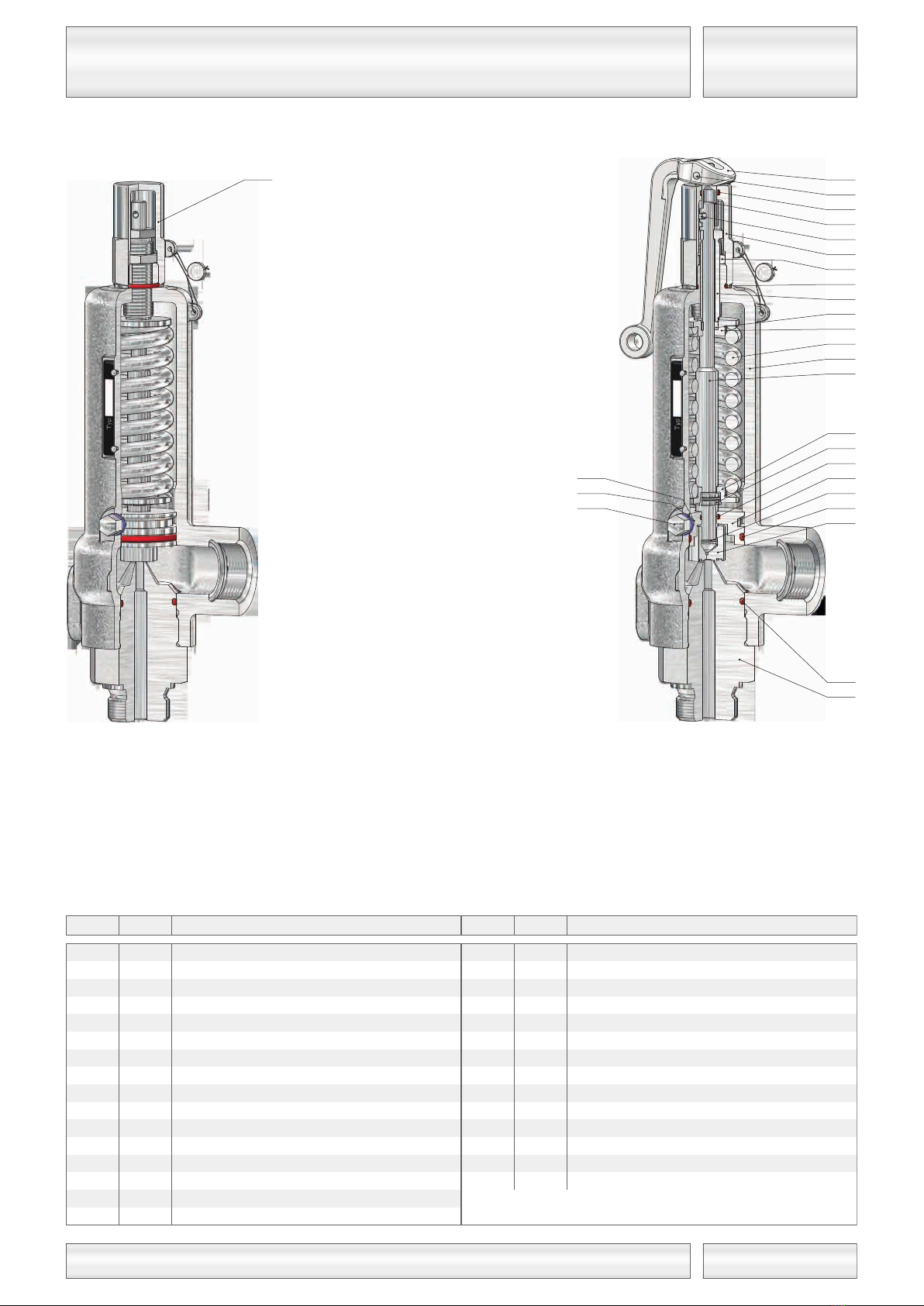

Relief-Valve, springloaded

for steam, gases and liquids in closed completion

GB

Typ 21

M 21-E

04 / 2014

001

030

060 *

080

085

inlet body

spring bonnet

disc, complete

spindle

adjusting screw

005 * o-ring

132 groove pin1

122 coupling

084 springplate, lower 133 groove pin

121 lifting cap

1

1

1

1

* expendable parts

1

1

056 lock nut2

057 screwed pin2

059 * o-ring2

1

560 disc

1

062 soft sealing

1

063 disc ring

1

1

1

086 lock nut1

1

1

082 springplate, upper1

081 spring1

125 lifting lever

130 * o-ring1

131 * o-ring1

Item DescriptionPiece Item DescriptionPiece

head Ahead C

120 cap1

112 split ring1

097 glide ring1

100 * o-ring1

101 * o-ring1

092 lock ring1

089 guide plate1

Niezgodka GmbH www.niezgodka.de

≥ 0,5%

GB

Manual Instructions

for safety and relief valves

15

EB_SV/EV

04 / 2014

Safety- / Relief-Valves are instruments of high quality and should be handled with care. The disc (060) and the seat (001 / 003) are

manufactured out of hardened or tempered steel and are grinded and lapped to give positive sealing. If the valve disc and seat were handled

improper or faulty they will get defect.

Function:

When the pressure before the Safety- / Relief-Valves reaches the set pressure, the valve commences to lift, i.e. open a little at first to discharge

a small amount of medium. If the pressure continues to rise, it will open further and more medium is discharged. At a max. pressure increase of

10% (5%), the stroke required for the mass flow to be discharged is reached. When the pressure drops to 10% (gases / vapours and gases) or

20% (incompressible medium / liquids) below the set pressure, the valve closes and no fluid escapes anymore.

Maintenance:

Safety- / Relief-Valves are designed regarding design and construction in such a way that an optimum of quality is achieved, and that they are

easy to service. A minimum of care and maintenance is the result when our fittings are applied. The maintenance work, however, is permitted to

be carried out only by trained personnel.

We suggest the following:

In and outlets are provided with protective caps. These are to be removed before the installation. The valves may not be thrown

(leakage/failure in operation may result).

The whole system has to be rinsed before installation of the valve! If the plant should not be sufficiently purified or in the case of an

inappropriate assembly, the valve may be leaky already upon first response. The assembly of the threaded valves should be

carried through without using hemp or PTFE-tape. Metal sealing rings are to be preferred.

The Safety- / Relief-Valves have to be fitted vertically with the spindle (080) in an upright position. For a perfect function in the long

run it is also necessary to install the valve without tension into the plant.

In order to prevent the misuse of the lifting lever (head "A") it is binding wire in the closed position. If the mounting is correct and the

pressure is arrived at 85% of the adjusted set pressure the lifting device can be set in motion. The same is valid for lifting heads "B",

"D" and "E": To check the head type "C", the valve should be exposed to response pressure only externally by gas or with a

sufficiently purified plant.

For the valves (particularly) used in steam applies:

Routining the functioning by operating the ventilation at least every 4 weeks.

Foreign substances in the pipeline (such as jointing materials) will seriously damage the seating area of the valve. By operating the

lifting device small deposits of foreign matters can be effectively cleared from the valve disc (060) and seat (001 / 003).

(In doing this, a clear stroke of the valve spindle (080) must be achieved).

The feed nozzle for the valve must be as short as possible and must have at least the same nominal width as the valve.

The pressure loss in the inlet pipe should not exceed 3 % of the set pressure.

The blow-off pipe should be mounted with downward gradient in sufficient dimensioning. Resulting condensate must be exhausted

safely. Inside the blow-off pipe the backpressure of max. 10 % of the set pressure should not be exceeded.

The operating pressure of the plant should be at least 5% below the closing pressure of the valve (pressure peaks in case of piston

pumps must be taken into consideration!). Thus a perfect closing of the valve after blow-off is ensured.

binding wire

protective caps

filling line emptying line

Niezgodka GmbH www.niezgodka.de

GB

Storage, transport and commissioning

15

LTI

04 / 2014

General:

Observe the following storage instructions:

Environment:

Temperatures:

Transportation:

Commissioning:

Delayed initial opening caused by so-called sticking (adhesion) effect of the seating (001 / 003) and disc (060) is quite normal after

transportation and longer storage of valves with a preset response pressure. This applies both to metal/elastomers sealing faces and highly

polished metal/metal faces.

When the valve has been fitted the sealing faces are separated by pressurisation higher than the actual response pressure and by operating the

venting lever.

The valve, together with the preset pressure response, is now fully functional, taking the permissible pressure increase/closing pressure into

consideration.

Attention!

• The regional safety regulations are to be observed.

• The material, pressure, temperature and flow direction specifications must be checked prior to commissioning.

• The valve data are to be checked for position (arrangement) in the system.

• Residues in pipelines and valves (welding beads, grinding dust, dirt etc.) lead to leakage or damage.

• Touching the valve can give rise to the risk of injury when it is operated at high medium temperatures of (>50°C)

or low temperatures of (>0°C).

• Remove the blocking screw (149), which may have been used, from the cap (120).

• Remove protective caps and lever fixtures prior to commissioning.

• Sticking, freezing or blockage of the valve is to be avoided without fail.

• When a blow-out pipe is not used, the medium can suddenly escape from the valve outlet aperture. Hazard!

• Large amounts of flow noise can be heard when blowing out.

Care is to be taken to ensure prior to putting a new system into operation or restarting a system that has been subject to repair or

conversion that:

• All work is completed in an orderly manner!

• The valve is in the correct function position.

• Safety devices are in place.

NI-Valves are high quality products which must be treated with care. The sealing faces on the seating (001 / 003) and disc

(060) are hardened, annealed, ground and lapped. Improper handling can cause them to be damaged, resulting in leakage

and inoperability. They must therefore be protected against shocks (throwing, impacting, hitting etc.). On valves equipped with

a venting lever etc., the lever must not be misused as a carrying handle. All valves are to be properly secured to prevent them

falling over or falling down in the course of transportation, fitting and maintenance.

Places of storage must be clean and dry.

NI-Valves should be stored at temperatures between 5°C to 35°C, the best being 10°C to 20°C. The instructions for disc

sealing must be complied with in the case of soft sealing valves.

Only use suitable packing materials for transportation. Inlet and outlet apertures are to be protected for transportation purposes

by caps or plugs which are only to be removed shortly prior to assembly.

Niezgodka GmbH www.niezgodka.de

GB

Instructions for maintenance

for safety and relief valves

15

WA_SV/EV

04 / 2014

Maintenance:

NI-Safety- / Relief Valves are designed regarding design and construction in such a way that an optimum of quality is achieved, and that they are

easy to service. A minimum of care and maintenance is the result when our fittings are applied.

For the replacement of spare-parts it is also recommended to have this work executed only in an authorized workshop. If no suitable repair

means are available it is best to return the complete safety valve to the plant of Niezgodka GmbH. All spare-parts supplied by us are suitable for

the installation into our safety- / relief valves without restriction. It is, however, necessary to state in the order the number of the delivery

note/invoices or the commission number since the safety- / relief valves supplied are adjusted to their particular application.

Test intervals:

The minimum test intervals for safety- / relief valves especially activated by steam are four weeks. Test intervals for other applications must be

determined by the user in compliance with the operation conditions. Tests and examinations are to be executed at least during each internal or

external examination of the pertaining pressure device.

Regular releasing:

The release device of safety- / relief valves must be actuated regularly in order to examine the function and to remove soiling, if any.

This is possible manually in the case of valves with valve head “A”, “B”, “E”, “M” and “H” at a pressure rate ≥ 85% of the set pressure.

Valves with head “C” (gas tight with cap) should be brought to the release pressure only externally with gas or at a 100% clean device.

Leaks:

Leaks may be caused in the case of safety- / relief valves due to soiling between seat (001 / 003) and disc (060) or through damage of the

sealing surfaces that were caused on account of soiling in the medium or by the medium itself. Soiling can be removed by causing the safety- /

relief valves through releasing to blow off. If it fails to remove the soiling in this way, it must be assumed that the sealing surfaces are damaged.

The damage can be removed by post-processing (lapping). The work involved should be carried out only in the plant of the manufacturer or by a

workshop authorized by the manufacturer. Leaks may also occur when the operating pressure is too close to the reaction pressure. In such a

case, the design of the safety- / relief valves is to be examined.

Corrosion protection:

NI-Safety- / Relief Valves that are not corrosion protected are provided with a protective paint cover in the plant of the manufacturer. In a moist

environment it may become necessary to apply later additional corrosion protection layers. In this case it must be seen to it that the function of

movable components (e.g. spindle (080) and disc (060)) is not affected. Heads with manual release, the blowing off space and freely blowing off

safety- / relief valves should not be painted later. For heavily corrosive conditions, safety- / relief valves made of special steel should be used.

For fürther information, see our website

Attention!

Care must be taken to ensure that the system is depressurised prior to assembly, dismantling or opening of the safety/relief valve.

The remaining dimensions and seal properties, preloading forces, tightening torques etc. are to be determined by the user

themselves in accordance with the operating instructions. In doing so special attention must be paid to the following:

Medium residues in the safety/relief valve or in the spring cap represent a serious chemical burning, burns and poisoning hazard.

It must, therefore, be established prior to removing a valve from the plant which medium could be present in the safety/relief valve.

Appropriate safety measures must be taken.

Niezgodka GmbH www.niezgodka.de

GB

Troubleshooting operating problems

for safety and relief valves

15

FB_SV/EV

04 / 2014

Use a heating jacket!

Fault RemedyPossible cause

Remove flange and threaded protection

caps

Icing incurred when blowing out

Either replace or readjust safety /

relief valve

The setting pressure is too high / too low

Regular brief venting or heating /cooling of

the safety / relief valve

Viscous / sticky / hardening medium

Replace safety / relief valvebellow designe (161) faulty, no longer

compensates counter pressure

Remove spindle blocking screw (149)

Safety / relief valve doesn’t respond

It must be possible to briefly vent the

safety/relief valve over ≥ 85% of response

pressure

Pressure below ≤ 85% of response

pressure

Can’t be vented

The operating pressure must be

≤ 90% of response pressure

The operating pressure is

≥ 90% of response pressure

Brief venting of safety / relief valve,

replace if necessary

Contamination between seating (001 / 003)

and disc (060)

Safety / relief valve seating leaky

Risk of caustic burning, burning and / or

poisoning

Use smaller safety / relief valveover-dimensioned safety / relief valve

Use larger valveSafety / relief valve too small

Injuries caused by fluid residues

Flutter

Opening pressure too high

Spindle blocking screw (149) not removed

Flange and threaded protection caps have

not been removed

Establish which fluid is in the safety /

relief valve before it is dismantled

Niezgodka GmbH www.niezgodka.de

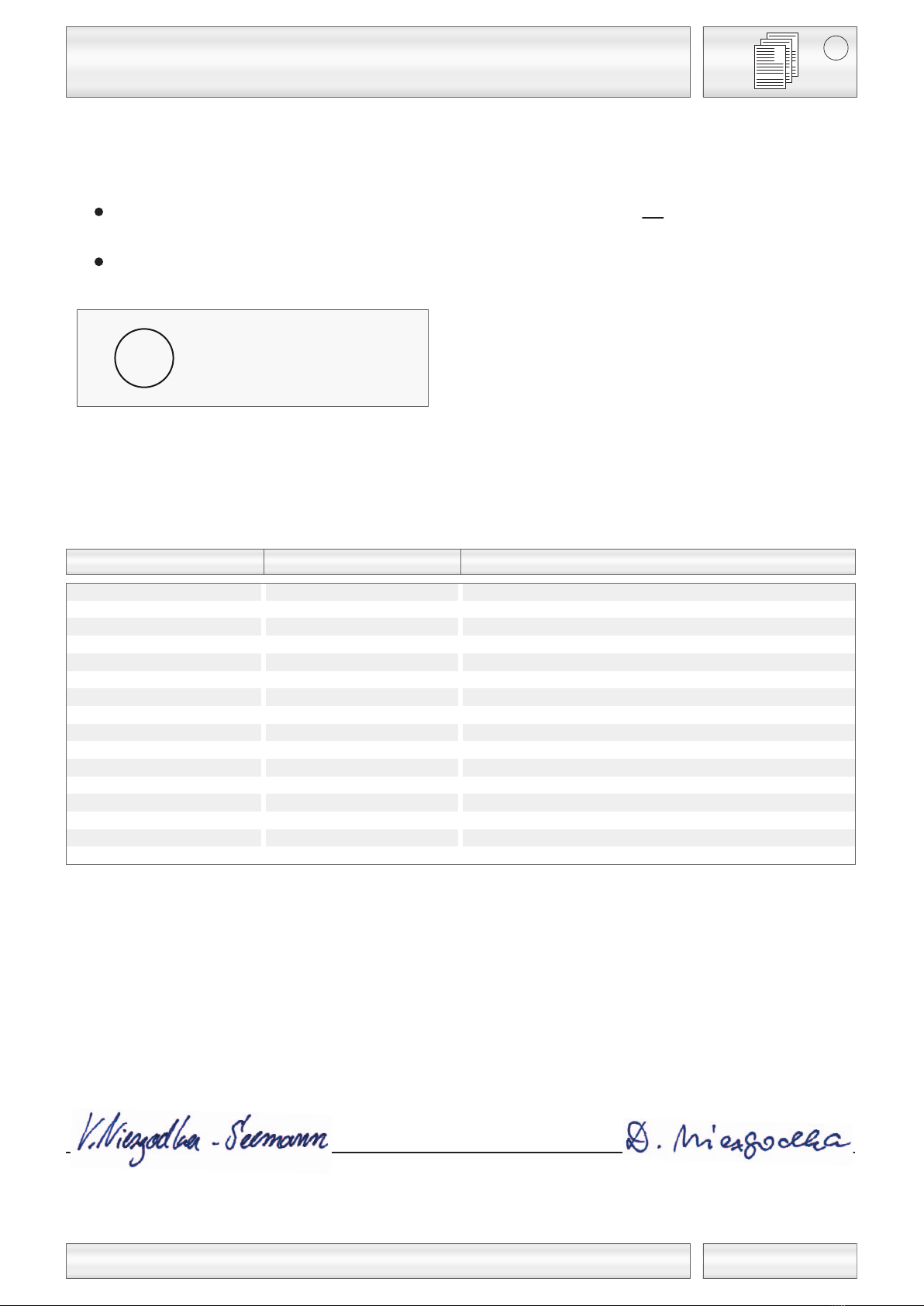

GB

1

Declaration of Conformity

according to Annex VII of Directive (PED) 97/23/EC

KON-3

04 / 2014

1

3

4

5

11

13

14

18

21, 22

24

33

35

9

91

90

SE-ÜR-91

DN 50

DN 25

DN 15

DN 10

DN 50

DN 25

DN 20

DN 50

DN 25

DN 25

DN 25

DN 50

DN 50

DN 50

DN 25

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

DN 10

DN 15

DN 8

DN 8

DN 10

DN 15

DN 10

DN 10

DN 20

DN 15

DN 15

DN 15

DN 25

DN 15

DN 15

DN 15

ManufacturerHamburg, 02.03.2014 authorized subscriber

The signing manufacturer confirms by this declaration that design, manufacturing and inspection of these pressure equipments

are in compliance with the directive 97/23/EC as well as with the national specifications DIN EN 12266, DIN EN 12516,

AD 2000-leaflet A4 match:

The below pressure equipments are falling under Article 3, Paragraph 3, and it is not allowed to provide them with

CE-marking which is spezified in annex VI.

To document the conformity with the directive 97/23/EC directly at the pressure equipment, it will provide with the

following sign.

Type Nominal Size Inlet Pressure accessory

Management: Dorrit Niezgodka, Verena Niezgodka-Seemann

Registered at the District Court Hamburg, HRB No. 29139

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Relief-Valve

Vacuum-Relief-Valve

Vacuum-Relief-Valve

Vacuum- and Pressure-Relief-Valve

Overflow-Control-Valve

PED: Pressure Equipment Directive

SEP: Sound Engineering Practice

PED

S

P

Niezgodka GmbH

Bargkoppelweg 73

DE-22145 Hamburg

Niezgodka GmbH www.niezgodka.de

GB

General Terms and Conditions of Sale and Delivery

2

AVL

04 / 2014

1. General

The following terms and conditions are part of any

agreement for supply.

Any deviations from these conditions will be effective

only if we have granted our prior written consent.

Conflicting or interfering purchase terms and

conditions of the Purchaser shall be invalid even if we

do not explicitly contradict to the conflicts or

interference.

The unconditional acceptance of the goods does not

invalidate the exclusive validity of these terms and

conditions.

Should any individual provision be void, illegal or

unenforceable, the validity of the remaining

provisions hereof shall in no way be affected.

2. Quotations / Orders

Our quotations are subject to confirmation regarding

price, quantity, delivery deadline and availability for

delivery.

Orders as well as verbal agreements shall become

binding for us only by our written confirmation.

Catalogue pictures and illustrations in quotations are

not binding in as far as a modification of design,

measurements and weights is subject to change

without notice.

3. Price and Payment

The prices shall be effective ex factory Hamburg,

without packaging material, unless agreed on

otherwise.

Payments must be made by money transfer. The

terms of payments listed in the order

acknowledgement or invoice resp. shall be in effect.

In case of delayed payments, we are entitled to

charge interest of delay.

4. Delivery Period

The delivery period results from the agreements

reached by the parties of the contract.

Meeting the deadline by the supplier requires that all

commercial and technical matters have been settled

first and the buying customer has met all his

obligations. Failing that, the delivery time will be

prolonged appropriately.

Meeting the deadline of the delivery period is

warranted under the reservation of our being

supplied correctly and in time.

Claims cannot be made against us in case we fail to

meet a delivery deadline.

5. Passage of Risk

The risks will pass on to the Purchaser at the latest

with the dispatch or collection of the goods to be

delivered, even a case of partial deliveries.

We will conclude a transportation insurance policy

only if the Purchaser has given explicit written order

to do so.

Partial deliveries are permissible.

6. Retention of Title to Ownership

The right of ownership in the item supplied will

remain with the Supplier pending receipt of all

payments resulting from the delivery contract.

The Purchaser assigns already now the claims

resulting from this transaction to the Seller if the

item supplied is resold prior to our receipt of

payment (extended retention of title to

ownership).

Behavior contrary to the contract, especially in

case of default of payment, entitles us to take

back the items supplied, after having sent a

reminder, and the Purchaser is obliged to

surrender the items.

The assertion of the retention of title to

ownership as well as the attachment of the items

supplied by us shall not mean the rescission of

contract by us.

Filing insolvency application on the part of the

Purchaser entitles us to withdraw from the

contract and request the immediate return of the

items supplied.

7. Warranty

Starting with the date of delivery, the statutory

warranty period is applicaple for our products.

Wearing parts are excluded from this provision.

The products are subject to a density test as well

as a final test after their assembly and pressure

adjustment. All tests are performed pursuant to

standard by means of air or water resp., on

examined and calibrated test stations / test

devices.

Test documents of the individual acceptance

tests / material tests will be kept in the archives

for a minimum period of ten years.

8. Liability

Notices of obvious defects must be given in

writing immediately after their detection, at the

latest, however, within eight (8) days after

receipt of the item supplied.

Other defects subject to liabilty must be reported

immediately after detection in writing.

If we decline to accept a claim for a warranty, the

claim made by the Purchaser is regarded as

waived unless contradicted within one month in

writing.

Accepted defects will be repaired without charge

in our Hamburg works or replaced by new items

without charge. The parts subject to complaint

have to be returned to us without charge.

We will bear the direct costs of repair or of the

replacement parts; in case the complaint is

justified, we will bear the costs of the

replacement part.

Delivery of new goods is effected on principle

subject to thorough examination of the defect

and its result with reference to the part

complained about. The Purchaser has to

reimburse the costs of examination if the claim

proves to be unjustified.

We are not liable for consequential damage as a

result of slight negligence unless a warranted

property has not been supplied.

In addition, no warranty is accepted in the following

cases: unsuited or improper use, wrong assembly or

putting into operation by the Purchaser or a third

party, normal wear, incorrect or negligent treatment,

improper maintenance or unsuitable operating

equipment.

We are not liable for consequences of unprofessional

repairs by the Purchaser or a third party. The same

applies to modifications of the items supplied without

our prior consent.

Assembly instructions are aimed at the know-how of

qualified personnel. Only skilled personnel should,

consequently, perform the assembly work.

9. Returns

Goods supplied are allowed to be returned only after

our prior written consent. Return shipping must be

made by prepaid freight.

In case of contract cancellation or returns of the

goods for reasons the Purchaser is liable for, the

Purchaser will be charged with the necessary costs

incurred relating to the return as well as the

dismantling performed.

Custom-made items as well as spare parts can, on

principle, not be taken back.

10. Statutory Limitation

All claims of the Purchaser, for whatever legal

reasons, are limited to 12 months.

11. Documentation

Any documentation included in the supply is not

allowed to be altered. Manufacturer marking on

products is not allowed to be removed. Further use

by a third party is only permitted with our expressed

consent.

12. Place of Jurisdiction

Place of performance for delivery and payment and

place of jurisdiction for both contract parties is

Hamburg.

Management: Dorrit Niezgodka, Verena Niezgodka-Seemann

Registered at the District Court Hamburg, HRB Nr. 29139

Niezgodka GmbH www.niezgodka.de

GB

Headquarters and missions abroad 1

FA

09 / 2014

Bickel & Wolf Bratislava, s.r.o.

Jarošova 1

SK - 83103 Bratislava

+421 249 204 730-9

www.bickelwolf.sk

Bickel & Wolf spol. s.r.o.

Náměstĺ 5. května 25

CZ - 25225 Jinočany

+420 257 320 278

www.bickelwolf.cz

Niezgodka GmbH

Bargkoppelweg 73

DE - 22145 Hamburg

+49 40 679 469-0

www.niezgodka.de

Armstrong - Kobilšek D.O.O.

Cankarjeva ulica 21

SI - 1234 Mengeš

+386 172 300 38

www.armstrong-kobilsek.si

+44 1482 210484

@ sales@flowstar.co.uk

www.flowstar.co.uk

Flowstar (U.K) Ltd.

Unit 1 / Gillet Street

Kingston-upon-Hull

GB - HU3 4JA

Perlwitz Armaturen GmbH

Dannenkamp 18

DE - 22869 Schenefeld

+49 40 853 153-0

www.perlwitz.de

Gustaf Fagerberg AB

PO-Box 12105

SE - 40241 Göteborg

+46 31 693 700

www.fagerberg.se

Lukrida UAB

Kovo 11 - osios g. 126

LT - 49380 Kaunas

+370 37 302 800

www.lukrida.lt

OY Konwell AB

Ruosilantie 10

FI - 00390 Helsinki

+358 9 894 6480

www.konwell.fi

+7 4724 831 458

www.ekoms.ru

Evropa Komplekt Servis GmbH

Belgorod Gebiet

Rzhevskoje Chaussee 1

RU - 309290 Schebekino

Fût-Ker Kft.

Csorvási út 18

HU - 5900 Orosháza

+36 68 410 639

@ info@fut-ker.hu

www.fut-ker.hu

Phone / E-Mail / WebsiteAddressCountry

Phone / E-Mail / WebsiteRepresentativesCountry

Germany

United Kingdom Ireland

Slovakia

Czech Republic

Slovenia

Sweden

Lithuania

Finland Estonia Latvia

Indonesia Malaysia Singapore

Norway

Russia CIS-States

Hungary

Table of contents

Other Niezgodka Control Unit manuals

Popular Control Unit manuals by other brands

Burkert

Burkert 6126 operating instructions

Yoshitake

Yoshitake DP-100 Series product manual

Nice

Nice WM100 Instructions and warnings for installation and use

Schako

Schako EasyBus EasyS-MV2 Installation, operating and maintenance

Vixen

Vixen Polar Fine Adjustment Unit DX instruction manual

Rutenbeck

Rutenbeck R-Control Plus Extension 4 installation instructions

PRASTEL

PRASTEL UNIK1E Technical Manual for the Installer

Russound

Russound TPM-1 instruction manual

LongSung Technology

LongSung Technology U6100 user manual

FrSky

FrSky R9M Lite Pro instruction manual

Allen-Bradley

Allen-Bradley ControlLogix 1756-ENBT user manual

Outform

Outform OF2021 Wi-fi connection guide