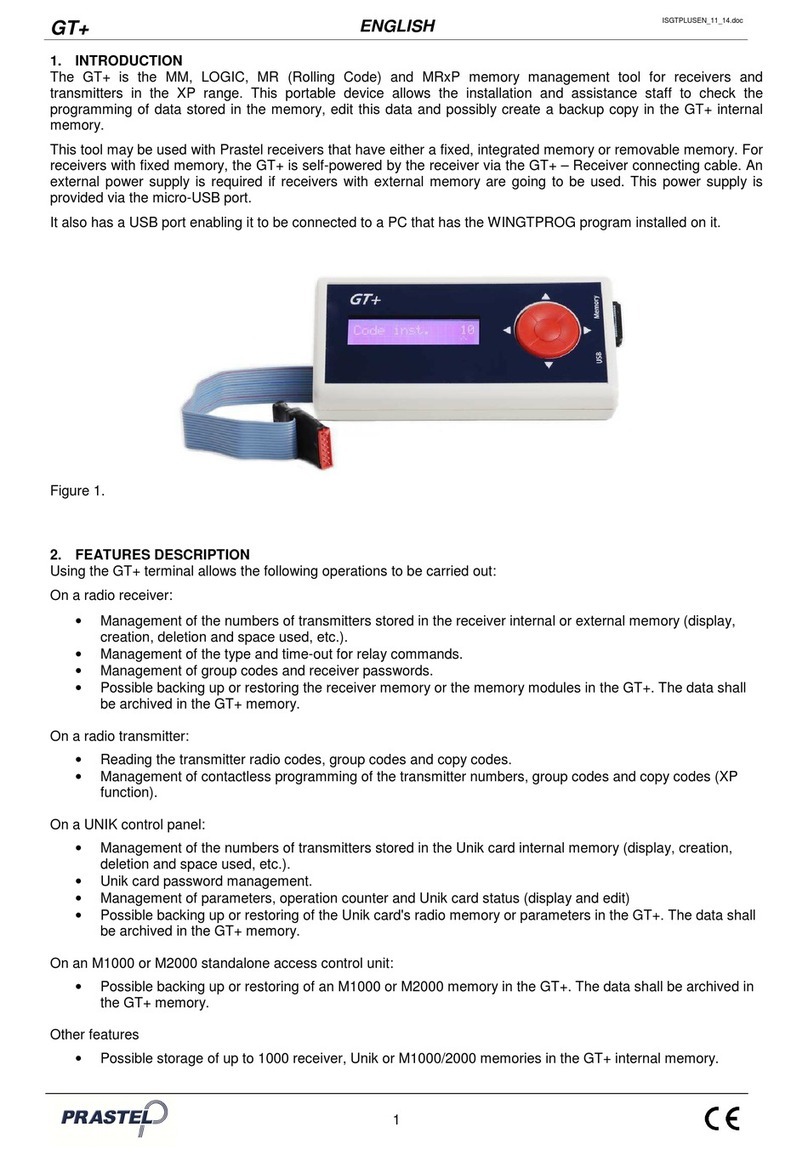

PRASTEL UNIK1E User manual

Technical Manual for the Installer

Attention!! Before installing, carefully read this manual.

N.B.

- Stateurop declines every responsib

ility in case of not observance of the normative in force in

the Country where the installation is made

The CE mark conforms to the European directive R&TTE 99/05CE

UNIK1E

CONTROL UNIT FOR ONE MOTOR

12VDC

ENGLISH

2

SUMMARY

Title Description Page

1•INTRODUCTION 3

2•MAIN FEATURES 3

3•TECHNICAL SPECIFICATIONS 3

4•CONNECTING AND TURNING ON THE CONTROL UNIT 4

5•EASY LEARNING PROCEDURE 5

6•PROFESSIONAL LEARNING ROUTINE 7

7•RADIOTRANSMITTERS PROGRAMMING AND ERASING 8

8•SAFETIES AND OPERATING LOGIC 9

9•CONTROL UNIT OPERATION 9

•Turning ON 9

•Automatic operation 9

•Step-by-step operation 9

•Pedestrian opening 9

•Obstacle detection 10

•Flashing warning light 10

•Quick closing after photocell triggering 10

•Slow down 10

•Emergency battery 10

10 •PROGRAMMING BY GTSYSTEM 10

11 •TROUBLESHOOTING 11

•SAFETY WARNINGS 12

ENGLISH

3

1. INTRODUCTION

UNIK1E is a universal self-learning control unit especially designed for the automatic control of 12VDC, 1 motor

driven accesses. Its innovative self-learning procedure makes for quick and easy installation and its three

trimmers permit fine adjustment of all main parameters, namely force, pause time and obstacle detection

sensitivity.

Are available :

-a quick self-learning routine thanks to which the unit automatically performs a learning operation to acquire

running times and determine slow down setting at ninety percent of opening and closing runs;

-a professional routine thanks to which the installer performs slow down triggering, remote pedestrian

opening, photocell-triggered instant reverse or reverse upon release.

2. MAIN FEATURES

•Management and control of 12/24VDC powered

•Quick and professional self-learning routines for acquisition of running and slow down times and of the

presence of safeties

•50-100% force adjustment via trimmer

•Motor speed adjustment

•0 to 60”stand-by time adjustment via trimmer

•0.1 to 3.0”obstacle detection triggering time adjustment via trimmer

•Customisable partial opening (for pedestrian transit)

•12V 15W electric lock expansion (optional ELU)

•Courtesy light expansion (optional LCU)

•Setting up for 12V 1.2Ah battery operation for optional emergency running

•Incorporated 433MHz rolling-code receiver

•40 remote code storage capacity

•Reprogrammable on-board Flash microprocessor via serial interface

•Control unit programming via GTSYSTEM

•Built to European reference Directive Standards (R&TTE 99/05/CE)

3. TECHNICAL SPECIFICATIONS

Control Unit power: 230 VAC

Motor output: 12VDC 80Watt (24VDC with optional transformer TRT12-24V100VA)

Motor Current: Max 10 Ampere

Accessories power: 12 VDC - 150 mA

Operating temperature: -20°C / + 55 °C

Programmable parameters:in EE-PROM

Functions manager: microprocessor with watchdog

ENGLISH

4

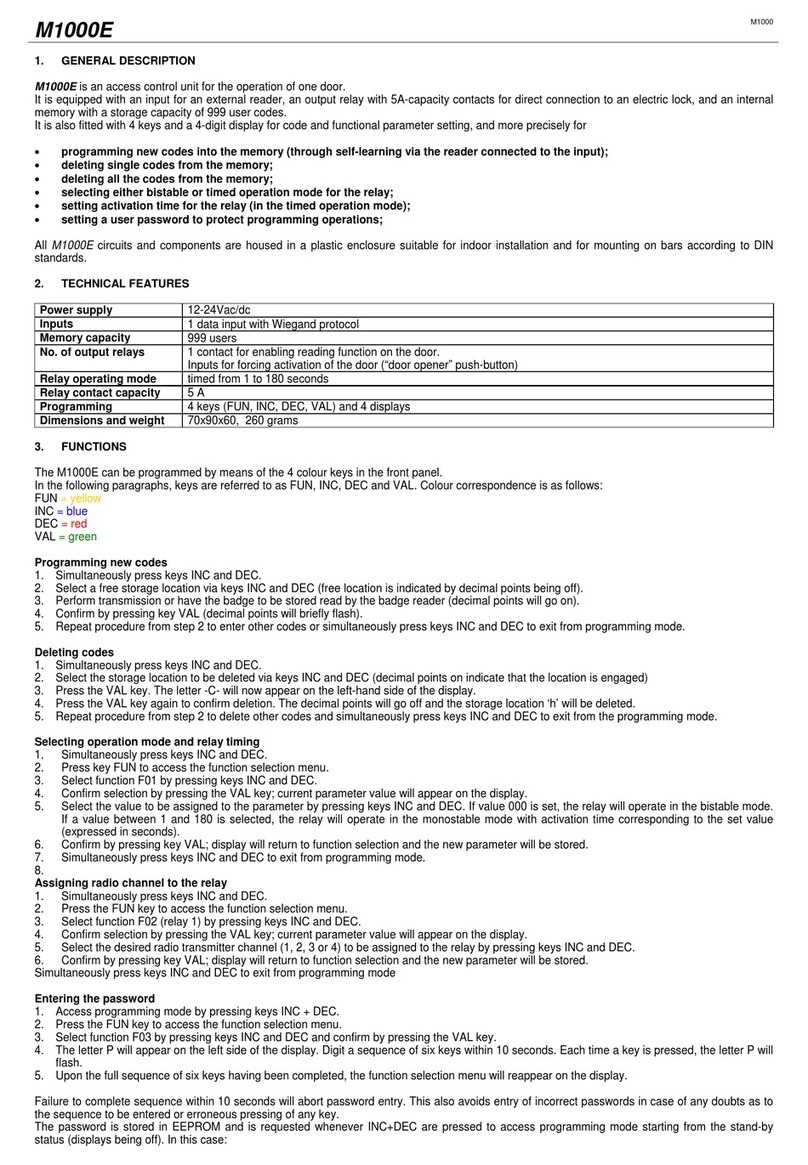

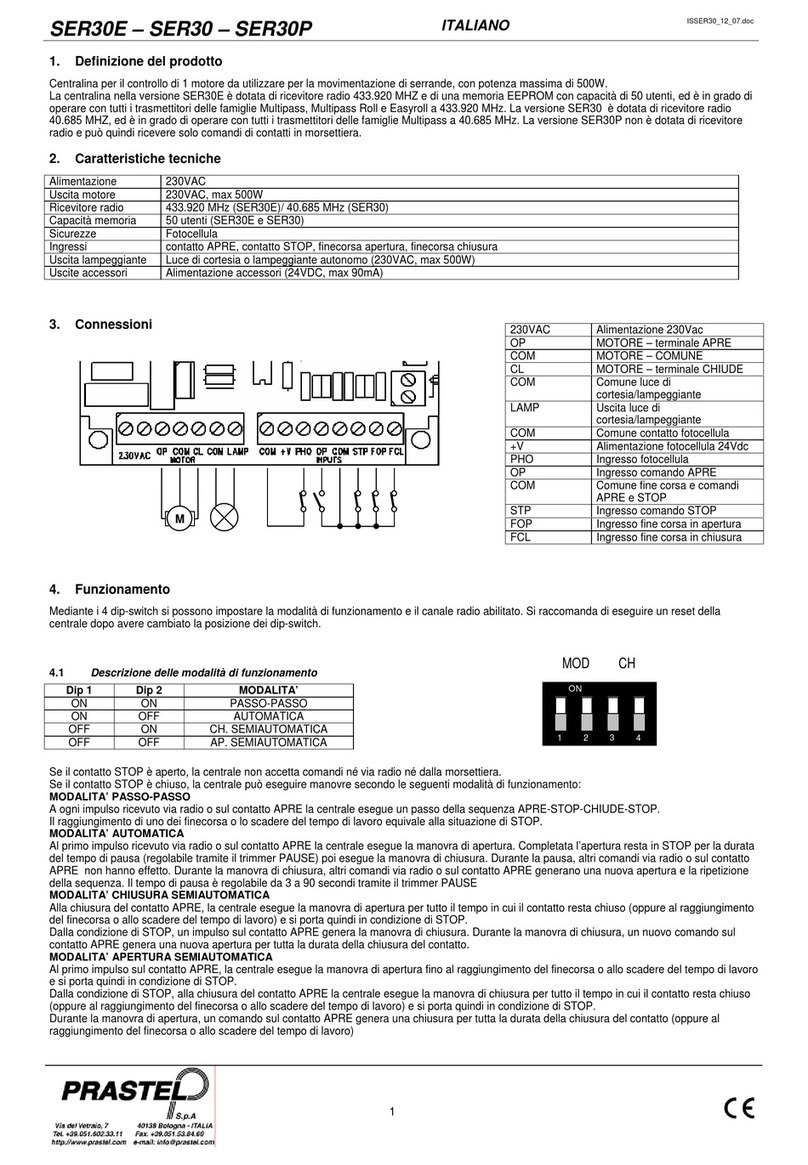

4. CONNECTING AND TURNING ON THE CONTROL UNIT

•Before installing the UNIK1E control unit carefully read “General Safety Precautions”.

•Secure the box in place through the appropriate mounting holes.

•Make sure the power line is fitted with an appropriate disconnector / isolating switch as required by

prevailing reference Provisions and Standards.

•Fit on the fairleads provided and route the cable making sure to keep power lines separate from control

ones.

•Connect power and control lines according to the diagram and instructions given below.

•Make sure that all terminal board inputs are correctly connected and operative.

GTSYSTEM

ELU Electro-lock

expansion

Radio Antenna

P1/SET learning key

10A battery fuse

Battery

Motor

Controls

Photocell

Radio channel

selector

Force Trimmer

Obstacle

Sensitivity

Trimmer

P2/RADIO learning key

Transformer

Secondary

Safeties test

selector

ENGLISH

5

ELECTRICAL CONNECTIONS

Note :

Depending on the voltage with which it is powered (12 or 24VAC), the control unit sets up to operate with 12 or 24

VDC motor. The UNIK1E control unit is supplied with a toroidal transformer with 12VAC secondary. The toroidal

transformer with 24VAC secondary is available on request (Prastel code TRT12-24V100VA).

If no programming is carried out, the control unit is set as follows:

•step-by-step mode with automatic closing cut out

•no slow down

•safeties enabled in closing mode

•no safeties in opening mode

•5 seconds opening for pedestrian access

•60% motor force

•1 second obstacle detection triggering

5. EASY LEARNING PROCEDURE

Once the control unit has been set up as described above, turn it off and then back on again or press the

P1/SET key on the card. Within five seconds of the control unit starting up again, as indicated by the yellow SET

LED flashing, keep the P1/ SET key pressed for one second to access “EASY LEARNING”.

The yellow SET LED stops flashing and stays on fixed to signal that “EASY LEARNING”mode has been

successfully accessed.

The easy learning routine automatically sets the following functions:

a) halfway opening for the pedestrian opening;

b) disabling of remote pedestrian opening.

1) The control unit checks for the presence of safeties

2) The control unit performs a three second pre-opening operation at the force set via the trimmer. As this

operation is underway, check that:

a) gate is actually opening otherwise RESET the control unit and switch over motor lead polarities.

b) upon completion of the foregoing repeat the learning routine from the start.

3) The control unit fully opens the gate to acquire full operating time, slowing down after having completed 90%

of the manoeuvre. The manoeuvre is completed upon gate reaching the stop and triggering obstacle

detection control.

4) After a three second pause the control unit initiates the closing operation, exiting from the automatic learning

mode upon gate being fully shut.

CONNECTION TERMINALS NOTES

Antenna 1 –2

Accessories power output 3 –2

Tx photocell power output 4 –2

Safety Opening 5 –7

Photocells 6 –7 Jumper in if not used

3 Power Positive (red)

8 Signal (grey)

Courtesy Light/Electric Lock

Expansion Module

7 Power Negative (black)

Start 9 –10

Pedestrian access 11 –10

Stop 12 –10 Jumper in if not used

Closing limit switch 13 –14

Opening limit switch 15 –14

16 Flashing light NegativeFlashing warning light

17 Flashing light Positive

Motor 18 –19

Battery output 20 –21

Transformer Secondary 22 –23

ENGLISH

6

Control unit RESET:

Press the P1/SET key

for 2 sec.

The unit performs a partial

opening operation.

Reverse leads in case of motor

running in reverse and repeat

operation.

Maximum force Step-by-step

funct.

Obs. detect.

Triggering time: 2.5”

OPERATION WITH QUICK PROGRAMMING

Once connected motors and the desired safeties place wings halfway. To upload transmitters press

P2/RADIO for 2 seconds, till the red led comes on, make a transmission and then press P2/RADIO again.

The yellow

LED starts

blinking

The yellow LED comes on

Closing

Re-opening

to end of run or stop

1”pause (stand-by)

Closing to end of

run or stop

Yellow LED goes off

Press the P1/SET

key within 5

seconds

End of self-learning

routine

JUMPER CH-RADIO: Channel 1 Channel 2

Radio channel Selection

JUMPER-TEST: Disabled Enabled

Safeties test Selection

FOR

Force

PAU

Pause

OBS

Obstacle Detect. Sens.

Minimum force Auto. Funct.

with fast

closing

Obs. detect.

triggering time : 0.1”

Medium force Auto. Funct.

with 3-60”pause

Obs. detect.

triggering time: 1”

CUSTOMISEABLE SETTINGS

•Slow down triggering at 90% of closing or opening run.

•Total opening of the wing for pedestrian transit.

•No setting of remote pedestrian opening.

Check Trimmer Adjustments

NOTE:

It is necessary to repeat the learning procedure any time the

trimmer Force/Speed is adjusted.

The position of trimmer PAU sets different functioning modes of the

board. Please refers to par. 9.

ENGLISH

7

6. PROFESSIONAL LEARNING ROUTINE

Once the control unit has been set up as described above, turn it off and then back on again or press the

P1/SET key on the card. Within five seconds, while the yellow SET LED flashes, keep the P2/ RADIO key

pressed for one second to access “PROFESSIONAL LEARNING”.

The yellow SET LED stops flashing and stays on fixed to signal that “PROFESSIONAL LEARNING”mode has

been successfully accessed.

1) The control unit checks for the presence of safeties

2) The control unit performs a three second pre-opening operation at the force set via the trimmer. As this

operation is underway check that:

a. wing is actually OPENING otherwise RESET the control unit and switch over motor lead

polarities.

b. upon completion of the foregoing re-run the learning routine from the start.

3) The control unit fully close the access.

4) Press either key P1/SET (manual command) or P2/RADIO (radio command) on the card to cause the

control unit to fully open the gate and acquire maximum motor(s) running time(s). Control unit

automatically exits “LEARNING”mode if left idle for more than four minutes.

5) Select channel 1 or press key P1/SET upon wing reaching the point at which slow down is desired to

slow down motor. Slow down of the motor is activated upon the above command being given. Without

the foregoing procedure the slow down function is disabled. The opening operation is completed upon

limit switch or obstacle detection control triggering or at most automatically after four minutes.

6) The subsequent RADIO or manual command causes the control unit to perform a full closing operation.

After three minutes of being left idle, the control unit in any case performs the operation automatically. If

operator controlled closing is selected, program photocell Operating Logic via Radio or Manually

proceeding as follows:

a. press transmitter CHANNEL 1 key or the P1/SET key on the control unit to obscure the

photocell and cause immediate stop while closing (uninfluential when opening);

b. press transmitter CHANNEL 2 key or the P2/RADIO key on the control unit to obscure the

photocell and cause immediate stop while closing or opening and reversal or resumption,

respectively, upon obstacle being removed.

Simultaneously press keys P1/SET and P2/RADIO for one second to exit from learning mode or proceed as

follows to program Pedestrian Opening:

7) Send another RADIO or Manual command to get the control unit to open the first wing and run

pedestrian opening time count. In case of RADIO command via:

a. Channel 1 or key P1/SET, pedestrian opening may only be performed manually (EDG terminal

input)

b. Channel 2 or key P2/RADIO, pedestrian opening may also be performed via a radio command

through Channel 2 or 4 depending on whether jumper “CH-RADIO”is in or not.

8) Upon the desired aperture being reached send another RADIO or Manual command to record

pedestrian opening time. Upon completion of pedestrian opening time acquisition the control unit

causes the wing to fully close. The unit automatically exits from the learning mode and is now ready to

operate. Perform several operations and check safeties and correct function and operating time

acquisition.

ENGLISH

8

7. RADIOTRANSMITTERS PROGRAMMING AND ERASING

By means of the radio receiver module integrated in the control unit you are allowed to store Stateurop radio

transmitters with dip-switches, with fixed and rolling codes.

7.1 ENTRY

•Power the unit.

•Press the “P2/RADIO”key: the red LED comes on indicating programming in progress.

•Perform a transmission by pressing any transmitter key.

•LED blinking indicates code entry in progress, upon completion of which LED becomes fixed again ready for

new code entry.

•Enter all transmitters by performing a transmission with each within no more than a ten second interval

between one and the other.

•To exit from routine at end of entry press key “P2/ RADIO”again, successful exit being indicated by LED

going off. Automatic exiting occurs in any case after ten seconds of transmitter being left idle.

•Code storage is retained even after powering out.

7.2 TOTAL CODE DELETION

•Press and keep pressed the “P2/RADIO”key until the red LED starts rapidly blinking (after about three

seconds).

•Press the “P2/RADIO”key again within six seconds to confirm deletion. Deletion is indicated by LED blinking

more rapidly.

7.3 AUTHORISATION OF NEW REMOTE “ROLLING CODE” TRANSMITTERS

An already authorised transmitter is required to authorise a new one without having to act on the receiver.

•Press and release the learning key accessible via the small aperture at the back of the transmitter, taking

care to be within the maximum reception range when performing this operation.

•Perform a transmission by pressing one of the channel keys of the transmitter to be authorised.

•Proceed as per the above steps for each transmitter to be authorised.

•Exiting occurs after ten seconds from last transmission.

•Check affirmative authorisation by performing an opening operation with each transmitter.

7.4 RADIO CHANNEL SELECTION

To select the desired radio channel which trigger operations, set jumper “CH-RADIO”as follows:

Jumper Active Radio Channel

Out Full opening: Channel 1

Partial pedestrian opening (if enabled): Channel 2

In Full opening: Channel 3

Partial pedestrian opening (if enabled): Channel 4

ENGLISH

9

8. SAFETIES OPERATING LOGIC

•Photocell (PHO input)

When triggered photocell causes:

- movement reversal when closing, either immediately or upon release as programmed;

- no effect when opening;

- no effect when opening a closed gate if set for immediate reversal, otherwise a delay until it is reset;

- closing inhibition in case of open gate.

Note:The control unit is endowed with a quick closing function so that when automatic closing is

enabled the resetting of a photocell that has triggered during opening or pause immediately causes the

gate to close without the unit waiting any further for pause time to expire.

•Opening Safety (EDG input)

Safeties, such as flush or pneumatic hips, etc., and regardless of whether testable or not, may be connected to

input “EDG”.

Safety activation causes:

- no effect during closing;

- movement reversal during opening for two seconds;

- opening inhibition when access is closed;

- closing inhibition when access is open.

•Logic STOP (STP input)

Logic STOP activation causes the stop of all the functions.

To reactivate the manoeuvre it is necessary to disengage the stop and give another command.

9. CONTROL UNIT OPERATIONS

9.1 TURNING ON

Upon turning on, the unit’s yellow SET LED starts blinking for five seconds indicating LEARNING mode

accessibility for reprogramming. Commence operations once the yellow LED has gone off. Persistent red LED

indicates failure of the EEPROM memory that contains necessary radio codes and unit's operating parameters.

Under such conditions, no operation may be performed until the unit is programmed all over again or the

EEPROM card replaced.

9.2 AUTOMATIC OPERATION

Set the “PAU”trimmer cursor to an intermediate position between 0 and the second-last notch according to

desired pause time to program automatic mode.

A radio command or one given via the “STR”input causes the control unit to:

- pre-blink for one second;

- actuate the motor;

- ceasing the opening upon limit switch triggering, or upon expiry of pre-set operation time.

pre-blink for two seconds after expiry of pause time before starting to close again by:

- actuating the motor

- ceasing the closing upon limit switch triggering, or upon expiry of pre-set operation time.

Note: With manual opening contact (terminal STR) closed, the control unit doesn't perform automatic

closing, for which, the contact must be reopened.

9.3 STEP-BY-STEP OPERATION

Turn the “PAU”trimmer cursor all the way down to cut out automatic closing and program step-by-step mode.

The step-by-step sequence is OPEN-STOP-CLOSE-STOP.

Opening and closing operations are performed as described in the foregoing sub-section.

9.4 PEDESTRIAN OPENING

A command given via the PEDESTRIAN OPENING input ("EDG" terminal) or radio (if enabled) causes the

control unit to open for 5 seconds or for the time set during the LEARNING routine (if performed).

Closing may take place either automatically (in case of the automatic closing function being enabled) or upon

giving a further manual command.

The full opening command always has priority over pedestrian opening so that a full opening command given

during pedestrian opening will cause to fully open.

ENGLISH

10

9.5 OBSTACLE DETECTION

The control unit is fitted with an “OBS”trimmer for selecting obstacle detection triggering delay time. This

function is useful as it permits to overcome any critical point where there may be slight jamming or to make up

for over sensitivity (e.g. triggering caused by current fluctuations on the motor).

The obstacle detection triggering causes:

- during opening a closure for 2 seconds

- during closing a complete opening

9.6 FLASHING WARNING LIGHT

The control unit is fitted with two output terminals (LAMP) for a FEBOLIX (12VDC 2W) flashing warning light.

The light comes on one and two seconds before opening and closing, respectively.

As the lamp is powered by direct current, a light featuring an incorporated resonant circuit must be connected to

the terminals. The light continues flashing throughout the operation after which it goes off.

In case of power failure the light flashes for the first four seconds of operation start up and then goes off.

9.7 QUICK CLOSING AFTER PHOTOCELL TRIGGERING

Quick closing after photocell triggering (PHO input) may be enabled by rotating the Pause trimmer

anticlockwise, in which case the control unit will:

a) resume and complete opening if interrupted during this operation and then automatically close again after

one second;

b) automatically re-close after one second in case of the photocell having triggered during pause with access

open;

c) fully open the gate closing it again after one second if interrupted during closing.

Without photocell triggering during opening and closing operations. Pause time is that set via the “PAU”trimmer.

9.8 SLOW DOWN

Slow down reduces wing thrust against stops thus avoiding damage to wing and stops. Slow down speed is

reduced by about two thirds. If desired, slow down must be intentionally enabled during the Learning routine.

Slow down start setting stays the same in opening and closing.

9.9 EMERGENCY BATTERY

The optional 12V, 1.2Ah battery has a maximum five-full-operation range within the first 24 hours of mains

power (230VAC) failure.

10.PROGRAMMING BY GTSYSTEM

The GTSYSTEM is a stand-alone multifunction terminal used for several Stateurop products for test or function

setting. In the case of UNIK1E the GTSYSTEM allows:

•display and modification of functioning parameters

•Visualisation of operation counter

•Visualisation of board states and diagnostic settings.

ENGLISH

11

11. TROUBLESHOOTING

FAILURE PROBABLE REASON POSSIBLE SOLUTION

230VAC power supply not present Check the main switch

Emergency STOP activated

Check possible switches or

commands on the STP input.

If STP input is not used, verify the

bridge on input STP.

Blown fuse Replace fuse with one of the same

value.

After a command with the remote

control or the key switch, the gate

doesn’t open

Motor cable not connected or

defective

Verify connection of the cable to

the right terminal of the board or

replace it.

The gate doesn’t close

The photocell beam is interrupted

by an obstacle or the photocell

doesn't work.

Remove the obstacle and verify

the photocell

The automation works with the key

switch, but not with the remote

control

The remote control is not

memorized in the unit, the battery

is low or the remote control is

faulty.

Memorize the remote control in the

unit or replace the battery

The gate starts, but then stops

The power of the motor is not

sufficient or the sensitivity of the

obstacle detection is too high.

Adjust setting of trimmers FOR

(Force) or OBS (Obstacle

detection)

There is an obstacle in front of the

wings, the hinges are jammed or

the stirrups of anchorage of the

motor is disconnected

Eliminate the obstacle from the

wings, lubricate or replace the

hinges. To fix the stirrup of the

motor.

After a command, the motor starts,

but the gate doesn't move

The electical lock doesn’t work Verify the connections of the

electrical lock or lubricate it

A wing opens and the other one

closes The connection it is not correct

Exchange the polarity of the cables

of the motor which doesn’t move

correctly

N.B.: - If the failure remains, please contact your Retailer or the nearest Assistance Center.

ATTENTION: before sending the remote control to a service center, verify if the batteries are flat. Many

remote controls sent for repairing have simply flat batteries.

SAFETY WARNINGS

These warnings are an integral and essential part of the product, and must be delivered to the user. Read them

carefully: they provide important installation, operating, and maintenance instructions. Keep this form and give it

to any persons who may use the system in the future. Incorrect installation or improper use of the product may

cause serious danger.

INSTALLATION INSTRUCTIONS

•Installation must be performed by a qualified professional and must observe all local, state, national and

European regulations.

•Before starting installation, make sure that the product is in perfect condition.

•Laying, electrical connections, and adjustments must be done to “Industry Standards”.

•Packing materials (cardboard, plastic, polystyrene, etc.) are potentially dangerous. They must be

disposed of properly and kept out of the reach of children

•Do not install the product in an explosive environment or in an area disturbed by electromagnetic fields.

•The presence of gas or inflammable fumes is a serious safety hazard.

•Provide an overvoltage protection, mains/knife switch and/or differential on the power network that is

suitable for the product and conforming to current standards.

•The manufacturer declines any and all liability if any incompatible devices and/or components are

installed that compromise the integrity, safety, and operation of the product.

•Only original spares must be used for repair or replacement of parts.

•The installer must supply all information regarding the operation, maintenance, and use of individual

components and of the system as a whole.

MAINTENANCE

•To guarantee the efficiency of the product, it is ess ential that qualified professionals perform maintenance

at the times and intervals required by the installer, by the manufacturer, and by current law.

•All installation, maintenance, repair and cleaning operations must be documented. The user must store

all such documentation and make it available to competent personnel.

WARNING FOR THE USER

•Carefully read the enclosed instructions and documentation.

•This product must be used for its intended purpose only. Any other use is improper and therefore

dangerous. The information contained herein and in the enclosed documentation may be changed

without notice, and are in fact provided in an approximate manner for application of the product. Stateurop

declines any and all liability in this regard.

•Keep this product, devices, documentation and all other items out of the reach of children.

•In case of maintenance, cleaning, breakdown or malfunction of this product, turn off the unit and DO NOT

try to repair it yourself. Call a qualified professional only. Disregard of this instruction may cause

extremely dangerous situations.

LIMITS OF WARRANTY

This product has a warranty of 24 months starting on the date of acquisition the product itself, and is valid for

the first purchaser only. The warranty will expire in the event of: negligence, incorrect or improper use of the

product, use of accessories not conforming to the manufacturer’s specifications, tampering by the customer or

by third parties, natural causes (lightning, flood, fire, etc.), insurrection, acts of vandalism, changes in

environmental conditions of the installation site. In addition, it does not cover parts subject to wear (batteries,

etc.). If the product has to be returned to Stateurop

. for repair, it must be sent postage paid. Stateurop

will return the repaired product to the sender COD. Under any other circum

stances, the product will be

refused upon receipt or held at the time of shipment. Purchase of this product implies full acceptance of all of

the terms of this warranty. In the event of dispute, the competent forum will be that of Bologna, Italy.

Table of contents

Other PRASTEL Control Unit manuals

PRASTEL

PRASTEL FSTYLE25A User manual

PRASTEL

PRASTEL EASY-PAD User manual

PRASTEL

PRASTEL M1000E User manual

PRASTEL

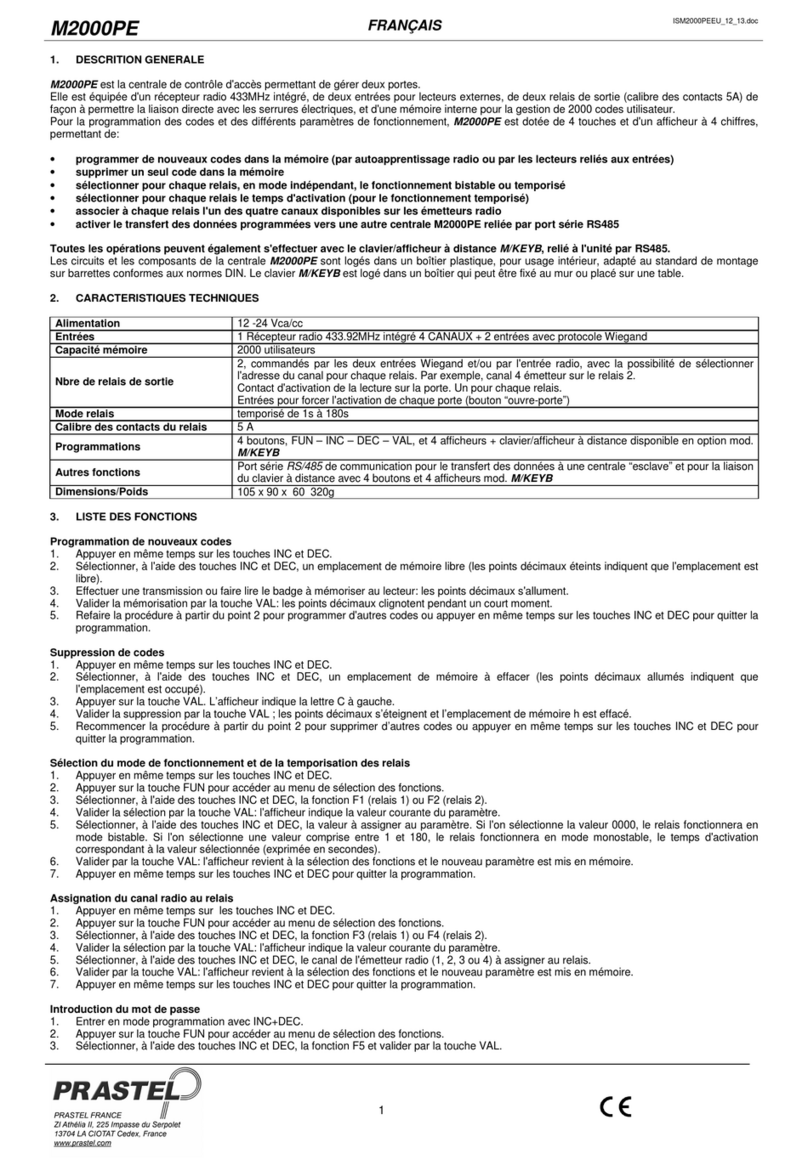

PRASTEL M2000PE User manual

PRASTEL

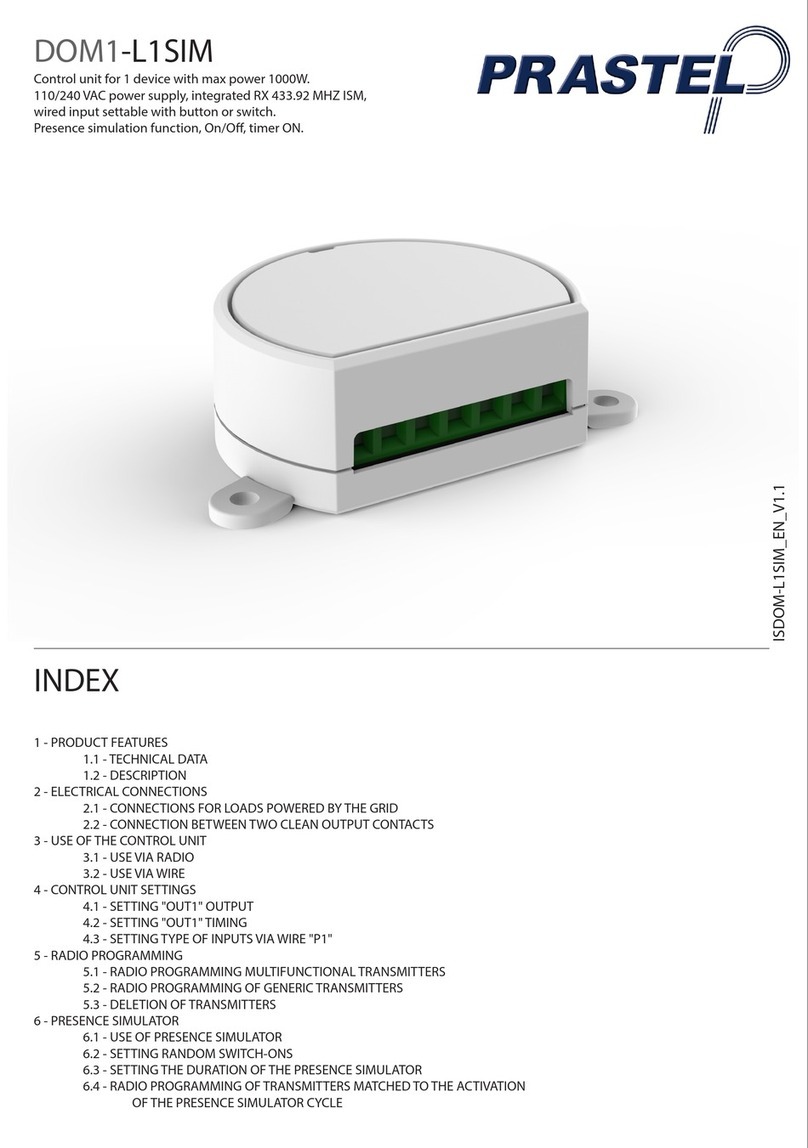

PRASTEL DOM1-L1SIM User manual

PRASTEL

PRASTEL UNIK3I-V4 Safety guide

PRASTEL

PRASTEL SER30E User manual

PRASTEL

PRASTEL MT15000/2 Owner's manual

PRASTEL

PRASTEL UNIK2E-V2 Technical document

PRASTEL

PRASTEL CNCR EURO/SER User manual

Popular Control Unit manuals by other brands

Norgren

Norgren FD67 manual

Texas Instruments

Texas Instruments LMH9235RRL-EVM user guide

KB Electronics

KB Electronics 9646 Installation and operation instructions

GMMC

GMMC NFC NUTSHELL KIT user manual

Supermicro

Supermicro MicroBlade MBI-6118D-T2 user manual

Bristan

Bristan MT753CP Installation instructions and user guide