Nihon Bisoh BISOMAC210 User manual

NIHON BISOH CO., LTD.

BISOMAC210

Specifications for North America 3P model

Electric Traction Hoist

Operator’s Manual

[with Overload Detection Device]

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

Any operation in violation of these instructions may result in bodily injury or death.

WARNING

+ All operators must read and completely understand this manual.

+ All operators must be thoroughly trained and certified in the use of the equipment, its

operational and safety features.

+ Only authorized and physically fit operators shall operate the equipment.

+ At the start of each work shift, daily test must be performed to ensure correct operation.

+ Any operations in violation of these instructions is operator’s own risk and may result in serious

injuries.

+ Keep this manual with the hoist at all time.

+ Use only spare parts and steel wire rope recommended by NIHON BISOH.

+ Use only machinery or incorporated component, which MUST COMPLY with UL1323, CAN/CSA

Z271-10 and national, regional, or local implementing.

+ Installation, dismantling and use of suspended scaffold shall be in accordance with Code of

Safe Practices (COSP) for Adjustable Suspended Scaffold which implemented by Scaffolding,

Shoring and Forming Institute (SSFI) and Scaffold & Access Industry Association (SAIA).

+ It is the responsibility of the user of this hoist to determine that this hoist is suitable to be used in

conjunction with any other equipment. The user must also determine that this hoist and other

components used will be in strict conformity with the provisions of Federal, State, National and

local ordinances and regulations.

Manufacturer: NIHON BISOH CO., LTD.

TABLE OF CONTENTS

0. READ BEFORE USE ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ1

1. FOR SAFE USEꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ5

1.1 General ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ5

1.2 Maintenance ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ6

1.3 Hazard Symbolsꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ6

2. SPECIFICATIONSꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ13

2.1 BISOMAC308 ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ13

2.2 BISOLOCK ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ14

2.3 BISOLOAD ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ14

2.4 Wire Ropeꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ14

2.5 Power Cable ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ15

3. FUNCTION AND DESCRIPTION OF EACH COMPONENT ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ16

3.1 BISOMAC210 TRACTION HOISTꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ16

3.2 BISOLOCK ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ19

3.3 BISOLOAD ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ20

4. WORK ENVIRIONMENTꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ21

5. SET UP INSTRUCTIONSꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ22

STEP 1 Installation of safety devices to BISOMACꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ24

STEP 2 Connecting to power supplyꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ26

STEP 3 Installation of suspension wire ropeꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ28

STEP 4 Installation of the hoistꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ29

STEP 5 Perform daily inspectionꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ29

6. OPERATING THE HOIST ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ30

6.1 Carrying the hoist ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ33

6.2 Operation methods of the hoistꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ33

6.2.1 Lifting and Emergency stop ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ33

6.2.2 Emergency controlled descent leverꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ34

6.2.3 Releasing procedure of BISOLOCK ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ35

7. DAILY TESTS AND INSPECTIONS ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ37

7.1 Tests and inspections: Rigging materials ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ37

7.2 Tests and inspections: Wire rope ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ38

7.2.1 Shape and size of wire rope ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ38

7.2.2 Shape and size of the end of wire ropeꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ39

7.3 Tests and inspections: Hoist ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ40

7.3.1 Lifting the platform and emergency stop function ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ41

7.3.2 Controlled descent function ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ42

7.3.3 BISOLOCK ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ43

8. PERIODIC MAINTENANCEꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ44

9. TROUBLESHOOTING AT JOB SITEꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ45

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 1

0. READ BEFORE USE

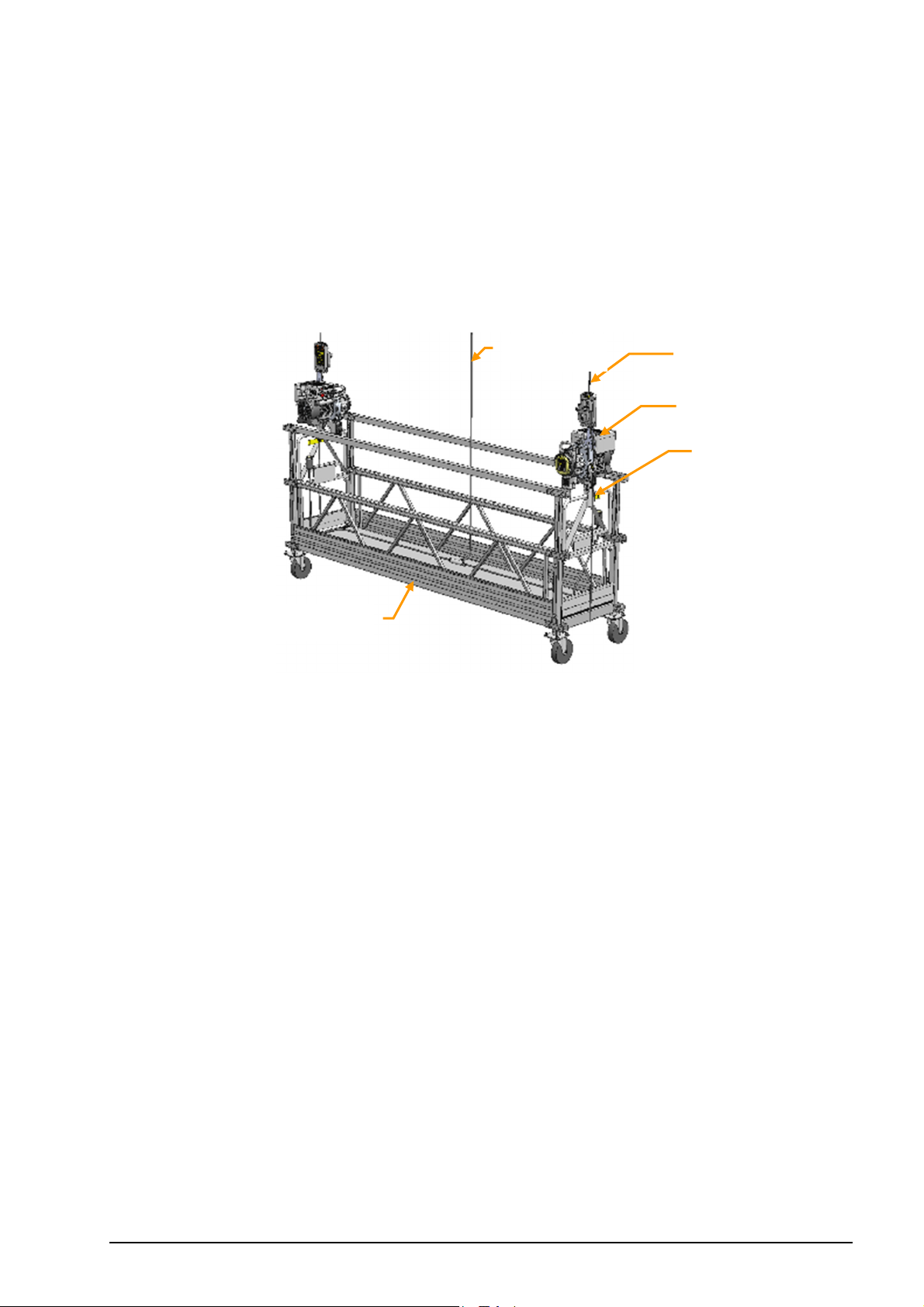

This Operator’s Manual is written for operators to use the equipment safely and properly. To

fully understand the usage of the equipment, please refer to the following instructions and system

compositions. (See picture-1) It is responsibility of the user of this equipment to determine

whether the equipment is safe according to this manual. Any operations in violation of the

instructions in this manual is operator’s own risk.

[System Components of the hoist and other applications]

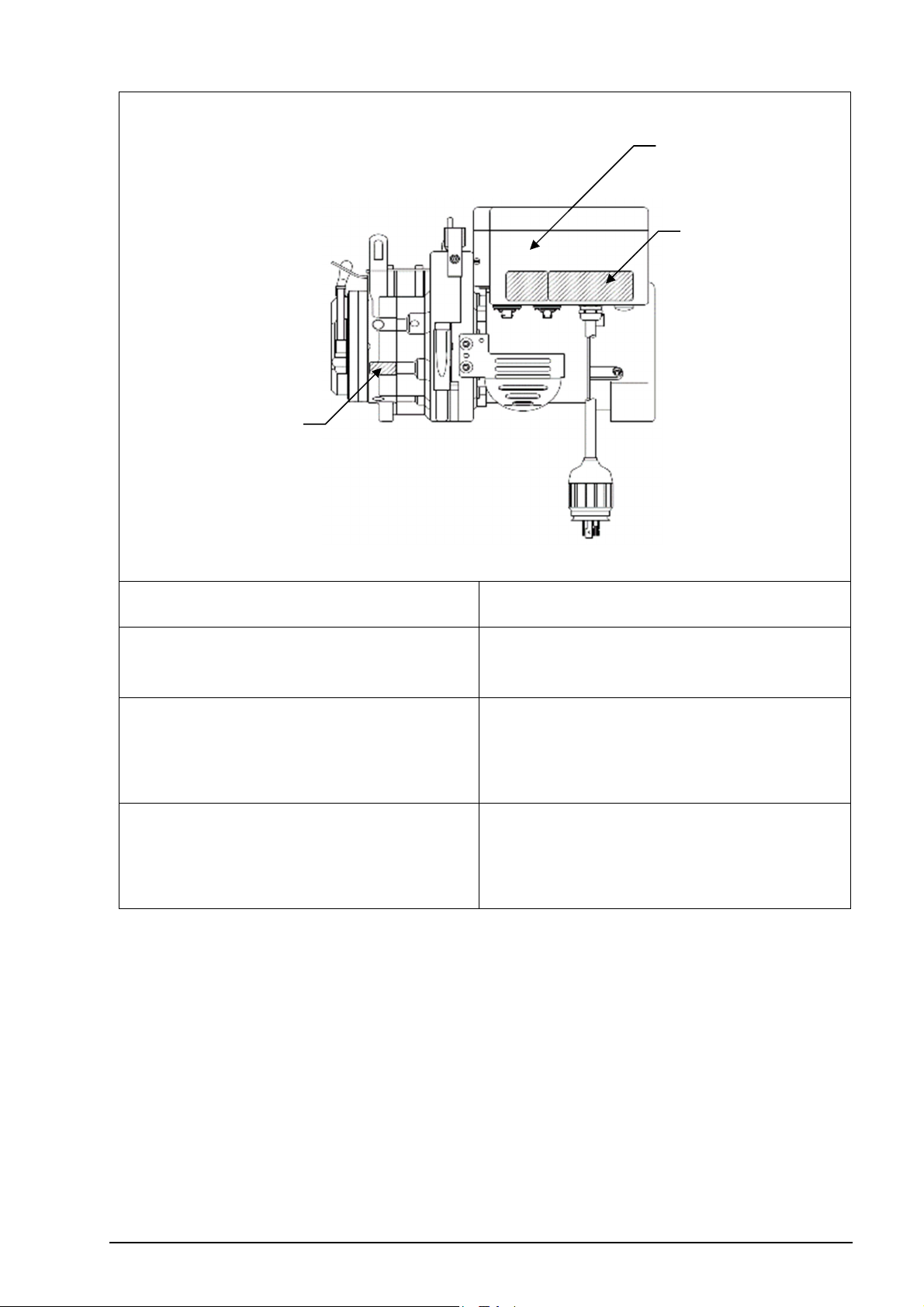

[Picture-1]

1. POWER SUPLLY TO THE EQUIPMENT MUST BE FITTED WITH;

a) Main switch

NOTE: Main switch or Junction box shall have key-lock.

b) Residual current device (or Ground fault circuit interrupter) of 30 mA.

c) Over current protection device (Automatic circuit breaker type-C)

NOTE: To avoid voltage drop due to cable length, make sure that the specifications of

power cable matches the requirement of the equipment.

2. USAGE ENVIRONMENT

Temperature Range: between 14 ゚F (-10 ℃) and 104 ゚F (+40 ℃).

Humidity: Less than 100 % (without inundation, condensation and freezing)

Protection Grade: IP54

Maximum Wind Speed: In accordance with the specifications of platform.

Altitude: 3280ft (1,000m) or lower

Electric Traction Hoist

Suspension wire rope

Platform

Stirrup

Power Cable

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

2

3. CAUTIONS BEFORE USING

a) Before using the equipment, operators must perform the daily test to ensure correct operation.

b) Before using the equipment, operators must confirm that there are no obstacles along the

movement of the equipment.

c) Before using the equipment, suspension system must be checked to ensure that platform is

stable at all times.

d) In case the area below platform is open to the public, preventive measures have to be taken to

safeguard the people below (Ex. Barriers, roof protected walk ways, etc.).

e) All hazards related to platform encountering obstruction are not completely covered by

platform’s safety devices. The operators shall check for obstructions along the travel of

platform.

f) Overload Detection Device may not cover platform in all configurations. The operators must

check that loading of platform does not exceed rated load of each platform.

g) An area on the platform must be available to allow operators to operate the hoist safely.

h) Use only certified safety harness, lanyard, rope grabs, and independent life lines at all times.

i) In the cold weather, lifting operation of the hoist may not be available smoothly. Also, the hoist

may not descend even emergency controlled descent lever is operated. Preventive measure

not the hoist to be cooled must be taken.

j) If the load on the platform is light, descent speed of emergency controlled descent may be

slower.

k) The main suspension wire rope must be vertically set and installed to the hoist.

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 3

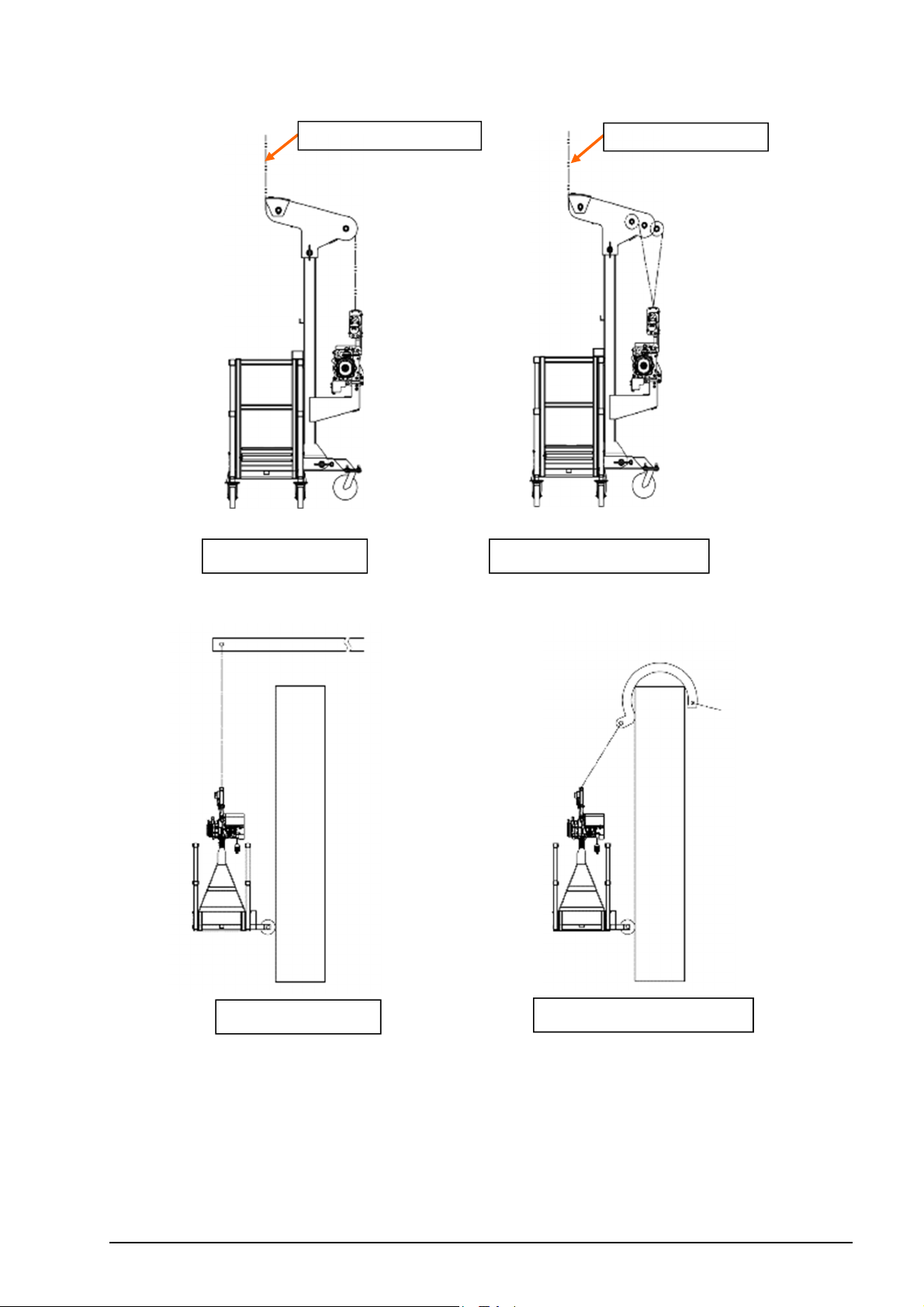

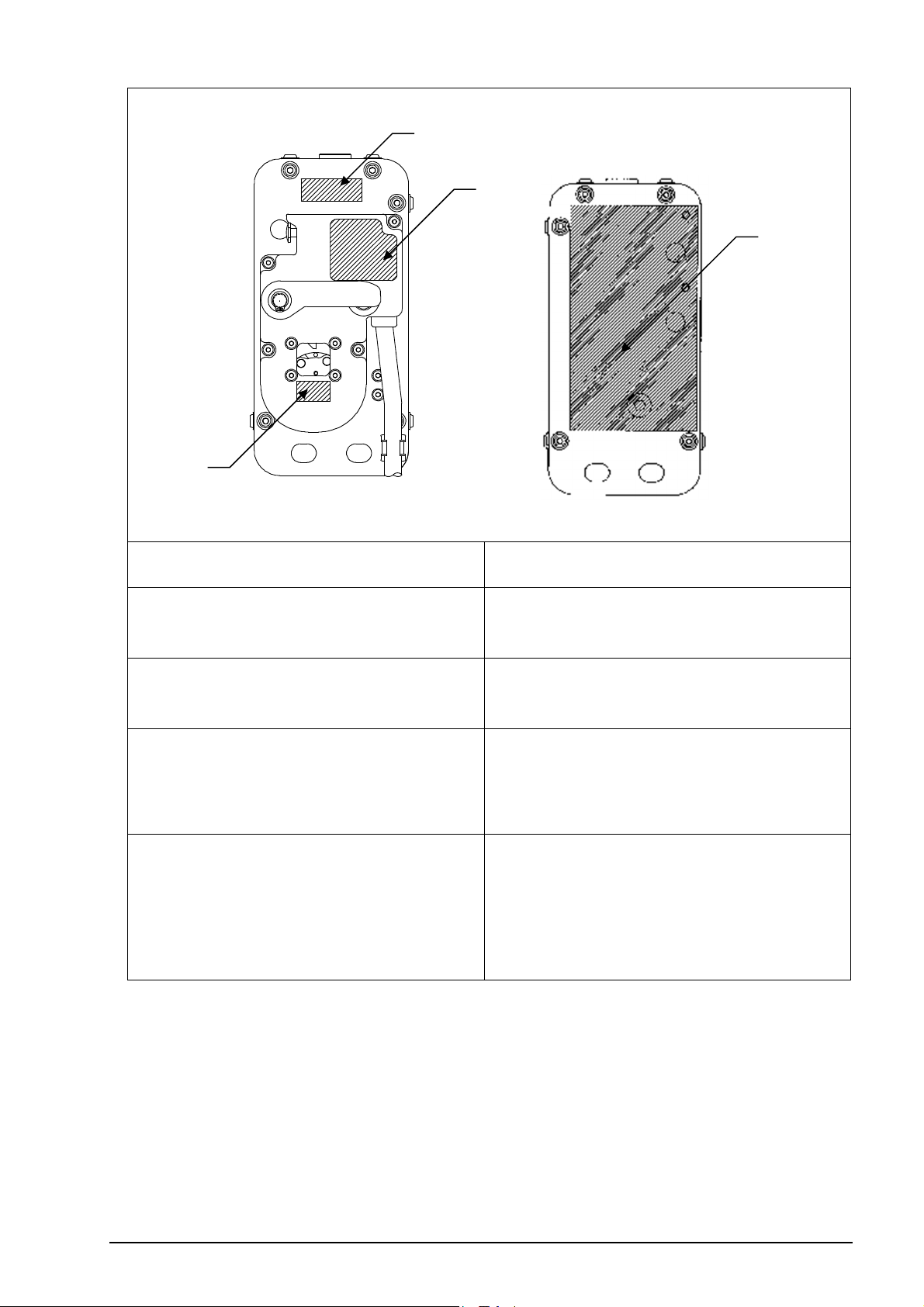

[Installation of the hoist 1]

[Installation of the hoist 2]

NOT vertically suspendedCorrect Installation

Correct Installation NOT vertically suspended

☓

Suspension wire rope

☓ ☓

Suspension wire

✔

✔

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

4

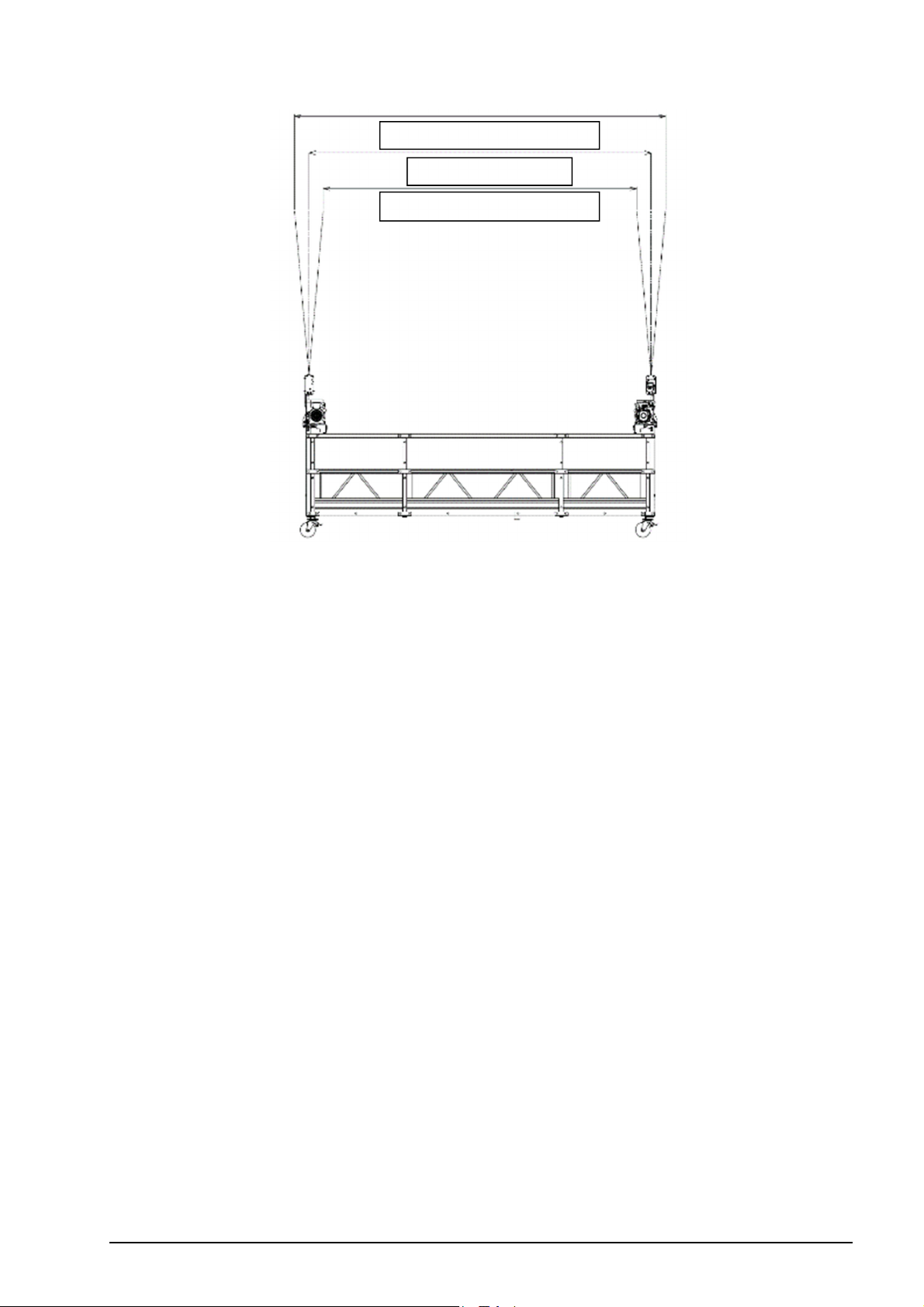

[Installation of the hoist 3]

4. CAUTIONS WHEN USING

a) Stop operating and notify supervisor if any faults which may damage to safety of the

equipment is found.

b) Having suitable communication means between operators and supervisor is recommended.

c) When not in use, unplug power cable and lock the equipment to protect from unauthorized

use.

d) If the hoist isn’t operated for more than 30 minutes in the cold weather, ascending operation

may not be operated smoothly. In that case, idle the hoist 30 seconds or operate descending

operation before ascending.

5. PROHIBITIONS

a) Do not use two or more units of the hoist with one wire rope.

b) Do not insert wire rope from the wire rope outlet of the hoist.

c) Do not tie and secure the discharged wire rope from the wire rope outlet.

d) Do not apply 20 kg or more pulling load to the discharged wire rope from the wire rope outlet.

e) Do not use the hoist in the water.

f) Do not use the hoist as a hoisting device for elevator which permanently installed.

g) Do not use the hoist as a traction device which pull horizontally.

h) Do not use the hoist as a medical traction device.

i) Do not use the hoist in potentially explosive atmosphere.

Correct Installation

NOT vertically suspended

NOT vertically suspended

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 5

1. FOR SAFE USE

1.1 General

This Operator’s Manual is written for operators to use the equipment safely and properly.

Electric Traction Hoist manufactured by NIHON BISOH Co., Ltd. BISOMAC210 Electric Traction

Hoist 3P model (referred to as the hoist) is consists of Hoisting Device (referred to as

BISOMAC), Fall Arrest Device (referred to as BISOLOCK) and Overload Detection Device

(referred to as BISOLOAD).

Components of

BISOMAC210

Electric Traction Hoist

NOTE: The word “Safety Devices” in this manual indicates BISOLOCK.

For the specification of each device, refer to “2. SPECIFICATIONS”.

1. Read and fully understand this manual before using this equipment.

2. The hoist is designed to be used to raise, support and lower platform.

3. Operating, handling, maintenance, inspection, and repairing of the hoist must be performed

only by trained and certified operators.

4. Daily test and inspection must be performed at the start of each work shift according to “7.

DAILY TEST AND INSPECTION”.

5. Troubleshooting shall be done if any problem which possibly caused by the hoist according to

“9. TROUBLESHOOTING” to find the cause of problem and take corrective action.

6. The hoist is used to raise, support and lower suspended scaffolds, work cages and bosun

chairs on, or in building(s) and structures. If used for any other purpose, you must take all

necessary precautions to be sure that both design and operation are hazard free, and such use

conforms with manufacturer’s specifications.

7. This instruction manual is not all inclusive. It is impossible to anticipate every possible way this

equipment may be used, and all possible hazardous situations. It is very important that you

determine for yourself whether the equipment is safe. You must understand the operating

characteristic of this hoist. You must understand how the hoist will operate in your application.

You must be certain not to put yourself or others in danger, or cause damage to property or

other persons.

II. BISOLOCK (Fall Arrest Device)

III. BISOLOAD (Overload Detection Device)

I. BISOMAC (Hoisting Device)

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

6

1.2 Maintenance

Handling, maintenance, inspections and repairs of the hoist must be performed by trained and

certified personnel according to Maintenance Procedure Manual of each device (separately

issued).

1.3 Hazard Symbols

Safety instructions are classified according to risk levels.

Symbol Term Meaning

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury and in

damage to property.

NOTE: NOTE

Indicates a potentially hazardous situation which, if not

avoided, may result in damage to the hoist or the hoist may

not operate properly.

Safety instructions attached to the hoist and safety devices

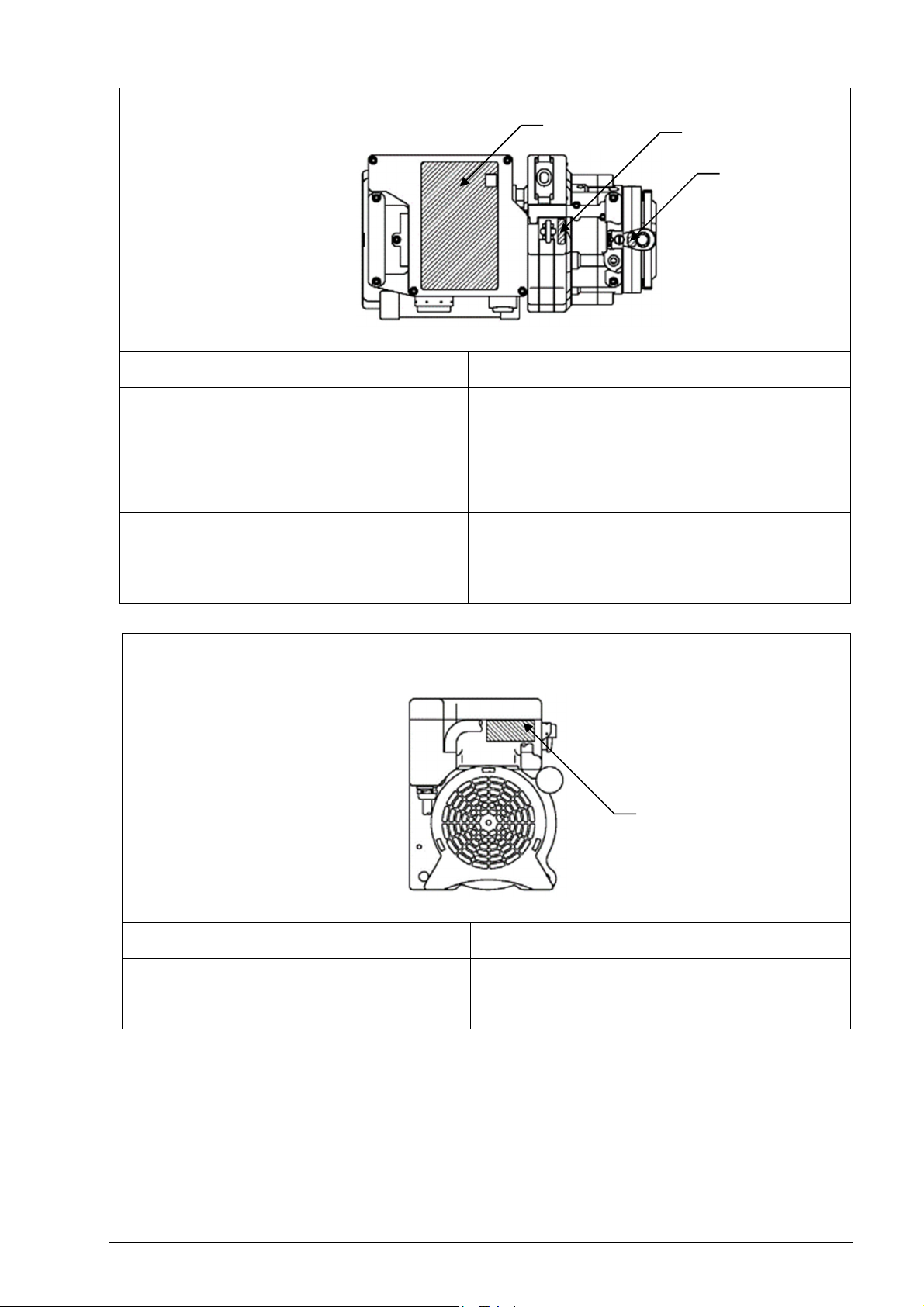

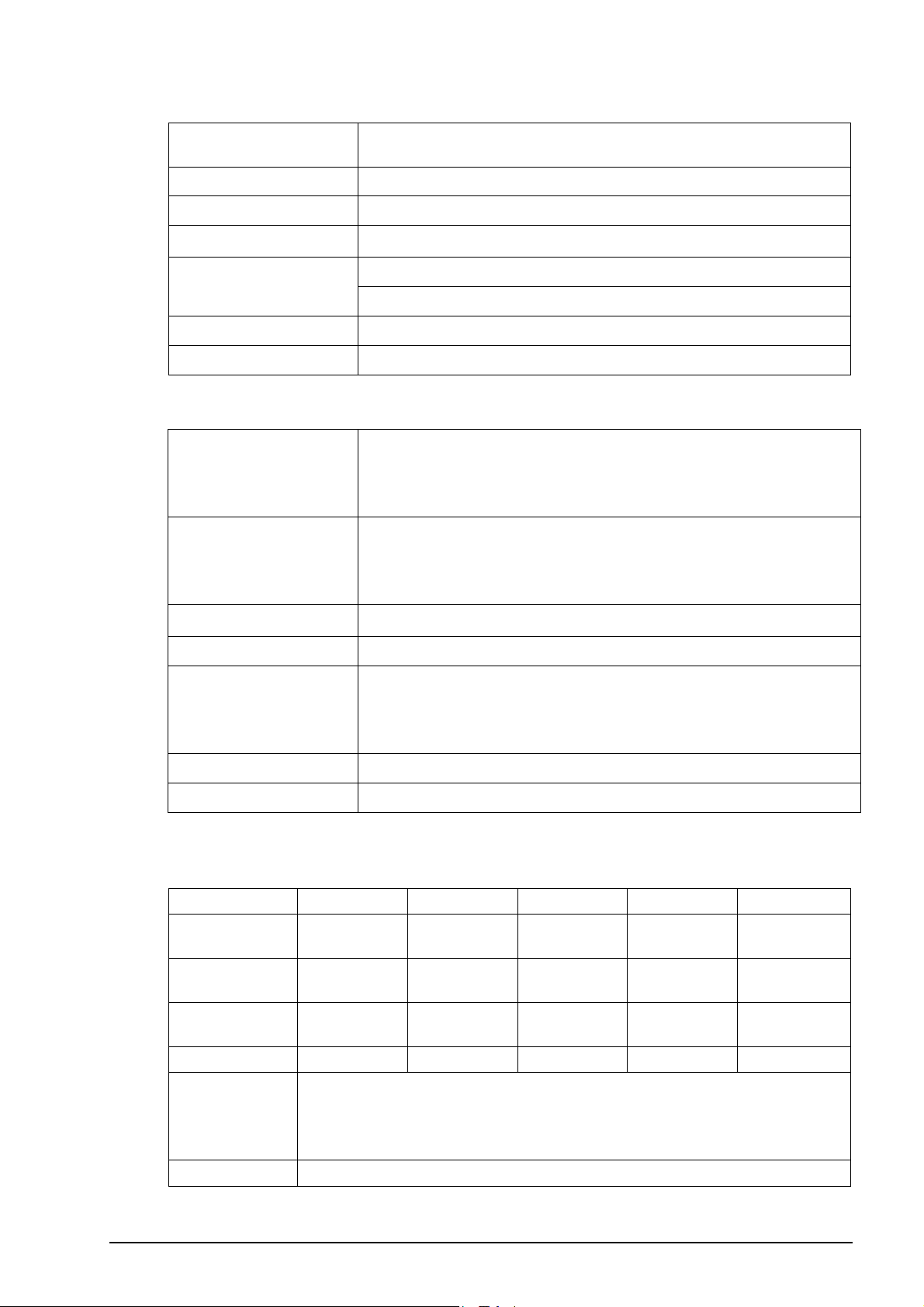

[BISOMAC Front side]

Description Meaning and Location

1. Emergency Control Descent &

Electromagnetic Brake Caution

●Instruction of Emergency controlled descent

●Instruction of Electromagnetic Brake

●Warning of skin burn

[Electromagnetic Brake]

1

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 7

[BISOMAC Upper side]

Description Meaning and Location

2. Lever Stopper

●Instruction of Lever Stopper

[Lever Stopper]

3. Max Lift

●Instruction of shackle’s limit load

[Casing A]

4. Specification and Operation

●Instruction of Specification and operation

●QR code to access Operator’s manual on

website

[Control Box Cover]

[BISOMAC Back side]

Description Meaning and Location

5. Restriction Use

●Instruction to the operator

[Control Box Cover]

4

2

3

5

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

8

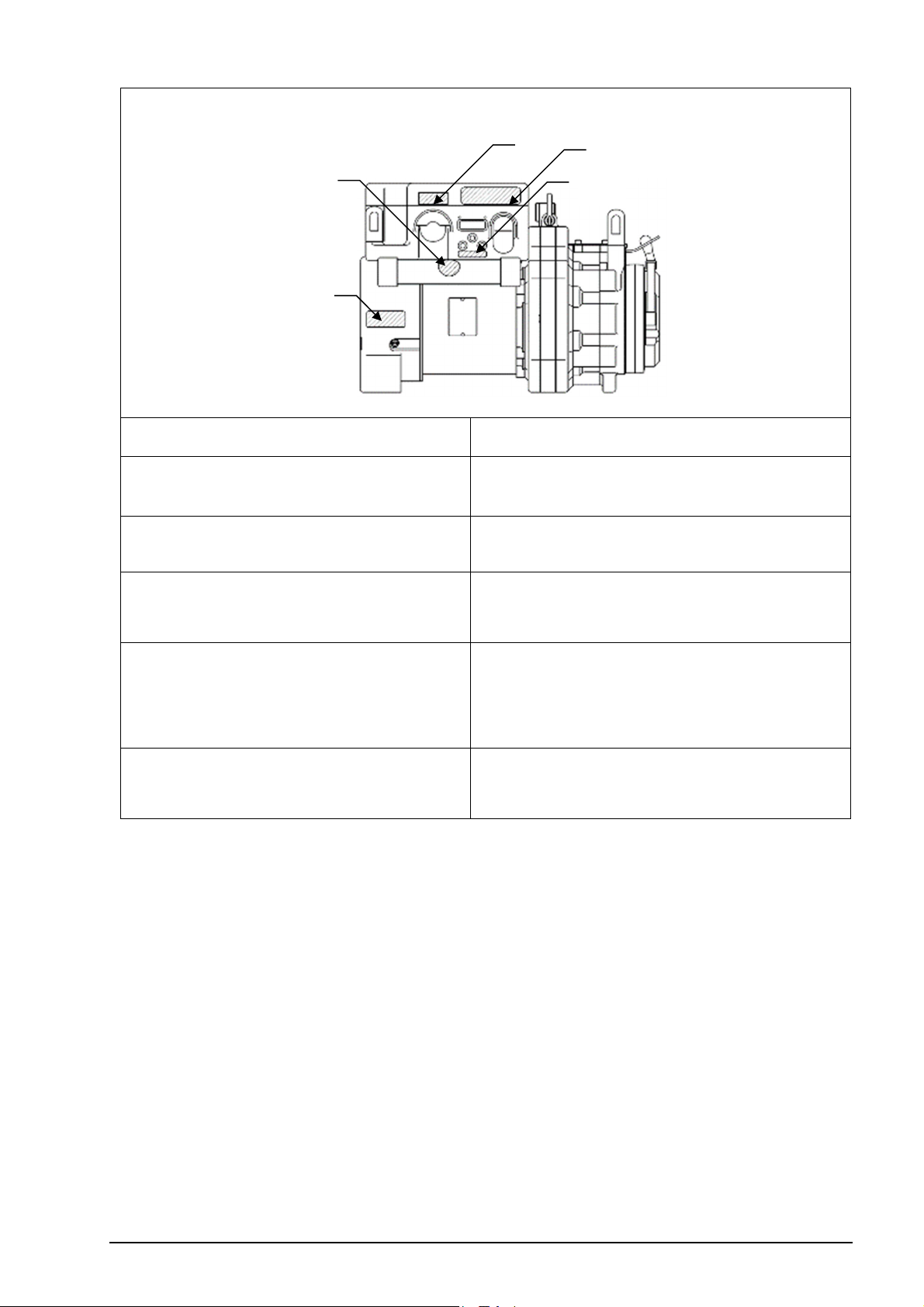

[BISOMAC Left side]

Description Meaning and Location

6. UL & CUL Classification

●Label of UL/CUL certification

[Control Box]

7. Emergency Stop Button

●Instruction of Emergency stop

[Control Box Cover]

8. Operator’s Manual

●Instruction of Operator’s Manual

[Operator’s Manual Storage]

9. Lamp

●Instruction of BISOLOAD(OL)and Different

Phase Detection (RP)

[Control Box]

10. Power Voltage

●Instruction of Voltage

[Fan Cover]

8

7

9

6

10

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 9

[BISOMAC Right side]

Description Meaning and Location

11. Gear 210

●Specifications of Gear Box

[Gear Box]

12. Plug mark

●Instruction of connecting plug of safety

device

[Control Box]

13. Plug connection

●Instruction of connecting plug of remote

control pendant switch

[Control Box]

12

11

13

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

10

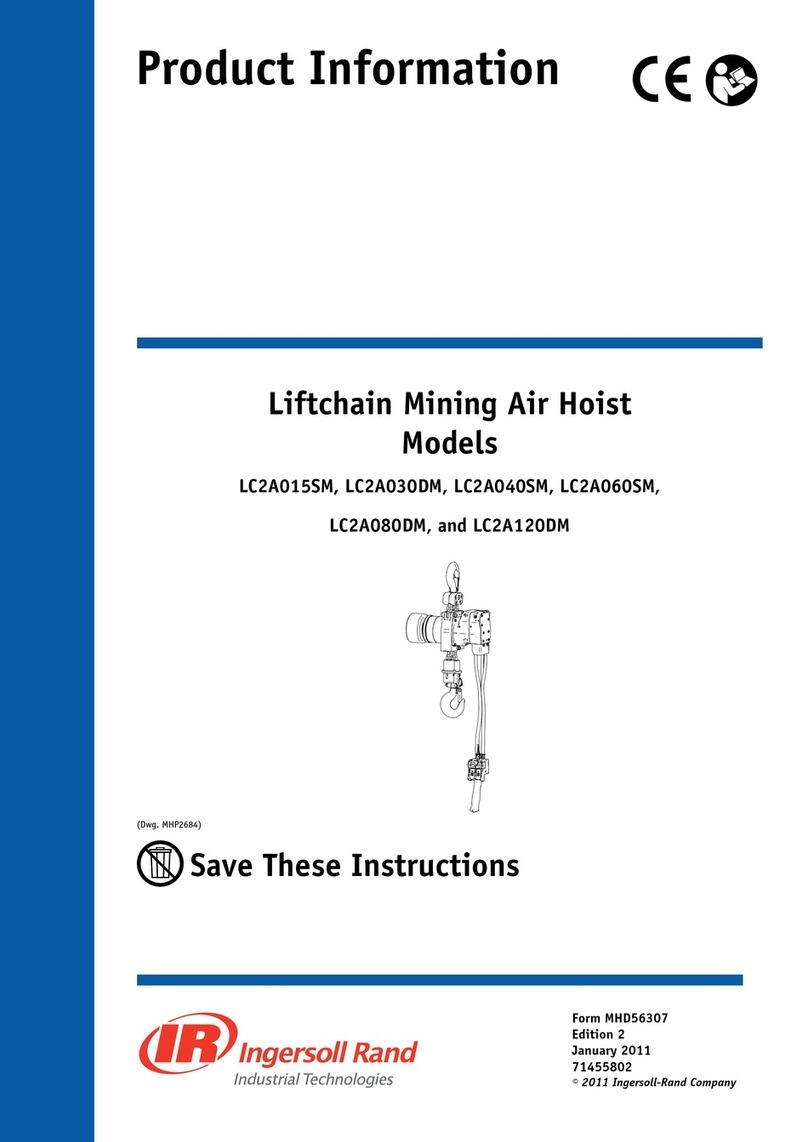

[BISOLOCK Front and Back side]

Description Meaning and Location

1. Instruction of inability of lifting

●Instruction of inability of lifting

[Side Plate 1]

2. Governor Inspection Window

●Instruction of Governor

[Governor Cover]

3. Overspeed Indicator&Reset

●Instruction of activation lamp

●Instruction of Release Lever

[Governor Cover]

4. Instruction of Overspeed Detection

Device

●Instruction of activation of the device

●Instruction of spec and operation of the

device

[Side Plate]

3

1

2

4

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 11

[BISOLOCK Left and Upper side]

Description Meaning and Location

5. Wire Rope Diameter

●Instruction of wire rope

[Side Cover 1]

6. Instruction of Manual Trip Button

●Instruction of Trip Button

[Governor Cover]

6

5

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

12

[

BISOLOAD Left and Right side]

Description Meaning and Location

2. Rated Load

●Instruction of rated load

[Guard]

3. Wire Rope Exit

●Instruction of wire rope outlet

[Rope Cover]

[

BISOLOAD Front side]

Description Meaning and Location

1. Instruction of Overload

Detection Device

●Instruction of BISOLOAD

[Limit Switch Cover LA]

1

2

3

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 13

2. SPECIFICATIONS

2.1 BISOMAC210

Model

Rated

Load

(kg)

Voltage Rated

Current

Wire Rope dia. BISOLOAD

Applicable

Standard

Nominal

Diameter Range

BISOMAC210

-3P1000

1000 lbs

(453 kg)

3Phase

208 V

7.5 A 5/16 in.

(8 mm)

0.315-0.331 in.

(8-.4 mm)

Yes

・UL1323

・CAN/CSA

-Z271-10

BISOMAC210

-3P1150

1150 lbs

(522 kg)

8.5 A

BISOMAC210

-3P1500

1500 lbs

(680 kg)

3/8 in.

(9 mm)

0.354-0.374 in.

(9-.5 mm)

BISOMAC210

-3P1258U

1250 lbs

(567 kg) 5/16 in.

(8 mm)

0.315-0.331 in.

(8-.4 mm)・UL1323

BISOMAC210

-3P1508U

1500 lbs

(680 kg)

Power Three Phase 208 V ±10 % (60 Hz)

Motor Power 1.5 kW(4 P)

Maximum Speed 35 ft/min(10.6 m/min)

Controlled Descent 52.5 ft/min(15.9 m/min) or slower

Minimum Load 60 minutes

Rated Operating TIme 440 lbs(200 kg)

Noise Level

64 dB

*Measured by noise meter setting at 1m away from the hoist. Noise

level may vary depending on the voltage or environment.

IP Rate IP54

Dimension (H×W×D)

*Incl. safety device 29.5 in.(749 mm)x 12.4 in.(315 mm)x 18.2 in.(462 mm)

BISOMAC Self-Weight 108 lbs(49 kg)

Weight

*Incl. safety device

130 lbs(59 kg)

{BISOLOCK: 11 lbs(5 kg)・Mounting Bracket: 2 lbs(1 kg)・

BISOLOAD: 9 lbs (4 kg)}

Control System Individual Control

Safety Features

1. Electromagnetic Brake

2. Descent Speed Control

3. Shutting down with Emergency Stop Switch

4. Different phase detection

5. Motor with built-in thermal protector (temperature sensing)

6. Fall arrest (BISOLOCK)

7. Overload detection (BISOLOAD)

Use Environment

Temperature Between 14 ゚F (-10 ℃) and 104 ゚F (+40 ℃)

Pressure Atmospheric pressure

Maintenance Cycle

1 year or 100 operating hours since last maintenance.

NOTE: It depends on the actual condition of use at work sites. (Refer

to “4. WORK ENVIRONMENTS”.

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

14

2.2 BISOLOCK

Model 1. BISOLOCK210-SP808US

2. BISOLOCK210-SP809US

Rated Load 1500 lbs(680 kg)

Activation Speed 98.4 ft/min(30 m/min)

Dimension (H x W x D) 10 in.(253 mm)x 4.7 in.(120 mm)x 4 in.(103 mm)

Self-weight BISOLOCK: 11 lbs(5 kg)

Mounting Bracket: 2 lbs(1 kg)

Control Feature Unable ascending when BISOLOAD is activated.

Voltage 208 V

2.3 BISOLOAD

Model

1. BISOLOAD210-1000US

2. BISOLOAD210-1150US

3. BISOLOAD210-1250US

4. BISOLOAD210-1500US

Rated Load

1. 1000 lbs(453 kg)

2. 1150 lbs(522 kg)

3. 1250 lbs(567 kg)

4. 1500 lbs(680 kg)

Dimension (H x W x D) 10.4 in.(264 mm)× 12.4 in.(314 mm)× 3.7 in.(95 mm)

Self-weight 9 lbs(4 kg)

Activation Load

1. 1500 lbs(1000 lbs × 150 %)

2. 1725 lbs(1150 lbs × 150 %)

3. 1875 lbs(1250 lbs × 150 %)

4. 2250 lbs(1500 lbs × 150 %)

Control Feature Unable ascending when BISOLOAD is activated.

Voltage 208 V

2.4 Wire Rope (Designated by NIHON BISOH)

No. 1 2 3 4 5

Nominal

Diameter 8.4 mm 8.0 mm 8.0 mm 8.2 mm 8.3 mm

Construction 5 × 26 4 × 39 4 × 40 6 × 19

IWRC 4 × 26

Min. Breaking

Load

51.5 kN

(5253 kg)

44.3 kN

(4520 kg)

44.5 kN

(4540 kg)

40.5 kN

(4131 kg)

45.0 kN

(4590 kg)

Finish Galvanized Galvanized Galvanized Galvanized Galvanized

Applicable

Model

・BISOMAC210-3P1000

・BISOMAC210-3P1150

・BISOMAC210-3P1258U

・BISOMAC210-3P1508U

NOTE Designated wire ropes by NIHON BISOH

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4 15

2.4 Power Cable

NOTE: Due to the various possible suspended platform loading situations and power sources,

it is impossible to specify the maximum length of the power cable exactly. When the

hoist is difficult to start up, take measures against voltage drop such as boosting

voltage and/or using thicker size of cable.

Type SOOW

Core and Size 3P: 4 cores, 10AWG minimum

Rated Voltage 600V

Length 500 ft(152 m)or shorter per a platform

No. 1 2 3

Nominal Diameter 9.5 mm 9.0 mm 9.2 mm

Construction 5 × 19 4 × 36WS 5 × 26

Min. Breaking

Load

64.0 kN

(6530 kg)

67.15 kN

(6850 kg)

66.8 kN

(6816 kg)

Finish Galvanized Galvanized Galvanized

Applicable Model ・BISOMAC210-3P1500

NOTE Not complied with

CAN/CSA-Z271-10 Designated wire ropes by NIHON BISOH

WARNING

1. Use only designated wire rope by Manufacturer

Using any other wire rope may cause BISOMAC and BISOLOCK malfunction. It could

result in serious injury or death due to falling or tilting of the platform.

Nihon Bisoh Co.,Ltd. BISOMAC210 3Phase MM2014/11 KH-2014008 Rev.4

16

3.FUNCTION AND DESCRIPTION OF EACH COMPONENT

3.1 BISOMAC210 TRACTION HOIST

BISOLOCK F

D N

G

E

M

J

C

L

K

B

Q

G

V

T

S

UA

BISOLOAD

Y

X

BISOMAC

Table of contents

Popular Chain Hoist manuals by other brands

Ingersoll-Rand

Ingersoll-Rand LC2A015SM Product information

CMCO

CMCO NEXT Truss StageLIFT NSL2.5 operating instructions

AMH

AMH X5SL02250 manual

KITO

KITO TCH Series instruction manual

TBEI

TBEI Rugby LR-416B Installation and operation manual

Parkside

Parkside PSZ 250 A1 operation and safety notes original operating instructions