Page - 5 - PSS 25 - 0304

3 Product Description

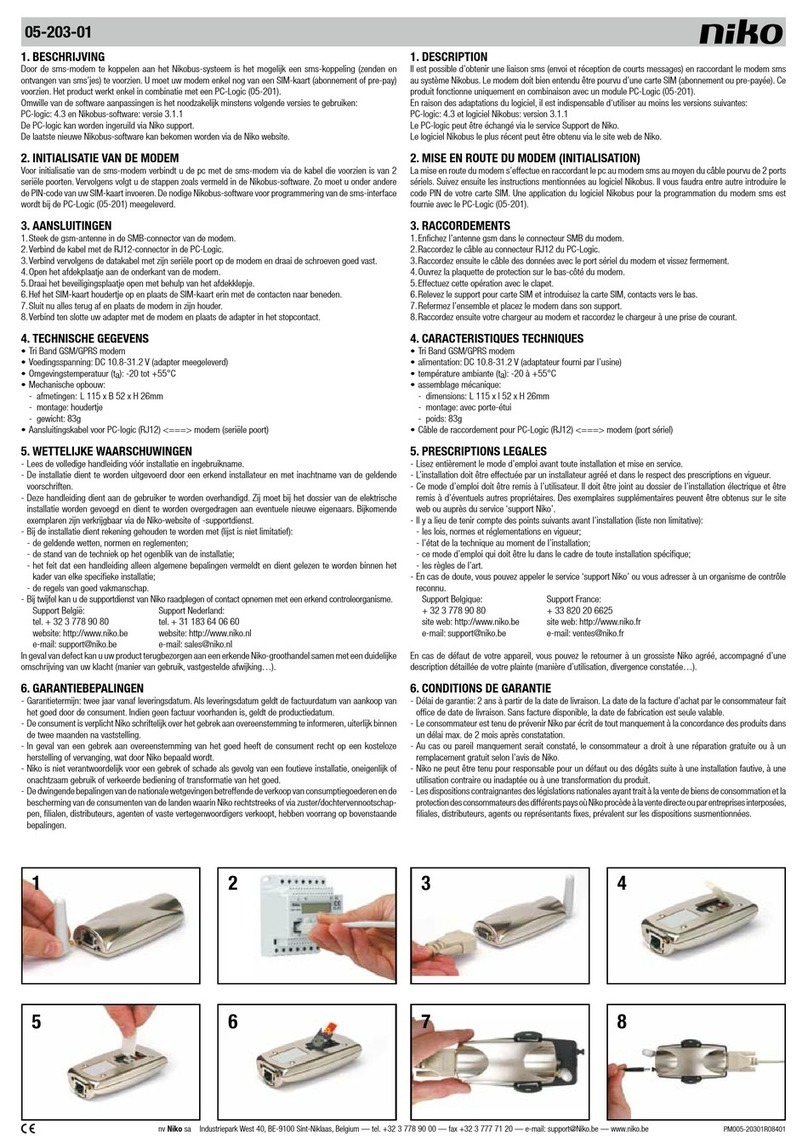

3.1 Parts

Horizontal running track system with detachable coupling for wall or ceiling fastening

as well as fastening to a steel girder above.

Internally running reels each with 4 ball bearing reels and a safety bolt which prevents

the reel falling due to axle or bearing break.

The running track system can be assembled lineally or follow a given track, allowed

through several curves. By dividing the track in several directions - track switches

are assembled which can lead into one or more different tracks. The running reels are

available in two levels of performance.

Reel Type T40 with vertical swivel vice 360° and ring nuts DIN 582.

Reel Type T20 with ball bearing oscillation and pivoted axle through an angle of max.

15°. Track stoppers of Type 25.X01 are screwed on the open end of the track.

Switch systems are delivered either with manual or automatically changing sliders.

The operation can be carried out manually or by chain pull.

3.2 Standards

The parts comply with EN 795 class D.

3.3 Construction

The track system is constructed for vertical assembly. Linear tracks or one following

a course.

Fastening: The tracks are attached to steel girders or masonry with coupling or with

angle support. The fastening distances are depicted at 4.1. It is permitted to exceed

this distance by max. 10% (through construction necessity)

Warning: Each fastening point must be capable of holding a load of 35kn.

At assembly the foundations must be checked and the holding strength of the

fastening points must be verified through protocol. At assembly onto steel

constructions- screws of DIN 933 M16 (8.8) must be used.

The free standing tracks are allowed to hang max. 300mm over the last fastening

coupling. If these distances are exceeded then additional fastening couplings are to be

built.