Nimbus Water Systems Giraffe Installation guide

7ft Mode 5ft Mode

8

7

5

4

3

3

2

1

8

9

7

6

5

4

3

2

1

What should be in your box

• Saddle

• Straight Frame - x2

• Pedals

• Centre Frame (With cranks)

• Quick Releases - x4

• Wheel Forks

• Wheel

• Pair of short chains

• Pair of long chains

• Pedal Wrench

with Seatpost

10

You are going to need a bicycle

pump, (Car Valve) a 15mm

Wrench and 4mm Allen Key.

10

9

6

INS-NIM-005-UK 1 of 2 www.nimbusunicycles.com | Copyright © 2015 Nimbus Unicycles

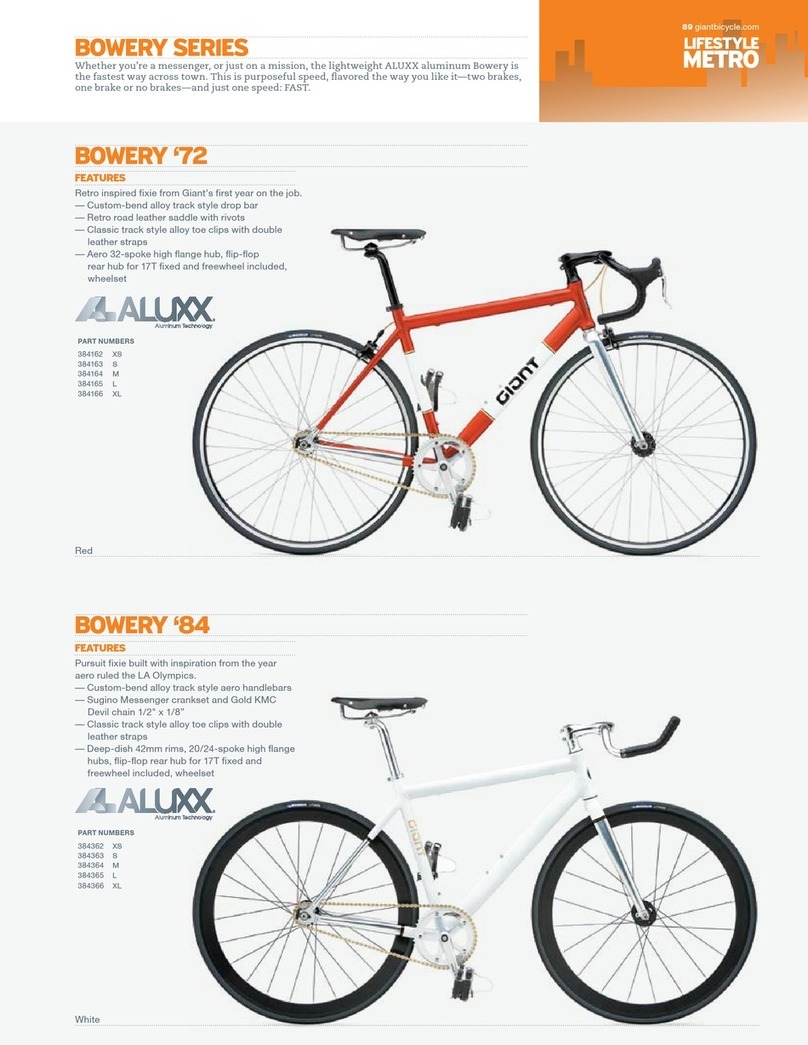

Your Nimbus girae is designed as a dual height compact performer’s girae. With practice it can be assembled

and disassembled in minutes to be packed way into a suitcase or box for transporting.

What you need to put your unicycle together, 10mm wrench, Pedal wrench, 5mm and 4mm allan key and

bicycle pump (Schrader Valve).

The Nimbus Performer Girae as supplied can be assembled as a 5 foot or 7 foot mode. These instructions will

detail assembly of both heights. Nimbus Unicycles can supply additional sections and chains so you can build

the

Assembling your Nimbus Performer Girae

Your unicycle comes in kit form and should only take 15 minutes to assemble. First, determine that you

have all the components. If there are any parts missing, contact your dealer immediately.

Fit one quick release lever through the lugs provided on the ends of the straight, wheel frame sections

& centre section.

Assemble the frame:

For a 5 foot girae assemble the frame section in the following order; straight section, centre

section (with cranks) and wheel fork section.

For a 7 foot girae assemble the frame section in the following order; straight section, centre

section (with cranks) and wheel fork section.

Insert the seat with seatpost into the frame. Set and tighten all the quick-releases by lifting the lever

and hold it vertical, then tighten the thumb screw on the opposite side until it is nger tight. Pull the

quick-release lever down to lock them in position. If it is too hard to pull the lever down slacken the

thumb screw a little; if it does not hold the seat solid - release the lever and tighten the thumb screw

more and then repeat the process.

Prepare the wheel for assembly. Loosen the 15mm nuts on the wheel until they are near the end of

their threads. Loosen the bolts on the chain tensioners until they are near the end of their adjustment.

Invert the frame so that the seat is on the oor and the wheel fork

section is pointing upwards.Now slide the wheel into the forks. The

chain tensioners and wheel nuts should be on the outside of the

forks. Allow it to slide to the bottom of the slots (not stopped by the

tensioners).

Select the appropriate chains for height the of unicycle you are

building and place them over the chain-rings and sprockets.

Pull the wheel upwards and slide the tensioners over the end of the

frame. Be careful to keep both chains on the chain-rings and

sprockets and making sure the wheel is straight. Then tighten the

15mm wheel nuts by hand.

Using the allen key provided tighten the bolts on the chain tension-

ers. Work on tensioning both chains at the same time; tighten each

bolt a couple of turns at a time. The chains are tensioned when both

chains have about ½”movement in them when you press them in

their centre. Spin the wheel to check that there are no tight spots on

the chains and that it rotates freely.

When assembling your unicycle for the rst time you may nd that

the chains are unevenly tensioned from front to rear. The Nimbus

design allows for ne chain adjustment. Loosen the 6 bolts on each

of the chain-rings by a couple of turns while the chain is under

tension. Rotate the wheel a couple of times then re-tighten. Should

this not alleviate any uneven tension in the chain contact your dealer.

Then tighten the 15mm wheel nuts using the spanner provided.

Fit the pedals onto their correct cranks by matching the letter on the

cranks with those on the pedals. Tighten VERY rmly using your

15mm spanner (the left hand crank has a reverse thread).

Pump your tyre up, remember you will be putting all your weight on

this single wheel, so pump it up more than you would your bike.

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.

L

L

K. I.

J.

2 of 2INS-NIM-005-UK www.nimbusunicycles.com | Copyright © 2015 Nimbus Unicycles

Things that can go wrong

Girae Unicycles are pretty durable, but they do need maintaining. Here are things to look out for:

Loose pedals; normally found when riding or by holding the pedal and wiggling it. Tighten immediately! Check that the saddle is the

correct way around relative to the cranks. Riding on loose pedals will destroy the cranks.

Loose cranks; this is normally characterised by a creaking noise. Tighten the axle bolt immediately! If this is left loose it will destroy the

crank and possibly the axle.

Tight or loose bottom brackets (the spindle that the cranks are attached to). Occasionally the bearings require either tightening or

slackening. This can be observed by either excessive movement on the cranks or by the cranks not moving freely. Re-tensioning of the

bearings requires specialist tools that can be found at your local cycle store.

Damaged chains. Tight and slack spots on the chains during rotation are normally caused by stretched or worn chains. Replace chain if

this happens as it will wear the sprocket and chain-rings.

Lubrication of chain. Should there be signs of rust or if the chain should appear dry it should be lubricated. The chains should be

lubricated with light oil; it should then be“dried”with a cloth to remove any excess.

•

•

•

•

•

•

•

•

•

Warning

Always make sure that all nuts and bolts are correctly tensioned before every ride.

Always treat giraes with care. Dismounting can be dangerous, you should always be aware of obstacles near you when riding especially

when dismounting.

When learning to ride a girae it is advisable to use a spotter to assist you.

Always try to catch the unicycle when dismounting, repeated dropping of the frame on the oor will cause damage to the seat and

frame.

Table of contents