TKR Group 83 30 5 A45 C68 Repair manual

83 30 5 A45 C68

R0-22.06-V3

Supplementary set

Translation of the original owner‘s manual

2

3

1.

2.

3.

4.

5.

Safety

1.1 General instructions 4

1.2 Explanation of symbols 5

1.3 Labelling 5

1.4 Scope of supply 6

1.5 Safety instructions 7

Technical data

2.1 Technical specications 9

2.2 Technical data 10

2.3 Device components 11

Application

3.1 Intended use 12

3.2 Working with the tool - basic principles 13

3.3 Mounting and commissioning 13

3.4 Application - single module 15

3.5 Application - double module 17

3.6 Completing an operation and tool storage 19

Maintenance

4.1 Troubleshooting 20

4.2 Regular checking and maintenance use 20

Service

5.1 Disposal 21

5.2 Warranty 21

5.3 Declaration of Conformity 22

This owner‘s manual is protected by copyright. Any use beyond the restrictions imposed by copyright legislation undertaken without the permission of the manufacturer is

illegal and punishable by law. This also applies to the extraction of individual illustrations and use of texts as excerpts.

4

1.1 General instructions

State-of-the-art

This tool is state-of-the-art technology. To ensure that the

equipment operates safely, it must be operated in a proper and

safety-conscious manner.

Technical changes

In the interests of quality assurance, we reserve the unrestricted

right to carry out technical changes as a result of further techno-

logical developments and product improvements without prior

notication.

Reading the owner's manual

Before using the tool, make sure you read the own-

er's manual carefully and understand it. This manual

must always be available where the product is used.

Handling

All the actions necessary to ensure correct operation are de-

scribed in the owner's manual. Any working methods other than

those approved by the manufacturer are prohibited.

Faults

If faults occur, the operator may only eliminate those faults

through their own actions where the corresponding remedy is

described.

Warranty

The manufacturer accepts no liability for damage or injury

caused by improper repair or the use of third-party replacement

parts.

No warranty will be provided for damage caused to the device

due to the tool being used incorrectly.

Environment

Make sure that the tool is set up in a work area which is free from

sources of corrosive liquids, greases or oils.

Declaration of Conformity

The tool has been manufactured in accordance with

international guidelines. The relevant declaration of

conformity (CE, UKCA, CB) is included with this owner’s

manual.

Risk of damage to the tool

The tool must only be used as described in the in-

struction manual. It is expressly forbidden to misuse

the tool or to use it for any other purpose. Please

make sure that you and your sta handle the tool

correctly.

Risk of damage to the tool

The tool is designed for max. 16000 applications

according to EN 13155:2020.

Risk of injury

In addition to the owner's manual and the binding

provisions of the accident prevention regulations

which apply in the country and at the place of use,

you must also comply with the general (accepted)

rules for safe and professional working.

Technical personnel

Only trained and instructed personnel are authorized to carry

out the repair / maintenance work on the vehicles and vehicle

components concerned.

5.3

5

1.2 Explanation of symbols

Follow the manual

Follow the general

instructions

Wear protective gloves

Wear safety shoes

Warning

General source of danger

Warning

Hands could become trapped

Please note the following!

Arrow to clarify compression

For more information,

see chapter …

Arrow showing direction

CE symbol

UK Conformity Assessment

Product certicate

https://www.tkrgroup.com/

83305A45C68.htm

Some chapters in this instruction manual use internationally recognised warning symbols, warning notes and general in-

struction symbols.

The individual symbols are explained below. Follow all the instructions and safety rules.

6

Ergänzungssatz

83 30 5 A45 C68_A 91

Serien-Nr.: 000000, KW: 46/21

Max. Tragfähigkeit / WLL: 55kg

Eigengewicht: 0,53 kg

TKR Spezialwerkzeuge GmbH

Am Waldesrand 9-11,

D-58285 Gevelsberg

Zu verwenden mit 83 30 5 A45 C70

und 83 30 5 A2D EB9

F

H

G

A

B

C

D

E

4

3

12

J KI

1.3.3

1.3.1

1.3.2

83 30 5 A45 C68

1.3 Labelling

A Manufacturer‘s label

B Part number

C

Serial number / Date of manufacture

D Dead weight

E Max. Nominal load

F CE mark / UKCA mark

Labelling on the tool

G Company address

H Instructions for use

I Follow owner’s manual

J Wear safety shoes

K Warning

General source of danger

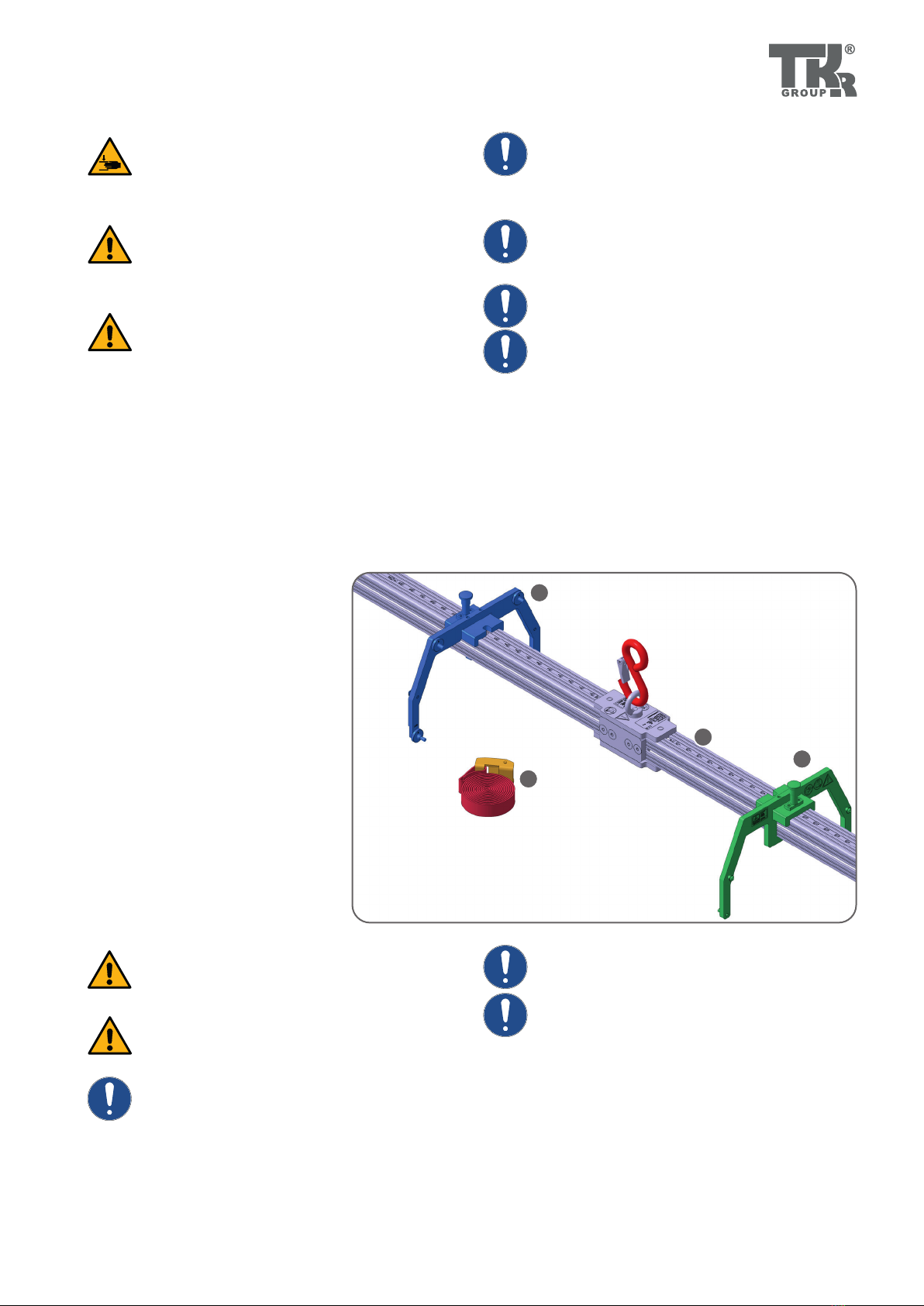

1.4 Scope of supply

Pos. BMW Part No. TKR Part No. Designation Pcs.

1 83 30 5 A45 C68_A BGR-BMW-00001815 Holding modul SE10-01 R 1

2 83 30 5 A45 C68_B BGR-BMW-00001816 Holding modul SE10-02 L 1

3 PSD-BED-00000400 Owner‘s manual german / english 1

4 PSD-BED-00000401 USB stick with language versions of the owner‘s manual 1

7

1.5 Safety instructions

CAUTION

If used with the wrong accessories, this may

cause material damage and bodily injury.

Not using original tools and original accessories will result in

a high risk to safety.Only original accessories and accessories

which have been approved by BMW may be used (see BMW

workshop manual).

Only use the screws provided or screws of the same size and

quality class.

No modifications may be made to the tool. The manufacturer

cannot accept liability for any conversion or modification of the

tool, nor for any resulting injury to persons or material.

CAUTION

Risk of material damage and bodily injury

The safety instructions must be read and understood before

repair.

Failure to do so may result in serious physical injury.

CAUTION

Risk of material damage and bodily injury

Untrained or uninstructed personnel are prohibited from

operating the tool. The tool must not be lent to untrained

persons.

Ensure that the tool is only operated by trained personnel who

are instructed in its use!

CAUTION

Risk of property damage and personal injury due

to falling load

Falling loads can cause serious injury or damage to property.

Before lifting, make sure that the load is correctly hooked in.

Risk of crushing and serious injury

Position hands and feet away from where there is a risk of

crushing.

Only use the tool on an even, dry, horizontal floor of sufficient

load-bearing capacity.

The tool is strictly approved solely for the

purposes for which the manufacturer has

designed it.

The tool must only be used for the activities described in this

owner’s manual. Never use the tool for any purpose except that

for which it is designed. Safety is no longer guaranteed if the tool

is used incorrectly.

The tool may only be used to lift the module approved by BMW.

The specified nominal load of 55 kg must not be exceeded.

The tool may only be used with the tool 83 30 5

A45 C70 mounted according to the instructions.

Wear safety shoes (according to ISO 20345, S2).

Wear protective gloves to prevent cut injuries.

Ensure that the owner’s manual is made

available to the operating personnel.

Each operator must carefully read and understand this owner’s

manual before using the tool for the first time. The instruction

manual must always be available where the product is used.

8

Follow the workshop manual from BMW AG.

Workshop manuals must be referred to under all

circumstances.

Follow the applicable national regulations for

the prevention of accidents.

In addition to the owner’s manual and the binding provisions of

the accident prevention regulations which apply in the country

of use, you must also comply with the general, accepted rules for

safe and professional working.

Pay attention to the nameplate and the labelling

on the tool. The tool and the labels on it must be

inspected visually every time before use.

Never throw the tool or allow it to fall.

When lifting and lowering the load, avoid bump-

ing into obstacles.

Using the device to carry people or climbing on

the raised load is not permitted.

Transporting the load over people is prohibited.

If any abnormality is identied, the tool must not be used.

Please contact Service ( 5.2).

9

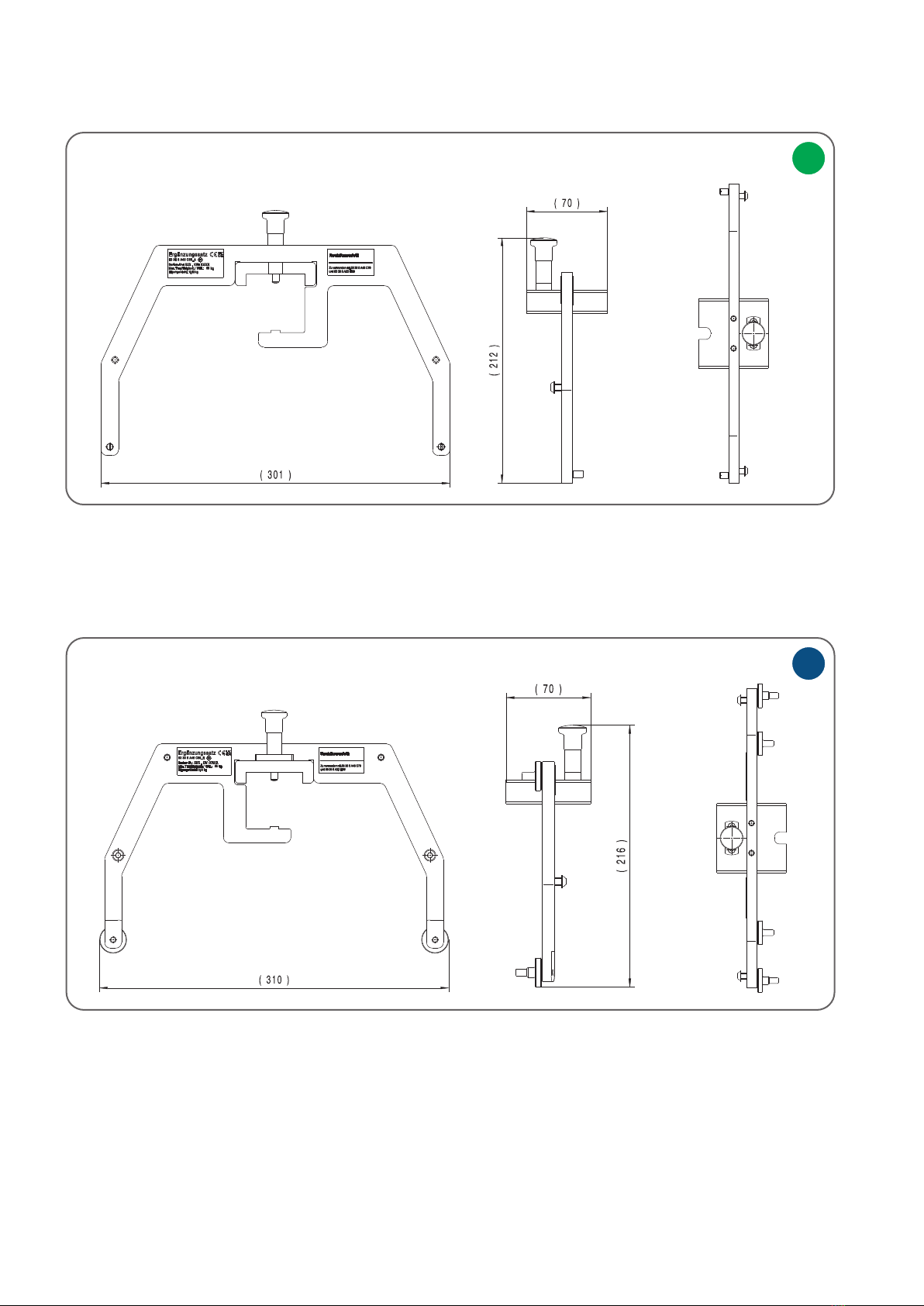

2.1 Technical Specifications

Holding modul SE10-01

Item number 83 30 5 A45 C68_A

Weight 0,53 kg

Max. Nominal load 55 kg

Dimensions (W x H x D) in mm 301 x 212 x 70

Coefficient for the static test 2 times (for deformation), 3 times (for fracture)

Temperature -20 °C to +60 °C / -4 °F to 140 °F

Holding modul SE10-02

Item number 83 30 5 A45 C68_B

Weight 0,61 kg

Max. Nominal load 55 kg

Dimensions (W x H x D) in mm 310 x 216 x 70

Coefficient for the static test 2 times (for deformation), 3 times (for fracture)

Temperature -20 °C to +60 °C / -4 °F to 140 °F

10

I

K

2.2 Technical data

Width: 310 mm

Height: 216 mm

Depth: 70 mm

Width: 301 mm

Height: 212 mm

Depth: 70 mm

front left top

front left top

83 30 5 A45 C68_B Supplementary set holding module SE10-02

83 30 5 A45 C68_A Supplementary set holding module SE10-01

11

D

D

FF

GG

AA

B

C

H

H

B

C

E

I

K

2.3 Device components

AScrew short M6 25 mm

BScrew long M6 30 mm

C

Parking position A/B

DLocking bolt

EShaft screw

FHolder

GSlider

HPan head screw M6 x 16

I Holding module SE10-01

K Holding module SE10-02

12

Intended use

Improper use

The tool kit 83 30 5 A45 C68 is used exclusively to carry a load of max. 55 kg as specified

by BMW AG.

The holders may only be used in conjunction with 83 30 5 A45 C70 retrofitted with

83 30 5 A2D EB9.

The load capacity of 55 kg stated on the 83 30 5 A45 C68 tool kit is the maximum nominal

load that may be lifted with this tool. The tools must not be used for any other purpose.

Lifting or lowering the tool is prohibited as long as persons are in the danger zone

of the load.

It is forbidden to stand under the load during the lifting or lowering process.

The operator must not initiate a lifting or lowering operation until he is satisfied that the

tool is properly secured.

It is forbidden to loosen the bolts of the tool when it is loaded.

When installing the tool, make sure that the operator is not endangered by the tool itself

or by the lifting equipment.

Lifting / lowering the load must be done slowly and carefully.

Consult the manufacturer before using the tool in special atmospheres (high humidity,

salty, corrosive, alkaline).

CAUTION

Risk of damage to property and personal injury

If the tool is defective, take it out of operation immediately.

Use only in conjunction with the accessories approved by the manufacturer and the

OEM (see OEM repair instructions and systems).

Use only in conjunction with a suitable lifting device that has sufficient load-bearing

capacity and stability

Make sure that the load does not swing / oscillate.

Only modules approved by BMW AG may be used.

3.1 Intended use

13

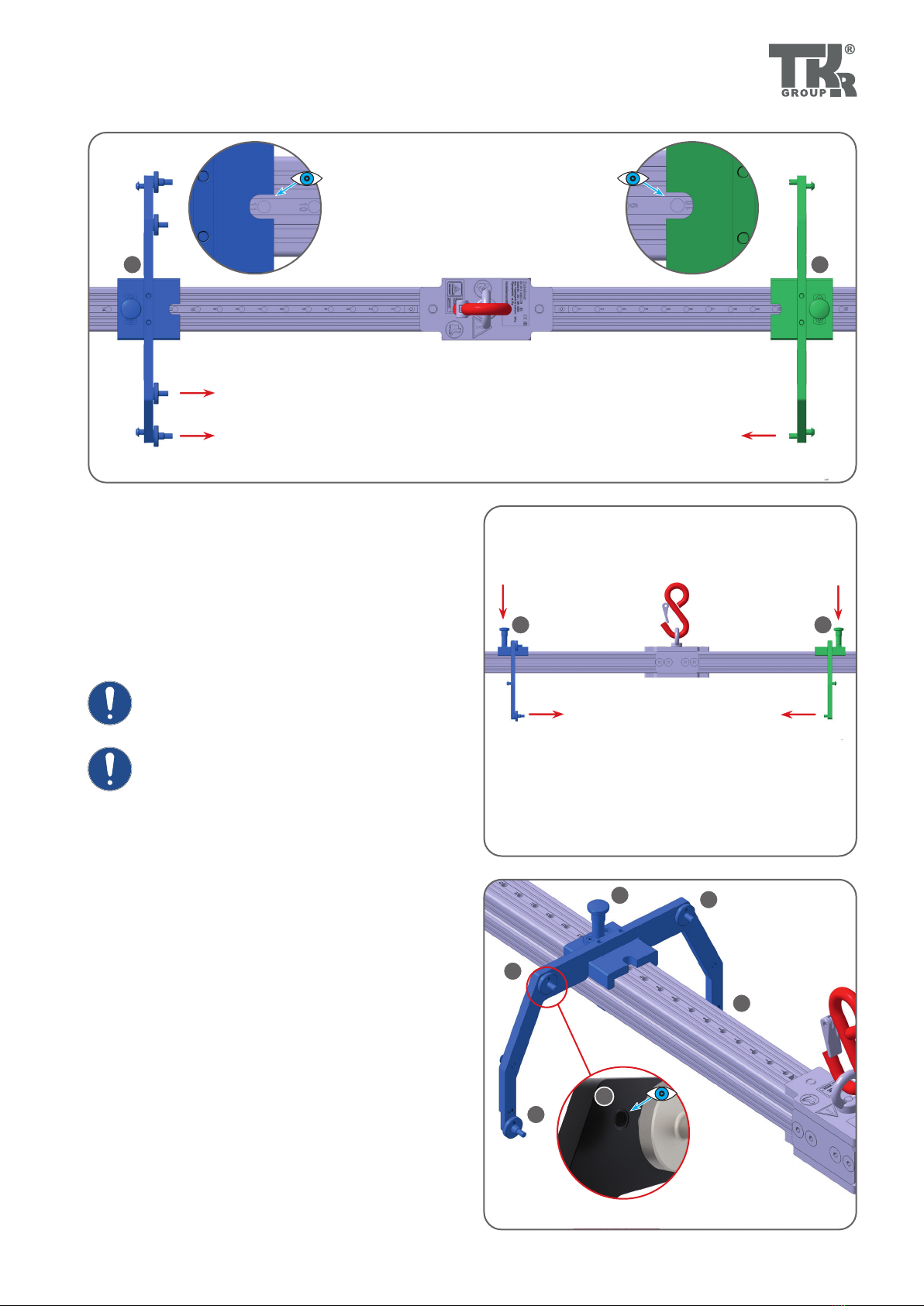

3.3.13.3.1

I

K

L

M

Risk of injury

The tool must be positioned so that there is no risk

of crushing.

Load capacity

Make sure that the rated load of 55 kg is not exceeded

when using the tool.

Stable positioning

The lifting device may only be used on level, fixed and

horizontal ground.

3.2 Working with the tool - basic principles

3.3 Mounting and commissioning

Warranty

The manufacturer accepts no liability for damage

caused by improper repair.

Incorrect operation of the device which results in

damage to the device excludes warranty.

Only use the screws supplied.

Only use the specified adjustment positions.

The lifting device may only be moved in the low-

est position.

Observe the lifting device and load during all

movements.

Follow the BMW repair instructions.

Remove and lift the module according to BMW

instructions.

Take into account the approval of the lifting device.

Take into account the permissible lifting weight

of the lifting device.

I Holding module SE10-01

KHolding module SE10-02

LTraverse

(83 30 5 A45 C70 &

83 30 5 A2D EB9)

MLashing strap

(Accessory 83 30 5 A45 C70)

14

3.3.2 3.3.3

3.3.4

3.3.5

D

D

D

L

N

L

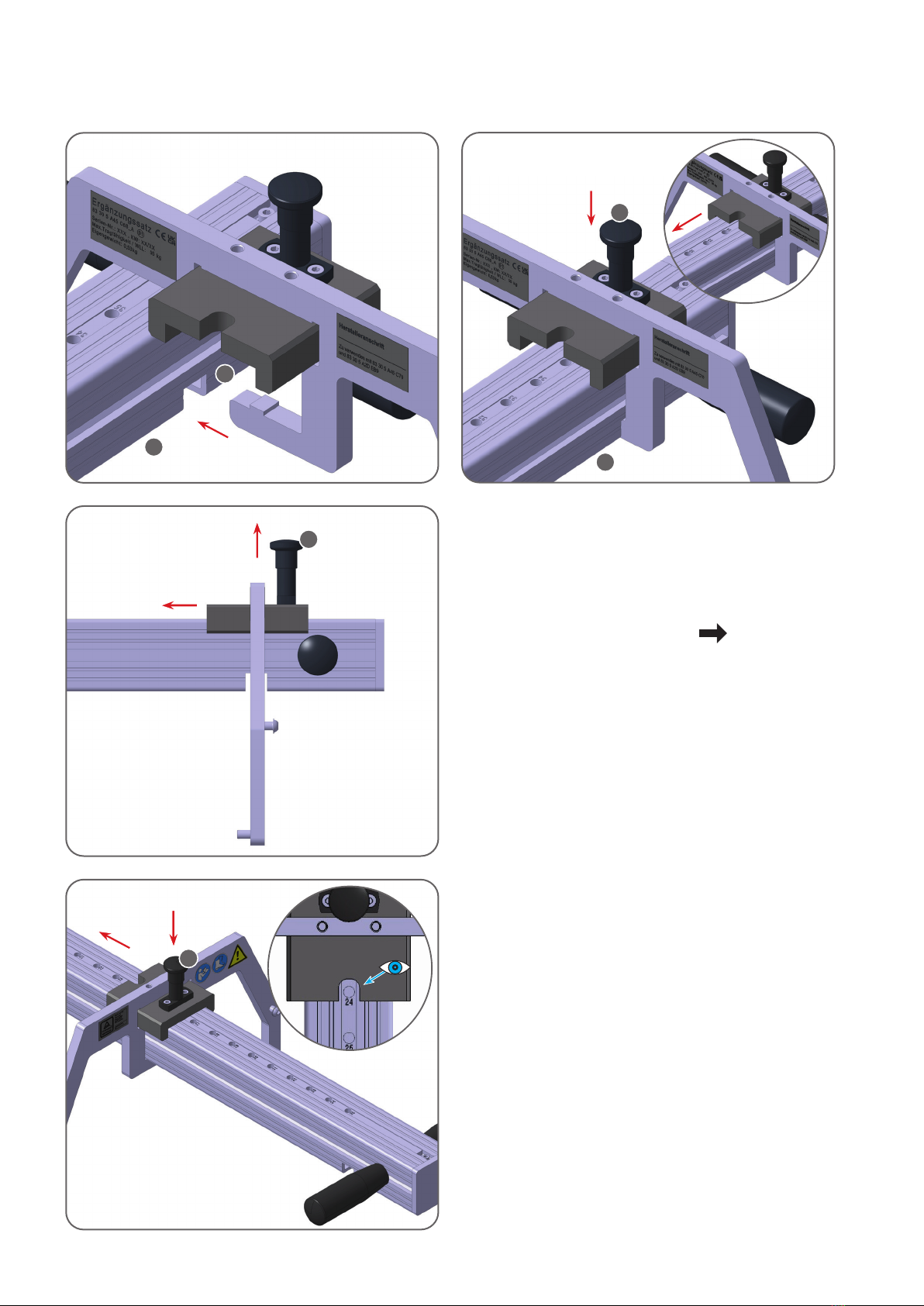

3.3.2 - 3.3.3

For the assembly of the supplementary set 83 30 5 A45 C68,

place the holders SE10-01 and SE10-02 on the traverse [L] via

the groove [N] on the underside of the profile, as required. Make

sure that both the screw „B“ and the screw „A“ for the intended

module are used for the SE10-02 holder ( 3.4, 3.5).

3.3.4 - 3.3.5

To move the holder on the profile, the locking bolt [D] must be

pulled up. Depending on the module, the holder must be moved

to the respective marking (1-35). Read the marking through the

recess in the slide (3.3.5).

15

3.4.1

3.4.2

3.4.33.4.3

D

D

D

A

A

B

B

C

IK

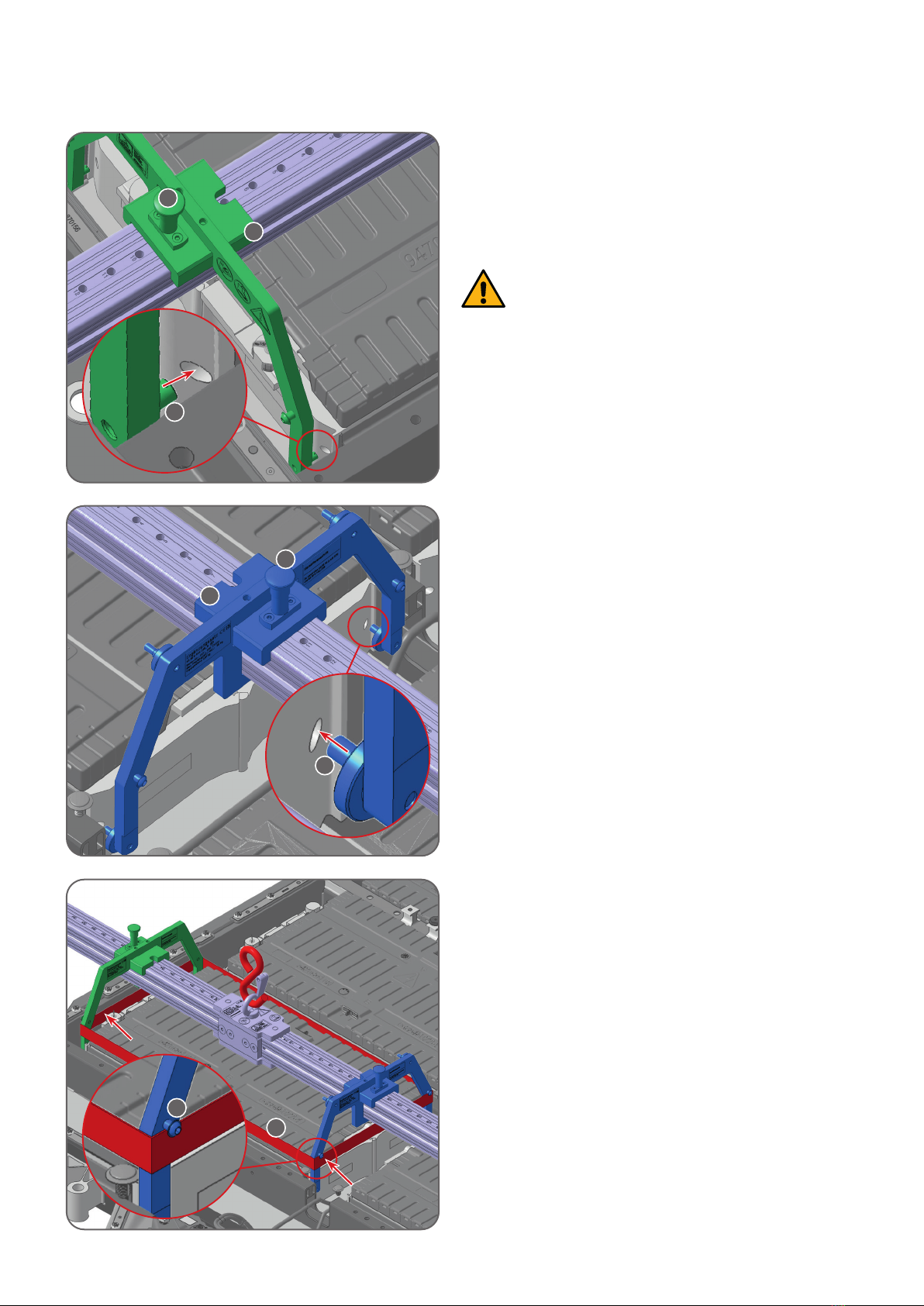

3.4.1 - 3.4.3 Setting position 7 and 8

For the correct use of the tool 83 30 5 A45 C68, slide the crane

operation holders to positions 8 [I] and 7 [K] and lock them

with the locking bolt [D]. Use the screws „A“ [A] on the SE10-02

[I] holder. Meanwhile, the screws „B“ [B] come into the parking

position [C] provided for this purpose. Make sure that the holders

are arranged symmetrically to avoid tilting or skewing of the tool.

Make sure that the holding pins always point in-

wards (3.4.1), otherwise the tool cannot be used.

Make sure that the holders are installed as shown

in the pictures.

3.4 Application - single module

16

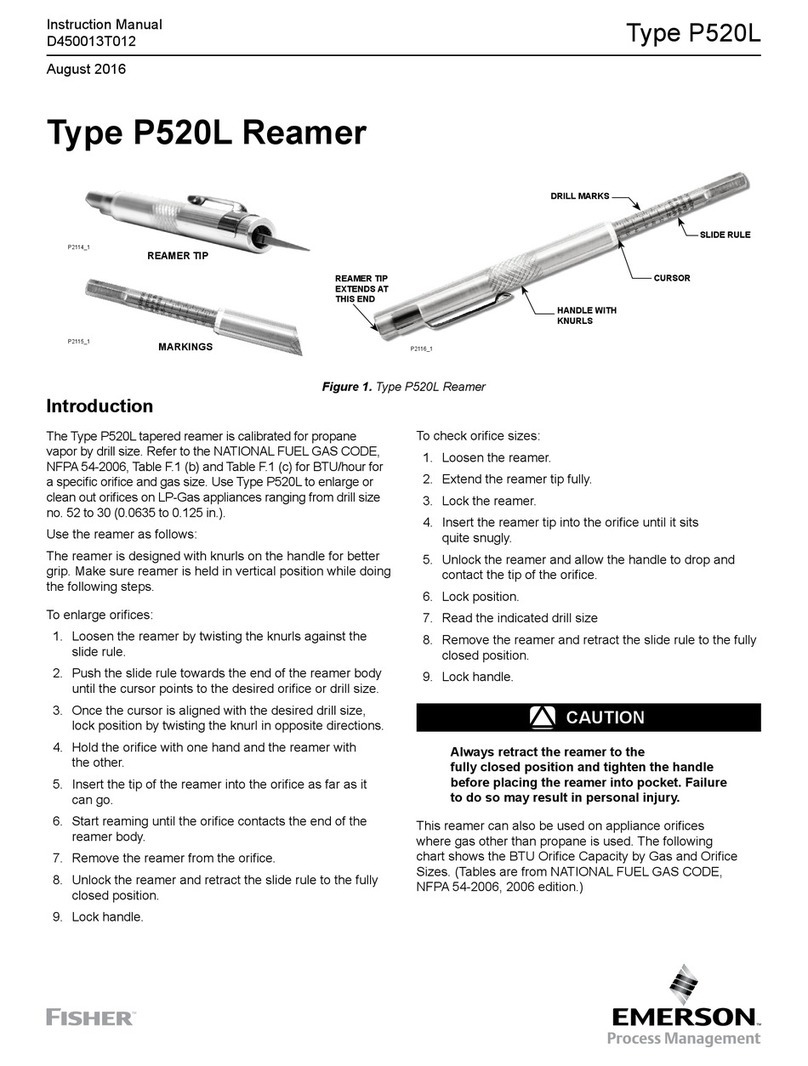

3.4.43.4.4

3.4.53.4.5

3.4.6

D

D

E

E

H

I

M

H

3.4.4 - 3.4.6

Insert the shaft screws [E] of the holders 83 30 5 A45 C68 into

the holes (3.4.4-3.4.5) of the single module. Fix with the locking

bolt [D] at position 7and 8. Connect the holders for securing

with the lashing strap [M] from the tool kit 83 30 5 A45 C70.

The single module may only be lifted when the

shaft screw [E] are fully seated in all mounting

holes and the lashing strap [M] is attached below

the pan head screw [H] (3.4.6).

17

3.5.1

3.5.2

IK

3.5.33.5.3

A

A

B

B

C

D

D D

3.5 Application - double module

3.5.1 - 3.5.3 Setting position 10 and 11

For correct use of the tool 83 30 5 A45 C68, slide the holders for

crane operation to positions 11 [I] and 10 [K] and lock them with

the locking bolt [D]. Use the screws„B“ [B] on the holder SE10-02

[K]. Meanwhile, the screws„A“ [A] come into the parking position

[C] provided for this purpose. Make sure that the holders are ar-

ranged symmetrically to avoid tilting or skewing of the tool.

Make sure that the holding pins always point in-

wards (3.5.1), otherwise the tool cannot be used.

Make sure that the holders are installed as shown

in the pictures!

18

3.5.43.5.4

3.5.53.5.5

I

K

3.5.63.5.6

M

D

D

E

E

H

3.5.4 - 3.5.6

Insert the shaft screws [E] of the holder 83 30 5 A45 C68 into the

holes (3.5.4-3.5.5) of the double module. Fix with the locking

bolt [D] at position 10 and 11. Connect the holders for securing

with the lashing strap [M] from the tool kit 83 30 5 A45 C70.

The double module may only be lifted when the

shaft screws [E] are fully seated in all mounting

holes and the lashing strap [M] is attached below

the pan head screw [H] (3.5.6).

19

3.6 Completing an operation and tool storage

Always examine the tool for possible damage be-

fore and after use.

Dismantle the tool from the crossbar.

Store tool lying down.

Always store the tool in a dry and safe place. Avoid

contamination.

Clean the tool before storing it.

Important!

Always store the lashing strap together with the

traverse in the designated place.

20

4.1 Troubleshooting

Fault Possible cause Remedy Chapter

Holder does not t

Wrong module Check module labelling 2.3

Wrong holder Only use holders that have been sent along 1.4

Holders points do not t

Wrong holder points Check the holder points 3.1

Incorrect holders Observe the labelling on the type plate 1.3

Module has play

Forgotten lashing strap Use the lashing strap of the tool kit

83 30 5 A45 C70 3.4, 3.5

Lashing strap fastened in the

wrong place

Attach the lashing strap underneath the pan

head screw. 3.4, 3.5

The holder does not sit properly

on the storage unit Wrong screw used Use correct screw 3.4, 3.5

Checks may only be carried out by qualified per-

sonnel. The tool must be inspected at least once a

year. If you are using the tool frequently, carry out

the inspection at shorter intervals. Essentially, the in-

spections are visual and functional ones, required to

evaluate the condition of parts in terms of damage,

wear, corrosion or other changes and to determine

the completeness and effectiveness of the safety fa-

cilities.

Repairs may only be carried out by the manufacturer

or by persons authorized by the manufacturer.

4.2 Regular checking and maintenance

Repair surface damage to prevent corrosion. Clean

the device every six months, when heavily contam-

inated or as necessary.

The checks must be arranged by the operator.

The nameplate must always be perfectly legible.

Otherwise the operating permit will be invalidated.

All screw connections must be checked regularly for

tightness.

Table of contents

Other TKR Group Tools manuals

Popular Tools manuals by other brands

Desoutter

Desoutter SB010-AB1600-S4Q manual

Emerson

Emerson Fisher P520L instruction manual

Gage Bilt

Gage Bilt GB745/206-500 Original instructions

RIDGID

RIDGID JobMax E Series Operator's manual

Parkside

Parkside PUS 4 A1 Operating instructions and safety instructions

Cessna

Cessna 172S Skyhawk Pilot operating handbook