Nira i7x User manual

NIRA i7x

Handbook

NIRA i7x Handbook version pA7, August 2016

© 2005-2016 Nira Control AB 2

© Copyright 2005-2016

This handbook is protected by copyright laws. It may not be redistributed in

any form without written consent of Nira Control AB.

Release 2016-08-30

The purpose of this handbook is to serve as a guide during installation and

calibration of NIRA i7x. Descriptions, content and specifications in this

handbook may be changed at any time. This handbook could contain errors –

therefore it should not be regarded as a definitive installation guide. Nira

Control AB is not responsible for any personal or property damages due to

errors in this handbook, the professional installing NIRA i7x is responsible for

the installation.

Misuse of NIRA i7x and/or NIRA rk can cause severe personal injury and

engine damage. Nira Control AB is not responsible for any injuries, accidents

or damages due to misuse or ignorance.

Repairs of NIRA i7x, e.g. replacement of parts, will affect the safety of the

product and are not allowed under any circumstances. Nira Control AB is not

responsible for any problems, accidents etc, caused by non-approved parts

or repairs not carried out by Nira Control AB.

NIRA i7x must be installed by professional automotive technicians in

accordance with the instructions in this handbook, following good practice.

NIRA i7x is only intended for racing use and not for use on public roads. It is

not certified for use on vehicles subject to emission standards unless the

appropriate waivers have been issued. Please check with the relevant

authorities for more information.

NIRA rk is protected by applicable software copyright laws. You may not

distribute this software without the written consent of Nira Control AB. You

may not copy this software. Your purchase of NIRA i7x includes a single

license to use NIRA rk together with NIRA i7x.

© 2005-2016 Nira Control AB 3

1 Overview ...................................................................................................5

1.1 Content of your NIRA i7x Package ....................................................5

1.2 Glossary.............................................................................................6

1.3 NIRA i7x Functionality .....................................................................11

2 Combustion, Lambda and Measurement Principles..................................14

2.1 Relationship Between A/F and Lambda ..........................................14

2.2 The Effect of Different Lambda Values............................................15

2.3 Measurement Principles ..................................................................16

2.4 Fuel delivery ....................................................................................19

3 Installing NIRA i7x....................................................................................22

3.1 Crank Position Sensor (CKP) and Trigger Wheel .............................22

3.2 Cam Position Sensor (CMP) .............................................................26

3.3 Throttle Position Sensor (TPS) .........................................................27

3.4 Manifold Absolute Pressure (MAP) and Intake Air Temp (MAT) ......28

3.5 Boost pressure sensor (pre throttle pressure sensor).......................29

3.6 Engine Coolant Temperature Sensor (ECT).....................................29

3.7 Manifold Air Temperature Sensor (MAT).........................................30

3.8 Lambda Sensor................................................................................30

3.9 Exhaust Gas Temperature. ..............................................................32

3.10 Anti Lag System (ALS) Switch ..........................................................32

3.11 Launch Control Button ....................................................................32

3.12 Aux Inputs .......................................................................................33

3.13 Ignition ............................................................................................33

3.14 Fuel Pressure Regulator (FPR)..........................................................34

3.15 Fuel Injectors ..................................................................................34

3.16 Boost Pressure Actuator ..................................................................35

3.17 IAC (Idle Air Control) .......................................................................37

3.18 Main Relay .......................................................................................39

3.19 Fuel Pump Relay..............................................................................39

3.20 Tachometer .....................................................................................40

3.21 ALS Solenoid ...................................................................................40

3.22 Wheel Speed Sensors......................................................................40

3.23 Aux Outputs ....................................................................................41

3.24 Mounting NIRA i7x in the Car..........................................................41

© 2005-2016 Nira Control AB 4

4 NIRA rk Software......................................................................................43

4.1 Installation of NIRA rk......................................................................43

4.2 Getting Started................................................................................44

4.3 Using NIRA rk ..................................................................................47

4.4 Parameters.......................................................................................49

4.5 PID Controllers ................................................................................60

4.6 Gauges ............................................................................................62

4.7 Logging ...........................................................................................65

4.8 Locking the i3d Data Set .................................................................68

4.9 FlexiPorts™ - Set up........................................................................68

4.10 Auto Fuel Calibration ......................................................................70

4.11 Ignition/Fuel Mapping.....................................................................70

5 Starting the Engine ..................................................................................70

5.1 Setting Up Parameters Offline.........................................................70

5.2 Going Online...................................................................................93

5.3 Quick Troubleshooting Guide .........................................................97

5.4 Other Adjustments ..........................................................................98

6 Mapping your Engine Using NIRA rk ........................................................99

6.1 Tables ..............................................................................................99

6.2 Calibrating Ignition..........................................................................99

6.3 Calibrating Fuel .............................................................................100

6.4 The Engine Runs Unevenly or Stalls ..............................................108

6.5 Adjusting the Boost Pressure Control............................................109

6.6 IAC –Idle Speed Control...............................................................109

6.7 ALS –response system ..................................................................110

6.8 Launch Control ..............................................................................111

6.9 Flat Shift ........................................................................................111

6.10 Traction Control.............................................................................113

7 Electrical Specifications..........................................................................117

7.1 Input ..............................................................................................117

7.2 Output...........................................................................................120

7.3 Communication .............................................................................122

© 2005-2016 Nira Control AB 5

1

Overview

NIRA i7x is a sophisticated electronic engine management system developed

specifically for racing. NIRA i7x controls ignition, fuel injection, idle speed,

boost pressure and several other engine functions. It can be used with many

different types of engines.

1.1 Content of your NIRA i7x Package

When you purchased NIRA i7x, you should have received the following:

NIRA i7x

Wiring harness

NIRA rk calibration software

Communication interface (Kvaser CAN-dongle)

1.1.1 NIRA i7x

NIRA i7x is a highly sophisticated, triple core microprocessor based engine

management system designed for motorsport applications. It controls

ignition, fuel injection, boost pressure, idle speed and several other engine

functions. NIRA i7x offers an unusual level of flexibility in how input signals

are interpreted and processed. It also gives you significant control over the

mapping of the output signals. This allows NIRA i7x to work with many

different sensors, actuators and engine types. Setup, configuration and

programming of NIRA i7x is done via the NIRA rk software.

1.1.2 Wiring Harness

One end of the wiring harness is pre crimped with NIRA i7x terminals. The

terminals are easy to connect to the right position in the NIRA i7x connector.

The other end of the harness is a set of pigtails used for connecting power,

ground, sensors and actuators. To simplify the work of installing the harness,

© 2005-2016 Nira Control AB 6

each wire in the harness is marked every 70 mm (~3”) with its function in

clear text. This makes it possible to cut the wire to desired length and still

read its function.

1.1.3 NIRA rk

NIRA rk is the calibration software that allows you to setup and configure a

large number of parameters in NIRA i7x. It is designed to run on a PC using

the Windows operating system and communicates with NIRA i7x via a Kvase

CAN-dongle.

The many functions of NIRA rk are described in detail starting in chapter 4.

NIRA rk is protected by applicable software copyright laws. You may not

distribute this software without the express written consent of Nira Control

AB. You may not copy this software other than for personal use. Your

purchase of NIRA i7x includes a single license to use NIRA rk together with

NIRA i7x.

1.1.4 Communication interface

The Kvaser CAN-dongle connects NIRA i7x to the PC running NIRA rk

software. The CAN-dongle connects to your PC via a USB port.

1.2 Glossary

Absolute pressure

Absolute pressure is measured starting at 0 kPa.

This is the pressure in vacuum. At sea-level the

absolute pressure is approximately 100 kPa, +/- 10

kPa depending on the weather (high or low

pressure.)

Alpha-N

Methodology to compute the amount of fuel to

inject based only on rpm and throttle angle.

Sometimes referred to as “throttle mapped.”

This mapping approach can be difficult to use and

requires a high resolution throttle position sensor

potentiometer.

On engines with aggressive camshaft profiles, the

pressure in the intake manifold fluctuates

significantly. In such cases it’s not possible to get a

© 2005-2016 Nira Control AB 7

stable MAP reading and throttle mapping is the

only workable approach.

ALS

Anti Lag System. Sometimes called “response

system.” Often used in racing and rally cars with

turbo engines. ALS maintains the boost pressure

even though the throttle is closed. With ALS

engaged, combustion in the exhaust manifold is

common.

Ambient pressure

The pressure around us; approx 90 –110 kPa

absolute pressure depending on the weather (low

or high pressure.) The pressure decreases with

altitude.

Csd

Crankshaft degrees. A four-stroke engine turns

720 crankshaft degrees during one complete

combustion cycle. (The camshaft turns half as fast

as the crankshaft and thus completes 360 degrees

during the four strokes.)

Default values

These are base values or recommended values.

EGTC

Exhaust Gas Temperature Control. Nira-developed

exhaust gas temperature measurement unit. Can

be connected to NIRA i7x.

GND

Ground (kl31)

Grounding can be done to the body, engine block

or directly to the battery. Ground is sometimes

referred to as minus or 0 Volt. Poor ground

connections can cause problems that are hard to

find. Make sure the ground connections are

proper.

MAP

Manifold Absolute Pressure. Pressure in the intake

manifold after the throttle plate. On a naturally

aspirated engine this varies between 25kPa and

100kPa.

MAT

Intake Air Temperature or Manifold Air

Temperature. Refers to the temperature of the air

in the intake manifold. The temperature can be as

much as 150 degrees hotter than the ambient air

temperature on a turbo charged engine.

The density of the air decreases with increasing

temperature. Therefore it’s important to be able to

measure the temperature accurately in order to

determine the engine load.

© 2005-2016 Nira Control AB 8

Premature detonation

(knock)

The flame front in the combustion chamber

advances at around 1 000 m/s instead of the

normal 100 m/s due to detonation instead of

controlled combustion.

Knocking results in very high local combustion

temperatures and damaging local detonations.

Pull-up resistor

A pull-up resistor connects an input or an output to

+12 V (or +5 V). It pulls up the voltage on the input

or output to +12 V (or +5 V).

Pull-down resistor

A pull-down resistor connects an input or an

output to ground (0V). It pulls down the voltage on

the input or output to ground level (0V).

Sequential injection

Each injector on/off is timed independently of all

other injectors.

By taking camshaft timing into account, the engine

can be made to run more smoothly and efficiently

and to provide more low-end torque.

Speed-density

A simple and straightforward method for

calculating the correct amount of fuel to inject

based on MAP, MAT and the engine speed.

Because MAP is used, any changes in ambient

pressure are accounted for.

Terminal 15 (kl 15)

Terminal 15 is a term used to describe battery

voltage (+12 V) after the ignition switch. Most

sensors and actuators used with NIRA i7x that

require battery voltage should be connected to

terminal 15.

Terminal 30 (kl 30)

Terminal 30 is a term used to describe battery

voltage (+12 V)

Terminal 31 (kl 31)

Se Ground

Throttle

The throttle is controlled by the gas pedal and

determines the amount of air entering the intake

manifold.

VE

(Volumetric Efficiency)

A V.E. value of 1.0 means that 100% of the cylinder

volume gets filled during the intake stroke. For

example, if the cylinder volume is 500 cc, the

engine breathes in exactly 500 cc of air.

Do not confuse V.E. with engine efficiency. A V.E.

value above 1.0 means there’s some amount of

supercharging due to resonance, which is unusual.

If, during calibration, the V.E. table has values

above 1.1, or the lambda table is not in line with

© 2005-2016 Nira Control AB 9

actual (measured) lambda, you may have made a

mistake.

Many standard engines have an average V.E. of

0.85.

60-2 lost

Common pattern on the crankshaft trig wheel. The

trig wheel has 58 tooth-window pairs, spaced 6

degrees apart. Two tooth-window pairs are

missing (“2-lost”) and the resulting wider window

serves as the reference point.

© 2005-2016 Nira Control AB 10

1.2.1 NIRA Rk Naming

Abbreviation

Meaning

Description

Als

Anti Lag System

-

Am

Air Mass

-

App

Accelerator Pedal Position

-

Bac

Boost Actuator Control

This is used if a

boost actuator is

used with position

feedback

Bc

Boost Control

Normally used in

Motorsport if not an

advanced boost

control is used (for

example VGT with

position feedback)

Bv

Base Variable

Variables to show

the user data. For

example Engine

Coolant temperature

Dge

Diagnostic

-

Di

Digital Input

-

Do

Digital Output

-

Es

Engine State

-

Esc

Engine Speed Control

-

Etm

Electronic Throttle Module

-

Fm

Fuel Mass

-

Ign

Ignition

-

Lmc

Lambda Module Control

-

Tpu

Time Process Unit

Processor that read

values from time

critical sensors (for

example crank

sensor)

Vh

Vehicle

Example traction

control variables

(TC).

© 2005-2016 Nira Control AB 11

1.3 NIRA i7x Functionality

NIRA i7x reads sensor values, processes the data and sends output signals to

various actuators.

NIRA i7x is a fully sequential engine management system for engines with up

to 8 cylinders.

By using the NIRA rk software, you have the ability to modify many of the

parameters that control the data processing and the output signals in NIRA

i7x.

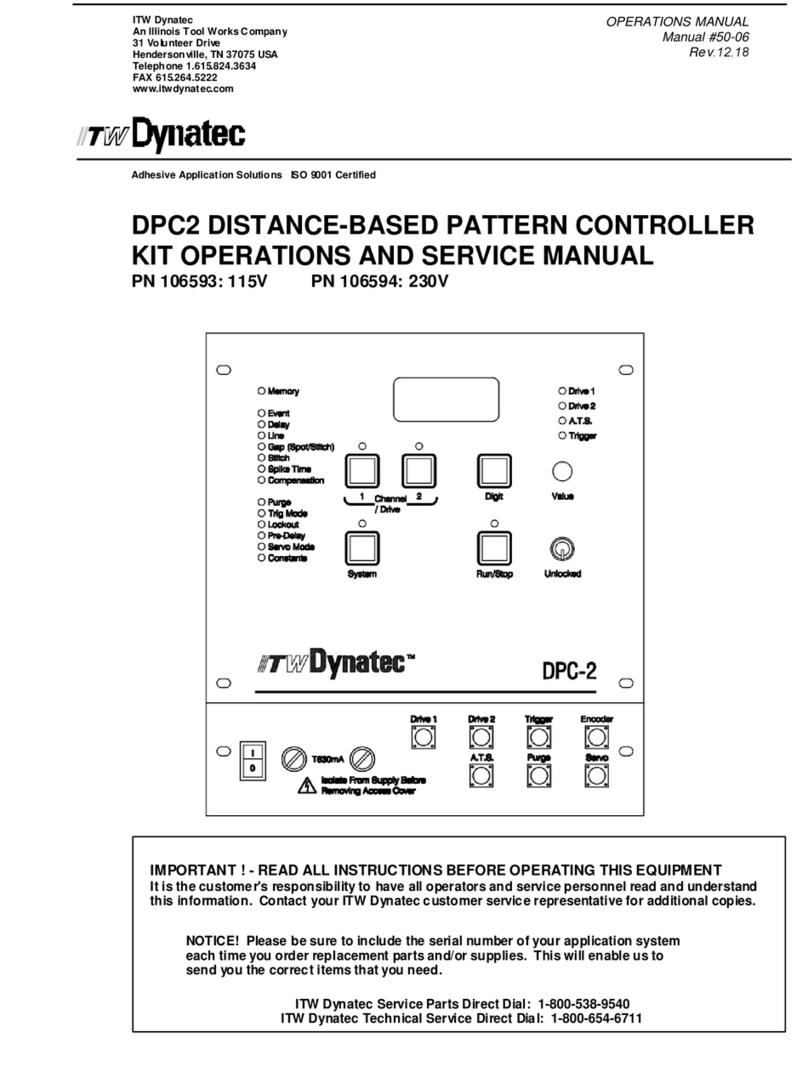

Picture 1-1: Overview of NIRA i7x inputs and outputs.

Picture 1-1 above shows the input signals and the output controls of NIRA

i7x. Section 1.3.1 below lists all sensors used by NIRA i7x. Section 1.3.2 lists

additional input controls used by NIRA i7x and section 1.3.3 lists output

functions.

1.3.1 Sensors

MAP sensor (Manifold Absolute Pressure)

Boost sensor (Pre throttle pressure measurement)

MAT sensor (Manifold Air Temperature)

CKP sensor (Crankshaft Position) Inductive or Hall

TPS (Throttle Position Sensor, measures the throttle butterfly angle)

CMP sensor (Cam Position. The crankshaft rotates two revolutions per

four strokes in a four-stroke engine. The camshaft rotates half as fast as

the crankshaft so it completes one revolution per four strokes. The

© 2005-2016 Nira Control AB 12

CMP sensor is used to determine in which of the two crank revolutions

the engine is. This is used during cranking.) Inductive or Hall

ECT (Engine Coolant Temp)

Fuel Temperature (for display purpose)

Fuel Pressure

Oil Pressure

Lambda sensor (NIRA i7x Street controls Bosch LSU 4.9 lambda

sensor without external electronics)

EGTC (Exhaust Gas Temperature. Measures the exhaust gas

temperature in the exhaust manifold where the headers collect. NIRA

i7x handles either digital egtc reading, resistive reading or 0-5V analog

input)

Flat Shift Switch

11 Aux inputs ( 3 Analog inputs, 6 Resistive temp sensors, 2 Digital

inputs)

1.3.2 Input Controls (driver controlled)

Switch for Anti Lag System (ALS, response system)

Button for Launch Control

1.3.3 Output Functions

NIRA i7x processes the input signals and controls the output signals in order

to manage the following actuators.

8 Fuel injectors (amount and sequence)

8 Ignition coils (timing and dwell time). NIRA i7x controls active coils

(with integrated drivers) or passive coils that are connected to NIRA

i7x via an external ignition driver

Boost pressure control valve (controls boost pressure H bridge or

PWM output)

IAC (Idle Air Control; controls engine idle speed via ignition

compensation and an IAC valve or motor)

Fuel pump relay

Main relay (for actuator power supply)

Fan relay (for controlling radiator fan)

Tachometer output (engine speed)

© 2005-2016 Nira Control AB 13

ALS solenoid (for additional bypass air)

4 Aux outputs ( Auxiliary relay control and 3 PWM outputs)

Electronic throttle actuator

In addition to standard engine management, NIRA i7x includes a set of

additional engine control strategies and functions. These are listed in section

1.3.4 and are described in detail later in this manual.

1.3.4 Additional Control Strategies/Functions

Launch Control –enables fast take-offs with stable, pre-programmed

torque values

Anti Lag System (ALS) –maintains boost pressure during shifts and

when letting off on the gas

Flat Shift –reduces engine torque to enable quick gear shifts

FlexiPorts™ - a very advanced function that controls fuel injection,

ignition, boost pressure and Launch Control in relation to input axes

configured during calibration

Acceleration Fuel Enrichment –advanced fuel enrichment during

acceleration

Cranking Fuel Enrichment –allows precision control of fuel injection

during cranking based on parameters such as ambient temp, time

since last cranking attempt etc

Alarms –adjustable alarm thresholds reduce the risk of engine

damage

Limp home –any input sensor value out of range is replaced with a

reasonable value to keep the engine running, albeit at reduced power.

Sets error code

Diagnostics –read error codes

Logging –advanced data logging and graphical analysis tools in NIRA

rk software

© 2005-2016 Nira Control AB 14

2

Combustion, Lambda and

Measurement Principles

For combustion to take place, oxygen needs to be available. The oxygen

content of the air changes with air temperature and pressure. In an engine

there are different ways of measuring the amount of air entering the engine,

but regardless of the technique used, some way of converting the

measurements into an absolute air mass is needed.

Once the air mass has been calculated, it’s possible to meter the amount of

fuel needed. The optimal air to fuel ratio, as measured in weight, depends on

the type of fuel.

For instance, 1 gram of standard gasoline should be mixed with 14.6 grams

of air to achieve complete combustion. This air/fuel ratio is known as the

stoichiometric ratio and is also referred to as lambda 1.0. A richer mixture

(more fuel) results in lambda < 1.0. A leaner mixture results in lambda > 1.0.

Lambda is central to the calibration of NIRA i7x and it’s important to

understand what it represents and how it’s used.

2.1 Relationship Between A/F and Lambda

A/F means Air-Fuel ratio. It’s always given as a ratio of masses. The

stoichiometric A/F is different for different types of fuel.

Example of stoichiometric A/F ratios:

Air/98 Octane Gasoline = 14.6

Air/Methanol = 6.8

Air/Ethanol = 9.0

Air/E85 = 11

© 2005-2016 Nira Control AB 15

Lambda is defined as:

λ= (actual air fuel ratio)/(stoichiometeric ratio)

The definition of lambda is the same regardless of fuel type, which is

advantageous, especially when switching between fuels.

Example of lambda calculation (using gasoline):

If an engine is running lean, the actual A/F may be 15.4:1.

λ= 15.4/14.6 = 1.05

If an engine is running rich, the actual A/F may be 14.0:1.

λ= 14.0/14.6 = 0.96

Some wide-band lambda sensors use A/F in their specs, so it is important to

understand the relationship between A/F and lambda.

2.2 The Effect of Different Lambda Values

If lambda is far from 1.0, the air-fuel mixture can’t be ignited. This causes

engine misfires. The point at which these occur depends on several different

parameters, such as the temperature in the combustion chamber, the

efficiency of the ignition system and how well mixed the air and fuel are.

Typically, lambda has to stay within the 0.7 –1.2 range.

If the air and fuel haven’t mixed fully before ignition, some amount of fuel will

be wasted. This is common, especially during transients and at low rpm’s.

Consequently, most engines run better when the mixture is a bit richer than

lambda 1.0. A good rule of thumb is 5-7% richer, or lambda 0.95-0.93.

Adding even more fuel usually lowers engine efficiency at a given intake air

pressure but it also cools the combustion chamber. This is exploited in turbo

charged engines where the boost pressure can be increased somewhat while

avoiding premature detonation, or engine knock.

The end result is that by running a turbo engine extra rich, you can gain more

power. On a normally tuned turbo engine, it’s common to adjust lambda

down towards 0.84. On an aggressively tuned engine, lambda may have to

go even lower if there are problems with the exhaust gas temperature being

too high.

© 2005-2016 Nira Control AB 16

2.3 Measurement Principles

All engine management systems have to determine engine position and

calculate the correct mass of fuel to inject for a given mass of air. The masses

of the fuel and air vary with temperature and pressure.

2.3.1 Angular positioning

The engine angular position of the crank shaft is crucial for accurate engine

control.

The most common types of sensors used for angular positioning in

automotive applications are

Hall sensor

Inductive sensor

Hall sensor

The Hall Effect is based on a magnetic field that affects electrons moving in a

conductor. The sensor is in need of power supply and the output is a square

wave with fixed voltage levels. The output level is equal or less the supply

voltage.

Example of CKP & CMP hall sensors plotted over one revolution. “CKP is a 24-1 pattern”

Inductive sensor

The inductive sensor or VR sensor (Variable Reluctance) uses the

phenomenon of induced voltage in the sensor. The voltage is induced when

ferrite steel passes the sensor and changes the flux through the sensor’s built

in magnet. Therefore the sensor is not in need of any power supply. The

output voltage from the sensor will go from negative to positive values. The

output levels from the sensor will increase proportionally to the speed of the

tooth passing the sensor.

© 2005-2016 Nira Control AB 17

Example of an inductive CKP sensor signal when a ”2 lost” is detected from a pulse wheel

with a ”60 – 2 lost” pattern

Zero crossing detection and crank polarity

When using an inductive sensor the system uses zero crossing detection to

determine the position of the crankshaft.

Examlpe of zero crossing detection for falling & rising edge.

The picture above shows two types of zero crossing.

The red circle shows zero crossing at the transition from high level to

low level, falling edge

The blue circle shows zero crossing at the transition from low level to

high level, rising edge. In the “lost gap” the zero crossing is widely

spread and can’t be uniquely defined

By swapping the polarity of the inductive sensor the signal will be inverted.

NIRA i7x uses zero crossing detection at falling edge, which means the scope

© 2005-2016 Nira Control AB 18

picture has to look like the pictures above. The level transition through the “2

lost”-gap cannot be falling in this case.

Example of wrong polarity at inductive sensor. The level transition through the gap is falling

and the zero crossing will be undefined in the blue circled area.

2.3.2 Volumetric Efficiency (VE)

For controlling the air mass flow through the engine, a volumetric efficiency

model can be used. The VE model uses Manifold Air Pressure or Throttle

Position sensor together with Engine Speed to choose a VE value. The VE

value is volumetric fill rate of the displacement and calculated for every

stroke. A VE value of 1 means that 100 % of the cylinder is filled with air

during intake stroke. For example, if the cylinder volume is 500 cc, the

engine breathes in exactly 500 cc of air while the intake valve is open.

VE to Fuel Mass

With the density of air, the volume can be converted to air mass filled into

the cylinder every stroke. Based on the air mass filled into the cylinder it is

possible to calculate fuel mass based on the desired A/F-ratio.

Volumetric Efficiency and Boost Pressure

The Volumetric Efficiency does not have to increase with increased boost

pressure. The intake air mass will increase and thus, the volume filled into the

cylinder contains compressed air. If high exhaust manifold pressure occurs,

the VE might even decrease.

© 2005-2016 Nira Control AB 19

2.3.3 Mass Airflow Sensors (MAF)

Most modern engines have MAF sensors. These essentially weigh the

incoming air before it enters the engine. The engine control system receives

information about how many grams of air/millisecond have passed through

the MAF sensor.

Using a MAF has a major advantage in that it reports only the amount of air

that actually enters the engine. Engine wear during a long life is factored in

automatically using this approach. Additionally, MAF sensors simplify the fuel

calibration significantly. This was especially important many years ago when

the computational power of the microprocessor in the engine management

system was limited.

Today, MAF is the standard because of strict emission standards that apply

during the entire life of the engine. There are, however, several

disadvantages:

MAF sensors are slow to react, expensive and sensitive to damage.

There are often problems using MAF sensors on aggressively tuned

engines because the sensor can break due to high airflow

The sensor itself is mounted in a housing, which represents a

restriction to the intake air

There are also problems with oil entering the intake tract from the

turbo due to the restriction

2.3.4 Alfa-N and Speed-Density

During the mid-1990’s many cars used speed-density systems. Speed-density

systems have no restrictions in the intake tract (as compared to MAF sensor

systems) and the precision was good enough over the lifetime of the engine

to meet the emission rules of the time.

On low cost vehicles, Alfa-N systems were common. Alfa-N systems are very

inexpensive to manufacture because they only require a high-precision TPS.

Unfortunately, as the engine wears, the TPS value no longer is a correct

measure of how much air the engine takes in and this leads to emissions

related problems

NIRA i7x has the capability to control fuel injection (and ignition) based on

speed-density, Alfa-N -- or a combination of the two.

2.4 Fuel delivery

See the example picture below over a fuel delivery system.

© 2005-2016 Nira Control AB 20

Fuel Rail

Fuel Pump

FPR

Fuel Tank

Manifold

Air

Pressure

Low fuel pressure

High fuel pressure

Low fuel pressure. Back flow

Manifold Air Pressure

Overview of fuel delivery system

Fuel Pump: The purpose is to pump fuel from the tank or catch tank

and pressurize the fuel rail

Fuel Rail: The hardware connection that feed the injectors with

pressurized fuel

FPR (Fuel Pressure Regulator): FPR controls the fuel pressure by

controlling backflow. The FPR is often adjustable to set the base

pressure.

A hose from the manifold is connected to the FPR with purpose to

increase or decrease the fuel pressure when manifold air pressure

changes. The most common is to increase the pressure in a linear

relationship

Injector: Injectors supply the engine with fuel by injecting fuel in the

inlet port. The injectors are electrically controlled by NIRA i7x.

2.4.1 Why use a Fuel Pressure Regulator with MAP Feedback

As described above, the fuel pressure is increased with raised manifold air

pressure. The reason for this is to keep the same pressure balance over the

injector.

Table of contents

Other Nira Controllers manuals

Popular Controllers manuals by other brands

Bray

Bray SERVO PRO 70 Series Operation and maintenance manual

ABB

ABB AC500-S Application note

Inficon

Inficon Cygnus 2 operating manual

Micronix

Micronix MP-21 Series Reference manual

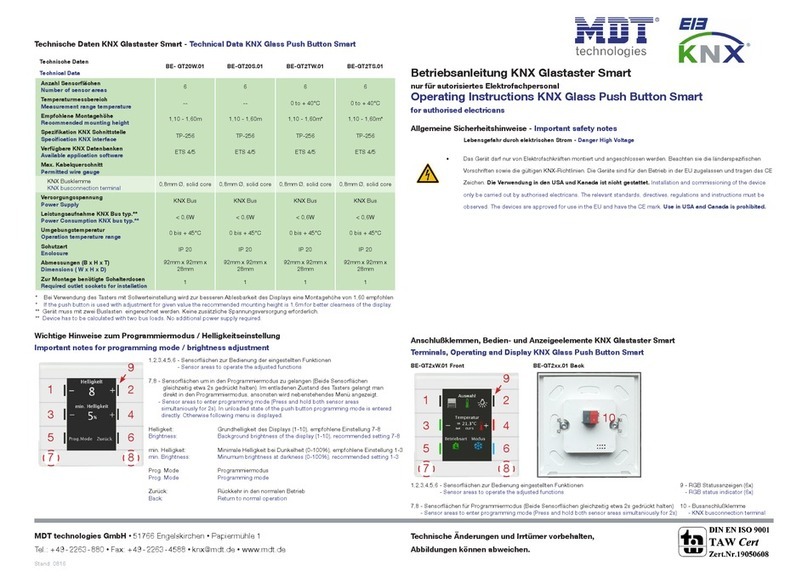

MDT Technologies

MDT Technologies BE-GT2TW.01 operating instructions

Samson

Samson TROVIS 5575 Mounting and operating instructions