Bray SERVO PRO 70 Series User manual

Series 70

SERVO PRO Version 3.0

Operation and Maintenance Manual

Your Global Flow Control Partner™

1

Series 70 Servo Pro

Operation and Maintenance Manual

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – www.bray.com

Table of Contents

1.0 Safety Instructions - Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1 Hazard-free Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2 Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.0 Description of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Configuration Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3 Configuration Switch Function Description. . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Factory Default Settings for Servo Pro Rev F or Higher . . . . . . . . . . . . . . . . . . . .6

2.5 Previous Revisions of Servo Pro. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.0 Quick Setup Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.0 Diagnostic Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.1 Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.2 Motor Power LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.3 Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.4 Status LED Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.0 Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Terminal Block Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.1 Power Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.2 Command Signal Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.3 Output Signal Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.4 Handwheel Switch Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.1.5 Travel Limit Switch Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.1.6 Torque Limit Switch Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.7 Feedback Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.1.7.1 Feedback Potentiometer Installation and Calibration . . . . . . . . . . . . . . . . . . . .16

5.1.8 Control Box Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.1.8.1 Control Box Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.0 Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

6.1 Troubleshooting Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2

Series 70 Servo Pro

Operation and Maintenance Manual

1.1 Hazard-free Use

This device left the factory in proper condition to

be safely installed and operated in a hazard-free

manner. The notes and warnings in this document

must be observed by the user if this safe condition

is to be maintained and hazard-free operation of

the device assured.

Take all necessary precautions to prevent damage

to the Servo Pro due to rough handling, impact, or

improper storage. Do not use abrasive compounds

to clean the Servo Pro, or scrape its surfaces with

any objects.

Configuration and calibration procedures are

described in this document. Proper configuration

and calibration is required for the safe operation

of the Servo Pro.

The control system in which the Servo Pro is installed

must have proper safeguards to prevent injury to

personnel, or damage to equipment, should failure

of system components occur.

This document does not cover every detail about

every version of the product described. It cannot

take into account every potential occurrence in

installation, operation, maintenance and use.

If situations transpire that are not documented

in sufficient detail, please request the required

information from the Bray Distributor or

Representative responsible for your area.

1.2 Qualified Personnel

A qualified person in terms of this document is one

who is familiar with the installation, commissioning

and operation of the device and who has appropriate

qualifications, such as:

• Is trained in the operation and maintenance of

electric equipment and systems in accordance

with established safety practices

• Is trained or authorized to energize, de-energize,

ground, tag and lock electrical circuits and

equipment in accordance with established

safety practices

• Is trained in the proper use and care of personal

protective equipment (PPE) in accordance with

established safety practices

• Is trained in first aid

• In cases where the device is installed in a

potentially explosive (hazardous) location – is

trained in the operation, commissioning,

operation and maintenance of equipment in

hazardous locations

1.0 Safety Instructions - Definition of Terms

READ AND FOLLOW THESE INSTRUCTIONS

SAVE THESE INSTRUCTIONS

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE

used without the safety alert symbol indicates a potential situation

which, if not avoided, may result in an undesirable result or state,

including property damage.

!

!

3

Series 70 Servo Pro

Operation and Maintenance Manual

!

WARNING

The actuator must only be installed, commissioned,

operated and repaired by qualified personnel.

The actuator is designed for installation inside

the Bray S70 Electric Actuator, and to position an

industrial quarter-turn valve. It must be installed

according to its intended purpose.

The Servo Pro controls the movement of an electric

actuator that generates large mechanical forces.

To prevent injury, installation, commissioning,

operation and maintenance must be carried out

under strict observation of the applicable safety

regulations.

The specifications of the examination certificate

valid in the applicable country must be observed.

This includes the actuator in which the Servo Pro

is installed.

Reference is specifically made here to observe

the applicable safety regulations for actuators

installed in potentially explosive (hazardous)

locations. This includes the actuator in which the

Servo Pro is installed.

Verify that the main electric power supplied to

the Servo Pro is compliant with the specifications

on the product label and the specifications in the

examination certificate valid in the applicable

country.

Avoid electrostatic discharges within hazardous

areas.

The housings and external connections on the

actuators (in which the Servo Pro is installed)

are designed for use in potentially explosive

(hazardous) locations and may only be opened

after all electrical power to the actuator has

been removed.

Correct and safe operation of the Servo Pro is

dependent upon proper transport, storage and

installation in addition to proper operation and

maintenance.

1.3 Intended Use

The actuator described in this guide has been

developed, manufactured, tested and documented

with all relevant safety standards taken into account.

If the handling rules and safety information

for configuration, calibration, installation and

maintenance are observed, and the product is used

for its intended purpose, there is normally no danger

with regard to material damage or personnel health.

1.4 Warranty Information

The content of this document is not part of, and

does not modify, a previous or current agreement,

undertaking or legal relationship. Bray Controls is

bound solely by the contract of sale, which also

contains the complete and exclusive warranty.

The contractual warranty conditions are neither

extended nor restricted by this document.

2.0 Description of Operation

The Bray Series 70 Servo Pro provides complete

control and monitoring of the Bray S70 Electric

Actuator.

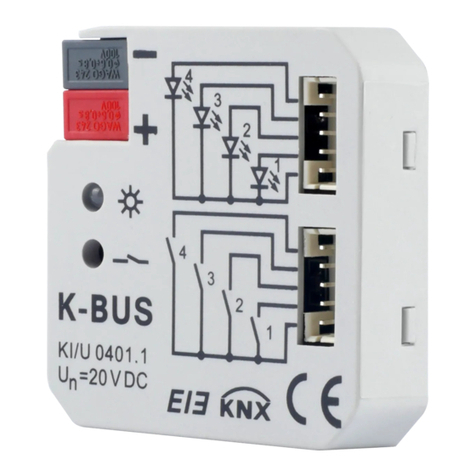

Figure 1: S70 Servo Pro

Revision F or Higher

The basic function of the Servo Pro is to position

the S70 Actuator in response to a command signal

from a process controller. The process controller

contains a desired process setpoint entered by the

user, and continually monitors the process variable

(such as flow rate, tank level, etc.) through some

type of sensor. Varying the command signal to the

Servo Pro will cause the actuator to change

4

Series 70 Servo Pro

Operation and Maintenance Manual

position, which will move the associated control

valve to modify the process variable. The process

controller continually calculates and transmits the

appropriate command signal to the Servo Pro to

maintain the process at the desired set point.

The command signal to the Servo Pro can be various

DC current, voltage or resistance ranges selected

by configuration switches.

The Servo Pro simultaneously provides a feedback

output signal representing the current actuator

position. The feedback signal can be various DC

current or voltage ranges selected by configuration

switches.

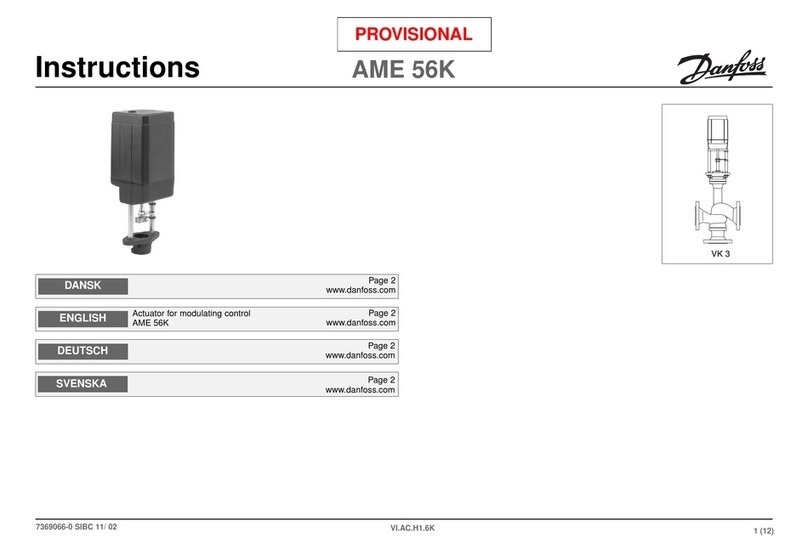

Figure 2: 110VAC or 220VAC Servo Pro Terminals

Revision F or Higher

2.1 Terminal Connections

CALIBRATE

+5 VDC

+5 VDC

INPUT (-)

INPUT (+)

OUTPUT (-)

MOTOR

CLOSE

MOTOR

OPEN

NEUTRAL

NEUTRAL

LINE POWER

OUTPUT (+)

FUSE

COMMON

COMMON

HANDWHEEL

STATUS

OPEN

CLOSE

COMMON

COMMON

CLOSE LIMIT

OPEN LIMIT

COMMON

OPEN

CLOSE

OPEN

SPEED

CLOSE

SPEED

DEAD BAND

HEATER

10987654321

S10

S9

S8

S7

S6

S5

S4

S3

S2

S1

ON

FB POT

CONTROL BOX TORQUE LIMIT

HIGH

VOLTAGE

SERVO

PRO

FEEDBACK

POT

CONTROL

STATION

HANDWHEEL

TORQUE

SWITCHES

TRAVEL

LIMIT

INPUT

SIGNAL

OUTPUT

SIGNAL

MOTOR

WIRING

INPUT

POWER

CALIBRATE

+5 VDC

+5 VDC

INPUT (-)

INPUT (+)

OUTPUT (-)

MOTOR

CLOSE

MOTOR

OPEN

NEUTRAL

LINE POWER

OUTPUT (+)

FUSE

COMMON

COMMON

HANDWHEEL

STATUS

OPEN

CLOSE

COMMON

COMMON

CLOSE LIMIT

OPEN LIMIT

COMMON

OPEN

CLOSE

OPEN

SPEED

CLOSE

SPEED

DEAD BAND

HEATER

10987654321

S10

S9

S8

S7

S6

S5

S4

S3

S2

S1

ON

FB POT

CONTROL BOX TORQUE LIMIT

HIGH

VOLTAGE

SERVO

PRO

FEEDBACK

POT

CONTROL

STATION

HANDWHEEL

TORQUE

SWITCHES

TRAVEL

LIMIT

INPUT

SIGNAL

OUTPUT

SIGNAL

MOTOR

WIRING

INPUT

POWER

Figure 2: 24VAC Servo Pro Terminals

Revision F or Higher

5

Series 70 Servo Pro

Operation and Maintenance Manual

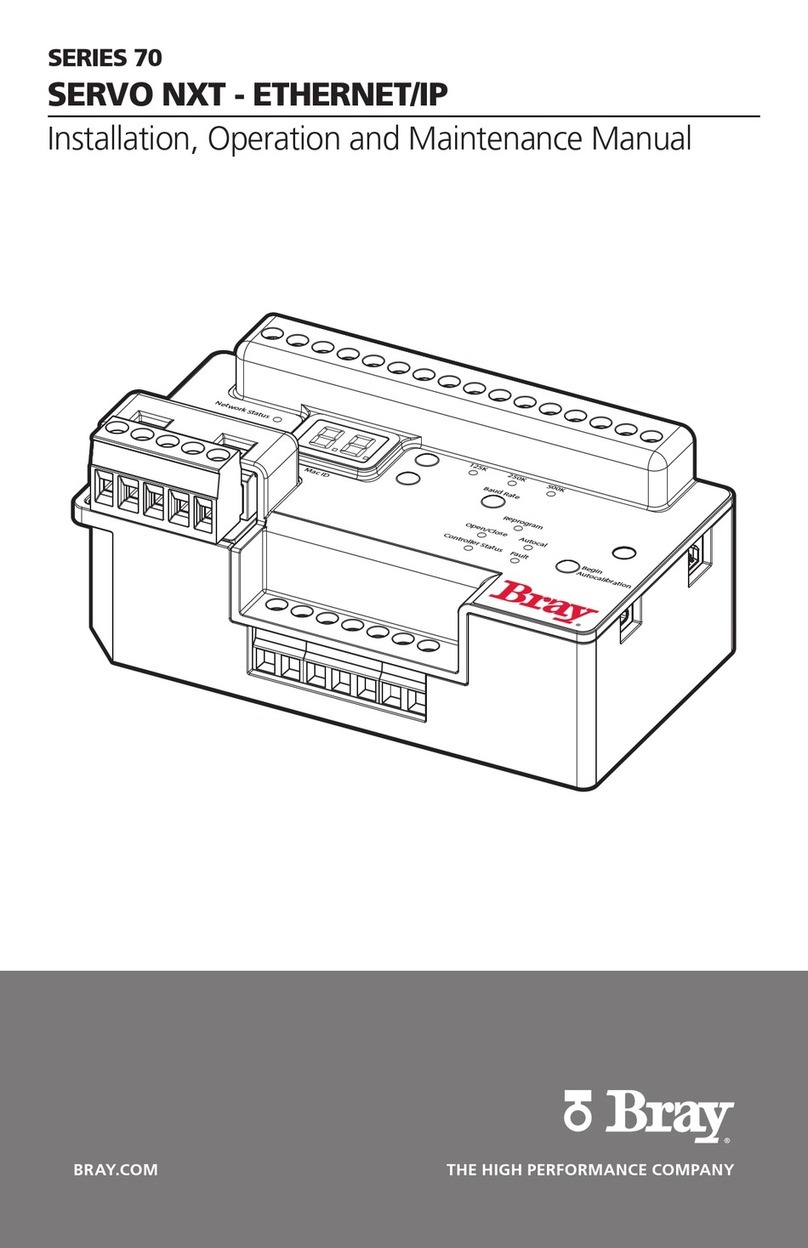

2.2 Configuration Switches

NOTICE

Disconnect all electric power to the Servo Pro prior to adjusting configuration switches. Reconnect

electric power only after all the configuration switches are in the proper position.

The configuration switches are located on the top edge of the Servo Pro Revision F or higher,

between the Calibration button and the Status LED.

Carefully observe the ON and OFF orientation for each section of the configuration switches when

selecting desired options

Table 1: Configuration Switch Chart for Servo Pro

Revision F or Higher

Switch Command Signal Input

4-20 mA DC 0-5 VDC * 0-10 VDC 2-10 VDC

1Off On On On

2Off Off On On

3Off Off Off On

Feedback Output Signal

4-20 mA DC 0-5 VDC 0-10 VDC 2-10 VDC

4Off On On N/A

5 On Off Off N/A

6Off On Off N/A

Forward

Acting

Reverse

Acting

7Off On

Fail in

Last Position

Fail

Enable **

8Off On

Fail

Close

Fail

Open

9Off On

10

Torque

Switch Enable

Torque

Switch Disable

Off On

*To control the Servo Pro with a remote potentiometer, set the Command Input to 0-5VDC

(see Command Signal Notice section; page 8).

**Fail position is the position that the Servo Pro will move the actuator when the control signal is

removed. It does not apply to 0-5VDC or 0-10VDC Command Signals.

6

Series 70 Servo Pro

Operation and Maintenance Manual

2.3 Configuration Switch Function

Description

Command Signal Input – the signal from the

process controller that represents the desired

actuator position.

Feedback Output Signal – the signal from the

Servo Pro that represents the current actuator

position.

Forward Acting – the actuator will move toward

the open direction with an increase in command

signal.

Reverse Acting – the actuator will move toward the

close direction with an increase in command signal.

Fail Enable – the actuator will move to a position

selected by the user upon loss of command signal.

NOTICE

The command signal is considered lost when it is

below the low limit of the selected range.

The command signal cannot be out of range when

0-5 VDC or 0-10 VDC are selected because 0 VDC

is a valid value.

The fail position will not be reached if command

signal AND electric power are both removed from

the Servo Pro. Electric power must be maintained

in order to move the motor in the actuator.

Fail in Last Position – The actuator will remain

in the position it reached when the command

signal was lost.

Fail Close – The actuator will move to the fully

closed position when the command signal is lost.

Fail Open – The actuator will move to the fully

open position when the command signal is lost.

Torque Switch Enable – The actuator will respond

to the optional switches connected to the torque

limit inputs. If the open torque switch is activated

(the switch has been tripped by the torque switch

cam) the actuator will not move any closer to the

fully open position. If the close torque switch is

activated (the switch has been tripped by the close

torque switch cam) the actuator will not move any

closer to the fully closed position.

NOTICE

If the Torque Switch Enabled option is selected, the

actuator must be equipped with properly set torque

switches wired to the Servo Pro. The absence of

properly set torque switches will prevent actuator

movement in one, or both, directions.

Torque Switch Disable – the Servo Pro will not

respond to any switches connected to the Torque

Switch inputs. This option should be used when

the optional torque switches are not installed in

the actuator.

2.4 Factory Default Settings for Servo

Pro Rev F or Higher

Unless specified by the user, the configuration

switches on the Servo Pro Revision F or higher are

set to the following default positions when shipped

from the Bray factory:

Switch 1 – Off

Switch 2 – Off

Switch 3 – Off

Switch 4 – Off

Switch 5 – On

Switch 6 – Off

Switch 7 – Off

Switch 8 – On

Switch 9 – Off

Switch 10 – On

The factory default settings will place the Servo Pro

Revision F or higher in the following configuration:

Command Signal - 4-20 mADC

Feedback Output Signal – 4-20 mADC

Forward Acting

Fail Enable

Fail Closed

Torque Switch Disable

7

Series 70 Servo Pro

Operation and Maintenance Manual

2.5 Previous Revisions of Servo Pro

The previous version of Servo Pro (Revision D) has

a different physical layout and configuration switch

arrangement than Revision F or higher.

Revision D does not include terminals for wiring

the Local Control Box, or for Torque Switches, or

for wiring the Anti-Condensation Heater.

NOTICE

The third character in the serial number indicates

the Revision Level of the Servo Pro.

There are two very distinct differences between

Revision D and F or higher: (a) the Configuration

switch arrangement, and (b) the physical layout

of the PCB. Please be sure to refer to the images

below, and or the serial number on the unit to

determine the Revision before attempting to set

the Configuration switches.

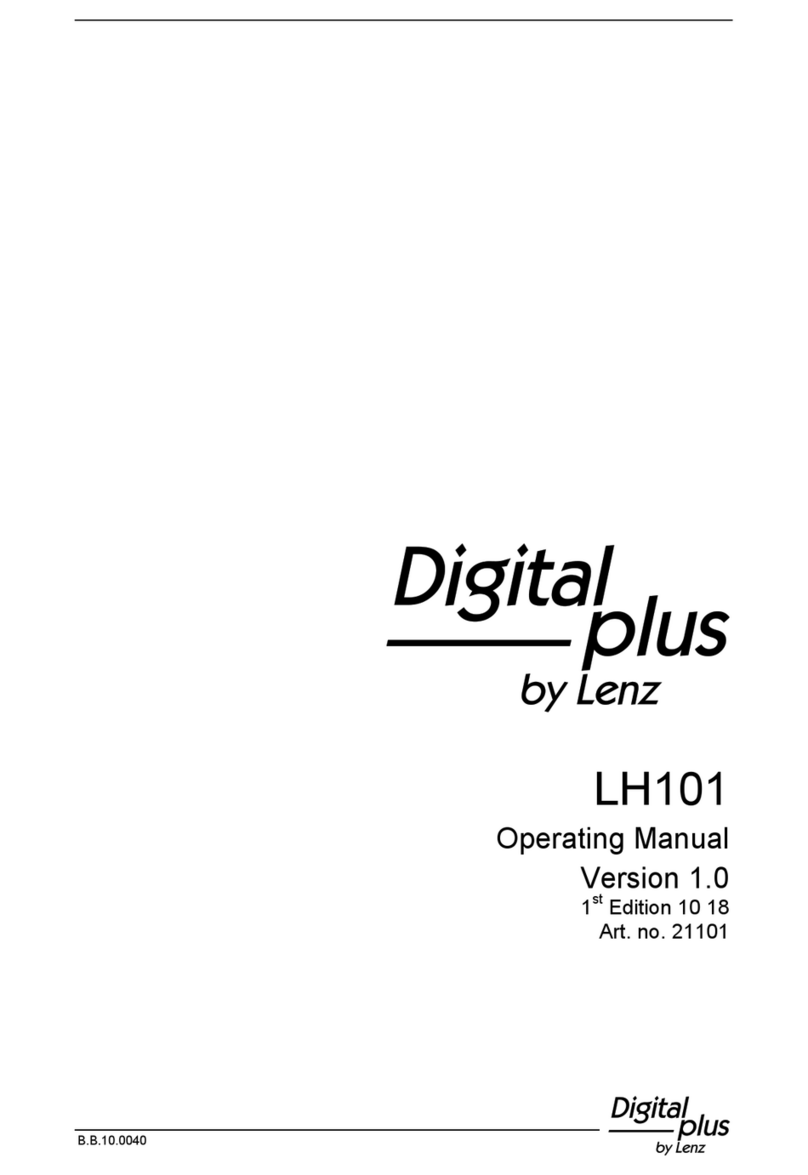

Figure 3: Photographic Comparison of Servo Pro Revision D and Revision F or Higher

Servo Pro Revision D Servo Pro Revision F or higher

8

Series 70 Servo Pro

Operation and Maintenance Manual

Switch Command Input

4-20 mA DC 0-5 VDC 0-10 VDC 2-10 VDC

1 On Off Off Off

2Off Off On On

3Off Off Off On

10 Off On On On

Output

4-20 mA DC 0-5 VDC 0-10 VDC 2-10 VDC

4 On Off Off N/A

5Off On On N/A

6Off On On N/A

Forward

Acting

Reverse

Acting

7Off On

Fail in

Last

Fail

Enable

8Off On

Fail

Close

Fail

Open

9Off On

Table 2: Configuration Switch Chart for Servo Pro

Revision D

3.0 Quick Setup Instructions

!

WARNING

Do not connect the electric power supply until

instructed to do so.

Refer to the Configuration Switch charts and

descriptions in Sections 2.1, 2.2 and 2.3 when

performing the Quick Setup.

A. Set the Command Signal Input configuration.

B. Set the Feedback Output Signal configuration.

C. Select the Operating Mode (Forward Acting or

Reverse Acting)

D. Select Fail Enable or Fail in Last Position

a. If Fail Enable is selected, then select Fail Open

or Fail Close with Switch 9

b. If Fail Enable is not selected, the actuator will

Fail in Last Position

E. Verify (or adjust) the travel stop limits in the

actuator

a. Bray actuators are shipped with the travel

switches in the factory default position - close

travel limit set at 0 degrees and the open travel

limit set at 90 degrees

b. Bray actuators equipped with Servo Pro have

the internal feedback potentiometer set in the

NOTE: The following chart is for configuration of an older model Servo Pro (Rev. D).

Please verify that the model you are using is the same model before consulting this chart.

9

Series 70 Servo Pro

Operation and Maintenance Manual

proper position to match the travel switch

factory default (fully close at 0 degrees and

fully open at 90 degrees)

c. If the travel switch settings are moved from

the factory default position, the internal

feedback potentiometer must be adjusted

to match the new travel switch setting. This

is done by performing a calibration routine.

d. For more details on setting the travel switch

settings, refer to the S70 Operation and

Maintenance Manual.

F. Select the Torque Switch Enable or Disable

a. If optional torque switches are installed in the

actuator, select Torque Switch Enable. The

optional torque switches must be properly

set and wired to the Servo Pro. Refer to the

S70 Operation and Maintenance Manual for

more information.

b. If optional torque switches are not installed

in the actuator, select Torque Switch Disable.

!

WARNING

Before applying the appropriate electrical supply

voltage, verify that the actuator and Servo Pro

have been properly wired to the factory supplied

wiring diagram.

NOTICE

To prevent noise coupling between conductors,

power lines and signal/communication lines should

not be routed together in the same conduit or cable

tray. If they must cross each other, then it should

only be done at right angles

Recommended distances below should be

maintained between power and signal/

communication conduit:

Metal Conduit:

Conductor carrying less than 20A = At least 4 in.

Conductor carrying more than 20A up to 100kVA =

At least 8 in.

Conductor carrying more than 100kVA =At least

1.5 ft.

Non-Metallic Conduit:

Conductor carrying less than 20A = At least 8 in

Conductor carrying more than 20A up to 100kVA =

At least 2 ft.

Conductor carrying more than 100kVA = At least

3 ft.

Please refer to NEC guidelines for proper wiring

techniques in USA. Other countries must follow

all local codes for safety requirements.

Shielding

Signal/communication lines should be shielded.

Shield must be grounded at one end only, preferably

at the controller. Grounding the shield at more than

one location can introduce noise in the circuitry by

forming ground loops.

G. Apply the command signal input

NOTICE

Ensure that your controller is able to provide the

proper command signal range given the following

input impedance values:

4-20 mA 200 Ohm

0-5 VDC >10 MOhm

0-10 VDC >10 MOhm

a. The command signal must be connected to the

proper terminals. Refer to the wiring diagram.

b. The command signal input must match

the range selected with the configuration

switches.

c. The command signal must be a valid value

(i.e., if 4-20 mA DC is selected, the value

must be no less than 4 mA and no greater

than 20 mA.)

d. Note: a good value to select for Calibration

would be mid-travel (i.e. 12 mA DC)

Isolation Transformers

For circuits that are located in the proximity of

excessive electrical noise generators, isolation

transformers should be used to filter and prevent

noise from entering into the circuitry.

Transient Suppression

Electromagnetic Interference (EMI) can result

from inductive loads, which can adversely affect

electronic circuits.

10

Series 70 Servo Pro

Operation and Maintenance Manual

Appropriately sized surge suppressors should

be installed whenever inductive loads such as

transformers, relays, solenoids, motors, etc. are

operated. This will help prevent transient EMI surges

from damaging the sensitive electronic circuits.

H. Apply the appropriate supply voltage to the

power input terminals.

a. Verify the Status LED is flashing normal

operation – a green “heartbeat” consisting

of a repeating pattern one second on and

one second off.

b. If the Status LED is flashing red, the problem

must be resolved before Calibration can begin.

Refer to the Troubleshooting section of this

manual and the Status Code Flash Table for

more information.

I. Accept or Adjust the Deadband - Optional

a. The factory default is midrange – the deadband

potentiometer is midway between fully

clockwise and fully counter-clockwise. If this is

acceptable, no further adjustment is necessary.

b. Rotate the deadband potentiometer clockwise

to increase the deadband.

c. Increasing the deadband reduces the

potential for the actuator to oscillate around

the desired setpoint. This oscillation is often

called “hunting.” An actuator responding

to a moving setpoint is not hunting, but is

operating properly.

d. Decreasing the deadband allows the actuator

to reach a position closer to the desired

position, as long as the actuator does not

oscillate (hunt) around the setpoint.

J. Accept or Adjust the Open Speed - Optional

a. The factory default is full speed – the open

speed potentiometer is in the fully counter-

clockwise position. If this is acceptable, no

further adjustment is necessary.

b. The full speed (fastest speed) of the actuator

is listed on the label.

c. Rotate the open speed potentiometer

clockwise to reduce the opening speed of

the actuator.

d. Reducing the opening speed of the actuator

can allow more precise positioning of the

actuator.

K. Accept or Adjust the Close Speed - Optional

a. The factory default is full speed – the close

speed potentiometer is in the fully counter-

clockwise position. If this is acceptable, no

further adjustment is necessary.

b. The full speed (fastest speed) of the actuator

is listed on the label.

c. Rotate the close speed potentiometer

clockwise to reduce the closing speed of the

actuator.

d. Reducing the closing speed of the actuator can

allow more precise positioning of the actuator.

NOTICE

Reducing the closing speed of the actuator can also

reduce the potential of water hammer damage.

Electric actuators are usually slow enough to avoid

water hammer even at the full speed setting – but

the user should verify this setting.

Shielding

Signal/communication lines should be shielded.

Shield must be grounded at one end only, preferably

at the controller. Grounding the shield at more than

one location can introduce noise in the circuitry by

forming ground loops.

L. Connect the Output Signal to the process

controller - Optional

a. Wire the positive conductor to the OUTPUT

(+) terminal.

b. Wire the negative conductor to the OUTPUT

(-) terminal.

c. Select the desired output signal range using

the Configuration switches 4, 5 and 6.

M. Connect the Anti-Condensation Heater –

Optional

a. Connect the wires from the Anti-Condensation

Heater to the HEATER terminals.

b. The Heater rating must match the voltage

rating of the Servo Pro.

11

Series 70 Servo Pro

Operation and Maintenance Manual

3.1 Calibration Procedure

The calibration procedure should be run when the

Servo Pro is first commissioned, and anytime that a

subsequent change is made to either the Servo Pro

Configuration or the actuator in which the Servo

Pro is installed.

1. Engage the actuator handwheel by pulling it

outward, and manually move the actuator to

the mid-travel position.

2. Disengage the actuator handwheel by pushing

it inward.

3. Press the Calibration button, hold it for a

minimum of 2 seconds, and release the button.

4. The Servo Pro should enter the Calibration routine

and move the actuator toward the fully closed

position. After reaching the fully closed position, it

will reverse travel and move toward the fully open

position. After reaching the fully open position,

the Servo Pro will write the calibration value to

memory, return to normal operation, and move

the actuator to the position that matches the

command input signal.

5. After a successful calibration, the Status LED will

return to the normal heartbeat pattern.

6. After an unsuccessful calibration attempt, the

Status LED will flash an error code of “red-

green-red-green.” For more information on the

error codes, refer to the Status LED Flash Code

Table. Correct the error and run the calibration

procedure again.

4.0 Diagnostic Indicators

The Servo Pro has several diagnostic indicators, such

as the Power LED, Motor Open LED, Motor Close

LED, and Status LED. The Servo Pro is constantly

performing self-diagnostics. These indicators assist

the user in confirming proper operation of the

Servo Pro, and troubleshooting various operational

problems.

4.1 Power LED

The Power LED will light solid green when the proper

electrical power is supplied to the Servo Pro power

terminals. If the Power LED is not solid green, then

the power supply is not working and the Servo Pro

will not function.

The fuse must be installed for the Power LED to light.

4.2 Motor Power LEDs

There are two Motor Power LEDs.

The Motor Open LED will light green when the Servo

Pro is powering the motor in the open direction. This

occurs when the current actuator position is below

the command signal (desired actuator position.) The

actuator should be moving in the open direction

when the Motor Open LED is lit.

The Motor Close LED will light red when the Servo

Pro is powering the motor in the close direction. This

occurs when the current actuator position is above

the command signal (desired actuator position.) The

actuator should be moving in the closed direction

when the Motor Close LED is lit.

4.3 Status LED

The Status LED is a bi-color LED (red/green) that

indicates various operational conditions of the Servo

Pro. The Status LED flashes the green “heartbeat”

pattern – a repeating cycle of one second ON

followed by one second OFF – to indicate normal

operation.

Any flashing pattern other than the green heartbeat

indicates either an advisory condition or an error

condition.

Advisory conditions are combinations of green

flashes. These indicate the Servo Pro is operating,

but it may not be in an optimal condition. An

example would be Reverse Acting mode selected.

The user may desire this condition, but it may also

be an oversight that requires correction.

Error conditions are combinations of red flashes.

These indicate the Servo Pro is not operating

properly. An example would be handwheel

engaged. The Servo Pro cannot move the actuator

motor in either direction when the handwheel is

engaged.

NOTICE

Any Status LED Flash Code with green flashes is

simply an advisory that should be noted and may, or

may not, require adjustment. Actuators can operate

properly while the Status LED is flashing green.

Any Status LED Flash Code that contains red flashes is

an error that must be corrected before the actuator

can operate properly.

12

Series 70 Servo Pro

Operation and Maintenance Manual

4.4 Status LED Flash Codes

Table 3 shows various diagnostic Flash Codes and

their descriptions.

If more than one advisory condition or error

condition exists, only one Flash Code will appear at

a time. The first condition must be corrected before

the second (or subsequent) Flash Code will appear.

Table 3: Status LED Flash Codes

No. Indication Description Possible Solution(s)

1

Steady Green Flash

(1 second on, 1 second

off) “Heartbeat”

Normal Operation Servo Pro Functioning Normally

22 Green Flashes Calibration Defaults

Loaded

Calibration may be acceptable, but if not,

adjust travel limits and restart the Calibration

33 Green Flashes Reverse Acting Mode

Selected

This is an advisory that the Reverse Acting

mode has been selected. Adjust Configuration

switch 7 if forward operation is required.

44 Green Flashes

HVAC 2-10 VDC

Command Signal

Selected

This is an advisory that the HVAC 2-10 VDC

input has been selected. Adjust Configuration

switches 1, 2 and 3 if this Command Signal is

not required.

51 Red Flash Handwheel engaged Push the Handwheel in towards the actuator

to Disengage

62 Red Flashes Command Signal Failure

Verify Command Signal, verify wiring, adjust

Configuration switches to match Command

Signal

73 Red Flashes Feedback Pot Fault

Verify feedback pot wiring, position the

feedback Pot cam correctly, see Feedback Pot

calibration notes

84 Red Flashes Limit Switch Fault

Verify wiring of limit switches, verify limit

switch cam settings, verify that both limit

switches are not tripped simultaneously (the

actuator cannot be fully open and fully closed

at the same time)

95 Red Flashes Torque Switch Fault

Verify that optional torque switches are

installed and wired correctly, reverse

direction of actuator, correct over-torque

condition – OR – if optional torque switches

are not installed, disable the torque switch

input setting Configuration switch 10 to ON.

10 6 Red Flashes Feedback Pot Wired In

Reverse

This check is only performed during

Calibration. Remove power from the Servo

Pro, correct the wiring to the feedback pot,

reapply power to the Servo Pro, and restart

the Calibration.

13

Series 70 Servo Pro

Operation and Maintenance Manual

5.0 Hardware Description

The microprocessor-controlled Servo Pro enhances

the operation of the S70 actuator by providing full

positioning control, supplying an actuator position

feedback signal, responding to various switch

input conditions, performing self-diagnostics and

indicating operational status.

The Servo Pro microprocessor eliminates the

need to adjust potentiometers during calibration.

Calibration is performed by simply pressing a button.

The Servo Pro will automatically seek the fully closed

and fully open travel limits and store the values in

non-volatile memory.

5.1 Terminal Block Connections

NOTICE

The Servo Pro will accept wire sizes ranging from

14 to 24 AWG.

18 AWG wire is recommended.

Larger wire than 14 AWG could damage the

terminal block connections and should not be

used.

Each terminal connection on the Servo Pro is clearly

labeled on the top silk screen to simplify wiring as shown

in Figures 2 and 3.

5.1.1 Power Input Terminals

The electric power supplied to the Servo Pro

drives the actuator motor, all the circuitry inside

the module, plus all the devices connected to the

module such as the limit switches, torque switches,

handwheel switch, control box, output signal and

anti-condensation heater.

NOTICE

The electric power supplied to the Servo Pro

must match the rating shown on the Servo Pro

nameplate.

Each different rating (100 VAC, 220 VAC or 24 VAC)

requires a different Servo Pro unit.

The Servo Pro must be installed in an actuator that

matches the rating shown on the Servo Pro name-

plate. For instance, a 110 VAC Servo Pro must be

installed in a 110 VAC actuator.

CAUTION

The terminal block connections designed for high

voltage are placed behind a solid line labeled

HIGH VOLTAGE on the silk screen. Dangerous

high voltage (110 VAC or higher) can be present

on any of these conductors when the Servo

Pro is operating. Use caution to avoid injury to

personnel or damage to equipment.

Do not connect any 110 VAC or 220 VAC conductors

to any terminal blocks outside this labeled area.

The Servo Pro is designed to accept a single phase

AC line voltage of the proper value.

The Live conductor should be connected to the

Live terminal. The Neutral conductor should be

connected to the Neutral terminal.

5.1.2 Command Signal Input Terminals

Apply the command signal input

NOTICE

Note: Ensure that your controller is able to provide

the proper command signal range given the

following input impedance values:

4-20 mA 200 Ohm

0-5 VDC >10 MOhm

0-10 VDC >10 MOhm

The Servo Pro accepts a command signal from the

process controller that represents the desired position

of the actuator. The customer wires the command

signal to an output from their process controller.

The command signal has polarity that must be

observed. Connect the positive conductor of the

command signal to the INPUT (+) terminal. Connect

the negative conductor of the command signal to

the INPUT (-) terminal.

The command signal has four different ranges

selectable through configuration switches.

A potentiometer 10k ohm (or larger) can be used to

generate a command signal. Wire one fixed terminal

of the pot to the terminal labeled +5 Volts. Wire

the wiper of the pot to the terminal labeled INPUT

(+). Wire the other fixed terminal of the pot to the

terminal labeled INPUT (-). Set the command signal

to 0-5VDC using Configuration switches 1, 2 and 3.

!

14

Series 70 Servo Pro

Operation and Maintenance Manual

Refer to the configuration Switch Chart in Section

2.2.

The potentiometer command signal option is

useful to demonstrate an actuator equipped with

a Servo Pro when a 4-20 mA DC calibration device

is unavailable.

CAUTION

Do not connect any high voltage power to the

command signal input terminals as damage could

result.

NOTICE

Shielding

Signal/communication lines should be shielded.

Shield must be grounded at one end only, preferably

at the controller. Grounding the shield at more than

one location can introduce noise in the circuitry by

forming ground loops.

The command signal supplied to the Servo Pro

must be isolated from all other external circuits.

5.1.3 Output Signal Terminals

The Servo Pro supplies an output signal that

represents the current position of the actuator.

The customer wires the output signal to an input

of their process controller.

The output signal has polarity that must be observed.

Connect the positive conductor of the output signal

to the OUTPUT (+) terminal. Connect the negative

conductor of the output signal to the OUTPUT (-)

RETURN terminal.

The output signal has four different ranges

selectable through configuration switches. The

available ranges are:

4-20 mADC

0-5 VDC

0-10 VDC

The output signal is sometimes called the

Retransmission signal, or position feedback signal.

The output signal is calibrated by the microprocessor

at the same time the command signal is calibrated.

CAUTION

Do not connect any high voltage power to the

output signal terminals as damage could result.

The Servo Pro provides an active (powered) output

signal. Do not apply any additional power source

to this circuit.

NOTICE

The output signal in the 4-20mA mode is limited to

a total maximum load impedance of 400 ohms. The

output signal in the 0-5V or 0-10V mode is limited

to a minimum load impedance of 10K Ohms.

The output signal should be isolated from all other

external circuits.

The process controller receiving the output signal

should be adjusted to allow for a +/- 2% variance.

There is no change in the output signal range if

Reverse Acting mode is selected. The output signal

always operates in Forward Acting mode.

5.1.4 Handwheel Switch Terminals

The Servo Pro monitors the position of the actuator

manual override handwheel through switches

connected to the handwheel terminals.

The wiring to the handwheel terminals is connected

at the factory and should not require any adjustment

by the customer.

NOTICE

If the actuator handwheel is engaged (pulled fully

outward) the Servo Pro cannot power the actuator

motor in either direction.

The actuator handwheel must be disengaged

(pushed fully inward) for the Servo Pro to power

the actuator motor.

!

!

15

Series 70 Servo Pro

Operation and Maintenance Manual

CAUTION

Do not connect any high voltage power to the

hand-wheel switch terminals as damage could result.

Engaging the handwheel prevents the actuator

motor from becoming energized, but it does not

remove electric power from the Servo Pro. Exercise

caution to avoid personnel injury or damage to

property.

5.1.5 Travel Limit Switch Terminals

The Servo Pro accepts signals from travel limit

switches installed in the actuator that indicate

when the fully closed and fully open positions are

reached. When a travel limit is reached, the Servo

Pro will not power the actuator motor any farther

in that direction.

The wiring to the travel limit switch terminals is

connected at the factory and should not require

any adjustment by the customer. If a field repair is

required,refer to the wiring diagram to make sure

the open limit switch is wired between the OPEN

LIMIT terminal and the COMMON terminal, and

the close limit switch is wired between the CLOSE

LIMIT terminal and the COMMON terminal.

Normal operation requires a closed contact between

OPEN LIMIT and COMMON, and between CLOSE

LIMIT and COMMON.

The travel switches are used during the calibration

routine to indicate the fully closed and fully open

actuator positions.

Refer to the actuator manual for information on

adjusting the travel limit switches.

NOTICE

A travel switch that is broken, improperly wired,

improperly adjusted or missing from the actuator can

result in an open contact which will be interpreted by

the Servo Pro as the actuator reaching the travel limit.

Do not activate both travel switches simultaneously

as this will create an error condition. The actuator

cannot be fully open and fully closed at the same time.

CAUTION

Do not connect any high voltage power to the travel

limit switch terminals as damage could result.

5.1.6 Torque Limit Switch Terminals

The Servo Pro accepts signals from optional torque

limit switches installed in the actuator that indicate

when an over-torque condition exists while the

motor is moving in the closed or open direction.

When a torque limit is reached, the Servo Pro will

not power the actuator motor any farther in that

direction.

The wiring to the torque limit switch terminals is

connected at the factory and should not require

any adjustment by the customer. Torque switches

cannot be added to actuators in the field because

factory calibration is required.

Normal operation requires a closed contact between

the TORQUE LIMIT OPEN and COMMON,

and between the TORQUE LIMIT CLOSE and

COMMON.

!

!

16

Series 70 Servo Pro

Operation and Maintenance Manual

NOTICE

A torque switch that is broken, improperly wired,

or missing from the actuator can result in an open

contact which will be interpreted by the Servo Pro

as the actuator being at its max torque limit.

If the optional torque switches are not installed,

select Torque Switch Disable by setting

Configuration switch 10 to ON.

CAUTION

Do not connect any high voltage power to the

torque limit switch terminals as damage could

result.

5.1.7 Feedback Potentiometer

The Servo Pro uses the signal from the internal

feedback potentiometer to determine the current

actuator position.

The wiring to the feedback potentiometer is

connected at the factory and should not require

any adjustment by the customer. If a field repair is

required, follow the instructions below:

5.1.7.1 Feedback Potentiometer Instal-

lation and Calibration

1. Install the internal feedback potentiometer next

to the actuator indicator shaft using the two

threaded mounting holes provided.

2. The potentiometer assembly must be mounted

in the correct orientation in order to successfully

calibrate the Servo Pro.

3. Remove the indicator rotor from the indicator

shaft so that the drive slot on the top is visible.

4. Engage the handwheel (pulling it fully outward)

and manually move the actuator to the fully open

(counterclockwise) position.

5. Use the black feedback pot knob to rotate the

black feedback pot cam until the raised green rib

on the pot gear (see Figure 4 below) is directly in-

line with the slot on the top of the indicator shaft.

6. The actuator is now ready for the calibration

procedure described in Section 3.1.

NOTICE

The wiring of the feedback pot is critical to proper

operation.

Connect the orange wire from the wiper pin of the

pot to the middle terminal.

Connect the gray wire from the fixed pin of the

pot that is closest to the wiper pin to the +5V

terminal.

Connect the white wire from the fixed pin of the

pot that is farthest from the wiper pin to the COM

terminal.

Connect a voltmeter between the middle terminal

and the COMMON terminal. Apply power to the

Servo Pro, move the actuator to the fully open

position, and the reading should be close to

+5 VDC. Move the actuator to the fully closed

position, and the reading should be close to 0 VDC.

CAUTION

Do not connect any high voltage power to the

feedback pot terminals as damage could result.

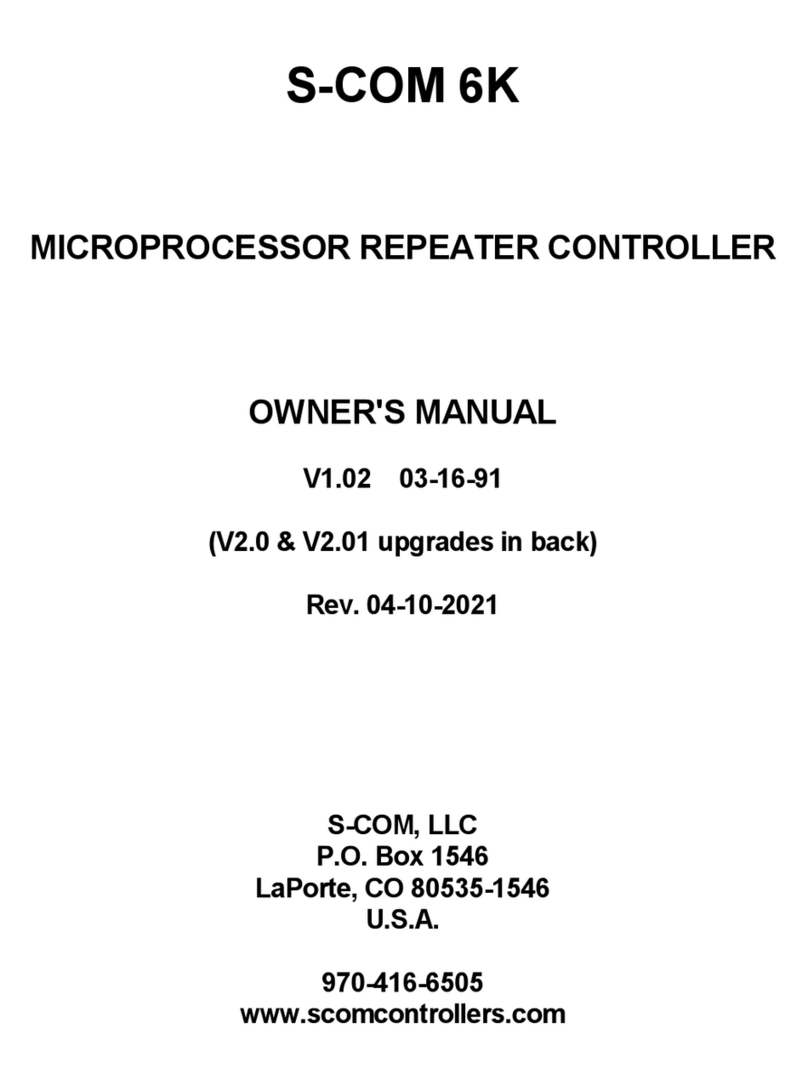

Figure 4: Feedback Pot Mounting and Positioning.

!

!

A Division of BRAY INTERNATIONAL, Inc.

13333 Westland East Blvd. • Houston, Texas 77041

Tel: 281.894.5454 Fax: 281.894.9499 www.bray.com

All statements, technical information, and recommendations in this bulletin are for general use only. Consult Bray representatives or

factory for the specific requirements and material selection for your intended application. The right to change or modify product design

or product without prior notice is reserved. Patents issued and applied for worldwide.

Bray®is a registered trademark of Bray International, Inc. |© 2016 Bray International, Inc. All rights reserved. |OM-70-002 06-2016

Table of contents

Other Bray Controllers manuals

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray Series 70 User manual

Bray

Bray 71 Seires User manual

Bray

Bray 70-003-113-536 Series User manual

Bray

Bray Series 70 User manual

Bray

Bray GAS Series User manual

Bray

Bray Series 70 User manual

Bray

Bray 98 Series User manual

Bray

Bray 73 Series User manual