CONTENTS

SWIMMING POOL HEAT PUMP.................................................................................................................... 1

Installation & Instruction Manual ................................................................................................................ 1

1. FOREWORD....................................................................................................................................................... 1

1.1. Statement......................................................................................................................................... 1

1.2. Safety Factors ................................................................................................................................... 1

2. OVERVIEW OF THE UNIT................................................................................................................................... 3

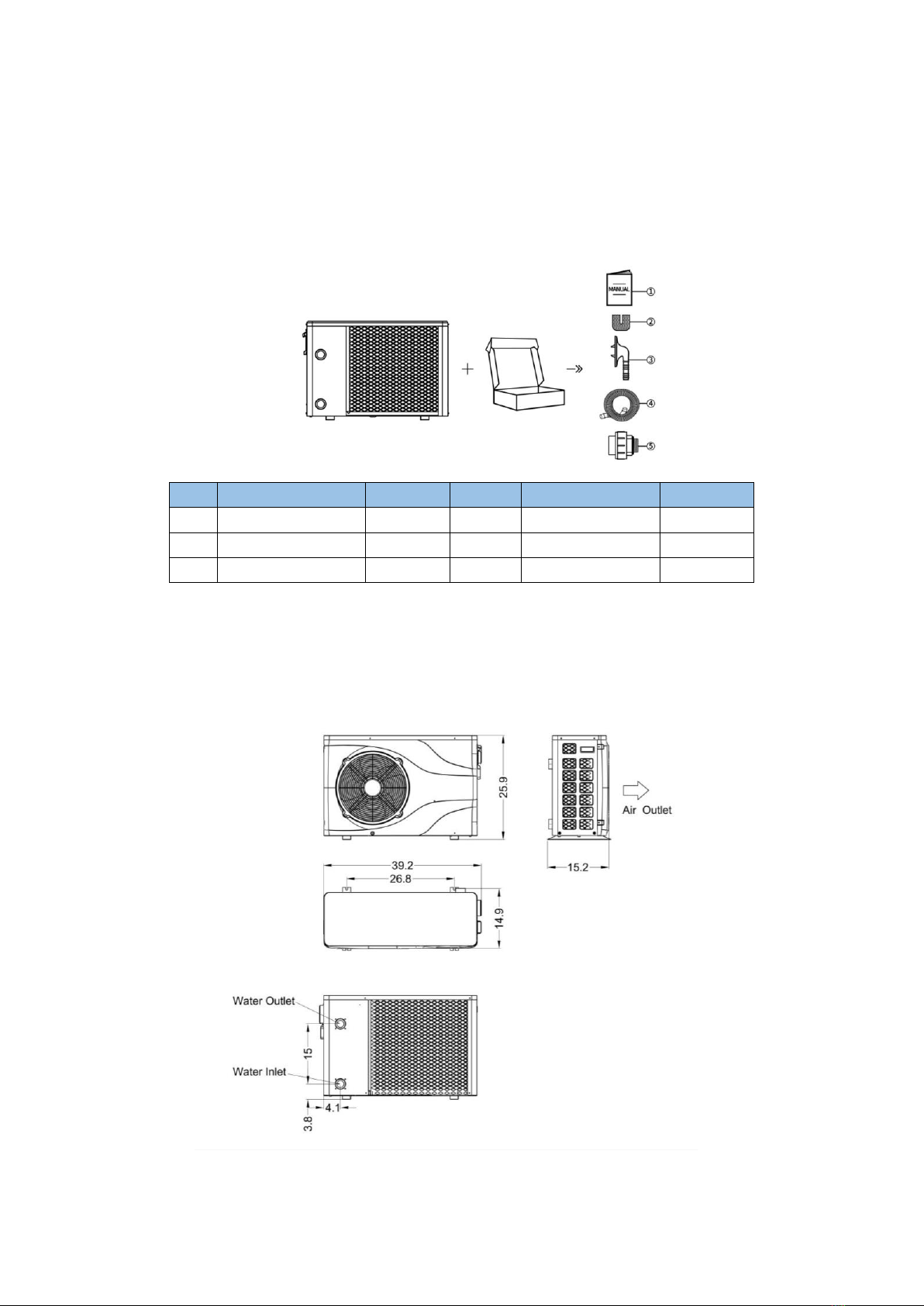

2.1. Accessories Supplied with the Unit.................................................................................................. 3

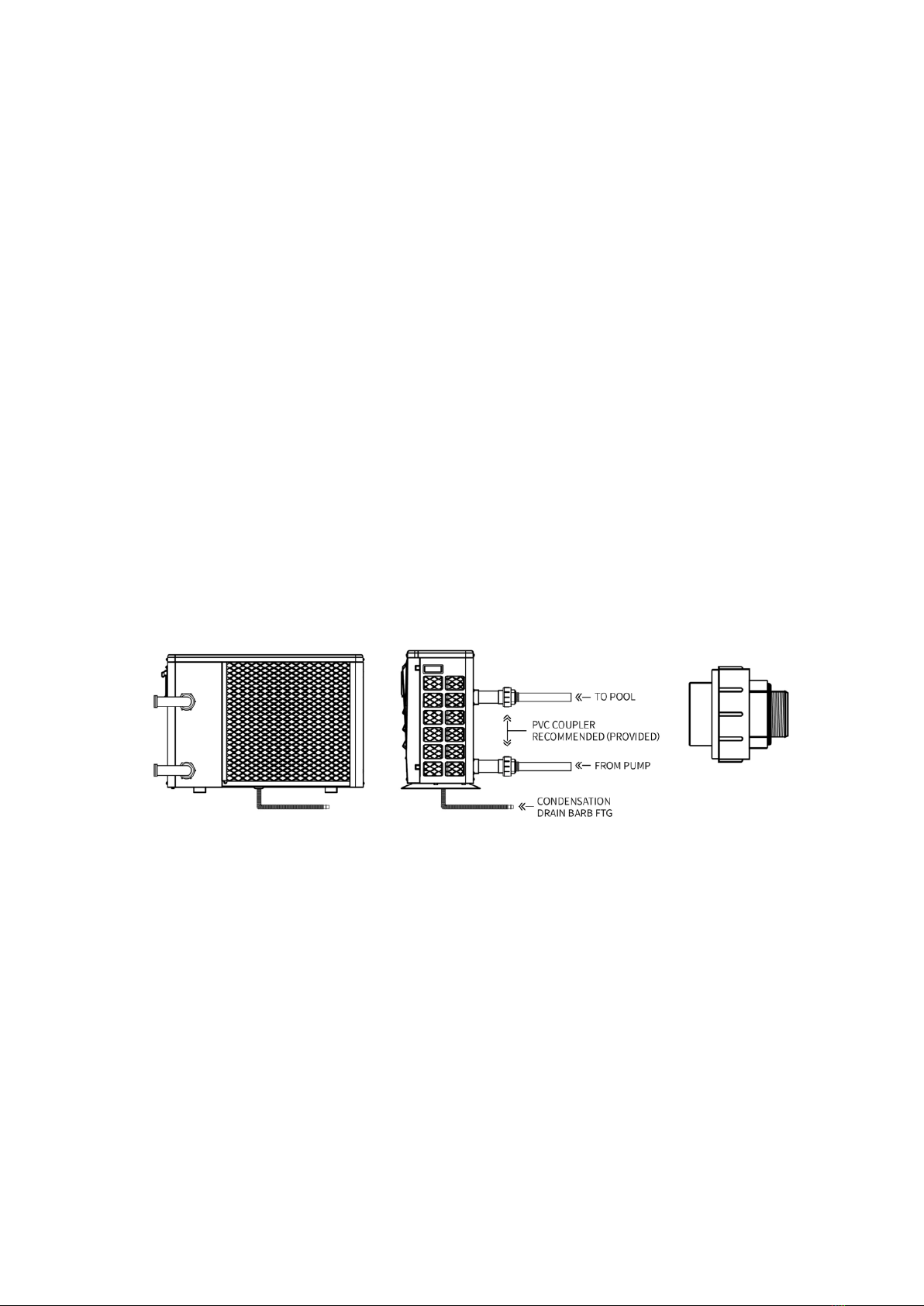

2.2. Dimensions of the Unit..................................................................................................................... 3

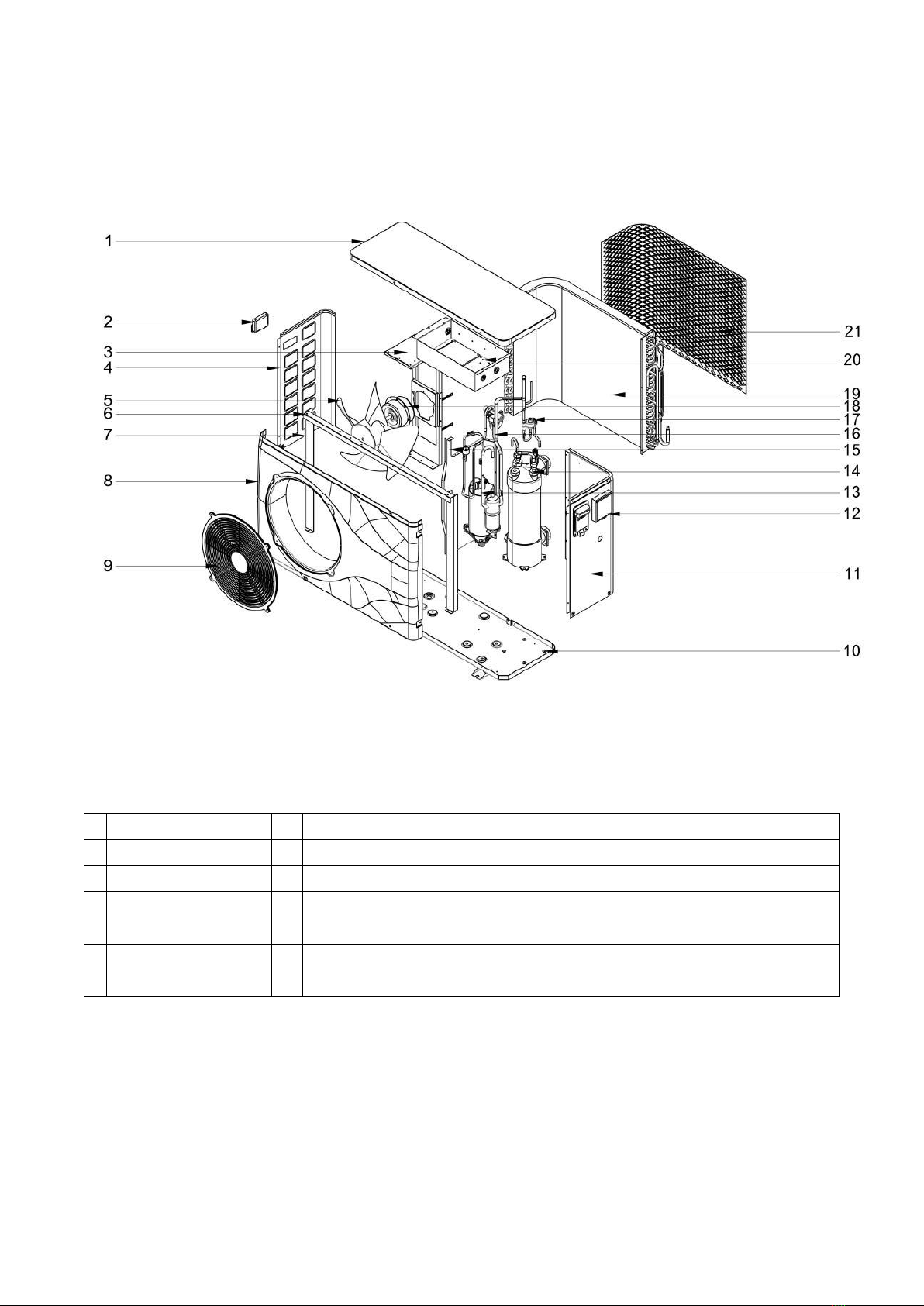

2.3. Main Parts of the Unit...................................................................................................................... 4

2.4. SPECIFICATIONS................................................................................................................................ 5

3. INSTALLATION ................................................................................................................................................... 5

3.1. Transportation .................................................................................................................................. 6

3.2. Notice Before Installation................................................................................................................. 6

3.3. Installation Instructions.................................................................................................................... 6

3.3.1 Pre-requirements ........................................................................................................................ 7

3.3.2 Heat Pump Installation................................................................................................................ 7

3.3.3 Location and Size......................................................................................................................... 7

3.3.4 Installation Layout ....................................................................................................................... 8

3.3.5 Electrical Installation ................................................................................................................... 9

3.3.6 Electrical Connection................................................................................................................... 9

3.4. Commissioning the heat pump after Installation:............................................................................ 9

3.4.1 Inspection Before First Trial Run ............................................................................................... 10

3.4.2 Trial Run:....................................................................................................................................10

4. REMOTE CONTROLLER OPERATION GUIDANCE .............................................................................................10

4.1. Control Panel Diagram.................................................................................................................... 11

4.2. Key Operating Instructions............................................................................................................. 11

4.3. System Status .................................................................................................................................13

4.4. Trouble Shooting ............................................................................................................................14

5. MAINTENANCE AND WINTERIZING........................................................................................................15

5.1. Maintenance........................................................................................................................................15

5.2. Winterizing ..........................................................................................................................................15