STANDARD SPECIFICATIONS................................................................................................................................................................ 1

INSTALLATION............................................................................................................................................................................................... 6

Connecting the Chain bucket................................................................................................................................. 6

Lubrication...........................................................................................................................................................................7

Circuit breakers..................................................................................................................................................................7

Power source cabIe........................................................................................................................................................ 8

Power source cabIe specications........................................................................................................................8

Adjusting the Trolley width....................................................................................................................................... 9

Setting the Trolley onto the beam........................................................................................................................10

Connecting the hoist to the trolley......................................................................................................................11

Connecting the Power source cabIe....................................................................................................................12

lnspection After lnstallation......................................................................................................................................13

INSPECTION & MAINTENANCE.......................................................................................................................................................... 14

INSPECTION BEFORE USE......................................................................................................................................................................14

MONTHLY AND ANNUAL INSPECTIONS...................................................................................................................................... 14

INSPECTION POINTS..................................................................................................................................................................................15

Hook & Chain lnspection.............................................................................................................................................17

ADJUSTING THE BRAKE............................................................................................................................................................................18

Adjusting the electromagnetic brake.................................................................................................................18

HOW TO USE THE CHAIN LIMIT GOUGE.....................................................................................................................................19

TROUBLESHOOTING..............................................................................................................................................................................20

CIRCUIT DIAGRAM.....................................................................................................................................................................................21

SPARE PARTS TABLE AND SPARE PARTS CODE TABLE........................................................................................................32

3. CONDITIONS OF USE

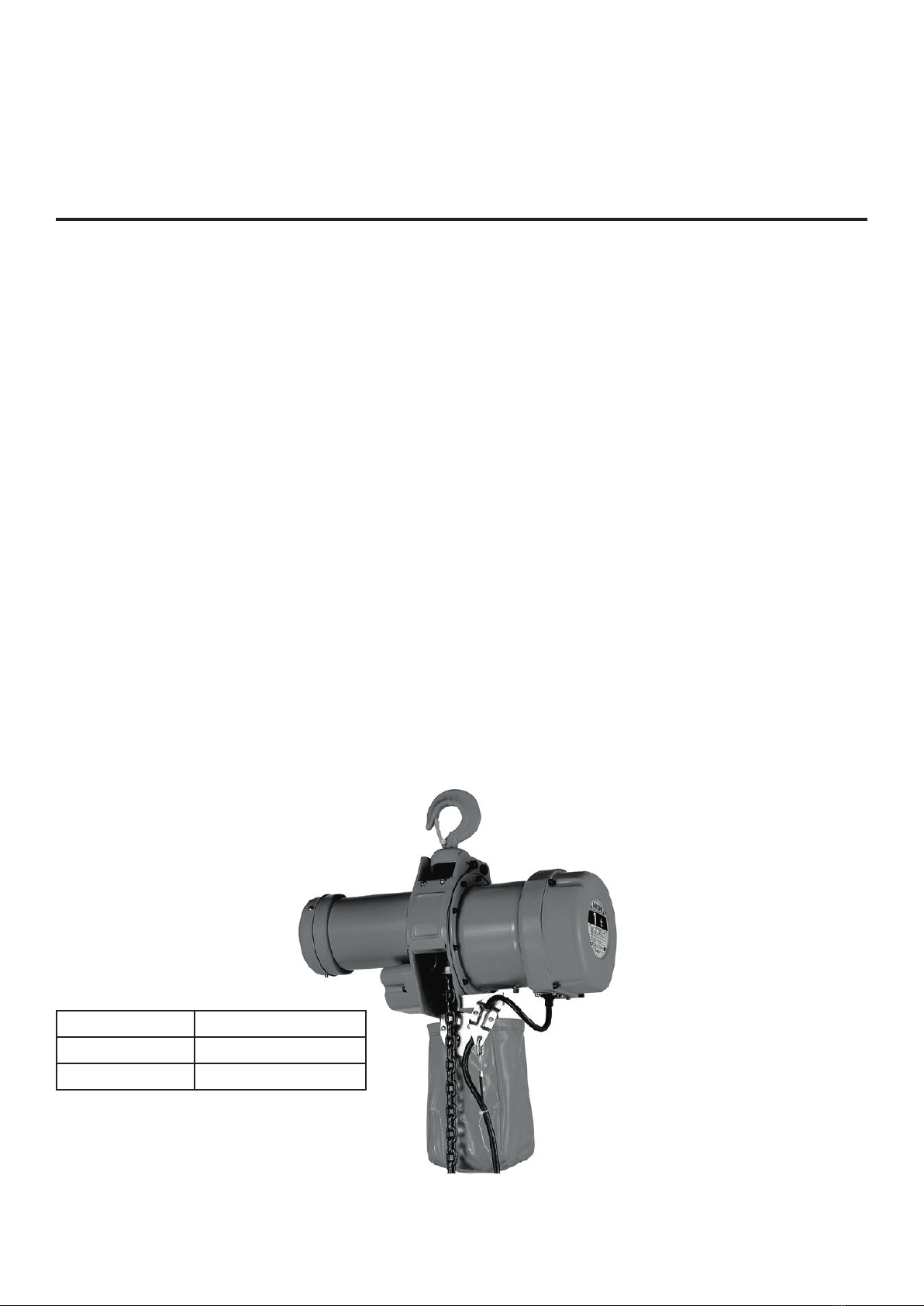

The MH-5 Series electric chain hoists and trolleys are designed for the vertically lifting, lowering and ho-

rizontal transportation of loads by operating the pendant push button switch, and must be used within

the following conditions:

1. Power source : As specied on name plate of the electric chain hoist, and motorized trolley.

2. Trolley beam : Trolley to be used only on the designated beams.

3. Temperature : / 15°C -/+ 40°C

4. Humidity : Under 90%

5. Protection : Hoist: IP43 (Do not use in rain or dusty environments.)

Trolley: IP42 (Do not use in rain or dusty environments.)

6. Enclosure status: Do not use in ambient conditions that contain steam or explosive gases.

7. Duty rating: Model MH5 30 minutes

Model MHT-5 20/20 minutes (slow / fast)

Model MHC-5 15 minutes

Model M-ET-5 30 minutes

8. Grade: Models MH-5, MHT-5, MHC-5, M-ET-5 M4 & M5

CONTENTS