Nitchi EC4 Series Manual

TROLLEYS MECHANICAL JOINING TYPE

MODELS: EET6, EGT5 AND EPT5

• Thoroughly read this operating instructions booklet before operating the

trolley and electric chain hoist.

• Carefully store this operating instructions booklet after reading it. This operating

instructions booklet contains important information that will be necessary when

inspecting and maintaining the trolley and/or electric chain hoist.

N.B.

The above information will be required when purchasing spare parts and when making inquiries.

Copy them from the name plate on the hoist and save them for future reference.

• The hoist operator must receive this operating instructions booklet!

• The hoist operator must read this operating instructions booklet!

Model/capacity

Serial no.

Date purchased

Customer’s notes:

NITCHI ELECTRIC CHAIN HOIST

OPERATING AND MAINTENANCE BOOKLET

• EC4 • ECT4 • ECC4

2

PREFACE

NITCHI products are made of the best selected materials, and processed through up-to-date

streamlined production facilities by skilled NITCHI engineers under severe quality control.

To assure absolute safety, dependability and satisfactory performance, ridged nal inspections and

tests in accordance with our own standards are carried out on the NITCHI products before they leave

the plant.

WARRANTY

NITCHI products are guaranteed to be free from any defects in materials or workmanship. lf any part or

parts proves defective within six months from the date of purchase, we will replace the part no-charge,

fOB Osaka, Japan, provided the part claimed defective is returned to our factory through authorized

NITCHI Distributors or Agents with transportation prepaid. However, we reserve the right to decline

responsibility for these when repairs are made or attempted by others or misused or carelessly

operated or maintained.

SAFETY PRECAUTIONS

Misuse of an electric chain hoist can cause dangerous situations such as dropping of the hoisted load

or electrical shocks. To ensure proper use, it is essential that this instructions booklet and the manual of

any other equipment that is to be used at the same time be read and fully understood before installing

or servicing the equipment.

Before use, the operator must be fully familiar with; the equipment, with all of the safety procedures

and the warning provisions. In this instructions booklet two categories “DANGER”and“CAUTION” .

EXPLANATION OF THE WARNINGS

DANGER DANGER are incorrect usages that can lead to death or serious injuries.

CAUTION CAUTION are incorrect usages that can lead to light injuries or property damage.

Situations classied as "CAUTION “ may result in serious conditions in some cases.

Precautions must be obeyed no matter what category they come under.

!

!

• Serious injuries are permanent disabilities, wounds that require hospitalization or prolong

outpatient treatment such as; loss of eyesight, injuries, burns, electrial shocks, and broken bones.

• Light injuries mean burns and electrical shocks that do not require hospitalization and prolong

outpatient treatment.

• Property damages are major losses to the building, equiment or machinery.

EXPLANATION OF THE SYMBOLS

Procedures that are forbidden (not allowed) during operation of the product. Examples are shown in

drawings or expressed in words near the symbol.

Procedures that are mandatory (that must be carried out) during the operation of the product.

Examples are shown in drawings or expressed in words near the symbol.

This symbol expresses that an eective ground wire is absolutely necessary .

Details will be shown in circuit diagrams, drawings or expressed in words near the symbol.

This symbol gives warning of electrical shocks that can occur when handling the product.

Details will be shown in drawings or expressed in words near the symbol.

This instructions booklet must be stored where it can be easily accessed by the user.

PROHIBITED

MANDATORY

GROUND

CONNECTION

ELECTRIC

HAZARD

N.B.

3

1. OVERALL HANDLING

2. IMPORTANT!!

The following warnings and safety procedures are essential for avoiding possible bodily injury and

property damage.

2.1 BASIC SAFETY PROCEDURES

CAUTION

NEVER lift more than the rated load marked on the hoist.

NEVER use the hoist to lift, support or transport people.

NEVER lift or transport loads over or near people.

ALWAYS read the operation and safety instructions.

2.2 SAFETY PROCEDURES PRIOR TO USE:

CAUTION

ALWAYS The operator of the hoist must be a person who is completely familiar

with all safety and operation procedures.

ALWAYS Check the hoist before use and conrm that the load chain is well

lubricated.

ALWAYS Check the brake before use.

ALWAYS Check the safety latches to see if they work properly. Broken and missing

safety latches must be replaced immediately.

ALWAYS Use genuine NITCHI parts and chains.

NEVER Modify the hoist.

NEVER Use modied or deformed hooks.

NEVER Use a hoist when malfunction, unusual performance, damage or

extensive wear are found.

NEVER Abuse the over-hoisting/over-lowering limit switch mechanism by using it

regularly.

NEVER Remove or obscure the warnings and nameplate on the hoist.

DANGER

The unit (electric chain hoist and trolley) must be operated only by people who fully understand the operating instruc-

tions booklets and the precautions on the warning name plates. People without the necessary qualications must not

operate the unit or carry out hook and sling connecting operations. lnspect the unit before operating it, and carry out

periodical inspections. Never hoist/lift people!

!

!

!

4

SAFETY PROCEDURES DURING OPERATION

CAUTION

ALWAYS Set the load properly in the hook.

ALWAYS Conrm that the safety latch has closed completely.

ALWAYS Take up the slack of the load chain and sling carefully, and make the initial

load lifto shock as small as possible.

ALWAYS Use a hoist within the“ Duty rating“ , ED % or time rating.

ALWAYS Avoid excessive inching and make sure that the hoist motor completely

stops before reversing the operating direction.

NEVER Allow your attention to be diverted when operating the hoist and never leave a suspended

load unattended.

NEVER Operate the hoist unless the load is centered underneath it.

NEVER Use the hoist with twisted, kinked, damaged or worn chain and never

attempt to lengthen the load chain.

NEVER Use the load chain as a sling and never apply the load to the tip of the hook.

NEVER Use the load chain so that it comes in to contact with an edge.

NEVER Allow the chain or hook to be used as a ground for welding and never touch them with

live welding electrodes.

NEVER Abuse the friction clutch by using it frequently. lmproper use can severely

damage the hoist and lead to serious injuries.

NEVER Pull on the pendant control cable.

MAINTENANCE SAFETY PROCEDURES

CAUTION

ALWAYS Have a qualied service person inspect the hoist periodically.

ALWAYS Clean the hoist thoroughly and keep the load chain well lubricated.

ALWAYS Only allow the friction clutch to be adjusted at an authorized NITCHI Service Shop .

NEVER Attempt to extend, repair or weld the load chain.

NEVER Touch live electrical parts.

!

!

5

3. CONDITIONS OF USE

The EC4 Series electric chain hoists and trolleys are designed for the vertically lifting, lowering and hori-

zontal transportation of loads by operating the pendant push button switch, and must be used within

the following conditions:

1. Power source : As specied on name plate of the electric chain hoist, and motorized trolley.

2. Trolley beam : Trolley to be used only on the designated beams.

3. Temperature : / 20°C ÷ 40°C

4. Humidity : Under 90%

5. Protection : IP54 (Do not use in rain or dusty environments.)

6. Enclosure status: Do not use in ambient conditions that contain steam or explosive gases.

7. Duty rating: Model EC4 30 minutes

Model ECT4 10/30 minutes (slow / fast)

Model ECC4 15 minutes

Model EET6 30 minutes

8. FEM group : Models EC4, EET6 1 Am

Models ECT4, ECC4 1 Bm

STANDARD SPECIFICATIONS................................................................................................................................................................ 1

INSTALLATION............................................................................................................................................................................................... 6

Connecting the Chain bucket................................................................................................................................. 6

Lubrication...........................................................................................................................................................................7

Circuit breakers..................................................................................................................................................................7

Power source cabIe........................................................................................................................................................ 8

Adjusting the Trolley width....................................................................................................................................... 8

Number of Spacer washers....................................................................................................................................... 9

Connecting the Hoist to the Motorized trolley.............................................................................................11

Connecting the Hoist to the Trolley......................................................................................................................12

Setting the Trolley onto the beam........................................................................................................................13

Connecting the Power source cabIe...................................................................................................................14

Connecting the Quick coupling.............................................................................................................................15

lnspection After lnstallation......................................................................................................................................16

INSPECTION & MAINTENANCE.......................................................................................................................................................... 17

INSPECTION BEFORE USE......................................................................................................................................................................17

MONTHLY AND ANNUAL INSPECTIONS...................................................................................................................................... 17

INSPECTION POINTS..................................................................................................................................................................................18

Hook & Chain lnspection............................................................................................................................................ 20

Care After lnstallation....................................................................................................................................................21

ADJUSTING THE BRAKE............................................................................................................................................................................22

Adjusting the electromagnetic brake............................................................................................................................................22

CIRCUIT DIAGRAM......................................................................................................................................................................................23

Caution.................................................................................................................................................................................. 23

POWER SOURCE CABLE SPECIFICATIONS..................................................................................................................................26

SPARE PARTS TABLE AND SPARE PARTS CODE TABLE............................................................................................................ 26

CONTENTS

6

STANDARD SPECIFICATIONS

HOOK SUSPENDED TYPE ELECTRIC CHAIN HOIST

EC4 250 kg • 500 kg • 1t ECJ4 1tw · 2t

Item

No.

Rated

load

Lift

(m)

Lifting speed

(m/min)

Motor output

(kW) Rating

(min)

Load chain Cable lenght Mini-

mum

head

room G

(mm)

Net

weight

(= kg)

Power

source

(m)

Pen-

dant

S (m)

50Hz 60Hz 50Hz 60Hz Type Nos. of

falls

EC40025 250kg

3.0

8.7 10.3 0.4 0.5

30

6.3

1

5.0

2.6

485

37

6.0 5.6 40

EC40050 500kg

3.0

8.6 10.1

0.9 1.1

2.6

250

660

40

6.0 5.6 43

ECJ4010 0 1tw

3.0

4.3 5.0 2

2.6 45

6.0 5.6 57

EC40100 1t

3.0

5.6 6.6

1.1 1.3 7.1

1

2.6

570

755

57

6.0 5.6 55

ECJ40200 2t

3.0

2.8 3.3 2

2.6 60

6.0 5.6 67

Item

No.

Rated

load

Hook

block

weight (kg)

Major Dimensions (mm)

A B D E F1 P Q

EC40025 250kg

0.7

245 245

137 149 20 660 795

EC40050 500kg

ECJ40100 1tw 2.4 167 119

25

715 225

835

EC40100 1t 0.9

255 255

150 168 710 200

ECJ40200 2t 5.0 191 127 30 770 240

890

1 . Values marked will dier in accordance with the height of lift.

2. The specications in the above table are subject to change without notice.

7

ELECTRIC CHAIN HOIST WITH MOTORIZED TROLLEY

Item No. Rated

Load

Lift

(m)

Traversing

speed (m/min) Motor

outpur

(kW)

Rating

(min)

Breadth

of beams

b (mm)

Mini-

mum

radius

for curve

(m)

Cable Length Mini-

mum

head

room G

(mm)

Net

Weight

(=kg)

50Hz 60Hz

Power

source

(m)

Pendant

S (m)

ECE40025 250kg 3.0

20

(10)

24

(12)

Refer to

page-9 1.0 1.0

3.0 495 66

6.0 6.0 69

ECE40050 500kg 3.0 0.2 3.0 530 68

6.0 30 6.0 72

ECJE40100 1tw 3.0 3.0 660 74

6.0 6.0 80

ECE40100 1t 3.0 3.0 565 80

6.0 6.0 84

ECJE40200 2t 3.0 3.0 780 112

6.0 6.0 119

0.4

Item No. Rated

load

Hook

Block

weight

(kg)

Major Dimensions (mm)

A B D E F1 H I K L M P Q U

ECE40025 250kg 0.7

245 245

123 149 20

b/2

+280

b/2

+240 280 32

-t

b-

41

670 195

99

+t

ECE40050 500kg

ECJE40400 1tw 2.4 153 119 25

715 225

835

ECE40100 1t 0.9

255 255

136 168 705 200

ECJE40200 2t 5.0 177 127 30 b/2

+325

b/2

+250 350 33-

t b-60 790 240 121

+t

910

1. Values marked will dier in accordance with the height of lift.

2. The specications in the above table are subject to change without notice.

3. The specications in the ( ) are for electric trolleys with half speed.

4. Please refer to the beam drawing on the right for the locations of dimensions b and 12.

5. Please refer to page-1 for the specications of the hoist (EC4).

ECE4 250 kg • 500 kg • 1t ECJE4 1tw • 2t

8

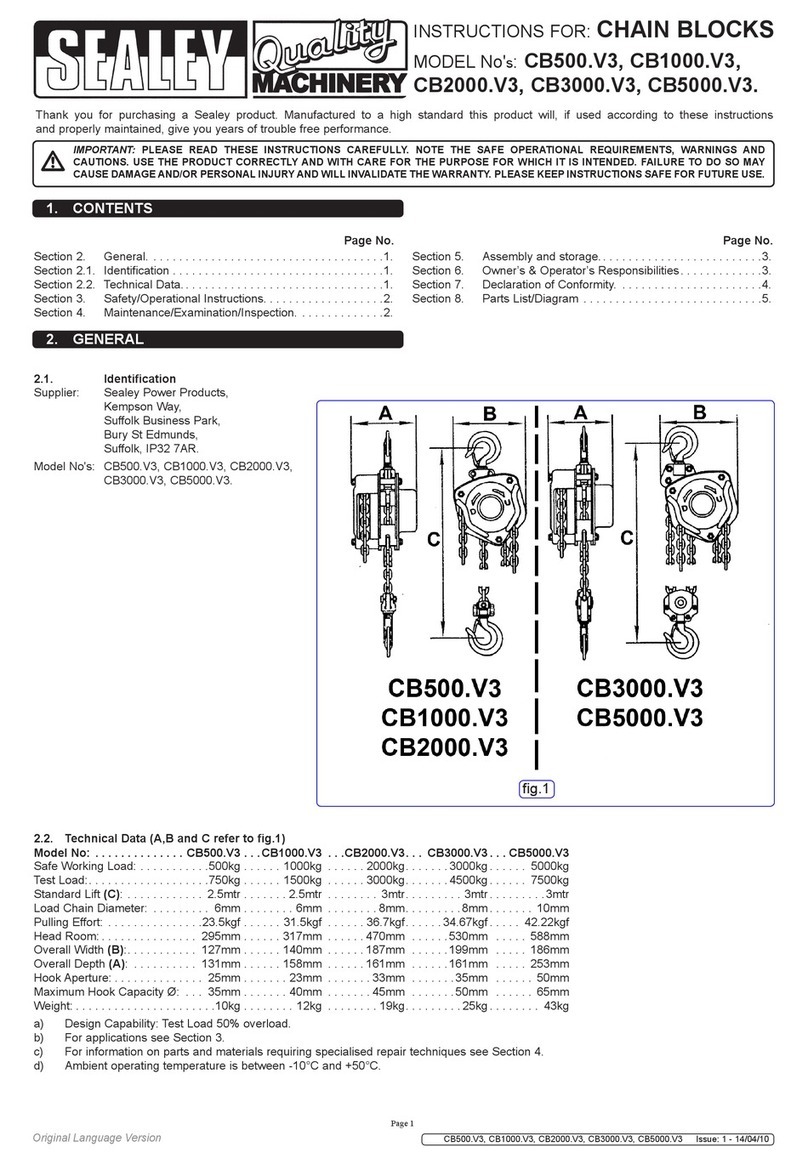

ELECTRIC CHAIN HOIST WITH GEARED TROLLEY OR PLAIN TROLLEY

ECG4 250 kg • 500 kg • 1t ECJG4 1tw • 2t

Item No. Rated

load

Lift

(m)

Mini-

mum

radius

for

curve

(m)

Cable length Mini-

mum

head

room

G

(mm)

Common specications

Power

source

(m)

Pen-

dant

S (m)

Major Dimensions (mm)

A B D E F1 I K L M P Q U

ECG40025 250kg 3.0

1.0

5.0

2.6 475

245 245

137 149 20

179 238 24

-t

b-

4

650 195

80

+t

ECP40025 6.0 5.6

ECG40050 500kg 3.0 2.6 510

ECP40050 6.0 5.6

ECJG40100 1tw 3.0 2.6 640 167 119

25

695 225

ECJP40100 6.0 5.6 815

ECG40100 1t 3.0 2.6 550

255 255

150 168 685 200

ECP40100 6.0 5.6

ECJG40200 2t 3.0 1.2 2.6 765 191 127 30 200 310 28

-t b-53 775 240 102

+t

ECJP40200 6.0 5.6 895

Item

No. Rated load Hook block

weight (kg)

Geared trolley Plain trolley

Hand chain

Amount of gear

trolley movement

when hand chain

is pulled 1 meter

(mm)

H

(mm) TNet weight

(=kg)

H

(mm)

Net weight

(=kg)

ECG40025 250kg

0.7

3.0

229 b/2 +190 72 + t

51

256

46

ECP40025 6.0 56 50

ECG40050 500kg 3.0 53 49

ECP40050 6.0 59 52

ECJG40100 1tw 2.4 3.0 59 55

ECJP40100 6.0 67 60

ECG40100 1t 0.9 3.0 64 60

ECP40100 6.0 71 64

ECJG40100 2t 5.0 3.0 138 b/2 +150 115 + t 86 292 79

ECJP40200 6.0 96 86

1. Values marked will dier in accordance with the height of lift.

2. The specications in the above table are subject to change without notice.

3. Please refer to the beam drawing on the right for the locations of dimensions b and t.

4. Please refer to page-1 for the specications of the hoist (EC4).

9

SUSPENDED TYPE 2-SPEED ELECTRIC CHAIN HOIST

Item

No.

Rated

load

Lift

(mm)

Lifting speed (m/min) Motor output (kW) Rating

(min) Load chain Cable Length Mini-

mum

head

room

G

(mm)

Net

weight

(=kg)

Fast Slow Fast Slow

fast Slow Type Nos.

of

Power

source

(m)

Pen-

dant

S

(m)

50Hz 60Hz 50Hz 60Hz 50Hz 60Hz 50Hz 60Hz

ECT40025 250kg 3.0 8.7 10.3 2.2 2.6 0.4 0.5 0.1 0.13

30 10

ø

6.3

1

5.0

2.6 485 39

6.0 5.6 42

ECT40050 500kg 3.0 8.6 10.0 2.2 2.6

0.9 1.1 0.23 0.28

2.6 520 43

6.0 5.6 46

ECTJ40100 1tw 3.0 4.3 5.1 1.1 1.3 2 2.6 660 49

6.0 5.6 54

ECT40100 1t 3.0 5.6 6.7 1.4 1.7

1.1 1.3 0.27 0.33 ø

7.1

12.6 570 56

6.0 5.6 60

ECTJ40200 2t 3.0 2.8 3.3 0.7 0.8 2 2.6 755 66

6.0 5.6 73

Item No. Rated load Hook Block

weight (kg)

Major dimensions

A B D E F1 P Q

ECT40025 250kg 0.7

245 245

137 149 20 660 195

ECT40050 500kg

ECTJ40100 1tw 2.4 167 119 25

715 225

835

ECT40100 1t 0.9

255 255

150 168 710 200

ECTJ40200 2t 5.0 191 127 30 770 240

890

1. Values marked will dier in accordance with the height of lift.

2. The specications in the above table are subject to change without notice.

ECT4 • 500 kg • 1t ECTJ4 1tw • 2t

10

SUSPENDED TYPE SINGLE-PHASE ELECTRIC CHAIN HOIST

ECC4 • 500 kg ECCJ4 1tw

Item

No.

Rated

load

Lift

(m)

Lifting speed

(m/min)

Motor output

(kW)

Rating

(mm)

Load chain Cable Length Mini-

mum

head

room G

(mm)

Net

weight

(= kg)

50Hz 60Hz 50Hz 60Hz Type Nos. of

falls

Power

source

(m)

Pen-

dant

S (m)

ECC40030 300kg

3.0

5.4 6.4

0.4 15 6.3

1

5.0 2.6

485 37

ECC40050 500kg 3.2 3.8 520 37

ECCJ40100 1tw 1.6 1.9 2 660 43

Item

No.

Rated

load

Hook Block

Weight

(kg)

Major Dimensions (mm)

A B D E F1 P Q

ECC40030 300kg

0.7

245 245

137 149 20 660 195

ECC40050 500kg

ECCJ40100 1tw 2.4 167 119 25 715 225

1. Values marked will dier in accordance with the height of lift.

2. The specications in the above table are subject to change without notice.

11

INSTALLATION

CONNECTING THE CHAIN BUCKET

PROHIBITED

MANDATORY

!

• Do not modify the chain bucket assembly.

• Always attach the chain bucket assembly before

raising the hoist into position.

DANGER

1. Connect the chain bucket assembly with

the chain bucket pins.

2. Feed the load chain into the chain bucket

gradually and neatly from the end.

3. The load chain may tangle and the hoist

may not operate correctly when the load

chain is placed into the chain bucket as-

sembly in one bundle.

4. The inside of the chain bucket assembly

must be cleaned periodically when the

hoist is used in an area where dust and

foreign matter can enter the chain bucket

assembly.

Open the split pin as shown in the drawing. Code Dimension A

(mm)

D1 260

D2 380

D3 480

CHAIN BUCKET APPLICATION TABLE:

!

Table 1

Table 2

0 3 6 9 12

Rated load

Type of chain

& numbers

of falls

Lift (m)

250kg . 300kg . 500kg 6.3 x 1 D1 D2 D3

1tw 6.3 x 2 D1 D2 D3

1t 7.1 x 1 D1 D2 D3

2t 7.1 x 2 D1 D2 D3

150 3 6 9 12

Chain bucket pin

Split pin

12

LUBRICATION

CIRCUIT BREAKERS

1. Lubricate the load chain before use with machine oil or gear oil.

2. When the gear section of the hoist is disassembled, always change the grease within the gear case.

Use heavy duty (disulde molybdenum) grease.

3. When the gear box section of the Motorized trolley is disassembled add an extra coat of heavy duty

grease (disulde molybdenum grease) to the gears. The gear box section normally does not need

to be regularly lubricated.

Paint the gear teeth section of the Gear wheel

and Pinion with cup grease.

1. Always install a circuit breaker.

The circuit breaker must be exclusively for the hoist and independent from other machinery.

2. Select an adequate capacity circuit breaker from Table 3.

Type of hoist Rated load Lifting motor (kW)

50Hz/60Hz

Traversing motor

(kW)

Circuit breaker

Capacity (A)

Hoist with

motorized

trolley

250kg 0.4/0.5

0.1/0.4/0.13/0.5

0.2

3 (5)

500kg

1tw

0.9/1.1

0.23/0.9/0.28/1.1

5 (10)

1t 1.1/1.3

0.27/1.1/0.33/1.3 0.4

2t

Hook suspension

hoist and hoist

with geared or

plain trolley

250kg 0.4/0.5

0.1/0.4/0.13/0.5 - 2 (3)

500kg

1tw

0.9/1.1

0.23/0.9/0.28/1.1 - 3 (5)

1t

2t

1.1/1.3

0.27/1.1/0.33/1.3 - 5 (10)

Single-phase

300kg

500kg

1tw

0.4 - 10 (15)

Table 3

Gear wheel

Pinion

13

POWER SOURCE CABLE

ADJUSTING THE TROLLEY WIDTH

1. With electric chain hoists that use the electrical cable power feeding method, always be sure to use

the appropriate sized cabtyre cable (tough-rubber sheathed cabIe).

2. Use a larger size cabtyre cable when the cable length is long, and when there is a possibility

that the hoist and the motorized trolley will be operated together at the same time.

3. Please refer to Table 12 for the specications of long cabtyre cables.

Adjust the width between the trolley wheels as follows:

1. Remove the Hexagonal nuts, and remove the side-plate.

2. Adjust the width by increasing or decreasing the number of inner spacer washers. Refer to Tables 4

and 5 for the appropriate combination of inner and outer spacer washers.

3. Tighten the Hexagonal nuts for the Stay bolts.

4. Conrm that the Top holder is positioned directly under the center of the trolley beam.

Incorrect installation of the Adjusting

Spacer washers

Wheel Side-plate

Hexagonal nut

Spacer washers

Top holder

14

NUMBER OF SPACER WASHER

EET6

BEAM SIZE 250kg - 1t 2t

EET6

INP IPE mm A B C D A B C D

12 58 11 0 0 11 - - - -

12 64 10 1 1 10 - - - -

14 66 10 1 2 9 - - - -

15 70 9 2 2 9 - - - -

14 73 9 2 3 8 - - - -

16 74 9 2 3 8 - - - -

18 16 82 7 4 4 7 8 0 0 8

20 90 6 5 6 5 7 1 1 7

18 91 6 5 6 5 7 1 1 7

22 98 5 6 7 4 6 2 2 6

20 100 4 7 7 4 6 2 2 6

24 106 3 8 8 3 6 2 3 5

22 110 3 8 9 2 5 3 3 5

26 113 2 9 9 2 5 3 4 4

28 119 1 10 10 1 4 4 4 4

24 120 1 10 10 1 4 4 4 4

30 125 0 11 11 0 3 5 5 3

32 131 - - - - 3 5 6 2

27 135 - - - - 2 6 6 2

34 137 - - - - 2 6 6 2

36 143 - - - - 1 7 7 1

38 149 - - - - 1 7 8 0

30 150 - - - - 1 7 8 0

40 155 - - - - 0 8 8 0

Table 4

Quantity and location

15

NUMBER OF SPACER WASHER

Quantity and location

EPT5 EGT5

BEAM SIZE 250kg - 1t 2t

EPT5 EGT5 EPT5 EGT5

INP IPE MM A B C D A B C D A B C D A B C D

10 55 17 0 0 17 0 0 0 34 - - - - - - - -

12 58 17 0 1 16 0 0 1 33 - - - - - - - -

12 64 16 1 2 15 0 1 2 31 - - - - - - - -

14 66 15 2 2 15 0 2 2 30 12 0 0 12 0 0 0 24

15 70 15 2 3 14 0 2 3 29 12 0 1 11 0 0 1 23

14 73 14 3 3 14 0 3 3 28 11 1 1 11 0 1 1 22

16 74 14 3 4 13 0 3 4 27 11 1 1 11 0 1 1 22

18 16 82 13 4 5 12 0 4 5 25 10 2 2 12 0 2 2 20

20 90 11 6 6 11 0 6 6 22 9 3 3 9 0 3 3 18

18 91 11 6 6 11 0 6 6 22 9 3 3 9 0 3 3 18

22 98 10 7 8 9 0 7 8 19 8 4 4 8 0 4 4 16

20 100 10 7 8 9 0 7 8 19 8 4 4 8 0 4 4 16

24 106 9 8 9 8 0 8 9 17 8 4 5 7 0 4 5 15

22 110 8 9 10 7 0 9 10 15 7 5 5 7 0 5 5 14

26 113 8 9 10 7 0 9 10 15 7 5 6 6 0 5 6 13

28 119 6 11 11 6 0 11 11 12 6 6 6 6 0 6 6 12

24 120 6 11 11 6 0 11 11 12 6 6 6 6 0 6 6 12

30 125 5 12 12 5 0 12 12 10 5 7 7 7 0 7 7 10

32 131 4 13 13 4 0 13 13 8 5 7 8 8 0 7 8 9

27 135 4 13 14 3 0 13 14 7 4 8 8 8 0 8 8 8

34 137 3 14 14 3 0 14 14 6 4 8 8 8 0 8 8 8

36 143 2 15 15 2 0 15 15 4 3 9 9 9 0 9 9 6

38 149 1 16 16 1 0 16 16 2 3 9 10 10 0 9 10 5

30 150 1 16 16 1 0 16 16 2 3 9 10 10 0 9 10 5

40 155 0 17 17 0 0 17 17 0 2 10 10 10 0 10 10 4

33 160 - - - - - - - - 2 10 11 11 0 10 11 3

42½ 163 - - - - - - - - 1 11 11 11 0 11 11 2

45 36 170 - - - - - - - - 0 12 12 12 0 12 12 0

Table 5

16

CONNECTING THE HOIST TO THE MOTORIZED TROLLEY

1

3

5

4

• Connect the electric trolley and motorized chain hoist

• connecting cable.

• lnsert the Plug (Plug housing) completely till it is locked.

• Next secure the Gasket and Connector cover positively.

• Loosen the fastening screws and

detach one-side of the wire hanger

as shown in the drawing.

• Insert the pendant cable wire,

reassemble and rmly tighten the

fastening screws.

• Conrm that the cables are connected

as shown in the drawing.

• Firmly screw in the tightening cap.

• The shape of The top helder pin is as shown in the drawing.

• lnsert the Top holder pin and set the Washer onto it.

• Lightly tighten the Nut by hand and insert the Split pin.

Connecting the cables:

Connecting the pendant cable:

Connecting 1tw and 2t

Plug housing

Receptacle housing Connector cover gasket

Fastening screw

Connector

cover

Wire hanger

Connecting

section of pen-

dant cable wire

Tightening cap

Top holder pin

Washer

Split pin

Nut

• Insert the split pin into

the top hook pin

• Open the split pin as

shown in the drawing.

Motorized trolley

Top hook pin

Electric chain hoist

Split pin

Wire hanger

Socket

Connecting

section of

pendant cable

2

• Connect the electric

chain hoist to the mo-

torized trolley as shown

in the drawing, and be

sure that the direction

of the electric chain

hoist and the motori-

zed trolley are correct.

• Insert the top hook

pin as shown in the

drawing and be sure to

use the correct hole.

17

CONNECTING THE HOIST TO THE GEARED TROLLEY (PLAIN TROLLEY)

1 2

Connect the trolley to the

electric chain hoist as

shown in the drawing and

be sure that the trolley

and electric chain hoist

are both facing the correct

direction.

lnsert the Top hook pin as

shown in the drawing, and

be sure to use the correct

hole.

3 4

lnsert the Split pin into the

hole of the Top hook pin

Open the Split pin as

shown in the drawing.

The connecting method of a Plain trolley is basically the same as the above.

Geared trolley (Plain trolley)

Electric chain

hoist

Insert into the hole

Top hook pin

Split pin

SETTING THE TROLLEY ONTO THE BEAM

PROHIBITED

!

• The trolley must be installed onto the trolley

beam only by qualied people with the neces-

sary knowledge.

DANGER

lnserting an assembled trolley from the end of the trolley beam:

• Remove the Stoppers at the end of the trolley beam, and insert the trolley.

• Replace and positively secure the stoppers.

1.

2.

3.

How to install the trolley when the assembled trolley can not be inserted from

the end of the trolley beam:

• Remove the Hexagonal nuts from the Stay bolts.

• Dismount the Plain-side plate.

• Set the Geared wheels on to the tread section of the trolley beam.

• While holding the Geared wheels in position, insert the Plain-side plate so that the Plain

wheels will be in position on the tread section of the trolley beam.

• Firmly tighten the Hexagonal nuts of the Plain-side plate side of the Stay bolts.

When the trolley beam is curved, install the trolley so that the geared wheels

are on the outside of the curve.

Motorized trolley Geared trolley

18

Stopper

Plain-side plate

Stay bolt

Motor

Gear wheel

Hand wheel

Gear wheel

Trolley beam

Trolley beam

Gear-side plate

Gear wheel

Gear wheel on the tread section

of the trolley beam.

The designs of the actual trolleys are dierent from

what are shown in the photograpghs and drawing.

Appearance of trolley correctly

installed on to trolley beam.

19

CONNECTING THE POWER SOURCE CABLE

PROHIBITED

!

• The hoist must be eciently grounded, and an inde-

pendent circuit breaker of the appropriate capacity

must be installed in the power source system.

DANGER

The power source systems of hoists connected to trolleys are as follows:

lnstall a messenger wire ( 6 mm steel cable) parallel to the trolley beam.

Hang the power source cable from the messenger wire with cable carriers, and be

careful not to twist the power source cable.

lnstall cable carriers at every 1.5 meters length of the power source cable.

The connections of the Power source cable must only be made at the Hoist,Termi-

nal box and Power source switch. Do not use Power source cables that are lengthe-

ned with connections.

The following power source feeding method can be used in place of the Messen-

ger wire method. Please consult an electrician for the most appropriate method for

your hoist: CABLE CARRIER METHOD,

TROLLEY DUCT METHOD &

TROLLEY WIRE METHOD

GROUND

CONNECTION

1.

1.

2.

3.

Messenger wire

Trolley beam

Power source switch

Cable carrier Terminal box

20

Disconnecting:

Loosen the Tightening cap.

Remove the Fastening screws from the Connector cover.

Slide the Connector cover gasket and Connector cover

out of the way.

Disconnect the Plug (Plug housing).

Pull the Plug (Plug housing) out while

pressing the section down.

Pull the Plug (Plug housing) out while

pressing the section down.

CONNECTING THE QUICK COUPLING

Disconnecting and Connecting the Quick coupling:

Connecting:

The connecting procedures are the opposite of the disconnecting procedures.

lnsert the Plug (Plug housing) positively.

While holding the cable and preventing it from rotating, screw in the Tightening cap.

Screw in the Tightening cap by hand, and do not use any tools.

Over-tightening will damage the Tightening cap.

1.

2.

3.

4.

Tightening cap

Connector cover

Inner lock type Outer lock type

This manual suits for next models

30

Table of contents

Other Nitchi Chain Hoist manuals

Popular Chain Hoist manuals by other brands

CM

CM Lodestar D8 PLUS Addendum

Sealey

Sealey CB500.V3 instructions

Columbus McKinnon

Columbus McKinnon Yale CPV Series Translated Operating Instructions

CMCO

CMCO Yale CPA ATEX 20-8 operating instructions

Sumake

Sumake HCH-500 instruction manual

Columbus McKinnon

Columbus McKinnon Entertainment-Lodestar B Operating, Maintenance & Parts Manual