Nitec EPR-203 User manual

OPERATION MANUAL

Robot Positioner

SAFETY INSTRUCTIONS

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and main-

tenance (servicing) instructions in the literature

accompanying the appliance.

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK)

NO USER-SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

SAFETY INSTRUCTIONS

PLEASE READ ALL THESE INSTRUCTIONS AND RETAIN FOR FUTURE REFERENCES.

FOLLOW ALL WARNINGS AND INSTRUCTIONS MARKED ON THE UNIT.

1.

Read Instructions

All the safety and operating instructions should be

read before the appliance is operated.

2.

Retain Instructions

The safety and operating instructions should be re-

tained for future reference.

3.

Heed Warnings

All warnings on the appliance and in the operating

instructions should be adhered to.

4.

Follow Instructions

All operating and use instructions should be

followed.

5.

Attachments

Do not use attachments not recommended by the

manufacturer as they may cause hazards.

6.

Accessories

Any mounting of the appliance should follow the

manufacturer's instructions, and should use a

mounting accessory recommended by the

manufacturer.

7.

External Cables

Connect the cables with VW-1 rated jacket to the

product. Cables consisted of wires suitable for the

rating of the intended load should be used. Other-

wise, use the cables specified by the manufacturer.

8.

External Cables Protection

Do not walk or place anything on the cable for this

would put unnecessary pressure on the cable. Set

all circuits in one place.

9.

Power Lines

An outside antenna system should not be located

in the vicinity of overhead power lines or other elec-

tric light or power circuits, or where it can fall into

such power lines or circuits. When installing and

outside antenna system, extreme care should be

taken to keep from touching such power lines or

circuits , as contact with them might be fatal.

10.

Object and Liquid Entry

Never push objects of any kind into this product

through openings as they may touch dangerous

voltage points or short-out parts that could result in

a fire or electric shock. Never spill liquid of any kind

on the product.

11.

Servicing

Do not attempt to service this product yourself as

opening or removing covers may expose you to

dangerous voltage or other harzards. Refer all ser-

vicing to qualified service personnel.

12.

Damage requiring Service

If the following situations occur, unplug Satellite

Selector Power-Cord from the outlet, turn off

power, and call qualified service personnel for

repair.

(a) If the External Cables had been damaged.

(b) If liquid has been spilled, or objects have fallen

into the product.

(c) If the product does not operate normally by

following the operating instructions.

Adjust only those controls that are covered by

the operating instructions as an improper ad-

justment of other controls may result in damage

and will often require extensive work by a

qualified technician to restore the product to its

normal operation.

(d) If the product has been dropped or the cabinet

has been damaged.

(e) When the product exhibits a distinct change in

performance - this indicates a need for service.

13.

Replacement Parts

When replacement parts are required, be sure the

service technician has used replacement parts

specified by the manufacturer that have the same

characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock or

other hazards.

14.

Safety Check

Upon completion of any service or repairs to this

product, ask the service technician to perform safe-

ty checks to determine that the product is in safe

operating conditions.

Robot Positioner

EPR-203

2

1

3

4

5

6

7

8

CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . 1

SPECIFICATIONS-FEATURES . . . . . . . . . 2

FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . 3

INSTRUCTION . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . 4

BEFORE OPERATION . . . . . . . . . . . . . . . 5

Page

DAILY MANTENANCE . . . . . . . . . . . . . . . 1

OPERATION CONDITION

AND WARNING . . . . . . . . . . . . . . . . . . . . 2

1

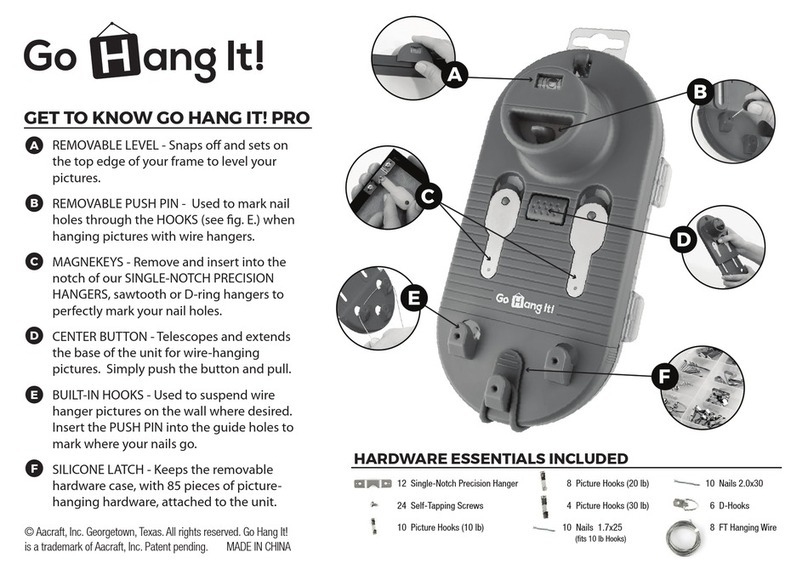

Configuration of NITEC System

1

GENERAL

This device is called Robot Positioner (EPR-203).

By installing Parabola antenna for TVRO and con-

trolling Satellite Selector, it automatically directs

the Parabola antenna to the designated satellite.

This is done by automatically moving the ap-

propriate Azimuth (AZ) and Elevation (EL).

This manual only contains instructions for

mechanical parts, and we recommend you also

refer to "Satellite Selector Operation Manual".

We hope that you gain more knowledge on this

device to take a full advantage of its features and

to take proper maintenance care. We are certain

that you will be satisfied with this device when

used correctly.

2

SPECIFICATIONS-FEATURES

SPECIFICATIONS

FEATURES

(1) Operates on controls by both Azimuth and

Elevation.

(2) All controls can be made from Satellite

Selector.

(3) Waterproof to allow the use in the rain.

2

Model Name

: EPR-203

Motor Power Supply

: 24 VDC (both azimuth and Elevation Motors)

Motor Rating

: 18 Watts (both azimuth and Elevation Motors)

Control Shaft

: 2-shaft control for azimuth and Elevation

Motor Rated Rotation Speed

: 3000 rpm (both azimuth and Elevation)

Internal Resolution

: Azimuth 0.01 degree/pulse

Elevation 0.0025 degree/pulse

Maximum Azimuth Range

: 180 degree (90 degree to 270 degree west longitude)

Maximum Elevation Range

: 40 degree (Upwards inclination 10 degree to 50 degree from the horizontal)

Pulse Encoder :

- Output Pulse

: 2-phase (A and B) pulse

- Output Pulse Rate

: 6 pulse/revolution

- Input Power Supply

: 24 VDC

ORG (Original) Detection

: 2-switch (One ea for azimuth and Elevation)

Repeatability

: 0,2 degree (when combined with the Satellite Selector)

Dimension :

- Outside Diameter

: 12.5 inches (318 mm)

- High

: 24.5 inches (625 mm)

Weight

: 60 lbs (27 Kg)

Driver Signal Line

: 4.6 ft (1.5 m)

(Attachment Cable)

Parabola Antenna Applied (Dish)

:

Weight Load

: 150 lbs (68.5 Kg) max 10 ft Dish or less

175 lbs to 290 lbs (79.6 Kg ~ 131.8 Kg) if counterbalanced

Wind Load (After installing the 150

lbs, 8 ft, Dish) :

Functional

: 38.5 mph (62 km/hr)

Survival

: 80 to 100 mph (129 km/hr ~ 161 km/hr)

3

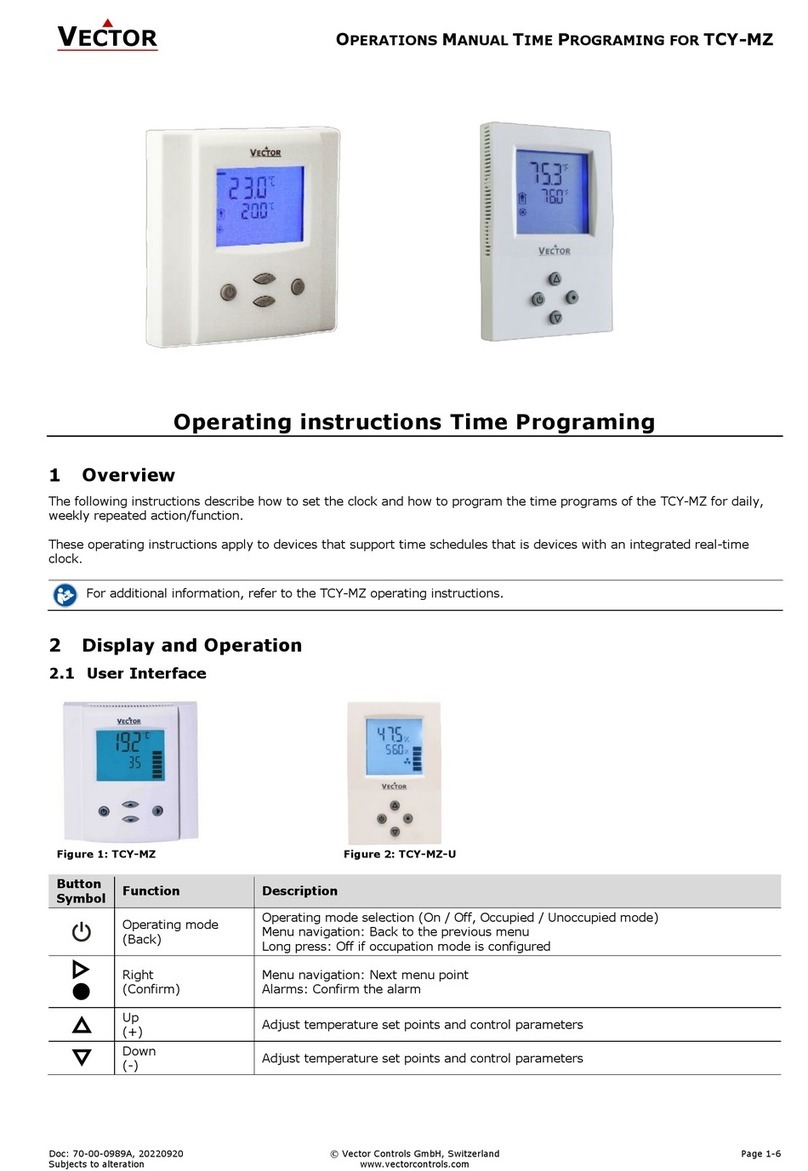

3

FUNCTIONS

4

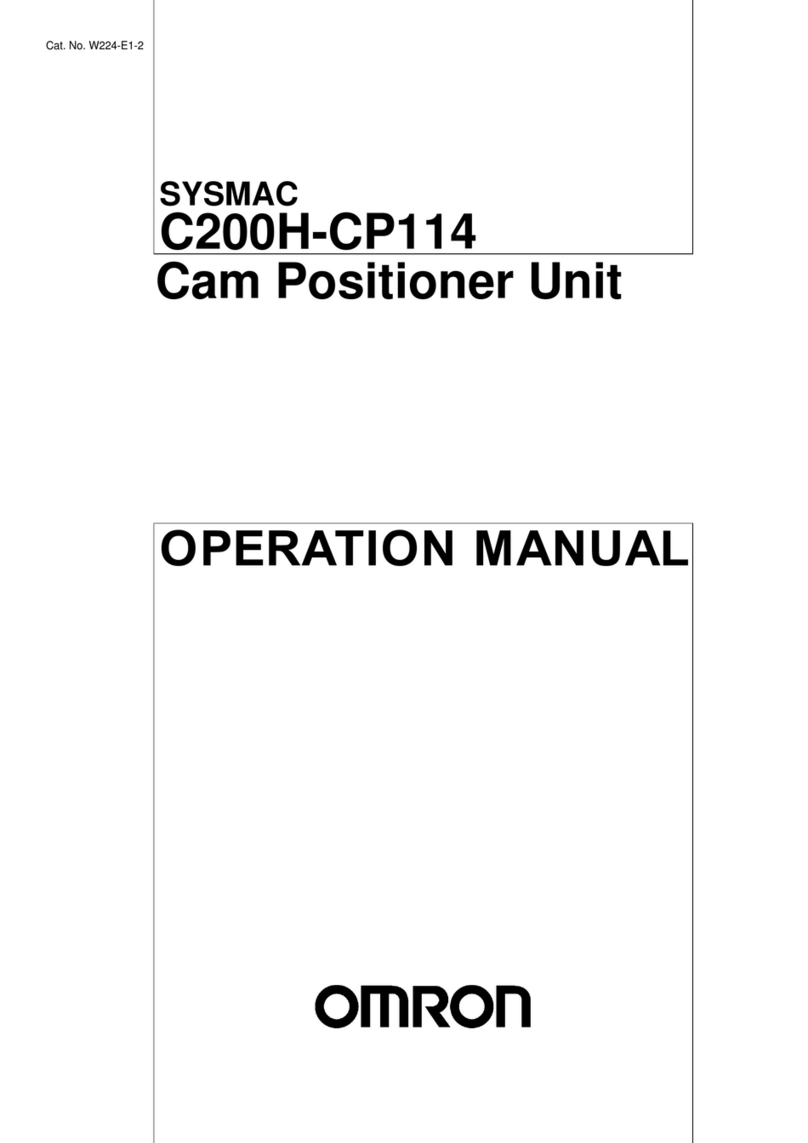

INSTRUCTION

5

INSTRUCTION

4

5

-1 Installation of Robot Positioner

5

-2 Installation of Dish

1. Do not install the Robot Positioner up-side down.

Bullhead installation side should be at the bottom.

2. Set "North" so that the arrow points to the direction of North.

3. Use bolts that match four 1/2" -13UNC screws on Bullhead installation side.

4. Use four 14 mm holes on Dish or Wedge Adapter installation flange side for installation of Dish or

Wedge Adapter.

5. Two persons should carry the Robot Positioner which weighs 60 lbs. (27 kg)

6. A spare fuse (4 A-250 VAC) is included in the carton.

Do not damage or lose this fuse.

To maintain its accuracy and to utilize its func-

tions to their maximum, the Robot Positioner

needs to be installed on a flat and sturdy base.

Therefore, when installing directly on the ground,

install on concrete with foundation bolts. If in-

stalling on the rooftop of a building or similar

position, install on the foundation similar to that.

Make sure that a big vibration from the surroun-

ding area does not reach the Robot Positioner.

The installation procedure is that first, place in-

stallation legs on concrete foundation, position

foundation bolts through four holes on installa-

tion legs, and fix the legs firmly with nuts. Next,

place the bottom of post on the legs and fix them

with four bolts. Then, cover the post with

Bullhead. Put them together with bolts around

the Bullhead pipe. These bolts are 3/8" -16UNC

bolts.

The next step is to fix the Robot Positioner into

Bullhead. We recommend you use a lift for in-

stallation. After you put the Robot Positioner on

Bullhead flange side, use 4-1/2" - 13UNC bolts

underneath the case to secure Positioner and

Bullhead in their place. (When a lift is not

available, work with two persons or more). Then,

turn Bullhead around to match the "North" make

and fix it with bolts on Bullhead.

All this series of work should be done using

gauge and other instruments to carefully main-

tain its horizontal and vertical position. At last,

connect the extension cable from Robot Posi-

tioner to Junction Box and this completes the in-

stallation work.

Follow the instructions by Dish manufcturer.

Piece the Dish assemble installation side correctly

to the Dish or Wedge Adapter flange side on

Robot Positioner. If dish assemble installation

side does not match the Robot Positioner installa-

tion side, place an installation metal instrument

between both sides and fix the Dish in its place.

Once the Robot Positioner is installed, there is

no need for readjustment mechanically or

electrically.

Please note the following at the time of

installation.

5

6

BEFORE OPERATION

7

DAILY MAINTENANCE

5

-3 Connecting the Attachement Cable

Robot Positioner has a 4.6 ft (1.5 m) Attachment

Cable with 18 numbered wires at the end, and

each wire is connected to an U-shaped pressure-

attached terminal. This terminal connects to the

terminal block of Junction Box, and then to the

terminal block of Rear Panel of Satellite Selector

via External Cables. The connection to terminal

block of Junction Box is done with matching the

wiring number of External Cables connected to

the Rear Panel of Satellite Selector with the

wiring number of Attachment Cable. This means

matching the wiring numbers indicated on

Attachment Cable of Robot Positioner and the

numbers indicated on the terminal block on Rear

Panel of Satellite Selector by using the External

Cables and connecting to the terminal block of

Junction Box.

When installation and cleaning of the device are

completed, you are ready to operate the

machine. Check if Attachment Cable from the

Robot Positioner is connected to the Satellite

Selector.

Also, make sure all nuts and bolts are securely

tightened. When you have checked that all parts

are correctly attached, you may turn on the

power switch to the Satellite Selector. For the

operation of Satellite Selector, refer to "Satellite

Selector Operation Manual"

To maintain the device's accuracy and to fully

utilize its functions, the following inspections

should be practiced regularly. In case you find

any trouble, switch off Satellite Selector and call

the qualified service personnel for repair.

[daily maintennace]

1) Do you see any impurities or dirt on the device ?

2) Does the operation noise sound normal ?

3) Is there any generation of heat ?

4) Are nuts and bolts tightened and in place ?

5) Is there any strange vibration while operation ?

6) Are there any other abnormal conducts ?

7) Are there any environmental factors that affect the

operation of the device ? (tree branches, buildings,

natural phenomenon, etc.)

8) Others

Make sure not to mistake the numbers "6"

and "9" on the c abl e . Th e un d e rli n e

indicates the bottom of the number.

• Note

6

8

OPERATION CONDITION AND WARNING

WARNING

When a hurricane or a tornado with wind velocity of 45 m/sec. or more is expected, detatch

the Dish beforehand or use chains or wires to securely attach the Dish to buildings and such.

We are not responsible for accidents due to your negligence.

The following conditions should be strictly observed for operation of the device.

1) Dish diameter 10 ft. or less

2) Dish depth 2 ft. or less

3) Dish weight 150 lbs. or less

(for 175 lbs. ~ 290 lbs. use counterbalance)

4) Dish shape parabola

5) Dish centeroid 20 inches or less from Dish or Wedge

Adapter installation flange side

6) Windload Operation wind pressure 17 m/sec. or less

Survival wind pressure 35 m/sec. or less

7) Temperature, Humidity Operation temperature - 20°C ~ +65°C

humidity 90% or less

Survival temperature - 30°C ~ +65°C

humidity 90% or less

PRINTED IN JAPAN

Table of contents

Popular Valve Positioner manuals by other brands

rotork

rotork YT-2600 Series product manual

Kongsberg

Kongsberg HiPAP 501 Product description

Festo

Festo CMSX-...-C-U-F1 series manual

DeZurik

DeZurik P200 Installation,operation and maintenance instruction

GEM

GEM 1434 mPos Installation, operating and maintenance instructions

GEM

GEM C67 CleanStar Installation, Operating and Maintenance Instructions for the Installer and the User

Leuze

Leuze BPS 37 Original operating instructions

Fisher-Rosemount

Fisher-Rosemount 3660 instruction manual

Spirax Sarco

Spirax Sarco SP500 Installation and maintenance instructions

Asco

Asco POSIMATIC 606 Series installation manual

PMV

PMV P-1500 manual

Samson

Samson 3730-4 Mounting and operating instructions