Contents

4 EB 8484-3 EN

5.10 Attachment of external position sensor...........................................................66

5.10.1 Mounting the position sensor with direct attachment........................................67

5.10.2 MountingthepositionsensorwithattachmentaccordingtoIEC60534-6 .........69

5.10.3 MountingthepositionsensortoType3510Micro-owValve...........................70

5.10.4 Mounting on rotary actuators........................................................................71

5.11 Attaching positioners with stainless steel housings...........................................72

5.12 Air purging function for single-acting actuators..............................................72

5.13 Pneumatic connections..................................................................................74

5.14 Connecting the supply air.............................................................................75

5.14.1 Signal pressure connection ...........................................................................75

5.14.2 Signal pressure gauges ................................................................................75

5.14.3 Supply pressure ...........................................................................................75

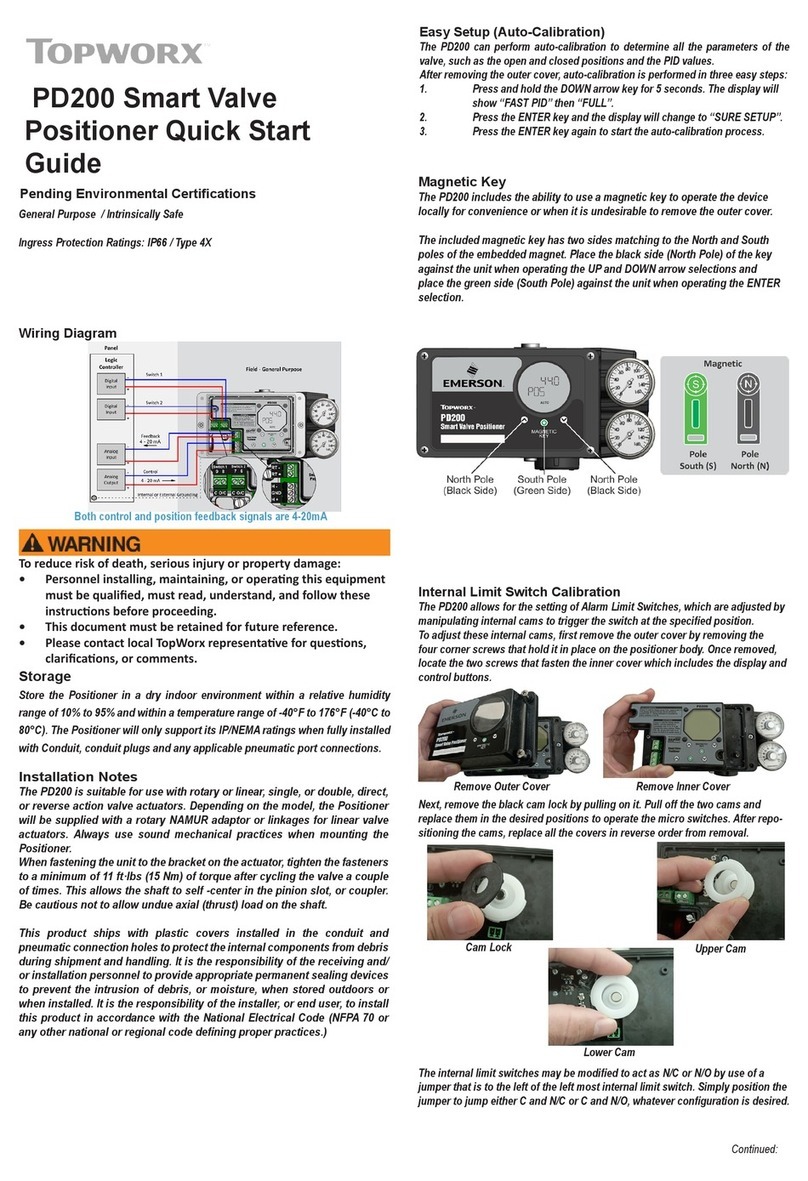

5.15 Electrical connections ...................................................................................77

5.15.1 Cable entry with cable gland........................................................................78

5.15.2 Connecting the electrical power ....................................................................78

5.15.3 Establishing HART®communication...............................................................79

5.15.4 SwitchingamplieraccordingtoEN60947-5-6 ............................................80

6 Optional additional functions.......................................................................81

6.1 Inductive limit contacts..................................................................................81

6.2 Software limit contacts..................................................................................81

6.3 Position transmitter.......................................................................................81

6.4 Forced venting.............................................................................................81

6.5 Binary input ................................................................................................82

6.6 Binary output...............................................................................................82

6.7 Adjusting the switching points.......................................................................86

6.7.1 Adjusting the CLOSED position .....................................................................86

6.7.2 Adjusting the OPEN position.........................................................................87

6.8 Turning the positioner shaft...........................................................................87

7 Operation...................................................................................................88

7.1 Rotary pushbutton........................................................................................88

7.2 AIRTOOPEN/AIRTOCLOSEslideswitch.....................................................89

7.3 Initialization key (INIT)..................................................................................89

7.4 Display .......................................................................................................90

7.4.1 Display icons...............................................................................................91

7.4.2 Changing the display's reading direction.......................................................93

7.5 HART®communication .................................................................................93

7.5.1 Dynamic HART® variables.............................................................................94