Nitronic HRC3070 User manual

Table of contents

Popular Measuring Instrument manuals by other brands

Newton

Newton T-DAR T2010MT Installation and operation manual

BGS technic

BGS technic 2188 instruction manual

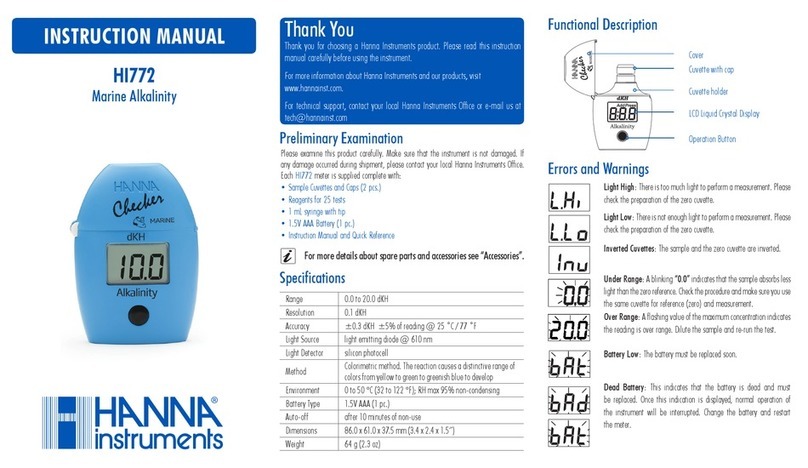

Hanna Instruments

Hanna Instruments Checker HI772 instruction manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS DO 6PLUS DISSOLVED OXYGEN TEMP instruction manual

Automation Dr. Nix

Automation Dr. Nix QNix 4200 instruction manual

Fema

Fema I3 Series user manual

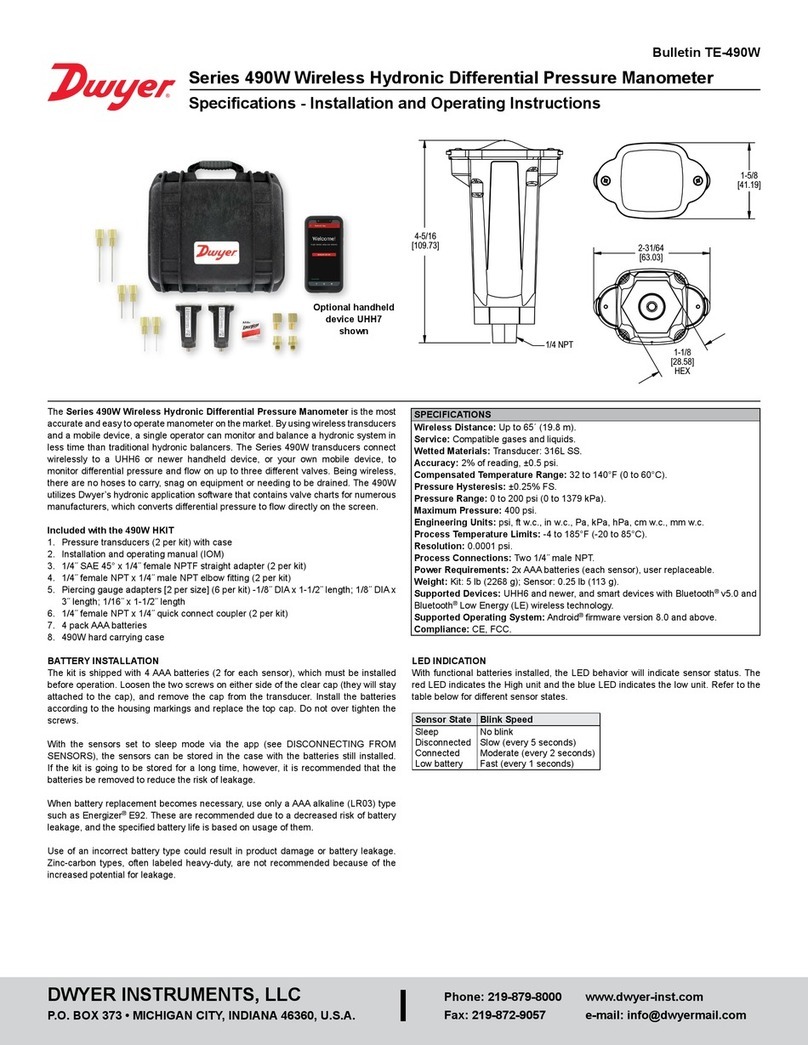

Dwyer Instruments

Dwyer Instruments 490W Series Specifications-installation and operating instructions

LSHTEC

LSHTEC 86192 user manual

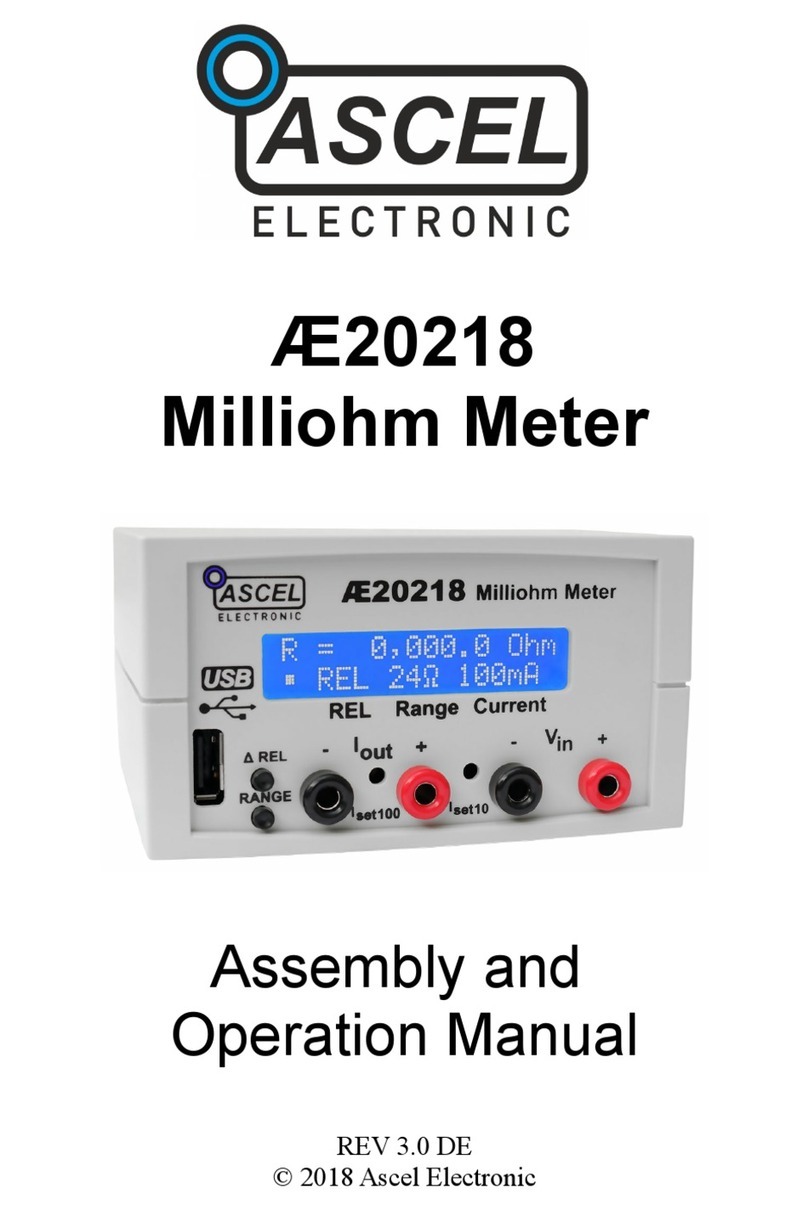

ASCEL Electronic

ASCEL Electronic AE20218 Assembly and operation manual

BTEK

BTEK WorldWEIGH BWS Series Technical manual

Topshine

Topshine TSGB02 user manual

Protimeter

Protimeter Grainmaster i instruction manual

Hach Ultra

Hach Ultra ORBISPHERE 3624 Operator's quick guide

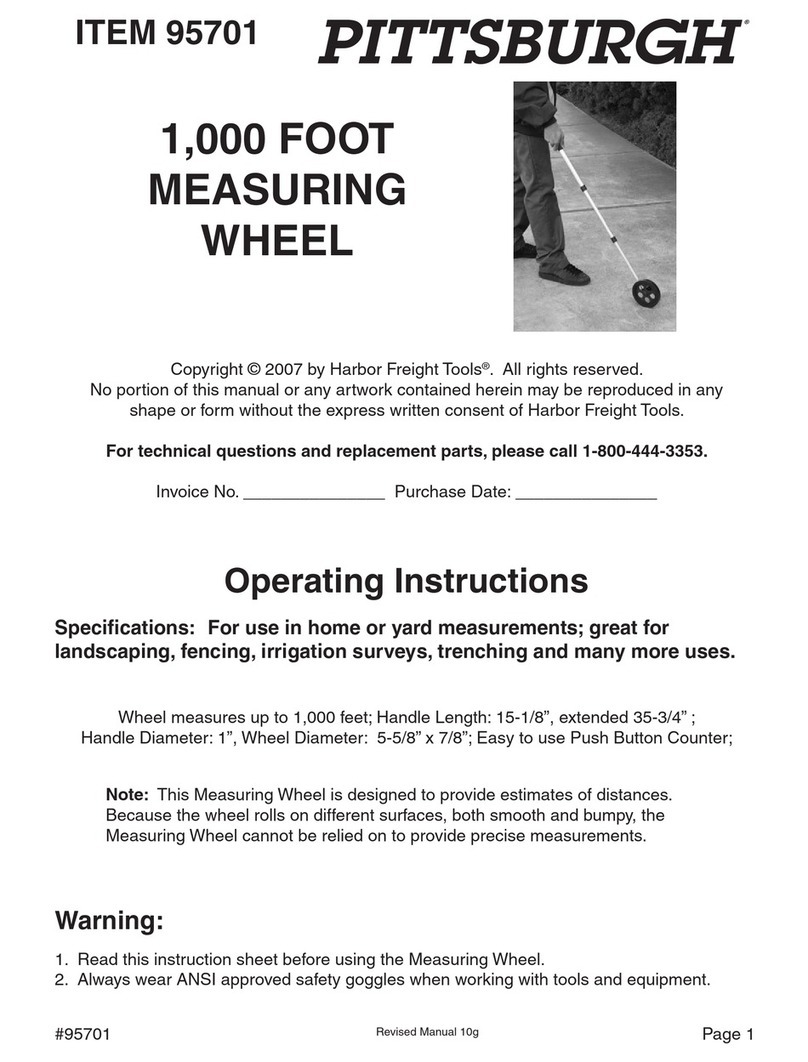

Pittsburgh

Pittsburgh 95701 operating instructions

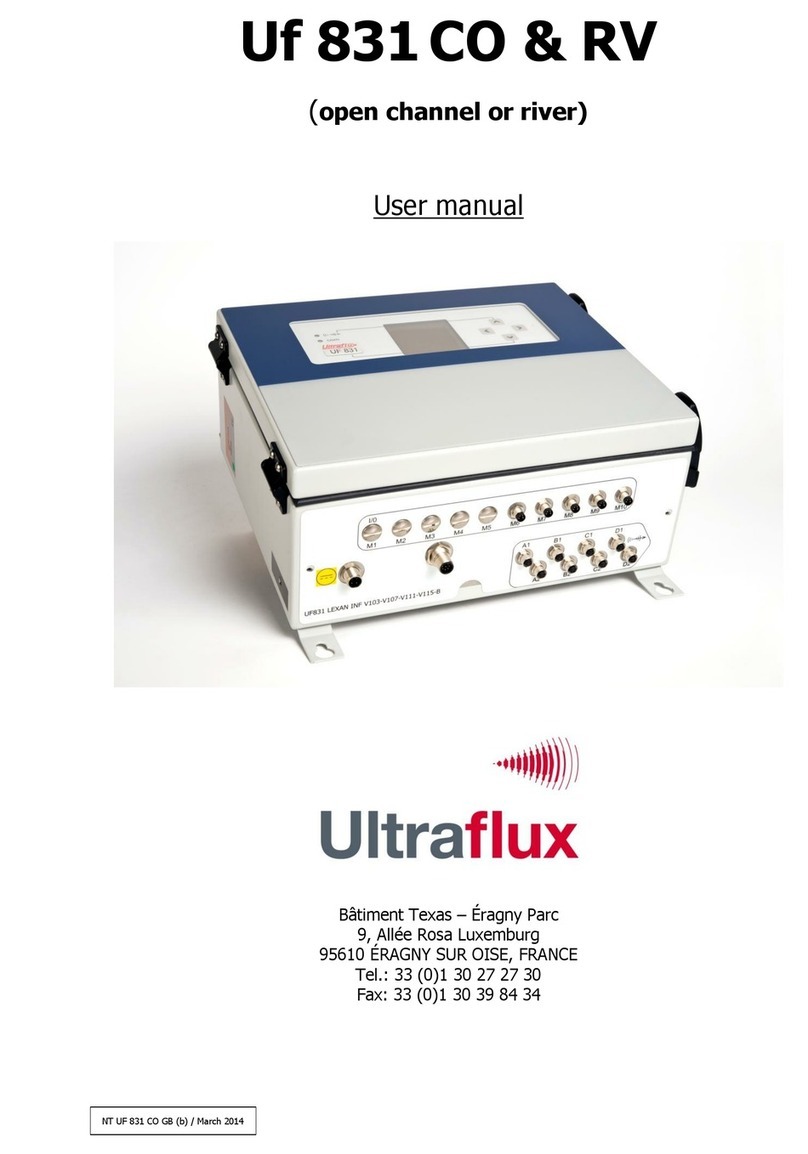

Ultraflux

Ultraflux UF 831 user manual

Axioma

Axioma QALCOSONIC F1 Technical description, installation and user instructions

Raycus

Raycus RFL-P200S+ User instruction

C-Dax

C-Dax MULTI BOOM 1018 Instruction leaflet