Page 7

BAROMETRIC PRESSURE SENSOR

The instrument internal barometric pressure

sensor is calibrated at the factory, and normally

requires no further attention. However, you may

wish to calibrate it against your own

instrumentation, or simply check the instrument

for accuracy.

CO2SENSOR

The sensor can be calibrated using either:

1) A source of 100% pure CO2gas at a

known elevated pressure (Partial

Pressure)

2) A known concentration of CO2gas at a

known pressure (Fraction)

3) A known concentration of dissolved

CO2(Dissolved)

The Partial Pressure method is generally

recommended when measuring at higher line

pressures, and requires a precise in-line pressure

gauge to perform.

For the Partial Pressure and Fraction methods,

shut off the sample flow to the sampling module,

then open the front panel and remove the CO2

sensor from its flow chamber. Do not disconnect

the cables or purge gas connections from the

sensor. Before calibrating, make sure that the grill

in the front of the CO2sensor is clean and dry.

Insert the sensor in the flow chamber, and tighten

with its collar.

The Dissolved method requires a known

concentration of CO2dissolved in liquid as a

reference sample, flowing in-line through the

sample line.

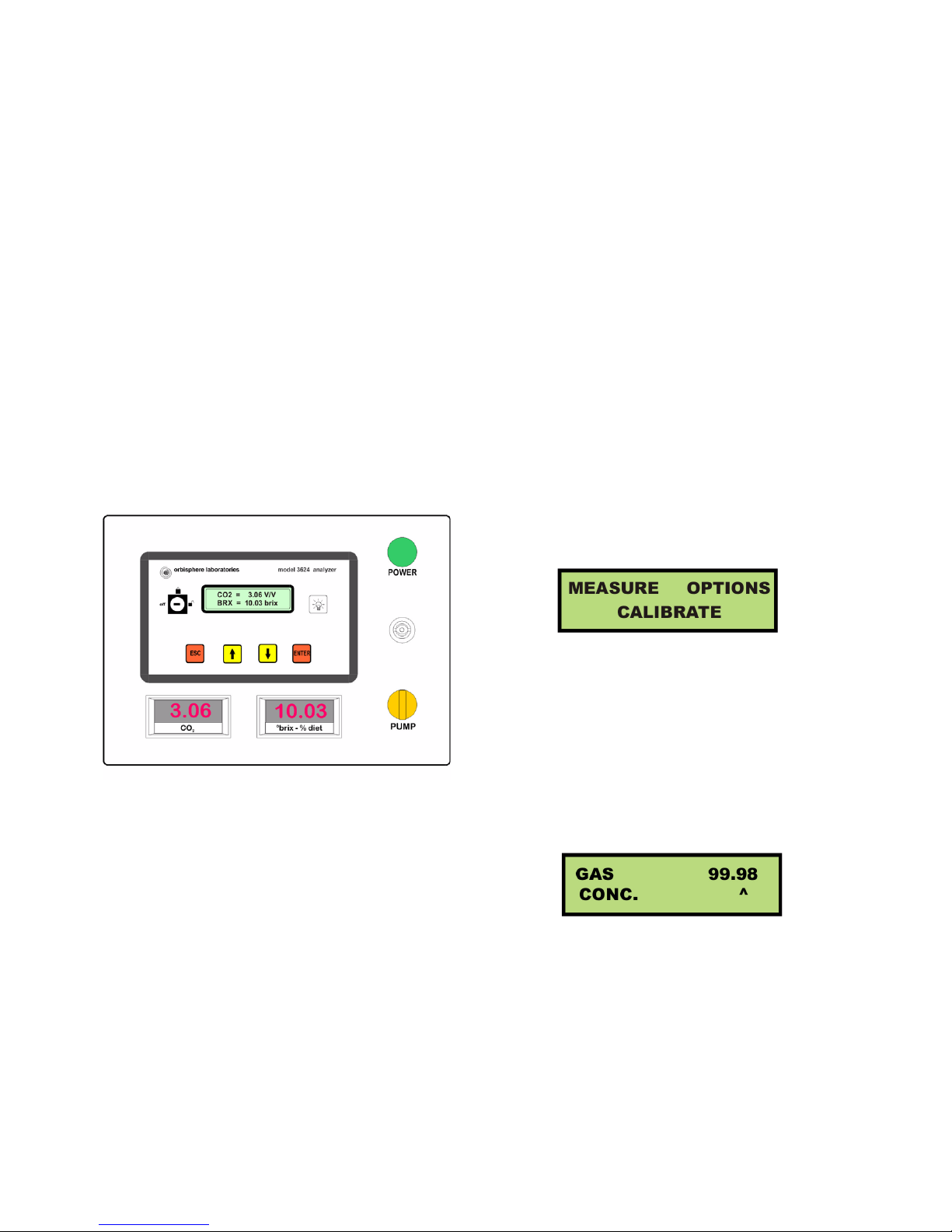

For all of the three methods described above,

expose the sensor to the gas and stabilize the

reading by operating in Measurement Mode for

about 30 minutes. After this time, press ESC and

select CALIBRATE from the main menu, followed

by SENSOR CO2 and the calibration method.

Then, select your calibration measurement unit.

Enter the gas concentration of the calibration

medium. Press ENTER to start the calibration

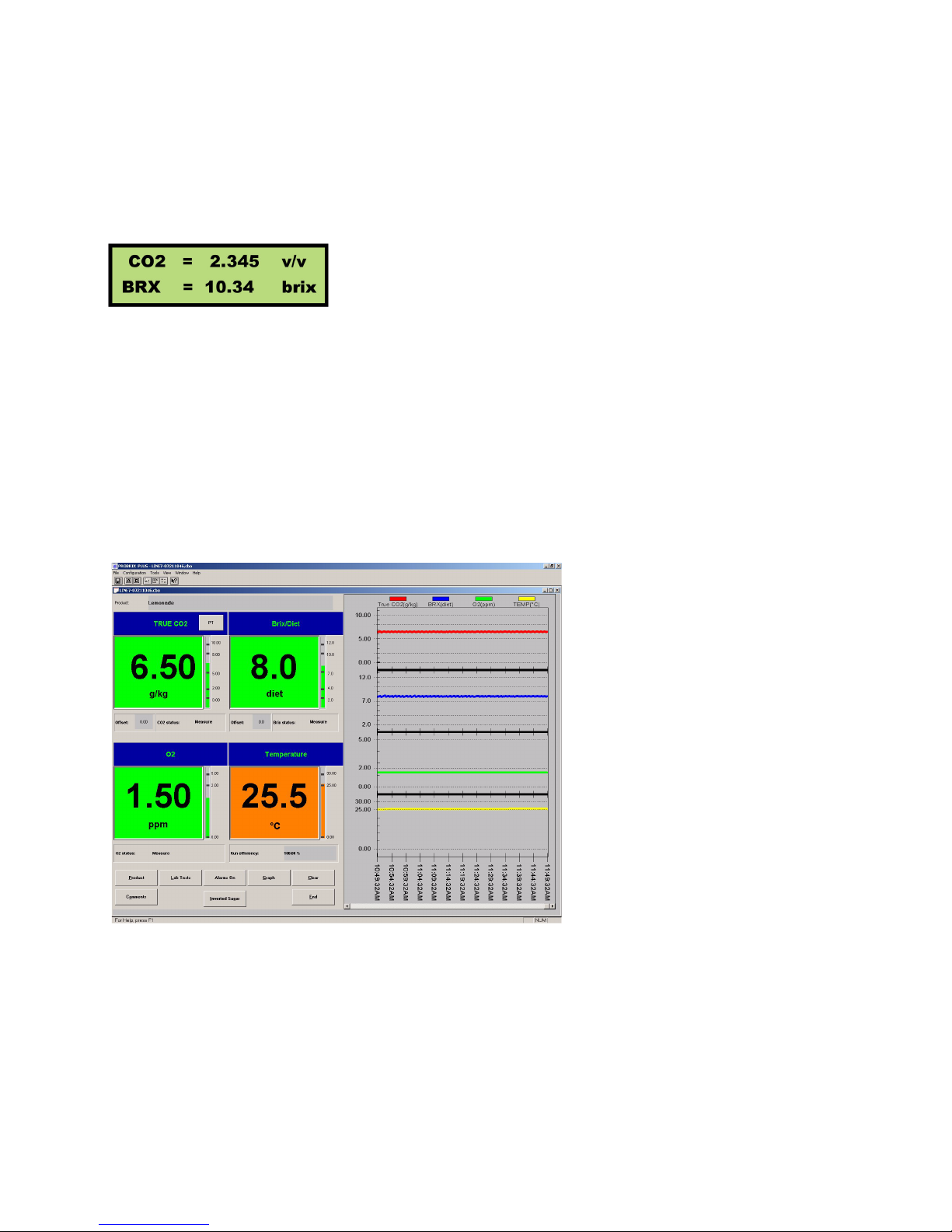

process. The instrument starts three calibration

cycles. The gas and temperature measurements

are displayed along with the current calibration

cycle number.

On completion of the three cycles, the instrument

then shows the sensitivity of the sensor as a

percentage of the sensitivity determined when

calibration was last performed.

This percentage must be between 50% and 150%

in order to calibrate. If the percentage is outside

the limits, you will see the CALIBRATION OUT

OF BOUNDS message. You will need to press

ESC to continue. Check that the membrane does

not need to be replaced and that no leaks are

evident.

If the percentage is within the limits press ENTER

to accept and complete the calibration process

(the message CALIBRATION COMPLETE will

appear briefly) or ESC to abort.

O2SENSOR

The In Air method places the O2sensor in water-

saturated air, to provide a known oxygen

reference against which to calibrate.

Shut off the pump and turn off the sample flow to

the sampling module. Open its front panel and

remove the O2sensor from its flow chamber. Do

not disconnect the sensor cable.

Dry the sensor thoroughly, before placing the

sensor storage cap under tap water. Shake off

any excess water, but leave a few drops inside

the cap. Then, loosely place the storage cap back

on the sensor, holding it in place by a few turns of

its collar.

Select CALIBRATE from the main menu followed

by O2 IN AIR to start the calibration. The process

is then similar to the CO2sensor calibration.

The Direct method calibrates the oxygen sensor

against a liquid sample containing a known level

of dissolved O2, flowing through the sample line.

Select CALIBRATE from the main menu followed

by O2 DIRECT and the calibration units. Then

enter the gas concentration of the calibration

sample to start the calibration. The process is

then similar to the CO2sensor calibration.

Calibration - From Instrument