3

NT UF 831 CO GB (b) / March 2014

TABLE OF CONTENTS

Note: A detailed table of contents is provided at the end of the manual.

Important: If you are unfamiliar with the transit time difference measuring technique, we recommend you start by

reading our training manual "Ultrasonic transit time flowmeter".

CHAPTER 1: OVERVIEW ........................................................................................ 5

1.1 Inputs/Outputs ...................................................................................................................6

1.2 Communication with the flow meter......................................................................................6

1.3 Recording possibilities .........................................................................................................6

1.4 Echo display .......................................................................................................................6

1.5 Other functions available .....................................................................................................7

1.6 Accuracy and availability......................................................................................................7

1.7 Dimensions and weight........................................................................................................7

1.8 Supply ...............................................................................................................................8

1.9 Protection against dust and immersion..................................................................................8

1.10 Power supply....................................................................................................................8

1.11 Environment for use of the cabinet .....................................................................................9

1.12 Cleaning the flow meter.....................................................................................................9

1.13 Composition of a measuring point.......................................................................................9

CHAPTER 2: SAFETY INSTRUCTIONS ................................................................. 10

2.1 Symbols used on the flow meter......................................................................................... 11

2.2 Assembly ......................................................................................................................... 11

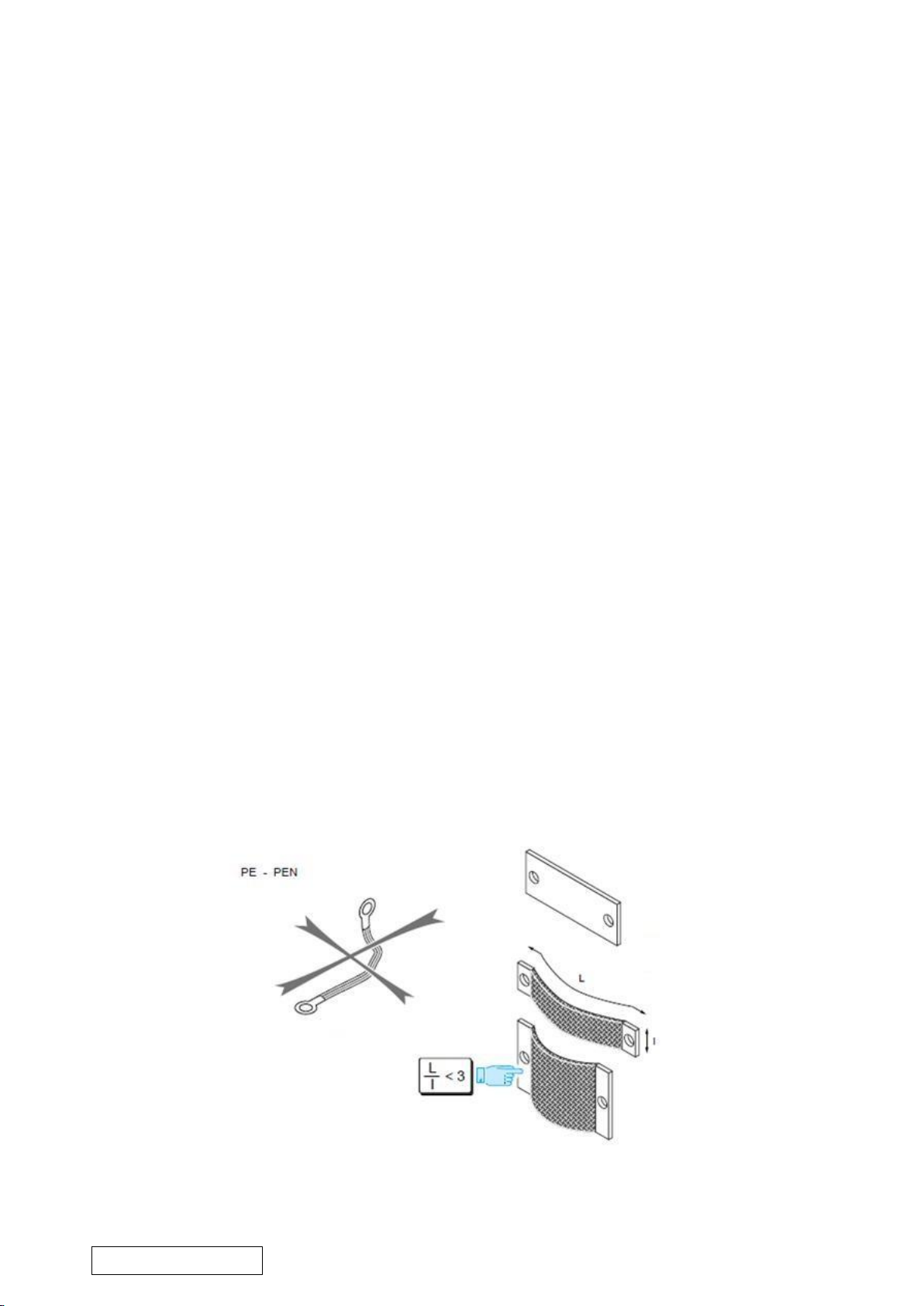

2.3 Wiring.............................................................................................................................. 12

2.4 Using the flow meter......................................................................................................... 12

2.5 Recycling the flow meter ................................................................................................... 13

2.6 Contact address................................................................................................................ 13

CHAPTER 3: INSTALLATION AND WIRING......................................................... 14

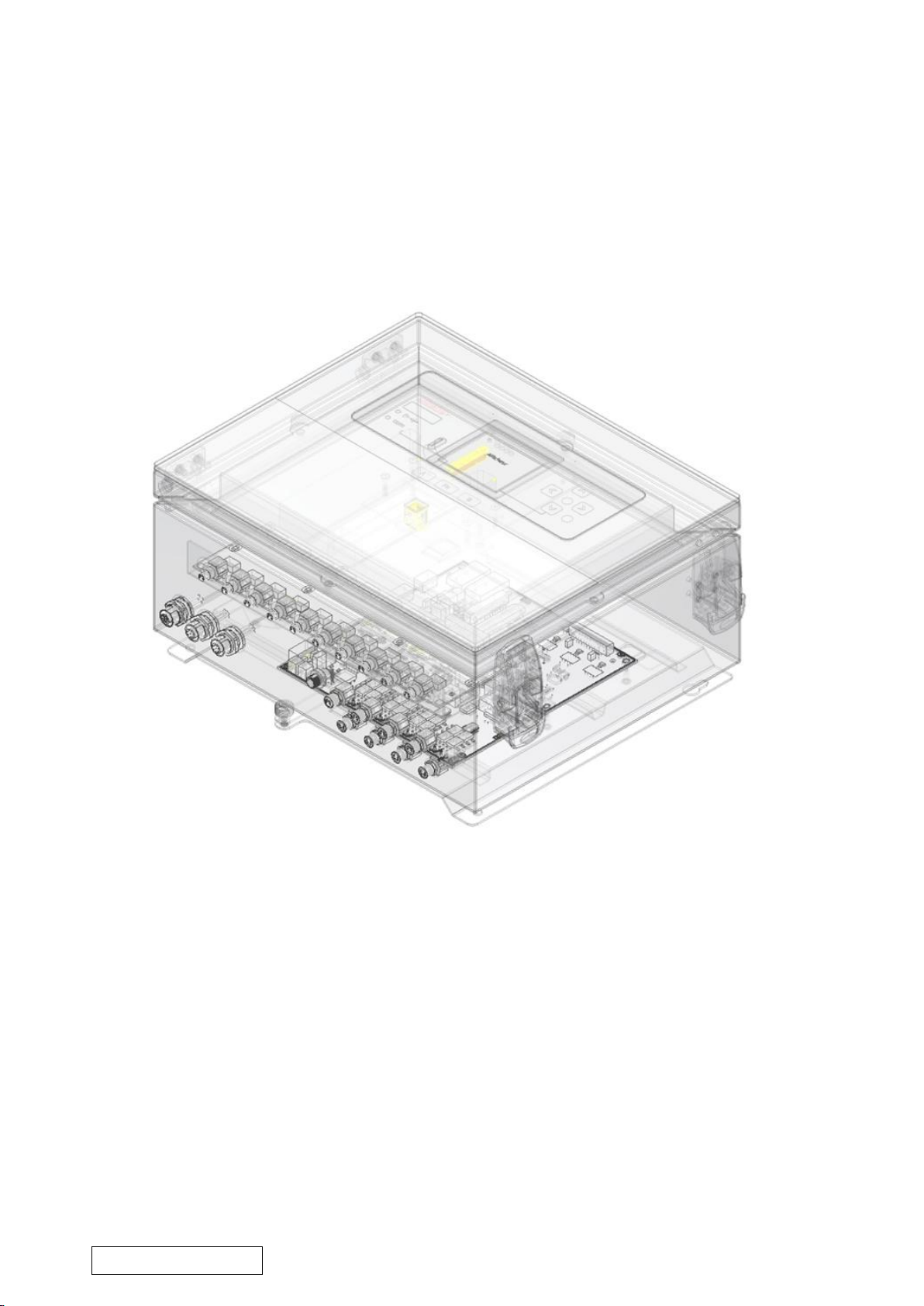

3.1 Opening the cabinet.......................................................................................................... 15

3.2 General procedures........................................................................................................... 16

CHAPTER 4: IMPLEMENTING A MEASURING POINT.......................................... 22

4.1 Choosing the measurement location ................................................................................... 23

4.2 Installing the probes ......................................................................................................... 23

4.3 Measurements to be taken on site ...................................................................................... 24

4.4 Analysing and processing data measured on site.................................................................. 24

4.5 Transferring the data collected to the converter................................................................... 25