Nitta PolySprint FP30-10-100 User manual

PSM-NIT-08008E

PolySprint™

Follow this manual when using Nitta PolySprint™Finger Puncher.

Please pass this manual to PolySprint™Finger Puncher users for a safe and

trouble-free operation.

F

Fi

in

ng

ge

er

r

P

Pu

un

nc

ch

he

er

r

F

FP

P3

30

0-

-1

10

0-

-1

10

00

0

Operation Manual

- 1 -

Contents

1. Safety Precautions ・・・・・・・・・・・・・・・・ 2

2. Confirmation of Product ・・・・・・・・・・・・・・ 3

3. Specifications ・・・・・・・・・・・・・・・・・・ 4

4. Use Environment ・・・・・・・・・・・・・・・・・ 4

5. Storage Environment ・・・・・・・・・・・・・・・ 4

6. Name of Each Part ・・・・・・・・・・・・・・・・ 5

7. How to Make a Finger Joint ・・・・・・・・・・・・ 6

8. Troubleshooting ・・・・・・・・・・・・・・・・・ 9

9. Maintenance ・・・・・・・・・・・・・・・・・・・ 9

10.Maintenance Record ・・・・・・・・・・・・・・・・ 12

11.Inspection ・・・・・・・・・・・・・・・・・・・・ 12

- 2 -

1. Safety Precautions

Please go over these safety precautions carefully to secure a correct and safe

operation of the PolySprint™Finger Puncher FP30-10-100.

Disregarding instructions marked with this symbol may lead

to death or serious injury.

Disregarding instructions marked with this symbol may lead

to injury or property damage.

WARNING

Do not use the PolySprint™Finger Puncher for any application other than

the intended purpose of making belts endless.

Use for any unintended purpose may cause an unexpected accident.

A person with experience and skills should always operate, maintain and

inspect the PolySprint™Finger Puncher.

Handling by an inexperienced person may cause injury.

Do not dismantle or remodel the PolySprint™Finger Puncher under any

circumstance. Please note the Finger Puncher uses a sharp blade.

Dismantling or remodeling the PolySprint™Finger Puncher may cause

physical injury.

For repair or inspection, please contact Nitta, your local distributor or agent in

your area.

Use a dry cloth for cleaning the PolySprint™Finger Puncher. To prevent

fire, do not use alcohol, benzine, thinner or any other inflammable solvent.

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

- 3 -

1. Safety Precautions- Continued-

Caution

Do not use the PolySprint™Finger Puncher under the following conditions:

・ Under a corrosive gas environment

・ Under an ambient temperature of 5℃or below

・ Under an ambient temperature of 40℃or above

・ Under a high humidity environment (humidity surpassing 85%)

・ In places exposing the puncher to steam or water drops

To prevent physical injury, use the PolySprint™Finger Puncher on a stable

working bench or table that will not collapse.

Before using the PolySprint™Finger Puncher, be sure to inspect the

puncher in accordance with the procedure described on page 12 to help

prevent injury.

2. Confirmation of Product

Thank you for choosing our PolySprint™Finger PuncherFP30-10-100.

Check that the product is exactly what you have ordered. Use of the

wrong product may cause injury.

2-1)Confirmation of Product

Confirm the following items upon accepting delivery of your order. Contact Nitta, your local

distributor or agent in your area if you find any deficiency or defect in your item.

①Are descriptions on the face plate the same as those of your order item? Please

confirm the model type.

②Has the product been damaged during transportation?

③Has a nut or screw slackened?

2-2)How to Read Face Plate

2-3)Inquiries

When making inquiries, please inform our sales representative of the model type and the

production serial number.

CAUTION

CAUTION

CAUTION

①Model type

②Production serial number

FP30-10-100

050001

CAUTION

- 4 -

3. Specifications

3-1)Outline of Finger Puncher

① PolySprint™Finger Puncher is exclusively designed for manually punching finger

spliceable Nitta PolySprint™belts with a cutting blade assembly.

② PolySprint™Finger Puncher is compatible with the following endless specifications:

Joint specifications: finger geometry 30mm long x 10mm pitch

Maximum belt width: up to 50mm

Maximum belt thickness: up to 2mm (2 plies or less)

.

3-2)Major Specifications of Finger Puncher

4. Use Environment

Ambient Temperature 5-40℃(no condensation)

Ambient Humidity 15-85%RH

Place of Use Indoors (free from dust, water)

Environment No inflammable, combustible or corrosive gas; no steam

Use the PolySprint™Finger Puncher under the above conditions.

5. Storage Environment

Ambient Temperature 5-40 ℃(no condensation)

Ambient Humidity 15-85%RH

Place of Use Indoors (free from dust, water)

Environment No inflammable, combustible or corrosive gas; no steam

When the PolySprint™Finger Puncher is not in use, it should be stored

under the above conditions.

Type FP30-10-100

Outer Dimension Puncher Body: 200 mm wide x 500 mm long x 504 mm* high

*170 mm when the lever is removed.

Weight 7.2kg

CAUTION

CAUTION

- 5 -

6. Name of Each Part

Handle

Knob

Cutting Sheet

Eject Plate

Clear Sheet

Belt Guide

Clear Sheet

Cutting Sheet

Cutting Blade

- 6 -

7. How to Make a Finger Joint

7-1) Required Tool (tool prepared in advance)

a. Finger Puncher (FP30-10-100)

b. Tape Measure or Ruler

(for measurement of belt length)

c. Ballpoint Pen or Felt Pen (for marking)

7-2) How to Measure Belt Length

①Set the belt along a tape measure or ruler and

make the first mark 200mm from the edge of the

belt. (See diagram to left.)

②Based on the first mark, make a second mark at

the ending point of the required belt length. (Put

both marks on the front side, i.e. on the operator

side.)

※ When consecutively making endless belts,

obtain required belt length and from the

second mark made at the preceding finger

joint, measure out the required belt length

and make another mark. Repeat the above

process. By doing this, punching can always

be made at the right position and there will

be no wasted belt.

Second Mark

200mm L= endless length

Belt First Mark

Operator

L= endless length

Second Mark

a.

b.

c.

- 7 -

7-3) How to Make a Finger Joint

①Adjustment of Eject Plate

Adjust the clearance between the eject plate

and the cutting sheet to be equal to the belt

thickness + about 0.5 mm. Make adjustment by

turning the four knobs. The eject plate, when

adjusted to the proper height for the belt, fulfills

its functions.

※ When processing belts with the same

thickness, make an adjustment once before

use; no further adjustment is necessary

thereafter.

※ Avoid any clearance between the knobs and

the eject plate. When the eject plate is not

adjusted to the proper height for the belt, the

belt may sometimes get stuck on the cutting

blade after punching.

②Inserting the Belt

Insert the belt between the eject plate of the

finger puncher and the cutting sheet, and line up

the first mark on the belt with the cutting guide

indicator of the finger puncher.

※ Insert the belt along the belt guide.

No clearance

E

j

ect Plate

Cuttin

g

Sheet

Knob

Belt thickness

+ about 0.5 mm

Insert

E

j

ect Plate

Cuttin

g

Sheet

Fit the mark on the

belt with the cutting

g

uide indicato

r

.

Cuttin

g

g

uide indicato

r

- 8 -

7-3) How to Make a Finger Joint - Continued-

③Hold the finger puncher in place with one hand

and push down the handle with the other hand

to punch the belt. (See diagram to left.)

※ Push down the handle of the finger puncher,

and the eject plate also comes down and

fixes the belt.

※ Do not put your hands close to the cutting

blade.

④Fit the second mark made on the belt with the

cutting guide indicator of the finger puncher and

punch out the belt to obtain the required endless

length. (The belt from edge to edge will be

endless length + 30 mm.)

※ When punching a long belt, you can insert

the rear–edge of the belt from the other side

of the finger puncher to avoid pulling the

entire belt through the finger puncher.

- 9 -

8. Troubleshooting

If there are any finger joints which are not cut out properly when a belt is punched,

follow the directions described in the “Maintenance” section on pages 9-11.

If the problem is not solved after following these directions, please contact Nitta,

your local distributor or agent in your area for advice.

9. Maintenance

9-1) How to Perform Maintenance

You can change the position of the cutting sheet and both sides of the cutting

sheet can be used. Adjusting the position may solve any problems where a

portion of the finger joint is not cut out.

The cutting sheet is consumable. Specify the cutting sheet for FP30-10-100 Finger

Puncher when you order a new one.

9-2) Required Tool

Hexagon wrench (3 mm)

9-3-1) How to change the position of the cutting sheet

①Loosen the four hexagon socket head cap

screws for the cutting sheet by using a hexagon

wrench.

※ Do not pull out hexagon socket head cap

screws. Just loosening hexagon socket

head cap screws is enough.

※ Do not loosen hexagon socket head cap

screws fixing the clear sheet.

Hexagon socket head

cap screws

Hexagon

socket head

cap screws

for fixing the

clear sheet

- 10 -

9-3-1) How to change the position of the cutting sheet - Continued-

②Change the position of the cutting sheet by

sliding it forward or back in the hole on the belt

guide.

※ At the time of shipping, the cutting sheet is

set in the center of the hole on the belt

guide.

※ The picture at left shows an example of

sliding the cutting sheet forward in the hole.

Make sure it’s set at the very edge of the

hole.

※ Both sides of the cutting sheet can be used

and it can be set in any of the three

positions; forward, center and back.

③Securely tighten the four loosened hexagon

socket head cap screws.

Belt Guide

- 11 -

9-3-2) How to reverse the cutting sheet

①Loosen the four hexagon socket head cap

screws which hold the cutting sheet in place and

take them out.

※ Never loosen hexagon socket head cap

screws which hold the clear sheet.

※ Be careful not to lose hexagon socket head

cap screws taken out of the finger puncher.

②Take out the cutting sheet from the finger

puncher.

※ Collars may sometimes drop when the

cutting sheet is taken out. Be careful not

to lose any collar.

③Reverse the cutting sheet to turn the unused

side up and insert it back to the finger puncher.

④Securely tighten the four hexagon socket head

cap screws.

Shown on the next page is a table for keeping maintenance records.

Cutting Sheet

Colla

r

Hexagon socket

head cap screws

- 12 -

10. Maintenance Record

When shipped

from Nitta

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

The cutting sheet

was reversed and

set in the center.

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

The cutting sheet

was replaced and

set in the center.

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

The cutting sheet

was reversed and

set in the center.

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

The cutting sheet

was replaced and

set in the center.

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

The cutting sheet

was reversed and

set in the center.

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

The cutting sheet

was replaced and

set in the center.

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

The cutting sheet

was reversed and

set in the center.

The cutting sheet

was slid forward.

The cutting sheet

was slid back.

11. Inspection

Inspection items date/staff date/staff date/staff date/staff date/staff

The puncher body is free of

damage or destruction.

All screws of the puncher body

are tightened.

The belt can be completely

punched out.

Make a copy of this page and use it for inspection prior to each use.

- 13 -

Aug,2014 Rev2 FP30-10-100-E

Table of contents

Popular Cutter manuals by other brands

Silver King

Silver King KutLett SKK2 Technical manual and replacement parts list

Duplo

Duplo DocuCutter DPC-400 Operation manual

Power Craft

Power Craft 54772 instruction manual

Makita

Makita 4131 instruction manual

Makita

Makita PC01 instruction manual

BN Products

BN Products DC Series Instructions & Parts Lists

SAINT-GOBAIN

SAINT-GOBAIN NORTON clipper TR 252 operating instructions

Royal Catering

Royal Catering RCGS 550 user manual

Land Pride

Land Pride RC5014 Operator's manual

Brutus

Brutus 13 in. Tile Cutter owner's manual

Makita

Makita 4100NH Original instructions

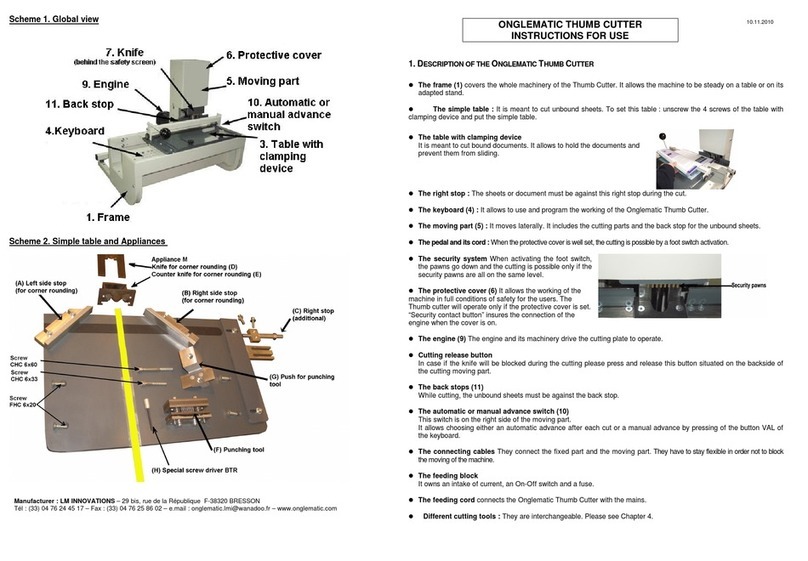

Onglematic

Onglematic Thumb Cutter Instructions for use