S Y M B O L S

Auf der Maschine - On the machine

Betriebsanleitung vor Inbetriebnahme sorgfältig durchlesen!

Please read operators manual carefully before putting the machine into operation!

Notice d’utilisation à lire attentivement avant la mise en service de la machine!

Leggere la manuale di istruzioni con attenzione prima dell'utilizzo della macchina!

¡Estas instrucciones se deben leer atentamente antes de poner en marcha la máquina!

Voor de ingebruikneming gebruiksanwijzing a.u.b. zorgvuldig doorlezen!

Læs betjeningsvejledningen omhyggeligt inden maskinen tages i drift!

Läs noggrannt igenom denna anvisning innan maskinen tas ibruk!

Les nøye gjennom instruksjonen i denne manualen!

Lue tarkasti tämä ohje ennen koneen käyttöönottoa!

Instrukcja obslugi, prosimy dok³adnie przeczytaæprzed uruchomieniem maszyny!

Ïåðåä ââîäîì âýêñïëóàòàöèþ âíèìàòåëüíî ïðî÷åñòü ñïðàâî÷íèê ïî ýêñïëóàòàöèè!

Tragen Sie beim Arbeiten mit dieser Maschine einen Gehörschutz.

Wear ear protection when working with this machine.

Portez un protège-oreilles lorsque vous travaillez avec cette machine.

Durante il lavoro con questa macchina indossate una protezione dell'udito.

Utilice una protección de los oídos durante los trabajos con la máquina.

Draag bij het werken met deze machine gehoorbescherming.

Husk at bruge lyddæmpende ørebeskyttelse hvis De arbejder med maskinen.

Använd hörselskydd vid användning av denna maskin.

Bruk hørselsvern ved bruk av maskinen.

Koneen kanssa työskennellessä on aina käytettävä kuulosuojaimia.

Podczas wykonywania prac za pomoc¹tego urz¹dzenia nosiæœrodki ochrony s³uchu.

Ïðè ðàáîòå ñýòèìè ìàøèíàìè èñïîëüçóéòå ïðîòèâîøóìíûå íàóøíèêè.

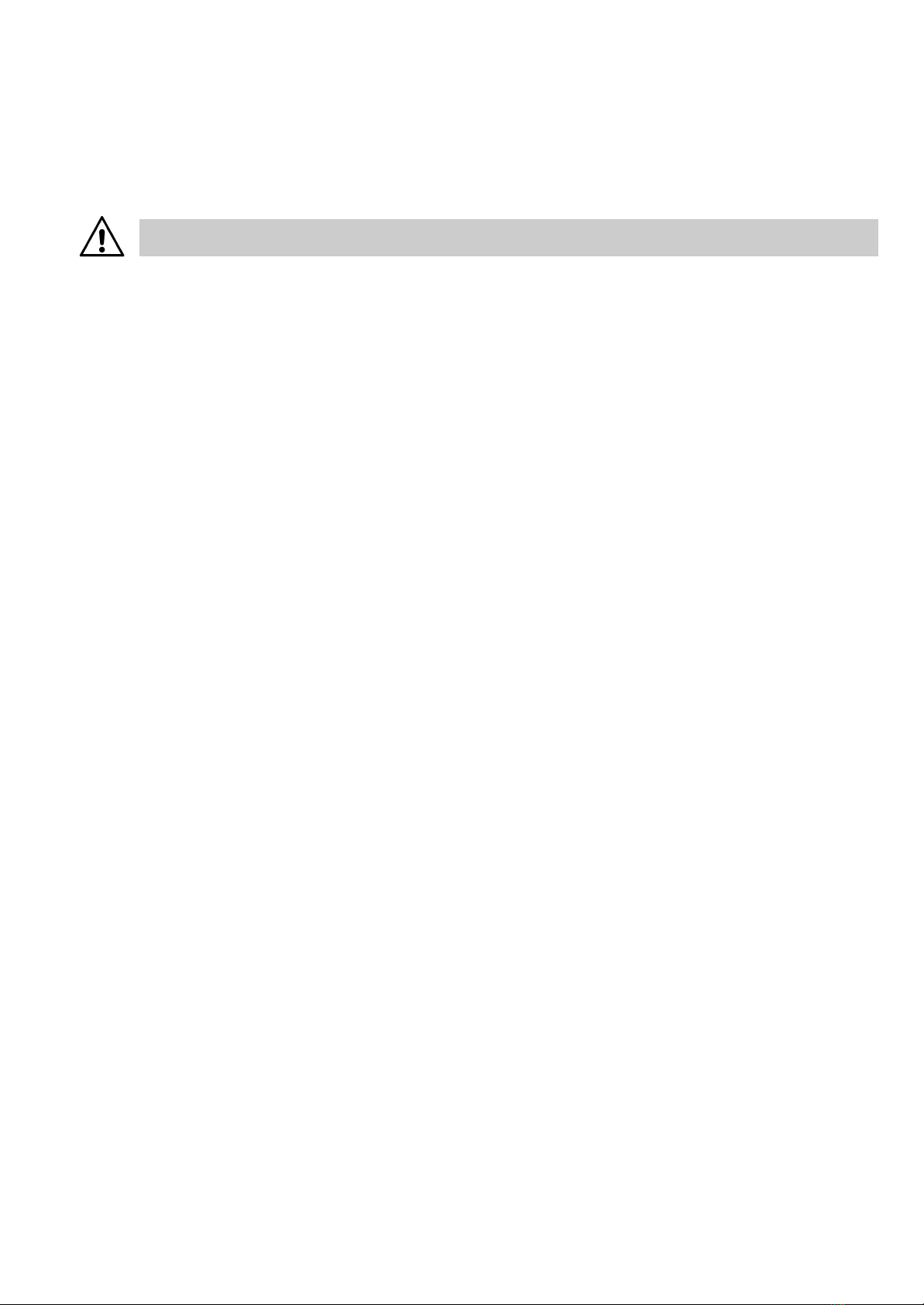

Überkopfbohren nur mit geeigneter Wasserfangeinrichtung.

Overhead drilling only with appropriate water-collecting ring.

Perçage au-dessus de la tête uniquement avec des collecteur d'eau.

Trapanazione sopratesta deve essere effettuata solo con dispositivo di raccolta dell'acqua.

Perforación de techos solamente se debe efectuar con instalación de recolección de agua.

Alleen bovenhands booren met geschikte wateropvangvoorziening.

Boring over hovedet må kun foretages med egnede indretning til opfangning af vand.

Borrning över huvudet får ske endast med vattensamlingsanordning.

Over hodet kjerneboring må kun utføres med egnet vannsamlingsring.

Yli pään poraus on oltava oikeat vedenkeräilylaite.

Wiercenie nad g³ow¹mo¿na wykonywaæwy³¹cznie z odpowiednimi urz¹dzenie do

wy³apywania wody.

Âåðòèêàëüíîå áóðåíèå «ââåðõ ÷åðåç ãîëîâó» òîëüêî ïðè ñîîòâåòñòâóþùåì

îñíàùåíèè äëÿ âîäîñáîðà.

Dieses Produkt entspricht den geltenden EU Richtlinien.

This product is in accordance with applicable EC directives.

Ce produit est conforme aux directives CE en vigueur.

Il presente prodotto è conforme alle vigenti direttive CEE.

Este producto cumple con la directiva CE vigente.

Dit product voldoet aan de geldende CE richtlijnen.

Dette produkt er i overensstemmelse med gældende CE-direktiv.

Denna produkt överensstämmer med gällande EG-direktiv.

Dette produktet er i overensstemmelse med EU direktiver.

Tämä tuote täyttää voimassa olevan Cedirektiivin vaatimukset.

Produkt ten jest zgodny z odpowiednimi dyrektywami EC.

Ýòîò ïðîäóêò ñîîòâåòñòâóåò äåéñòâóþùèì äèðåêòèâàì ÅÑ.

In der Bedienunganleitung - In the operators manual

Sicherheitshinweis, bitte besonders beachten!

Security advise, please take special care!

Instruction de sécurité, a respecter particulièrement, s’il vous plait!

Indicazione di sicurezza, considerare specialmente, per favore!

Estas llamadas de atención se deben atender especialmente!

Gelieve veiligheidsvoorschrift aandachtig te bestuderen!

Sikkerhedsanvisning. Udvis størst mulige forsigtighed!

Säkerhetsförslag, var extra försiktig!

For din egen sikkerhet, vennligst vær ekstra forsiktig!

Turvallisuusohje, ole hyvä ja noudata erityistä huolellisuutta!

Wskazówka bezpieczeñstwa, prosimy zachowaæszczególn¹ostro¿noœæ!

Óäåëèòü îñîáîå âíèìàíèå óêàçàíèÿì ïî òåõíèêå áåçîïàñíîñòè!