Nitto TGF450 Series User manual

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

1/47

TGF450 Series

Thermal Mass Flowmeter

User’s Manual

Nitto Instruments Co.,Ltd Japan

Hefei Comate Intelligent Sensor Technology Co,. Ltd

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

2/47

Dear Customer:

Thanks for choosing our flowmeter products. Please read this manual carefully to know how to

install and use this product to ensure its best performance. If you should encounter a problem when

using the product, please do not hesitate to let us know. We are going to take no responsibility if the

flowmeter is damaged because of anyone repair or replace any parts of it with our permission.

Support

Please reach to us according to the contact information below to get support or update of our VFM60

vortex flowmeter:

zWebsite

http://www.comatemeter.com

zTelphone:

+86-0551-63653542

zE-mail:

supports@ comatemeter.com

Place an order

If you need to place an order or need to know the status of your processing orders, please contact us

according to below information:

Phone: +86-0551-63653542

Website: www.comatemeter.com

Email: sales@comatemter.com

Address:2nd floor, Building D2, Hefei Innovation Industrial Park,No.800 Wangjiang West Road,Hefei

Tech Development Zone, Hefei, China

Postal code:230088

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

3/47

TABLEOFCONTENTS

SUPPORT.........................................................................................................................................2

PLACEANORDER............................................................................................................................2

1GENERAL......................................................................................................................................6

1.1MODELNUMBERANDGENERALSPECIFICATION.........................................................................6

1.2PACKINGLIST.............................................................................................................................6

1.3STORAGE...................................................................................................................................6

1.4MEASURINGPRINCIPLE..............................................................................................................6

2INSTALL........................................................................................................................................7

2.1FINDMOSTSUITABLELOCATION................................................................................................7

2.2REQUIREMENTONSTRAIGHTPIPELINE.....................................................................................8

2.3REQUIREMENTONINSERTIONDIRECTION.................................................................................9

2.4PROCEDUREOFINSTALLATION.................................................................................................10

9)INSERTTHEMETERTOTHEDEPTHSASCALCULATEDWITHTHEHOTTAPMOUNTINGTOOL.

(PLEASEREFERENCETOTHEMANUALOFHOTTAPMOUNTINGFORDETAILS).NOWHOLDTHE

SLEEVE(PARTNO.3)WITHAWRENCHANDTIGHENTHENUT(PARTNO.4)WITHANOTHERWRENCH.

MAKESURETHENUTSLEEVEISHOLDINGTHEMETERTIGHTENLY..................................................13

3WIRING......................................................................................................................................13

3.1WIRINGFORTERMINALBOARD...............................................................................................14

3.2SHELLGROUNDINGANDELIMINATIONOFINTERFERENCE........................................................15

3.4REQUIREMENTONWIRING......................................................................................................15

4DISPLAY......................................................................................................................................16

4.1INTRUCTIONOFMULTI‐FUNCTIONALLCDDISPLAY...................................................................16

4.2UNITOFTHEVARIABLEDISPLAYED...........................................................................................17

4.3THREEBUTTONSETTING..........................................................................................................18

4.4TOTALFLOWDISPLAYING.........................................................................................................18

4.5STATUS....................................................................................................................................19

5SETTING.....................................................................................................................................19

5.1HOWTOSET............................................................................................................................19

5.1.1CODESETTING......................................................................................................................19

5.1.2DIGITALSETTING...................................................................................................................20

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

4/47

5.2SETTINGLIST............................................................................................................................22

CHART5.1CODESETTINGADDRESS...............................................................................................22

CHART5.2DIGITSSETTINGADDRESS..............................................................................................25

5.3EXAMPLEOFSETTING..............................................................................................................26

5.4PASSWORDSETTINGINSTRUCTION..........................................................................................26

6INSTRUCTIONOFRS485MODBUSCOMMUNICATION.................................................................27

6.1INTERFACEREGULATION..........................................................................................................27

6.2COMMENDS............................................................................................................................29

6.3CALCULATIONOFCRCPARITYCODE.........................................................................................31

6.4THEFLOATDATEFORMATOFTHEINSTRUMENT.......................................................................31

6.5THESEQUENCEOFTHEFLOATDATEBYTESOFINSTRUMENT.....................................................32

6.6MODBUSERRORREPONSE.......................................................................................................32

6.7EXAMPLESOFCOMMUNICATION.............................................................................................33

7INTRODUCTIONOFHARTCOMMUNICATIONPROTOCOL.............................................................33

7.1HARTCOMMANDS...................................................................................................................33

7.1.1COMMAND0:READTRANSMITTERUNIQUEIDENTIFIER........................................................34

7.1.2COMMAND1:READPRIMARYVARIABLEVALUE(PV).............................................................34

7.1.3COMMAND2:READPRIMARYVARIABLE’SCURRENTANDPERCENTAGEVALUE......................34

7.1.4COMMAND3:READPRIMARYVARIABLECURRENTANDDYNAMICVARIABLES......................35

7.1.5COMMAND6:WRITEPOLLINGADDRESS...............................................................................35

7.1.6COMMAND11:READUNIQUEIDENTIFIERASSOCIATEDWITHTAG.........................................36

7.1.7COMMAND12:READMESSAGE.............................................................................................36

7.1.8COMMAND13:READTAG,DESCRIPTOR,DATE......................................................................36

7.1.9COMMAND14:READPRIMARYVARIABLESENSORINFORMATION:DEVICESERIALNUMBER

ANDLIMITS...................................................................................................................................37

7.1.10COMMAND15:READPRIMARYVARIABLEOUTPUTINFORMATION......................................37

7.1.11COMMAND16:READFINALASSEMBLYNUMBER.................................................................37

7.1.12COMMAND17:WRITEMESSAGE.........................................................................................38

7.1.13COMMAND18:WRITETAG,DESCRIPTOR,DATE...................................................................38

7.1.14COMMAND19:WRITEFINALASSEMBLYNUMBER...............................................................38

7.1.15COMMAND34:WRITEPRIMARYVARIABLEDAMPINGVALUE..............................................39

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

5/47

7.1.16COMMAND35:WRITEPRIMARYVARIABLERANGEVALUES.................................................39

7.1.17COMMAND36:WRITEPRIMARYVARIABLEUPPERLIMITVALUE..........................................39

7.1.18COMMAND37:WRITEPRIMARYVARIABLELOWERLIMITVALUE.........................................40

7.1.19COMMAND40:ENTER/EXITPRIMARYVARIABLECURRENTMODE.......................................40

7.1.20COMMAND45:TRIMPRIMARYVARIABLECURRENTDACZERO............................................40

7.1.21COMMAND46:TRIMPRIMARYVARIABLECURRENTDACGAIN............................................41

8MAINTAINING.............................................................................................................................41

8.1HOWTOCHANGETHETRANSMITTER’SDIRECTION..................................................................41

8.2REPLACEATRANSMITTERCIRCUITBOARDS.............................................................................42

8.3REMOVETHEFLOWMETER......................................................................................................42

8.4HOWTOCLEANTHESENSORS..................................................................................................43

9TROUBLESHOOTINGANDREPAIR................................................................................................43

9.1SAFTYINTRODUCTION.............................................................................................................43

9.2TROUBLESHOOTINGANDREPAIR.............................................................................................43

9.3SELF‐DIAGNOSEFUNCTION......................................................................................................45

10REMARK...................................................................................................................................45

APPENDIX.....................................................................................................................................46

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

6/47

1 General

Every TGF450 thermal mass flowmeter will be carefully inspected before delivered to users.

Please carefully check if there is any damage on the package and product when you received them

Please check if the package contains all the accessories according to 1.2 or your purchase order.

Please make sure the person in charge of this device has carefully read this manual and understand its

descriptions.

1.1 Model Number and General Specification

Please check if the model number and specifications on the name plate match your requirement on the

purchase order.

Please kindly record the model number and instrument ID code, which will be required if you need and

service or support from us.

1.2 Packing List

When you recived the package, please check if it contains the items as below:

TGF450 thermal mass flowmeter x1

User’s manual x1

Calibration certificate x1

Quality certificate x1

Cable (For remote type only, length according to customer’s requirement)

Counter flanges (For wafer type, or for flanged type when customer requied so)

Screws and bolt (For wafer type, or for flanged type when customer requied so)

1.3 Storage

If the product needs to be stored for a long period before use, please be awared of below:

(1) The product should be kept in the origin package and same as it was when received.

(2) Please store the product in a proper location according to the requirements below:

Not in a uncovered field.

Not in a location where could have great vibration.

Please keep the enclosure of the meter closed.

The ambient temperature, atmospheric pressure and humidity should be:

Temperature: -20~+60℃;RH:5%~99% ;Pressure:86~106Kpa

1.4 Measuring principle

TGF450 Series Thermal Mass Flowmeter measures gas mass flow base on thermal diffusion theory and thermal

principle of Newton , It have two RTD sensor (ref to picture 1.2) located in the flow. One RTD is heated to T1 by a

heating power rate of P, the other is not heated but to measure the medium temperature T2. So there is a

temperature difference TD=T1-T2 . TD reach max when mass flow is 0. When the mass flow Q increases, the heat

on T1 is taken away so the T1 decline and the TD become smaller. So there is a certain relationship between

heating power rate P, difference of temperature TD and mass flow Q as below:

P/ T

D = K1 + K2 F(Q)K3

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

7/47

Picture 1.2 Principle

The K1,K2 and K3 in above equation is constant related to the character of medium . So the mass flow Q can be

get through measuring the heating power rate P and difference of temperature TD . In actual application, there are

two different method, one is consistent current method (keep the P unchanged) and the other is consistent

temperature method (keep TD unchanged)

2 Install

2.1 Find Most Suitable Location

2.1.1 Ambient temperature

Please avoid installing the flowmeter at a location where temperature could dramaticly changes. If the

meter is under heavy heat radiation, please implement effective heat insulation and venting method.

2.1.2 Atomosphere

Please do not install the meter at a locaition where the atomosphere contains a high level of corrosive

substance. If can not install the meter at a better location, please make sure there is enough venting.

2.1.3 Vibration

The meter should not be installed at a location where could have strong vibration. If the mounting

pipeline could have heavy vibration, the pipe line should be holden steady by some supporting racks.

2.1.4 Caution

(a) All screws and bolts should be tighen.

(b) Make sure there is not leakage point on the connection.

(c) The process pressure should not be higher than the meter’s rated pressure.

(d) Once the meter is under pressure, please do not screw the bolts and screws.

(e) When measuring harzad gas, do not breath the gas in

(f) If the meter is insertion mounted, please the outer of the connection part should be sealed with

proper sealant.

(g) If the meter is insertion mounted,

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

8/47

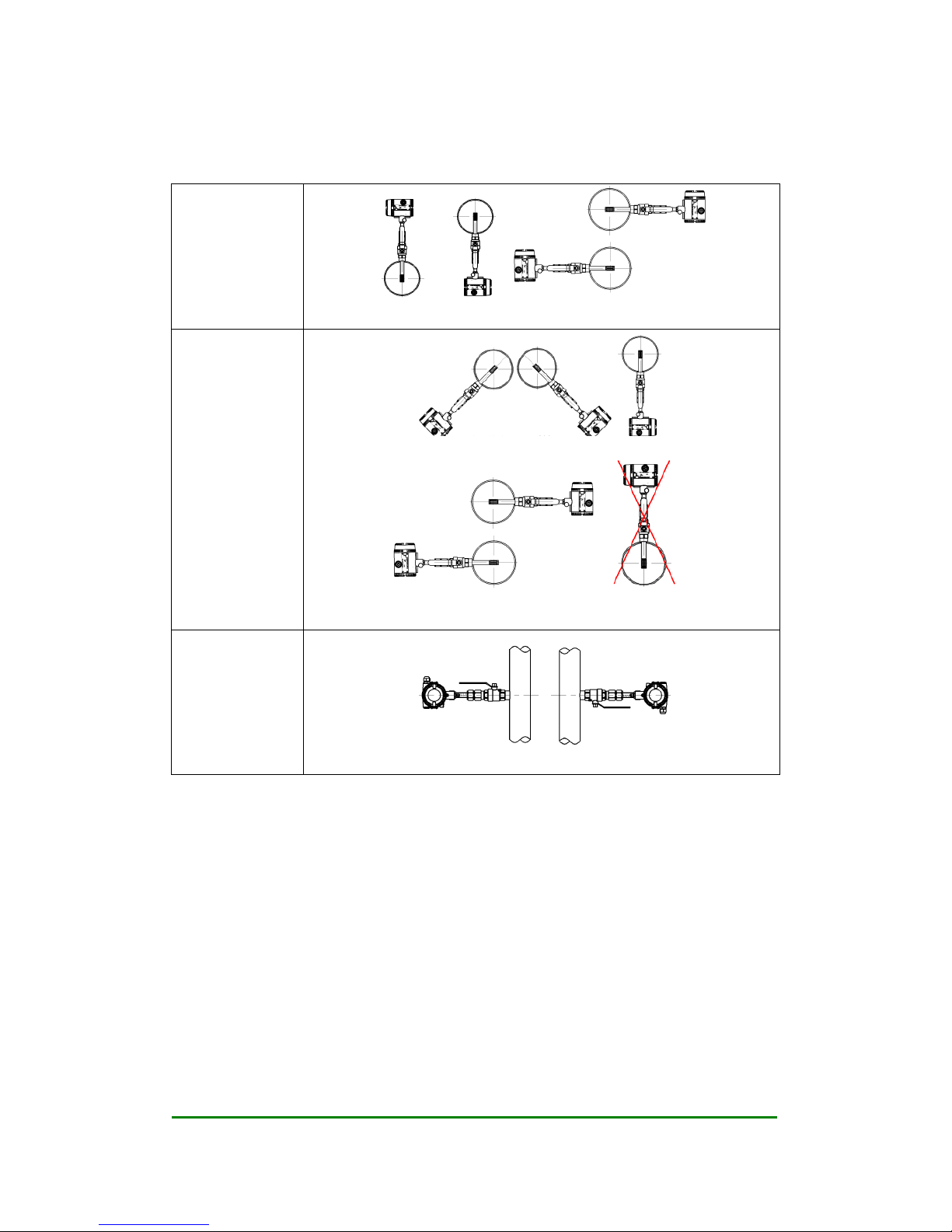

2.2 Requirement on straight pipe line

Standard

Curved pipe line in the

upstream or downstream

Curved pipe line that may creat

turbulence in the upstream or

downstream

There are valves or pressure

controller or any other device

may cause turbulence in

upstream or down stream of the

flowmeter

If the pipeline of the flowmeter

is upsized

If the pipeline of the flowmeter

is downsized

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

9/47

2.3 Requirement on insertion direction

On a horizontal

pipe line, normal

air or gas

Above or under the pipeline Side of the pipe line

On a horizontal

pipe line, high

humidity air or wet

natural gas.

45 degree under the pipe line or just under the pipelien

On the side of the pipe. Do not recommend to install the meter above the

pipeline

On a vertical

pipeline, when the

density of the gas is

higher than air

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

10/47

2.4 Procedure of installation

2.4.1 Nut sleeve insertion (No flow in pipeline)

1) Drill a hole on the position where the meter will be installed, Ø 13mm (± 0.5 mm)

2) Clean the burrs and sharps on where will be welded

3) Weld the MNPT 1/2” socket (Part No.1) on the open hole vertically. The socket and the open hole

should be concentric, and vertical to the center line of the pipe line

4) Connect the 1/2” ball valve (Part No.2) with FNPT threads on both ends to the socket. Seal the

thread connection with thread sealant. Please note the lever on the ball valve should be point to up

when the valve is open

5) Insert the flowmeter into the ball valve and the socket, connect the sleeve (Part No.3) on the meter

and the ball valve, seal the thread conection part with thread sealant. Tighten the nut (Part No.4) with

hand.

6) Calculate the insertion depth. The sensor should be in the middle of the pipe area, insertion

depth S=A/2+B+C. Please reference to the picture below

A: Inner diameter of the pipeline

B: Thickness of the pipe line

C: The distance between the top of the pipeline and the upper end of the nut when the nut is fixed

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

11/47

7) Adjust the direction of the flowmeter: Make sure the derection mark on the probe (Part No.5) is

pointing to the direction as the flow goes. Please reference to the picture below.

8) Insert the flowmeter to the depth S as calculated previous, now hold the sleeve (Part No.3) with

a wrench and tighen the nut (Part No.4) with another wrench. Make sure the nut sleeve is holding

the meter tightenly.

Remark: If flow rate higher than 90Nm/s or pipe size larger than DN400, will require 19mm

diameter probe, mounted in 1” ball valve and 1” socket and 22mm hole

2.4.2 Nut sleeve insertion (flow and pressure in pipeline)

1) Weld the MNPT 1/2” socket (Part No.1) on the pipeline vertically. The socket should be vertical to

the center line of the pipe line

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

12/47

2) Connect the 1/2” ball valve (Part No.2) with FNPT threads on both ends to the socket. Seal the

thread connection with thread sealant. Please note the lever on the ball valve should be point to up

when the valve is open.

3) Drill a hole with the hot tap hole opener, Ø 13mm (± 0.5 mm). (Please reference to the manual of

hot tap mounting for details)

4) Make sure the senor of the meter is with in the sleeve on the flowmeter, so the sleeve can protect the

sensor.

5) Connect the sleeve with the ball valve with the thread, please seal the 1/2” NPT thread connection

with thread sealant, (the ball valve should be closed)

6) Calculate the insertion depth. The sensor should be in the middle of the pipe area, insertion

depth S=A/2+B+C. Please reference to the picture below

A: Inner diameter of the pipeline

B: Thickness of the pipe line

C: The distance between the top of the pipeline and the upper end of the nut when the nut is fixed

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

13/47

7) Adjust the direction of the flowmeter: Make sure the derection mark on the probe (Part No.5) is

pointing to the direction as the flow goes. Please reference to the picture below.

8) Open the ball valve, please make sure that procedure 1~7 is operated properly before opening the

ball valve. The sleeve should be connected to the ball valve tightenly that the meter can not be ejected

out.

9) Insert the meter to the depth S as calculated with the hot tap mounting tool. (Please reference to the

manual of hot tap mounting for details). Now hold the sleeve (Part No.3) with a wrench and tighen

the nut (Part No.4) with another wrench. Make sure the nut sleeve is holding the meter tightenly.

Remark: If flow rate higher than 90Nm/s or pipe size larger than DN400, will require 19mm

diameter probe, mounted in 1” ball valve and 1” socket and 22mm hole

3 Wiring

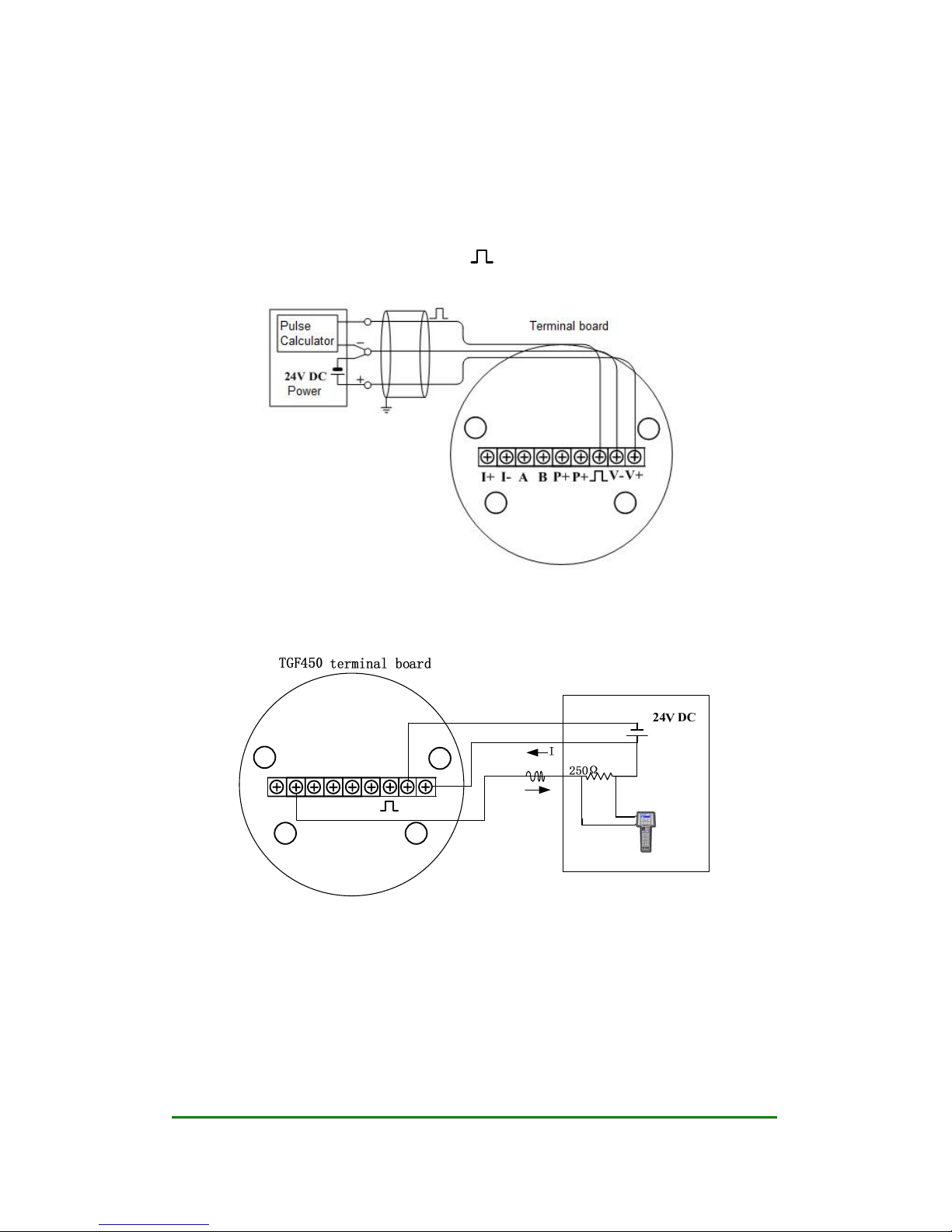

The terminal board of TGF450 is as picture 3.1 below

Picture 3.1 TGF450 terminal board

On above board, V+ and V- are for power, the DC power should be within 15VDC~32VDC.

is pulse output terminal. A, B are “+” and “-” for RS485Modbus communication, I+ and I- are +

and – for 3-wire or 4-wire 4~20 mA. P+,P- are for pressure transmitter .

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

14/47

3.1 Wiring for terminal board

3.1.1 Wiringfor 3-wire pulse output

TGF450 use a current pulse output with 50% duty ratio. If the pulse reciving instrument require

voltate pulse, please add a resistor between “ ” and “V-”, the resistance should be within

500ohms~1000ohms, and power consumption should be no less than 0.5W.

Picture 3.2 Wiring of TGF450 3-wire pulse output

3.1.2 Wiringfor 3-wire HART@4~20mA

V-

BAI+ I- P+ P+ V+

Picture 3.3 Wiring of TGF450 3-wire HART@4~20mA

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

15/47

3.1.3 Wiringfor 3-wire HART@4~20mA

V-

BAI+ I- P+ P+ V+

24V DC

Picture 3.4 Wiring of TGF450 4-wire HART@4~20mA

3.1.4 Wiring for RS485

V-

BAI+ I- P+ P+ V+

Picture 3.5 Wiring of TGF450 RS485

3.2 Shell grounding and elimination of interference

In TGF450 thermal mass flowmeter the power supply of signal processing circuit is transferred from

outside power supply by a isolation type DC-DC transmitter with advanced grounding technology . The

field frequency interference can be isolated well.

When using this product , the “V-” of power supplier should not be connected with the ground .When

this product is used in a environment with strong interference , the shell should be clean connected with

earth through cable , so the interference can be eliminated .

3.4 Requirement on wiring

1) Please do not conduct wiring when the power is on in a explosive environment.

2) Please open the rear cover first, then inert the cable into back zone of housing thourgh the

water-proof cable gland.

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

16/47

3) Conduct wiring according to 3.2.

4) If possible, please conduct the wiring according to picture 3.6 to avoid the water get into the housing

through the cable.

Picture 3.6 Wiring instruction

4 Display

TGF450 thermal mass flow meter provide with local display and setting. Users can display several

variables on the local multi-funcational LCD display. The transmitter also has 3 buttons so users can do

setting on it.

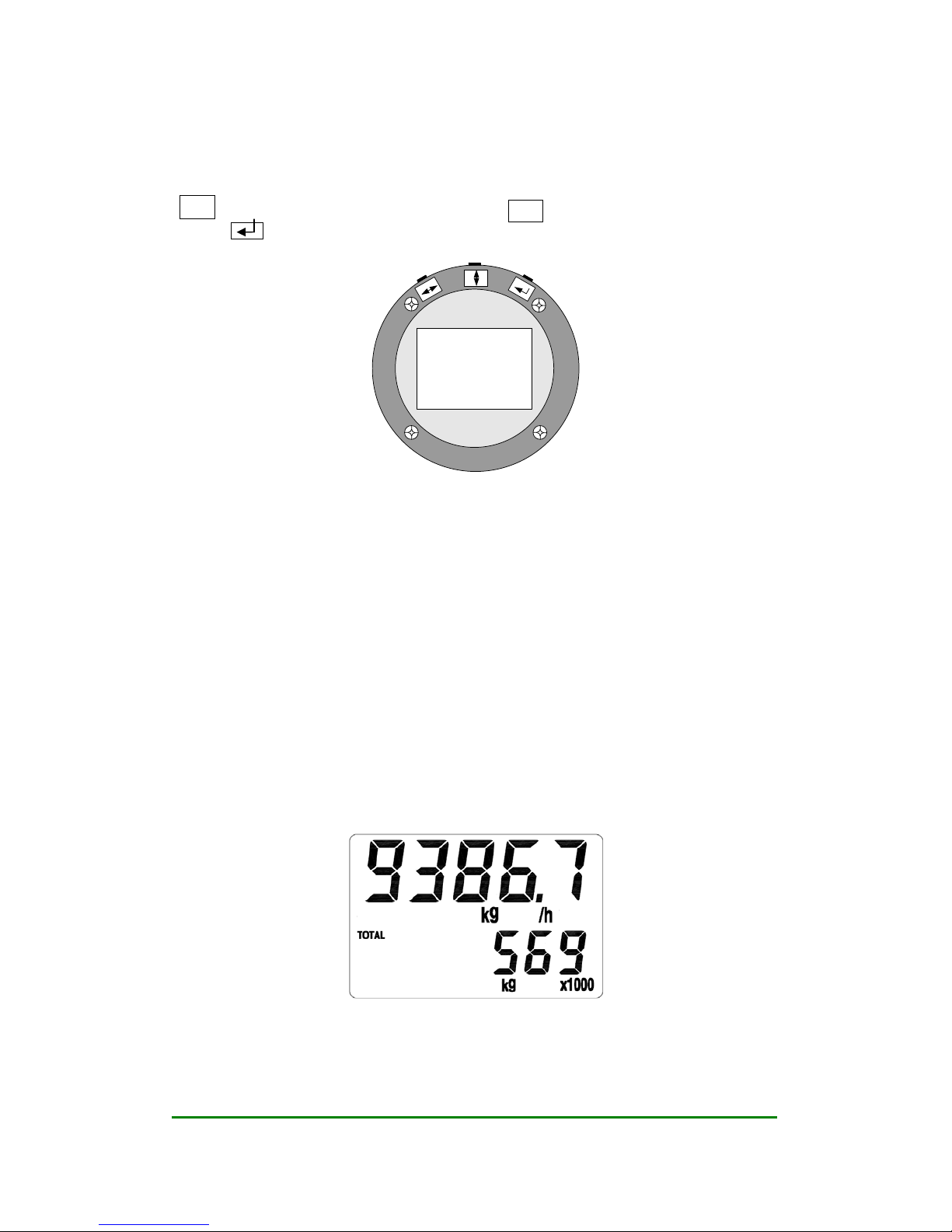

4.1 Intruction of multi-functional LCD display

TGF450 thermal mass flow meter has a display to indicate “Temperature” “Flow rate” “Total flow”

and more parameters. Please reference to picture 4.1 below.

Pitcure 4.1 TGF450 display

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

17/47

The LCD display has 2 areas to display the content, the upper row, the lower row. The upper

row displays the flow rate/mass flow/standard flow rate. Below the upper row shows the unit of the

variable displayed in upper row.

The lower row display indicates other variables, such as temperature/ pressure/ total flow/ density.

And below the lower row shows the unit of the variable displayed in lower row.

Please reference to picture 4.2 for display

Picture 4.2 Flow rate and total flow display

TGF450 multi-varibale version can also display temperature. Users can switch the parameter

displayed by using the buttons and the parameter will be displayed for 30 seconds. Please reference to

picture 4.3 for mass flow and temperature displaying. Users can also fix the lower row to display a

parameter consistently.

Picture 4.3 Mass flow and temperature display

You can also set the lower row to display several variables in circular turn.

4.2 Unit of the variable displayed

The variables that can be displayed in lower row and their units that can be displayed are as the chart

4.4 below.

Subject Variable Unit Circular display code

TOTAL Total flow N3

m,3

m,L,kg or t 01

Temperature ℃ 02

Pressure MPa or kPa 03

Frequency Hz 04

Density kg/ 3

m 05

Chart 4.4 The displayed units

Remark: Clients can select the unit, pressure need separate pressure sensor

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

18/47

4.3 Three button setting

TGF450 series thermal mass flowmeter has three buttons on the top of the displayer, which are:

↔ (will be mentioned as “L-R button” below), b (will be mentioned as “U-D button”

below), (will be mentioned as “Enter button” below). Please reference to below picture

Picture 4.5 buttons

When under working, use “U-D button” to switch the displaying content, use “L-R button” can switch

to the left and right digits of total flow. “Enter button” is to dispay the entire digits of total flow

directly.

When the flowmeter is under setting mold, the “L-R button” means move to left and right to select the

digit, the “U-D button” means to set the digit to a number, the “Enter button” means “confirm”. All the

“Digital setting” and “Code setting” of VFM series vortex flowmeter is made through these 3 buttons.

Please reference to related article for details.

4.4 Total flow displaying

TGF450 can display the total flow with 9 digits left to decimal point and 3 digits right to it.When

there is more than six digits, the total flow reading will be displayed in two times. One time

displays the right digits and the other displays the left digits. You can use the “L-R button” to

switch between the right digits and left digits. The left digits will be displayed with a mark of

“x1000”. Please reference to picture 4.6

Picture 4.6 Displaying the left digits, a “x1000” mark is displayed

If you want to check the right digits now, please pressure the “L-R button”, the display will be as

picture 4.7 below.

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

19/47

Picture 4.7 Displaying the right digits

According to picture 4.6 and 4.7, the total flow is 569864.581 kg.

4.5 Status

TGF450 series thermal mass flowmeter have three different statuses as below

Working status

Setting status

Calibration status

When under working status,please follow the instruction in 4.1 to switch the parameter displayed.

When under setting status, you can set the flowmeter, while the flowmeter is still processing, so setting

will not have effect on the measuring. In next chapter, there will be instruction of how to do setting.

The calibration of the flowmeter have been finished in manufacture’s lab before delivery, including

temperature and pressure calibration if required and the setting of high-limit and low-limit of 4~20mA

stimulation output. Thus customers do not to set any more.

5 Setting

Note: Every TGF450 thermal mass flowmeters has been set according to requirement before

delivery, please do not change setting unless it is necessary and under correct instruction!

TGF450 thermal mass flowmeter have digital setting and code setting. Use code setting to set

parameters such as damping and output signal. Use digital setting to set parameters related to a number,

such as pipe size, flow range, factor.

5.1 How to set

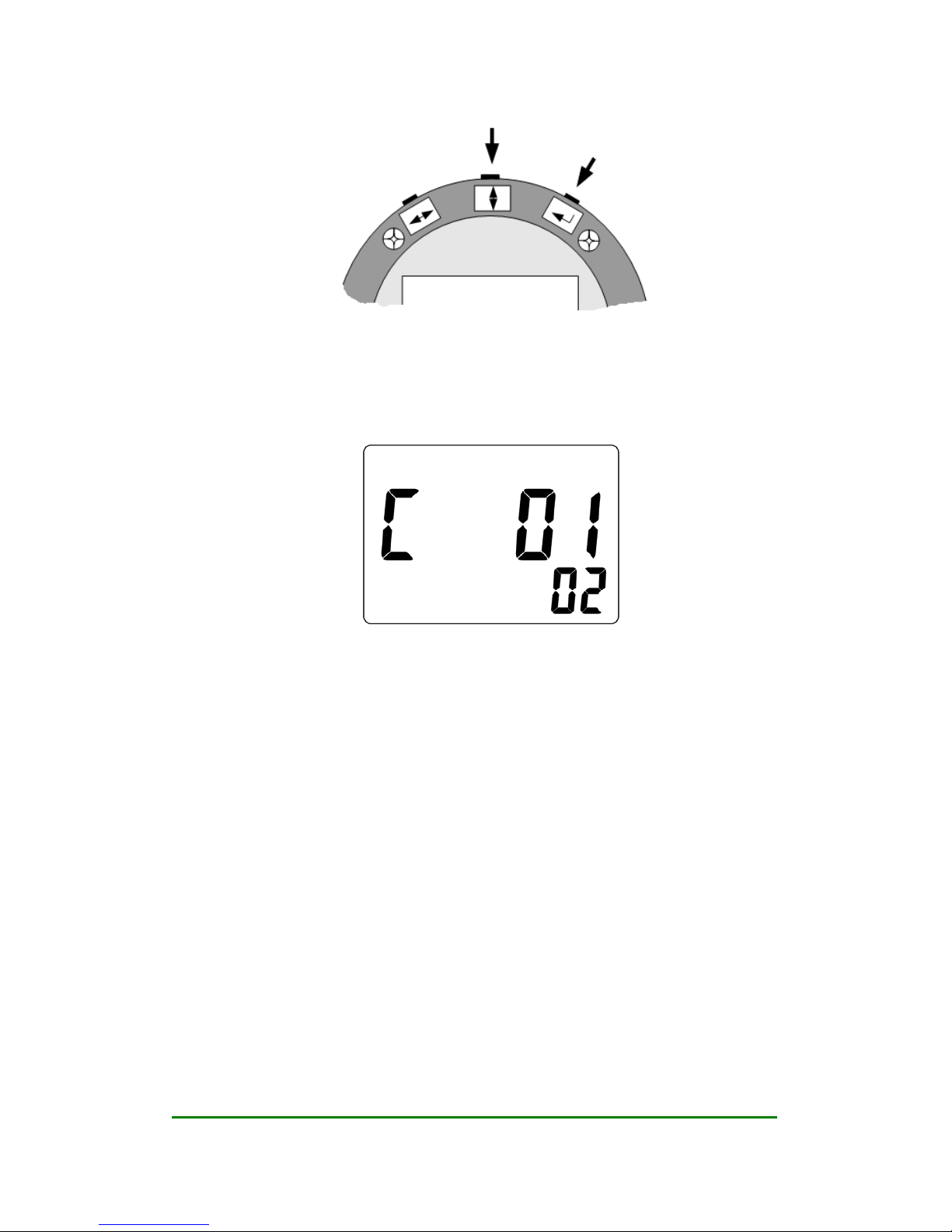

5.1.1 Code setting

Under working status, to enter code setting, please hold “Enter button” then press “U-D button” at the

same time. Please reference to picture 5.1.

User’s Manual Rev1.0

Date:15/07/2015 User’s Manual

20/47

Picture 5.1 enter and quit code setting

When in code setting, the first row will display the reference number of the code setting, and the

lower row will display the contents of this parameter. The digit that is flashing is the digit under

setting. Please reference to picture 5.2, which means C01=02, that is set the pre-heating time to 2

seconds.

Picture 5.2 code setting

When under code setting, Now ,user can use “L-R button” to choose which digit on the displayer

are to be set , and use “R-D button” to switch the digit to 0~9 . The first time of pressing “Enter

button” means to set the lower row, when under this situation, users can still use “L-R button” or

“U-D button” to set. Press “Enter button” again to check if the setting is available. If setting is

available, the display will not flash, when user can still press “L-R button” or “U-D button” to set

again. When display is not flashing, pressure “Enter button” to save and go to next setting.

If want to quit code setting, same as entering, please hold “Enter button” then press “U-D button”

at the same time.

5.1.2 Digital setting

Under working status, to enter code setting, please hold “Enter button” then press “L-R button” at the

same time. Please reference to picture 5.3.

Table of contents

Other Nitto Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Freiberg Instruments

Freiberg Instruments lexsyg research MANUAL AND DOCUMENTATION

Wallbox

Wallbox MID METER installation guide

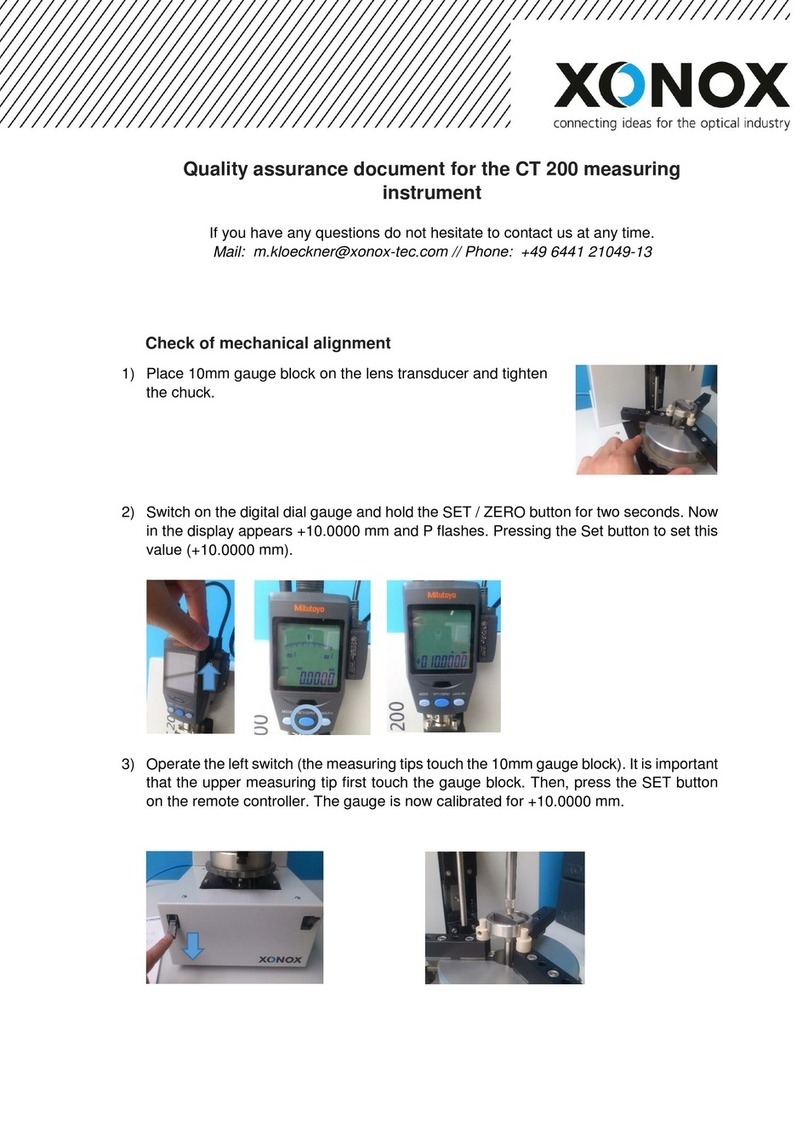

XONOX

XONOX CT 200 Quality assurance document

Hanna Instruments

Hanna Instruments HI 88703 instruction manual

Roughneck

Roughneck 24923 owner's manual

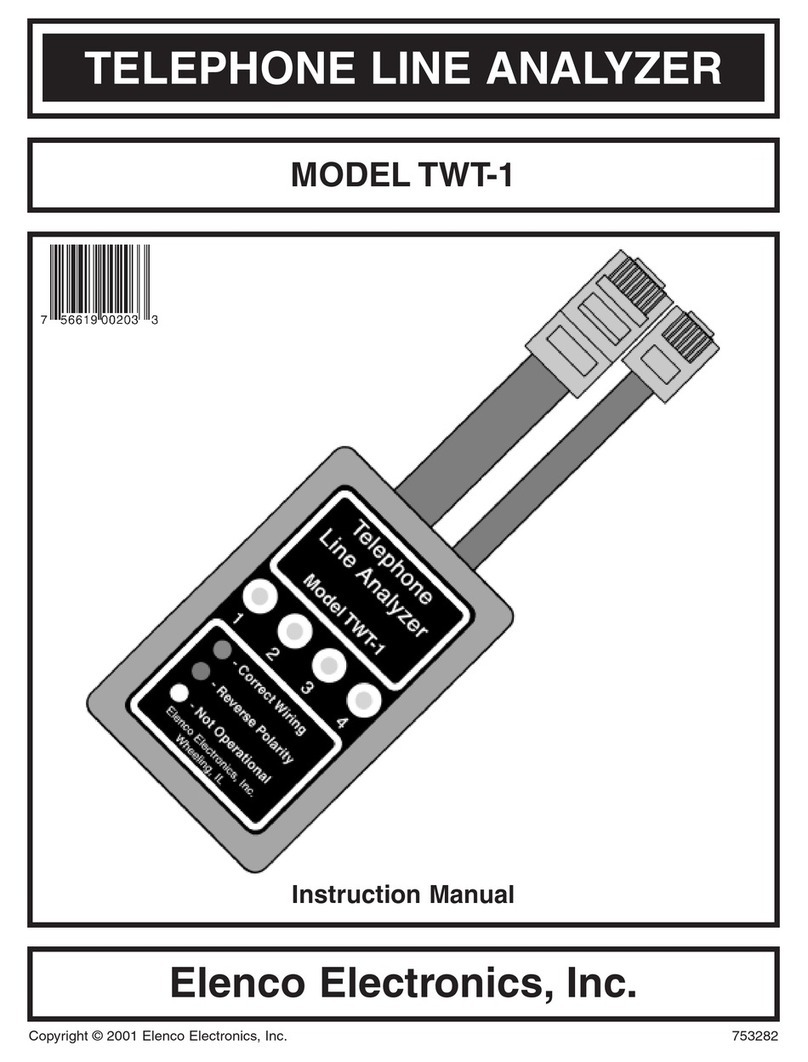

Elenco Electronics

Elenco Electronics TWT-1 instruction manual