NiuBol NBL-W-FGS User manual

NBL-W-FGS Fruit Growth Sensors

Changsha ZOKO LINK Technology Co., Ltd

1

Product introduction

Fruit Growth Sensors are highly accurate

electronic measuring instruments with automatic

temperature compensation.

The instrument can be used to easily

monitor the influence of environmental factors on

the growth of plant fruits and stems. The data

collector or computer measures the daily growth

and long-term growth changes of the plant in real

time through the signal change of the caliper

bridge tension probe.

Technical Parameters

Model No.

NBL-W-FGS

Voltage

DC12-24V

Signal output

RS485/4-20mA/0-

5V

Measuring range

A:0-50mm

B:0-100mm

C:0-150mm

D:0-250mm

Communication

MODBUS

Baud Rate

9600

Average Power

Consumption

0.3W

Lifetime

大于 1000000 次

Accuracy

±1%

Movable length

Maximum

measuring range

+3mm

Working temperature

-40-80℃

Working humidity

0-95%RH

length of line

2.5m

IP rate

IP65

Installation

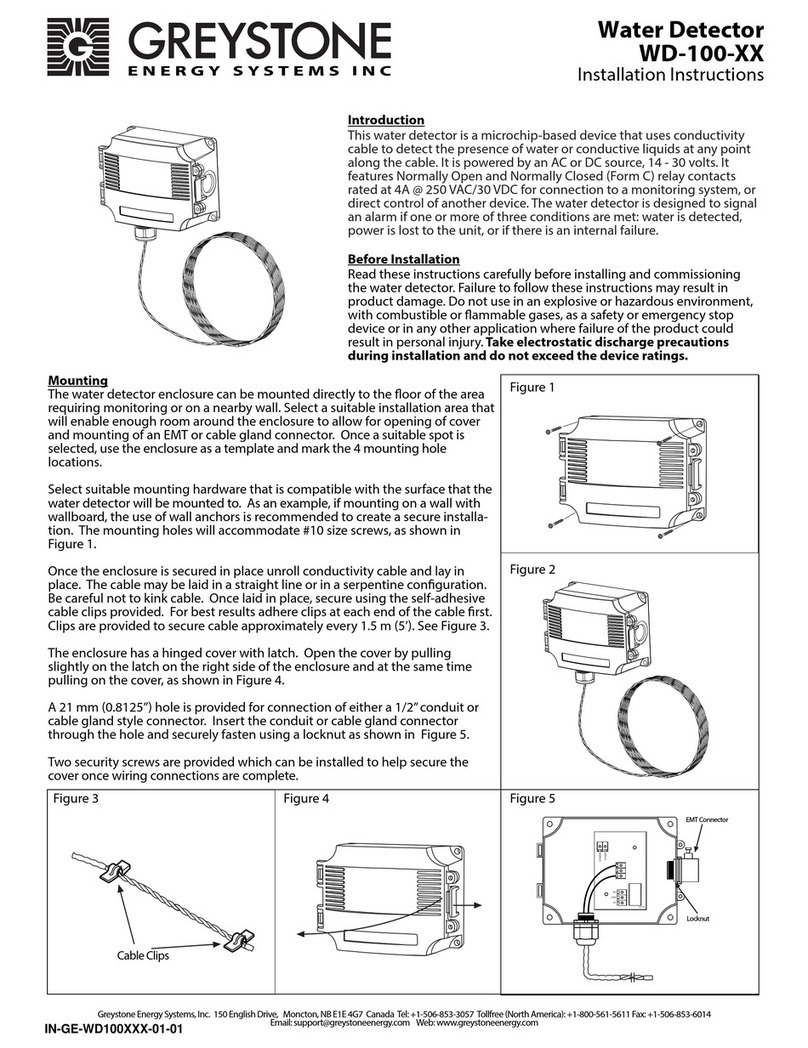

Wiring method

(1) If equipped with the collector produced by our

company, directly use the sensor line to connect

the sensor to the corresponding interface on the

collector.

(2) If the transmitter is purchased separately, the

wiring sequences of the transmitter supporting

lines are as follows:

(3)Transmitter voltage and current two output

wiring methods:

Line color

output signal

voltage

current

communi

cation

Red

+

+

+

Black

(Green)

-

-

-

Yellow

Voltage

signal

Current

signal

A+

Blue

B-

NBL-W-FGS Fruit Growth Sensors

Changsha ZOKO LINK Technology Co., Ltd

2

(Wiring in voltage output mode)

(Wiring in current output mode)

Calculation formula

Voltage type:

Example: 0-100mm range, 0-5V output

Calculation formula:

L=(V/5*M)mm

(L is the measurement indication, V is the output

voltage, M is the measurement range)

Current type:

Example: 0-100mm range, 4-20mA output

Calculation formula:

L=(I-4)*M/16

(L is the measurement indication, I is the output

current, M is the measurement range)

MODBUS Communication Protocol

1. Serial port format

Data bit 8 bits

1 or 2 stop bits

Check digit None

Baud rate 9600 The interval between two

communications is at least 1000ms

2. Communication format

【1】Write device address

Send: 00 10 Address CRC (5 bytes)

Return: 00 10 CRC (4 bytes)

Note: 1. The address bit of the read/write

address command must be 00.

2. Address is 1 byte, ranging from 0-255.

Example: send 00 10 01 BD C0

return 00 10 00 7C

【2】Read device address

Send: 00 20 CRC (4 bytes)

Return: 00 20 Address CRC (5 bytes)

Description: Address is 1 byte, the range is 0-255

Example: Send 00 20 00 68

return 00 20 01 A9 C0

【3】Read real-time data

Send: Address 03 00 00 00 01 CRC

Description: As shown in the figure below:

Code

Functional Definition

Remark

Address

Station number

(address)

03

Function code

00 00

Start address

00 01

Read Points

CRC

CRC Check code,

front low and back

high

Return: Address 03 02 XX XX CRC

Description:

Code

Functional Definition

Remark

Address

Station number

(address)

03

Function code

02

Read Unit Bytes

XX XX

Data (High front and

low back)

Hex

CRC

CRC Check code

Steps to calculate CRC code:

1. The preset 16-bit register is hexadecimal

FFFF (that is, all 1). Call this register the CRC

register;

2. XOR the first 8-bit data with the low bit of the

NBL-W-FGS Fruit Growth Sensors

Changsha ZOKO LINK Technology Co., Ltd

3

16-bit CRC register, and put the result in the

CRC register;

3. Shift the content of the register to the right by

one bit (towards the lower bit), fill the highest

bit with 0, and check the lowest bit;

4. If the lowest bit is 0: repeat step 3 (shift again)

If the lowest bit is 1: XOR the CRC register

with the polynomial A001 (1010 0000 0000

0001);

5. Repeat steps 3 and 4 until the right shift is 8

times,so that the entire 8-bit data has been

processed;

6. Repeat steps 2 to 5 to process the next 8-bit

data;

7. The final CRC register is the CRC code;

8. When putting the CRC result into the

information frame, exchange the high and low

bits, with the low bits first.

Electrical Connection Precautions

In order to ensure safety, the electrical

connection should be done by professionals.

Because static electricity can damage the

internal electronic components of the instrument,

the performance of the instrument will be

reduced or damaged. The manufacturer

recommends the following measures to prevent

the instrument from being damaged by static

electricity:

Discharge static electricity from your body

before touching any of the meter's electronic

parts, such as printed circuit boards and the

components on them. This can be done by

touching a grounded metal surface of an

instrument case, or a metal conduit or pipe;

To reduce static buildup, avoid excessive

movement. Ship static-sensitive components in

an antistatic container or packaging;

To discharge static electricity from the user's

body and keep static electricity dischargeable,

wear a wrist static arrestor connected to a

grounded wire;

Use an antistatic floor or bench liner if possible.

Instrument maintenance

Maintenance schedule

Maintenance

task

Cycle

Remark

Clean the

sensor

Weekly

Cleaning

frequency can be

determined

according to the

specific

application

Check the

sensor for

damage

Monthly

Calibrate the

sensor

3D calibration has been done

before leaving the factory,

and users do not need to

calibrate. In special cases, it

can be carried out according

to the maintenance schedule

required by the competent

authority.

Clean the sensor

Clean the outer surface of the sensor with water.

If debris remains, wipe it with a damp soft cloth

or gently brush it with a soft brush.

Do not place the sensor where it will be exposed

to direct sunlight or through reflection.

After-sales service

The device has no moving parts and does

not require complex routine maintenance on

site.

If the user opens the device by himself or

damages the safety seal on it, he will no

longer enjoy our quality assurance and

guarantee.

If there is any problem with the equipment,

you can contact the company's staff to

analyze and answer the problem;

NBL-W-FGS Fruit Growth Sensors

Changsha ZOKO LINK Technology Co., Ltd

4

If the equipment needs to be returned, please

carefully pack the instrument according to the

original packaging and mail it to our company,

and attach the detailed fault instructions of the

instrument.

Contact Us

Contact: +8615367865107/+8618073152920

Zip code: 421000

Email:[email protected]

Email: [email protected]

Website: http://www.niubol.com

Address: Room 103, Area D, Houhu Industrial

Park, Yuelu District, Changsha City, Hunan

Province,China

Other NiuBol Security Sensor manuals