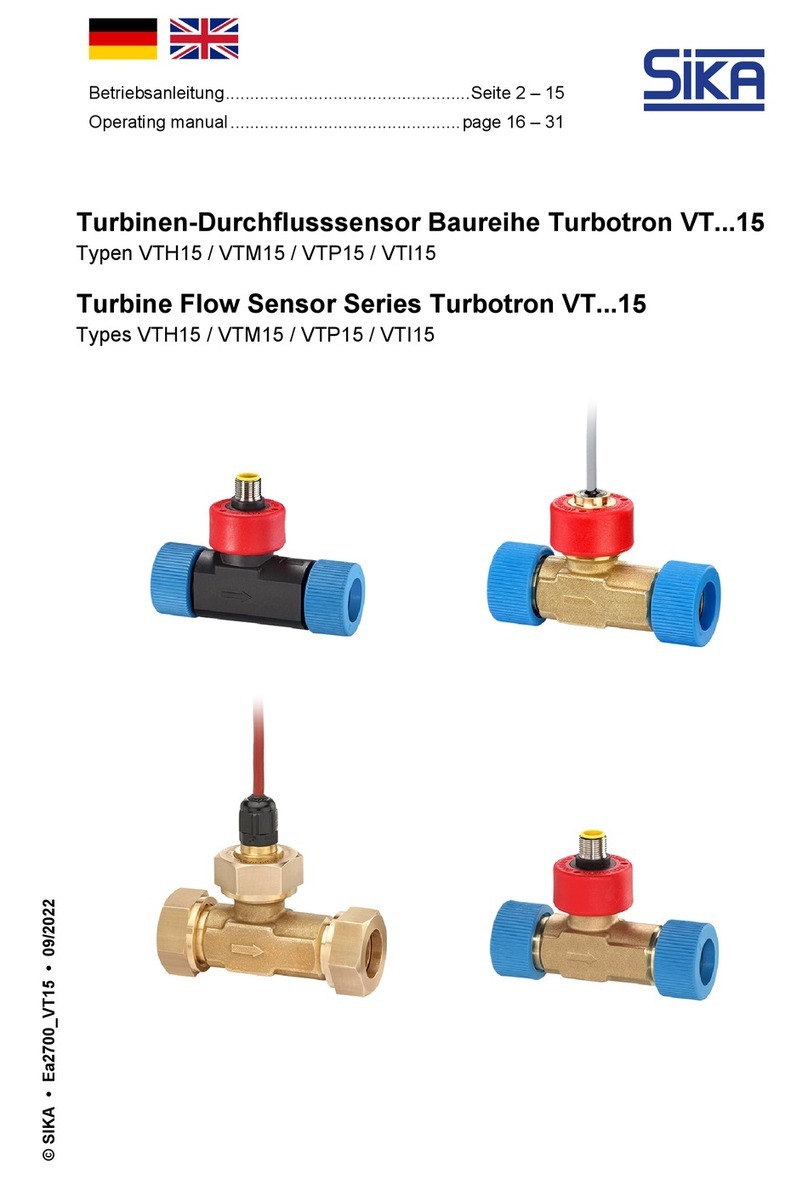

Nivus CSM Series Owner's manual

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 1

Technical Instructions for

Correlation Sensors and external Electronic Box

(Original technical instructions – German)

as of Firmware Version:

1.58 (POA

-V2)

1.59 (OCL

-L1)

1.58

(CS2)

1.

64 (EBM)

NIVUS GmbH

Im Taele 2

75031 Eppingen, Germany

Phone: +49 (0) 72 62 / 91 91 - 0

Fax: +49 (0) 72 62 / 91 91 - 999

Internet: www.nivus.com

Branch offices

page 2

®

NIVUS AG

Hauptstrasse 49

8750 Glarus, Switzerland

Phone: +41 (0)55 6452066

Fax: +41 (0)55 6452014

E-mail: swiss@nivus.com

Internet: www.nivus.de

NIVUS Austria

Mühlbergstraße 33B

3382 Loosdorf, Austria

Phone: +43 (2754) 567 63 21

Fax: +43 (2754) 567 63 20

Internet: www.nivus.de

NIVUS France

14, rue de la Paix

67770 Sessenheim, France

Phone: +33 (0)3 88071696

Fax: +33 (0)3 88071697

E-mail: info@nivus.fr

Internet: www.nivus.fr

NIVUS U.K. Ltd

Wedgewood Rugby Road

Weston under Wetherley

Royal Leamington Spa

CV33 9BW, Warwickshire

Phone: +44 (0)1926 632470

Internet: www.nivus.com

NIVUS U.K.

1 Arisaig Close

Eaglescliffe

Stockton on Tees

Cleveland, TS16 9EY

Phone: +44 (0)1642 659294

Internet: www.nivus.com

NIVUS Sp. z o.o.

ul. Hutnicza 3 / B-18

81-212 Gdynia, Poland

Phone: +48 (0) 58 7602015

Fax: +48 (0) 58 7602014

Internet: www.nivus.pl

NIVUS Middle East (FZE)

Building Q 1-1 ap. 055

P.O. Box: 9217

Sharjah Airport International

Free Zone

Phone: +971 6 55 78 224

Fax: +971 6 55 78 225

E-mail: Middle-East@nivus.com

Internet: www.nivus.com

NIVUS Korea Co. Ltd.

#2502 M Dong, Technopark IT Center,

32 Song-do-gwa-hak-ro,

Yeon-su-gu, INCHEON, Korea 406-840,

Phone: +82 32 209 8588

Fax: +82 32 209 8590

E-Mail: [email protected]

Internet: www.nivuskorea.com

NIVUS Vietnam

21 Pho Duc Chinh, Ba Dinh,

Hanoi, Vietnam

Mobile (VN) 012 0446 7724

E-Mail: vietnam@nivus.com

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 3

Copyrights and property rights

This document and its contents are proprietary to NIVUS GmbH and are

not to be reproduced or copied without the express written permission of

NIVUS GmbH.

Violations oblige to compensation.

Important Note

This instruction manual may exclusively - even in parts - be copied or translated in any

other way with the express written consent of NIVUS GmbH.

Translation

If the device is sold to a country in the European Economic Area (EEA)

this instruction handbook must be translated into the language of the

country in which the device is to be used.

Should the translated text be unclear, the original instruction handbook

(German) must be consulted or the manufacturer contacted for clarifica-

tion.

Copyright

No part of this publication may be reproduced, transmitted, sold or dis-

closed without prior permission. Damages will be claimed for violations.

All rights reserved.

Names

The use of general descriptive names, trade names, trademarks and the

like in this handbook does not entitle the reader to assume they may be

used freely by everyone. They are often protected registered trademarks

even if not marked as such.

Technical Instructions for

Correlation Sensors

Page 4 Correlation Sensors – Rev. 07 as of 20.04.2016

®

1General.................................................................................5

2Safety Instructions ..............................................................7

2.1 Used signs and definitions ............................................................7

2.2 Safeguards and precautions .........................................................8

2.3 Liability Disclaimer.........................................................................8

2.4 User’s Responsibilities..................................................................9

2.5Device Identification....................................................................10

2.6 Sensor Versions..........................................................................13

3Overview and Intended Use..............................................19

3.1 Overview .....................................................................................19

3.2 Intended Use...............................................................................25

4Specifications ....................................................................27

4.1 Water-ultrasonic sensor, type CSM-V100...................................27

4.2 Water-ultrasonic sensor, type CSM-V1D0..................................27

4.3 Electronic Box, type: EBM...........................................................28

4.4 Air Ultrasonic-Sensor Mini, type DSM.........................................28

4.5 Water-ultrasonic combi sensor, type POA..................................29

4.6 Air Ultrasonic-Sensor, type OCL-L1............................................30

4.7 Water-ultrasonic combi sensor, type CS2...................................31

4.8 Equipment...................................................................................32

4.8.1 Delivery .......................................................................................32

4.8.2 Receipt ........................................................................................32

4.8.3 Transport.....................................................................................33

4.8.4 Return..........................................................................................33

4.8.5 Installation of Spare Parts and Parts subject to wear and tear...33

5Installation..........................................................................34

5.1 Installation Instructions................................................................34

5.2 Electrical Installation....................................................................34

5.3 Sensor Design and Dimensions..................................................35

5.4 Sensor Installation.......................................................................44

5.5 Mounting the protection hose for the sensor, type CS2..............44

5.6 Plug wiring and Sensor Cable.....................................................45

5.7 Cable extension...........................................................................48

5.8 Pressure compensation element for CSM Sensors....................50

5.9 Pressure compensation element for POA- and CS2- sensors ...52

6Table of Resistiveness......................................................56

6.1 Resistiveness Legend.................................................................58

7Maintenance and Cleaning ...............................................59

7.1 Water-US Combi Sensor with Pressure Measurement...............59

7.2 Air-Ultrasonic Sensor ..................................................................61

7.3Pressure Compensation Element for CSM Sensors...................61

7.4 Pressure Compensation Element for POA and CS2 Sensor......62

7.5 Customer Service Information.....................................................62

8Dismantling/Disposal........................................................62

9Accessories (optional)......................................................63

10 Table of Pictures................................................................64

11 Certificates and approvals................................................66

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 5

1 General

Important

READ CAREFULLY BEFORE USE

KEEP IN A SAFE PLACE FOR LATER REFERENCE

This Technical instruction is an original instruction for Correlation Sensors and

external Electronic Box is intended for the initial start-up or the connection of the

sensors. This manual is oriented exclusively to qualified expert personnel.

Read this Technical instruction carefully and completely prior to installation and

connection since it contains relevant information on this product. Observe the

notes and particularly follow the warning notes and safety instructions.

Keep this manual in a safe place and make sure it is available for the users of

this product at any time.

If you should have problems to understand information contained within this

Technical Instruction either contact the manufacturer or one of the distributors

for further support. The manufacturer cannot be held responsible for damage to

persons or material due to incorrectly understood information in this instruction.

In case of selling the sensors, this Technical instruction shall be provided to the

purchaser since it is a part of the standard delivery.

The sensor installation is described in the separate >Installation Instructions for

Correlation and Doppler Sensors<. This document is part of the standard deliv-

ery and must be read necessarily prior to sensor installation.

Detailed information on how to operate the complete system can be found in the

accompanying instruction transmitter instruction manual.

Technical Instructions for

Correlation Sensors

Page 6 Correlation Sensors – Rev. 07 as of 20.04.2016

®

Personnel requirements

Installation, commissioning and maintenance shall be executed only by person-

nel meeting the demands as follows:

- Expert personnel with relevant training an appropriate qualification

- Personnel authorised by the plant operator

Qualified personnel

within the context of this documentation or the safety notes on the product

itself are persons who are sufficiently familiar with installation, mounting, start-

ing up and operation of the product and who have the relevant qualifications

for their work; for example.

- Training, instruction or authorisation to activate/deactivate, isolate, ground,

and mark electric circuits and devices/systems according to the safety en-

gineering standards.

- Education and instruction according to the standards of safety engineering

regarding the maintenance and use of adequate safety equipment.

- First aid training

Applicable documentation

For the installation and operation of the complete system extra instruction man-

uals or technical descriptions may be required apart from this manual.

- Instruction manual for the flow measurement unit NivuFlow 750

- Technical Instructions for iXT or MPX

- Installation Instruction for correlation and Doppler sensors

These manuals are provided with the auxiliary units or sensors.

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 7

2 Safety Instructions

2.1 Used signs and definitions

The general warning symbol indicates the risk of personal injuries or death.

In the text section the general warning symbol is used in conjunction with the

signal words described below.

DANGER

Warning of danger to persons

Indicates an immediate high risk which may result in death or severe personal

injury if not avoided.

DANGER

Danger of electric shock

Indicates a possible danger by electrical power with moderate risk which may

result in death or severe personal injury if not avoided.

WARNING

Warning of danger to persons

Indicates a possible danger with moderate risk which may result in death or

(severe) personal injury if not avoided.

CAUTION

Warning of personal injuries or material damage

Indicates a possible danger with moderate risk which may result in minor or

moderate personal injury or material damage if not avoided.

Important Notes

Indicates situations that may result in damage to property and/or loss of data,

if not avoided.

Contains information that needs to be highlighted.

Notes

Indicates situations that do not result in personal injury.

Technical Instructions for

Correlation Sensors

Page 8 Correlation Sensors – Rev. 07 as of 20.04.2016

®

2.2 Safeguards and precautions

WARNING

Preventing electromagnetic discharge

It is indispensable to eliminate the risk of explosive atmospheres by using a

gas warning unit prior to executing installation or maintenance works.

Please observe to avoid electrostatic charge during this procedure!

Avoid unnecessary movements to reduce the risk of building up electrostatic

energy.

Make sure to discharge static electricity from your body before you begin to

install the sensors.

WARNING

Germ contamination

Please note that due to the operation in the waste water field the measure-

ment system and cables may be loaded with dangerous disease germs. Re-

spective precautionary measures must be taken to avoid damage to one’s

health.

Wear protective clothing.

WARNING

Observe regulations for health and safety at work

Before starting installation work, observing the work safety regulations need

to be checked.

Failure to do so may cause personal injury.

WARNING

Do not disable safety devices!

It is strictly prohibited to disable the safety devices or to change the way they

work.

Failure to observe may cause personal injury as well as to sys-tem damage.

2.3 Liability Disclaimer

The manufacturer reserves the right to change the contents of this document

including this liability disclaimer without prior notice and cannot be held respon-

sible in any way for possible consequences resulting from such changes.

For connection, initial start-up and operation as well as maintenance of the sen-

sors the following information and higher legal regulations of the respective

country (e.g. VDE regulations in Germany) such as applicable Ex regulations as

well as safety requirements and regulations in order to avoid accidents shall be

observed.

The safety-related values of the connected the sensors shall comply with the

technical specifications or the specifications contained in the according EC type

examination certificate.

Interconnecting several active devices within an intrinsically safe circuit may re-

sult in different safe maximum values. In such cases the intrinsic safety may be

impaired!

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 9

All operations on the device which go beyond installation or connection

measures in principle shall be carried out by NIVUS staff or personnel author-

ised by NIVUS due to reasons of safety and guarantee.

Operate the sensors only in technically perfect working order.

Improper Use

Not being operated in accordance with the requirements may impair the safety.

The manufacturer is not responsible for failures resulting from improper use.

2.4 User’s Responsibilities

In the EEA (European Economic Area) national implementation of the frame-

work directive 89/391/EEC and corresponding individual directives, in particu-

lar the directive 89/655/EEC concerning the minimum safety and health re-

quirements for the use of work equipment by workers at work, as amended,

are to be observed and adhered to.

In Germany the Industrial Safety Ordinance must be observed.

The customer must (where necessary) obtain any local operating permits re-

quired and observe the provisions contained therein. In addition to this, he must

observe local laws and regulations on

- personnel safety (accident prevention regulations)

- safety of work materials and tools (safety equipment and maintenance)

- disposal of products (laws on wastes)

- disposal of materials (laws on wastes)

- cleaning (cleansing agents and disposal)

- environmental protection.

This technical description is part of the standard delivery and must be availa-

ble to the user at any time.

The safety instructions contained therein must be followed.

Technical Instructions for

Correlation Sensors

Page 10 Correlation Sensors – Rev. 07 as of 20.04.2016

®

2.5 Device Identification

The instructions in this manual apply only for the type of sensor or the units de-

picted on the title page.

The article number can be found where the cable enters the sensor body as well

as on a nameplate on the end of the cable. This nameplate is protected against

weathering and abrasion by using a transparent shrunk-on hose and contains

the following:

- name and address of manufacturer

- CE label

- type and serial number

- year of manufacture

- Ex label (on Ex-version sensors only) as mentioned in chapter 3.2.

In case of enquiries and ordering replacement parts it is important to specify ar-

ticle number as well as the serial number of the respective transmitter or sensor.

This ensures correct and quick processing.

ëYou can find the declaration of conformity at the end of this manual.

Fig. 2-1 Nameplate flow velocity sensor, type CSM

Fig. 2-2 Nameplate flow velocity sensor, type CSMD

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 11

Fig. 2-3 Nameplate Electronic Box, type EBM

Fig. 2-4 Nameplate level sensor, type DSM

Fig. 2-5 Nameplate flow velocity sensor, type POA

Technical Instructions for

Correlation Sensors

Page 12 Correlation Sensors – Rev. 07 as of 20.04.2016

®

Fig. 2-6 Nameplate level sensor, type OCL-L1

Fig. 2-7 Nameplates flow velocity sensor, type CS2

Fig. 2-8 Ex-label for each sensor; type POA, CS2, OCL-L1

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 13

2.6 Sensor Versions

The sensors are available in various constructions (wedge and pipe sensors)

and additionally vary in terms of Ex-Version, cable lengths, sensor connection

(cable end for direct connection or configured plug / plug-on filter element) as

well as various special versions and materials.

The article number can be found where the cable enters the sensor body as well

as on a nameplate on the end of the cable. This nameplate is protected against

weathering and abrasion by using a transparent shrunk-on hose.

Fig. 2-9 Type key for water-ultrasonic sensors, type CSM

CSM- Type Sensor with spatial allocation of flow velocities

V100 Without Level Measurement

KT Wedge sensor made of PVDF; ground plate 1,4571

XX Special construction

V1D0 mit Druckmesszelle

KT

XX Special construction

Approvals (ATEX)

0none

EEx zone 1

Cable Length

07 7 m

15 15 m (only type V1D0)

C

D

CSM-

Sensor Connection

Connection to electronic box, type

RD incl. pressure compensation

element

Connection to electronic box,

type RD

Wedge sensor made of PPO with PEEK

sensor face; ground plate 1.4571

Technical Instructions for

Correlation Sensors

Page 14 Correlation Sensors – Rev. 07 as of 20.04.2016

®

Fig. 2-10 Type key for Electronic Box, type EBM

Fig. 2-11 Type key for air-ultrasonic sensors, type DSM

EBM-V1L1

Construction

RD Wedge sensor

XX Special construction

Approvals (ATEX)

0none

EEx zone 1

Cable Lengths

03 3 m

10 10 m

15 15 m

20 20 m

30 30 m

50 50 m

99 100 m

XX Special length upon request

SConnection to PCM Pro and PCM 4

K

EBM-V1L1

Cable end pre-configured for

connection to OCM Pro CF

Sensor Connection

Electronic box for connection of 1x CSM and 1x DSM Sensor

incl.suspension bracket and mounting plate, IP 68

DSM-L0 Air-ultrasonic sensor for non-contact level measurement

Construction

KWedge sensor

X Special construction

Sensor Version

SStandard version made of PPO, ground plate 1.4571

XSpecial construction

Transmitting Frequency

12 Standard frequency

XX Special construction

Approvals (ATEX)

0none

EEx zone 1

Cable Lengths

07 7 m

15 15 m

BConnection to electronic box

DSM-L0 B

Sensor Connection

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 15

POA- Type

V200 without Level Measurement

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

KP Wedge sensor made of high resistant full PEEK, ground plate 1.4571

KX

RT Pipe sensor made of PPO with PEEK sensor face; pipe body 1.4571

RP Pipe sensor made of high resistant full PEEK; pipe body 1.4571

RX Pipe sensor, special construction

V2H1 with ultrasound from bottom up for Level Measurement

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

KP Wedge senor made of high resistant full PEEK, ground plate 1.4571

KX

RT Pipe sensor made of PPO with PEEK sensor face; pipe body 1.4571

RP Pipe sensor made of high resistant full PEEK; pipe body 1.4571

RX Pipe sensor, special construction

V2D0 with Pressure Measurement Cell for Level Measurement

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

KX Wedge sensor, special construction

V2U1

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

KX Wedge sensor, special construction

Approvals (ATEX)

0none

EZone 1

10 10 m

15 15 m

20 20 m

30 30 m

50 50 m

99 100 m

XX Special length upon request

1B 10 m, FEP coated*

2B 20 m, FEP coated*

3B 30 m, FEP coated*

5B 50 m, FEP coated*

9B 100 m, FEP coated*

XB Special length / special construction*

Sensor with spatial allocation of flow velocities

covering a maximum of 16 scan layers

Wedge sensor, special construction (e.g. made of high resistant full PEEK

with ground plate made of Hastelloy or Titanium).

Wedge sensor, special construction (e.g. made of high resistant full PEEK

with ground plate made of Hastelloy or Titanium).

Cable Length (max. 150 m /

with pressure measurement cell up to 30 m)

with Pressure Measurement Cell and ultrasound from

bottom up for Level Measurement

Technical Instructions for

Correlation Sensors

Page 16 Correlation Sensors – Rev. 07 as of 20.04.2016

®

Fig. 2-12 Type key for water-ultrasonic sensors, type POA (V+H)

Fig. 2-13 Type key for water-ultrasonic sensors, type for NFP (V)

Sensor Connection

K

L

F

S

Pipe Length

0(only for wedge sensor)

2

20 cm (standard)

330 cm (minimum length for ball stop valve)

440 cm (minimum length for retractable fitting)

XSpecial pipe length in dm, price per dm

G20 cm + extension thread

POA-

* = Cable not possible for sensor type V2D0 and V2U1

Connection to PCM Pro and PCM 4 for Types

V2D and V2U, portable version incl. plug and

exchangeable filter element

Connection to PCM Pro and PCM 4 for Types

V20 and V2H, portable version incl. Plug

Cable end pre-configured for connection to

OCM Pro CF type V20 and V2H

Cable end pre-configured for connection to

OCM Pro CF Type V2D and V2U

POA- Sensor with spatial allocation of flow velocities covering a maximum of 16 scan layers

V200

RT Pipe sensor made of PPO with PEEK sensor face; pipe body 1.4571

RP Pipe sensor made of high resistant full PEEK; pipe body 1.4571

RX Pipe sensor, special construction

Approvals (ATEX)

0none

EZone 1

Cable Length - max. 150 m (FEP coated upon request)

10 10 m

15 15 m

20 20 m

30 30 m

50 50 m

99 100 m

XX Special length upon request

Sensor Connection

K

Pipe Length

2

20 cm (standard)

330 cm (minimum length for ball stop valve)

440 cm (minimum length for retractable fitting)

XSpecial pipe length in dm, price per dm

G20 cm + extension thread

POA- K

Cable end pre-configured for connection to

OCM Pro CF type V20 and V2H

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 17

Fig. 2-14 Type key for air-ultrasonic sensors, type OCL-L1

OCL-L1 Active air-ultrasonic sensor

Construction

KWedge sensor

X Special construction

Sensor Version

S

Standard version made of PPO, cable: PUR

XSpecial construction

Transmitting Frequency

12 120 kHz

XX Special construction

Approvals

0none

EEx zone 1

Cable Length (max. 150 m)

10 10 m

15 15 m

20 20 m

30 30 m

50 50 m

99 100 m

XX Special length upon request

Sensor Connection

K

S

OCL-L1 K

Cable end pre-configured for

connection to OCM Pro CF

Connection plug for PCM Pro

and PCM 4

Technical Instructions for

Correlation Sensors

Page 18 Correlation Sensors – Rev. 07 as of 20.04.2016

®

Fig. 2-15 Type key for water-ultrasonic sensors, type CS2

CS2- Type Correlation sensor for large dimensions

V100 without level measurement

RP Pipe sensor made of high resistant full PEEK; pipe body 1.4571

RX Pipe sensor, special construction

SP Rod sensor made of highly resistant full PEEK, pipe material 1.4571

V200 without level measurement

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

V2H1 with ultrasound from bottom up for level measurement

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

V2D0 with pressure measurement cell for level measurement

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

V2U1 with pressure measurement cell and ultrasound from bottom up for level measurement

KT Wedge sensor made of PPO with PEEK sensor face; ground plate 1.4571

Approval (ATEX)

0none

EZone 1

Cable Length (max. 150 m / with pressure measurement cell up to 30 m)

10 10 m

15 15 m

20 20 m

30 30 m

50 50 m

99 100 m

XX Special length upon request

Sensor Connection

KConnection to OCM Pro CF, Type V20 and V2H

LConnection to OCM Pro CF, Type V2D and V2U

Rfor pipe sensors for connection to OCM Pro CF, Type V10

F

S

Pipe Length

0(only for wedge sensor)

220 cm (standard)

330 cm (minimum length for stop ball valve)

440 cm (minimum length for retractable fitting)

XSpecial pipe length in dm, price per dm

G20 cm + extension thread

CS2-

Connection to PCM Pro and PCM 4 for type V2D and V2U,

incl. plug and replaceable filter element

Connection to PCM Pro and PCM 4 for type V20 and V2H,

incl. plug

Technical Instructions for

Correlation Sensors

®

Correlation Sensors – Rev. 07 as of 20.04.2016 Page 19

3 Overview and Intended Use

3.1 Overview

1. Flow velocity wedge sensor, type POA-V2H1/V2U1

2. Flow velocity wedge sensor, type POA-V200/V2D0

3. Flow velocity wedge sensor, type CS2

4. Pipe sensor, type CS2, with sensor screw connection and retaining element

5. Pipe sensor, type POA, with sensor screw connection and retaining element

6. Air-ultrasonic sensor, type OCL-L1

7. Flow velocity wedge sensor, type CSM

8. Flow velocity wedge sensor, type CSMD

9. Air-ultrasonic sensor, type, DSM

10. Electronic Box, type EBM

Fig. 3-1 Sensor overview and Electronic Box

Technical Instructions for

Correlation Sensors

Page 20 Correlation Sensors – Rev. 07 as of 20.04.2016

®

1. Ground plate

2. Sensor for flow velocity measurement

3. Sensor body

4. Cable gland

5. Sensor cable

6. Plug with spigot nut

Fig. 3-2 Overview wedge sensor, type CSM

1. Ground plate

2. Sensor for flow velocity measurement

3. Sensor body

4. Cable gland

5. Sensor cable

6. Sensor for level measurement using pressure

7. Pressure compensation element

8. Plug with spigot nut

Fig. 3-3 Overview wedge sensor, type CSM-D

This manual suits for next models

12

Table of contents

Other Nivus Accessories manuals

Popular Accessories manuals by other brands

Huawei

Huawei RRU3268 installation guide

Sunshower

Sunshower PURE WHITE installation guide

Siemens

Siemens SITRANS FSS200 installation manual

Rockwell Automation

Rockwell Automation Allen-Bradley Photoswitch Bulletin 45FVL... installation instructions

Beurer

Beurer HD 100 Instructions for use

Lincoln Electric

Lincoln Electric COOLARC 21 Operator's manual