Nivus P-Series User manual

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 1

Instruction Manual for

NivuMaster P-Series Ultrasonic Sensors

(Original Instruction Manual – German)

NIVUS GmbH

Im Taele 2

75031 Eppingen, Germany

Phone +49 (0)72 62 - 91 91 - 0

Fax +49 (0)72 62 - 91 91 - 999

Internet: www.nivus.com

®

Representatives

Page 2

NIVUS AG

Hauptstrasse 49

CH - 8750 Glarus

Tel.: +41 (0)55 6452066

Fax: +41 (0)55 6452014

E-Mail: swiss@nivus.com

Internet: www.nivus.de

NIVUS Austria

Mühlbergstraße 33B

A – 3382 Loosdorf

Tel.: +43 (0)2754 567 63 21

Fax: +43 (0)2754 567 63 20

Internet: www.nivus.de

NIVUS Sp. z o.o.

ul. Hutnicza 3 / B-18

PL - 81-212 Gdynia

Tel.: +48 (0) 58 7602015

Fax: +48 (0) 58 7602014

Internet: www.nivus.pl

NIVUS France

14, rue de la Paix

F - 67770 Sessenheim

Tel.: +33 (0)3 88071696

Fax: +33 (0)3 88071697

Internet: www.nivus.com

NIVUS U.K.

P.O. Box 342

Egerton, Bolton

Lancs. BL7 9WD, U.K.

Tel.: +44 (0)1204 591559

Fax: +44 (0)1204 592686

Internet: www.nivus.com

NIVUS U.K.

Wedgewood Rugby Road

Weston under Wetherley

Royal Leamington Spa

CV33 9BW, Warwickshire

Tel.: +44 (0)1926 632470

Internet: www.nivus.com

NIVUS U.K.

1 Arisaig Close

Eaglescliffe

Stockton on Tees

Cleveland, TS16 9EY

Phone: +44 (0)1642 659294

Internet: www.nivus.com

NIVUS Middle East (FZE)

Building Q 1-1 ap. 055

P.O. Box: 9217

Sharjah Airport International

Free Zone

Tel.: +971 6 55 78 224

Fax: +971 6 55 78 225

E-Mail: Middle-East@nivus.com

Internet: www.nivus.com

NIVUS Korea Co. Ltd.

#411 EZEN Techno Zone,

1L EB Yangchon Industrial Complex,

Gimpo-Si

Gyeonggi-Do 415-843,

Tel. +82 31 999 5920

Fax. +82 31 999 5923

E-Mail: kor[email protected]

Internet: www.nivus.com

NIVUS GmbH

10520 Yonge Street,

Unit 35B, Suite 212

Richmond Hill, Ontario

L4C 3C7 Canada

Phone: + 1 647 860 8844

Internet: www.nivus.com

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 3

Translation

If the device is sold to a country in the European Economic Area (EEA)

this instruction handbook must be translated into the language of the

country in which the device is to be used.

Should the translated text be unclear, the original instruction handbook

(German) must be consulted or the manufacturer contacted for clarifica-

tion.

Copyright

No part of this publication may be reproduced, transmitted, sold or dis-

closed without prior permission. Damages will be claimed for violations.

All rights reserved.

Names

The use of general descriptive names, trade names, trademarks and the

like in this handbook does not entitle the reader to assume they may be

used freely by everyone. They are often protected registered trademarks

even if not marked as such.

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 4 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

1 Contents

1.1 Table of Contents

1Contents...............................................................................4

1.1 Table of Contents..........................................................................4

1.2 Ex-Approval sensors (option)........................................................6

2Overview and use in accordance with the requirements.7

2.1 Overview .......................................................................................7

2.2 Use in accordance with the requirements.....................................8

2.3 Specifications ................................................................................9

3General Notes on Safety and Danger...............................10

3.1 Danger Notes..............................................................................10

3.1.1 General Danger Signs.................................................................10

3.1.2 Special Danger Notes .................................................................10

3.2 Device Identification....................................................................11

3.3 Installation of Spare Parts and Parts subject to wear and tear...12

3.3.1 List of Spare Parts.......................................................................12

3.4 Turn-off procedure.......................................................................12

3.5 User’s Responsibilities................................................................12

4Functional Principle ..........................................................13

4.1 General........................................................................................13

4.2 Device Versions ..........................................................................13

4.2.1 Flood protection sleeve (Option).................................................14

4.2.2 DIN-Flange Versions (Option).....................................................15

5Storing, Delivery and Transport.......................................16

5.1 Receipt ........................................................................................16

5.1.1 Delivery .......................................................................................16

5.2 Storing.........................................................................................16

5.3 Transport.....................................................................................16

5.4 Return..........................................................................................16

6Installation..........................................................................17

6.1 General........................................................................................17

6.2 Installation and Connection of NivuMaster Sensors ...................17

6.2.1 General........................................................................................17

6.2.2 Sensor Dimensions.....................................................................18

6.2.3 Sensor Installation.......................................................................21

6.2.4 Sensor Connection......................................................................24

6.3 Overvoltage Protection Precautions............................................25

7Initial start-up.....................................................................26

7.1 General........................................................................................26

8Troubleshooting ................................................................27

9Table of Resistiveness......................................................27

10 Maintenance and Cleaning ...............................................27

11 Emergency.........................................................................28

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 5

12 Dismantling/Disposal........................................................28

13 Table of Pictures................................................................28

14 Index...................................................................................29

15 Declaration of Conformity.................................................30

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 6 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

1.2 Ex-Approval sensors (option)

The approval is only valid in connection with the respective indication on the

sensor nameplate.

The complete EC-Type Examination Certificate is available on the Internet at

www.nivus.com.

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 7

2 Overview and use in accordance with the requirements

2.1 Overview

1 Sensor

2 two Screw nuts G1" PVC

3 Flood protection sleeve (option)

4 Holder bracket (option)

Fig. 2-1 Overview

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 8 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

2.2 Use in accordance with the requirements

The NivuMaster series ultrasonic sensors are intended to be used for non-

contact fill level measurement in conjunction with the according NivuMaster

transmitters. Here the allowed maximum values as specified in chapter 2.3 shall

be adhered to. All cases varying from these conditions and not passed by

NIVUS GmbH in writing are left at owner’s risk.

The device is exclusively intended to be used for purposes as described above.

Modifying or using the devices for other purposes without the written consent of

the manufacturer will not be considered as use in accordance with the require-

ments.

Damages resulting from this are left at user’s risk.

The device is designed for a lifetime of approx. 10 years. After that period an

inspection in addition with a general overhaul shall be made.

Ex-Protection

The Ex-version of the sensor is designed to be used in areas with explosive at-

mospheres (zone 1 or zone 0).

The transmitter always has to be installed outside of Ex-zones!

Approval (option)

Sensor:

II 2GD Ex m II T6

(also available as II 1GD Ex ia IIC T6, only in con-

junction with intrinsically safe transmitter (ia))

The approval is only valid in connection with the respective indication on the

transmitter or the sensor nameplate.

For installation and initial start-up the conformity certificates and test certifi-

cates of the respective authorities must be followed.

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 9

2.3 Specifications

Type:

P-M3

P 03

P 06

P 10

P 15

P 25

P40

Measurement

range: 0.07 to

2.4 m 0.125 to

3 m 0.3 to 6 m 0.3 to

10 m 0.5 to

15 m 0.6 to

25 m 1.2 to

40 m

Frequency:

125 kHz 75 kHz 50 kHz 41 kHz 30 kHz 20 kHz

Enclosure materi-

al: Valox 357 Valox 357

PVDF Valox 357

Enclosure protec-

tion:: IP68

Temperature:

-30 °C to 95 °C

(operation in hazard-

ous area -30 °C to

75 °C)

-40 °C to 95 °C

(operation in hazardous area -40 °C to 75 °C)

Beam angle:

12° 12° 10° 9° 10° 7°

Ex-approval:

II 2GD Ex m II T6 (also available II 1GD Ex ia IIC T6, in connection with

an intrinsical transmitter (ia) only)

Cable length:

5 m, 10 m, 20 m, 30 m, 50 m and 100 m, special length on request

Option

Flange

not available - flanges for nominal diameters 80

/ 100 / 150 / 200 mm, ANSI 3" /

4" / 6" / 8" with Teflon-coated

sensor face for aggressive me-

dia, max. 70 °C

not available

Coating

not available

with soft foam sensor face for

dusty bulk solids not available

Flooding

- with submergence shield

- to generate echo loss in flooded condition

- no soiling if sensor face is getting flooded, no need to

clean the sensor face

not available

additional

-

with insulation adapter for decoupling if sensor thread is screwed directly into

metal threads (P 03 with thread on cable side)

- sensor aiming kit for bulk material applications

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 10 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

3 General Notes on Safety and Danger

3.1 Danger Notes

3.1.1 General Danger Signs

Cautions

are framed and labelled with a warning triangle.

Notes

are framed and labelled with a “hand“.

Danger by electric voltage

is framed and labelled with the Symbol on the left.

Warnings

are framed and labelled with a “STOP“-sign.

For connection, initial start-up and operation of the NivuMaster Ultrasonic-

Sensors the following information and higher legal regulations (e.g. in Germany

VDE), such as Ex-regulations as well as safety requirements and regulations in

order to avoid accidents, must be observed.

All operations, which go beyond steps to install, to connect or to program the

device, must be carried out by NIVUS staff only due to reasons of safety and

guarantee.

3.1.2 Special Danger Notes

Please note that due to the operation in the waste water field, transmitter, sen-

sors and cables may be loaded with dangerous disease germs. Respective

precautionary measures must be taken to avoid damage to one’s health.

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 11

3.2 Device Identification

The instructions in this manual are valid only for the type of device indicated on

the title page.

The type ID label is wrapped around the sensor and contains the following

specifications:

- Name and phone number of manufacturer

- CE label

- Type and serial number

- Year of manufacture

- Ex-label (on Ex-version devices only) as mentioned in chapter 2.3.

It is important for enquiries and replacement part orders to specify article num-

ber as well as serial number of the respective transmitter or sensor. This en-

sures correct and quick processing.

Fig. 3-1 Nameplate of sensors

Fig. 3-2 Ex-label zone 0 and 1 for sensors, type P03 / PM3

Fig. 3-3 Ex-label zone 0 and 1 for sensors, type P06, P10….

This instruction manual is a part of the device and must be available for the

user at any time.

The safety instructions contained within must be followed.

It is strictly prohibited to disable the safety contrivances or to change the way

they work.

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 12 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

3.3 Installation of Spare Parts and Parts subject to wear and tear

We herewith particularly emphasize that replacement parts or accessories,

which are not supplied by us, are not certified by us, too. Hence, the installation

and/or the use of such products may possibly be detrimental to the device’s abil-

ity to work.

Damages caused by using non-original parts and non-original accessories are

left at user’s risk.

3.3.1 List of Spare Parts

1. sensor complete

2. counter nut

3. holder bracket

3.4 Turn-off procedure

For maintenance, cleaning and repairs (authorised staff personnel only) the

device shall be disconnected from mains and shall be prevented from being

turned on again unintentionally.

3.5 User’s Responsibilities

In the EEA (European Economic Area) national implementation of the frame-

work directive 89/391/EEC and corresponding individual directives, in particular

the directive 89/655/EEC concerning the minimum safety and health require-

ments for the use of work equipment by workers at work, as amended, are to be

observed and adhered to.

In Germany the Industrial Safety Ordinance must be observed.

The customer must (where necessary) obtain any local operating permits re-

quired and observe the provisions contained therein.

In addition to this, he must observe local laws and regulations on

- personnel safety (regulations on safety at work)

- safety of work materials and tools (safety equipment and maintenance)

- disposal of products (laws on wastes)

- disposal of materials (laws on wastes)

- cleaning (cleansing agents and disposal)

- environmental protection

Connections:

Before operating the device the user has to ensure, that the local regulations

(e.g. for operation in channels) on installation and initial start-up are taken into

account, if this is both carried out by the user.

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 13

4 Functional Principle

4.1 General

The ultrasonic sensor sends ultrasonic impulses, where the amplitude of the

sonic energy sent will exhibit reciprocally proportional decrease to the square of

the measurement distance. The maximum performance is sent along a vertical

line off the sensor face and the tapered border of the sonic lobe is defined at

50 % performance (-3dB). The measured angle is called the beam angle. The

medium to be measured will reflect these sonic impulses as echoes and trans-

mits this signal to the transmitter. Now the distance is calculated from the sonic

transit time.

For special applications there are special constructions and versions (such as

Teflon-coated flange versions for aggressive media, flood protection sleeves for

applications where sensors may be immersed or sensors with Ex approval for

use in Ex zone 1 or zone 0) available.

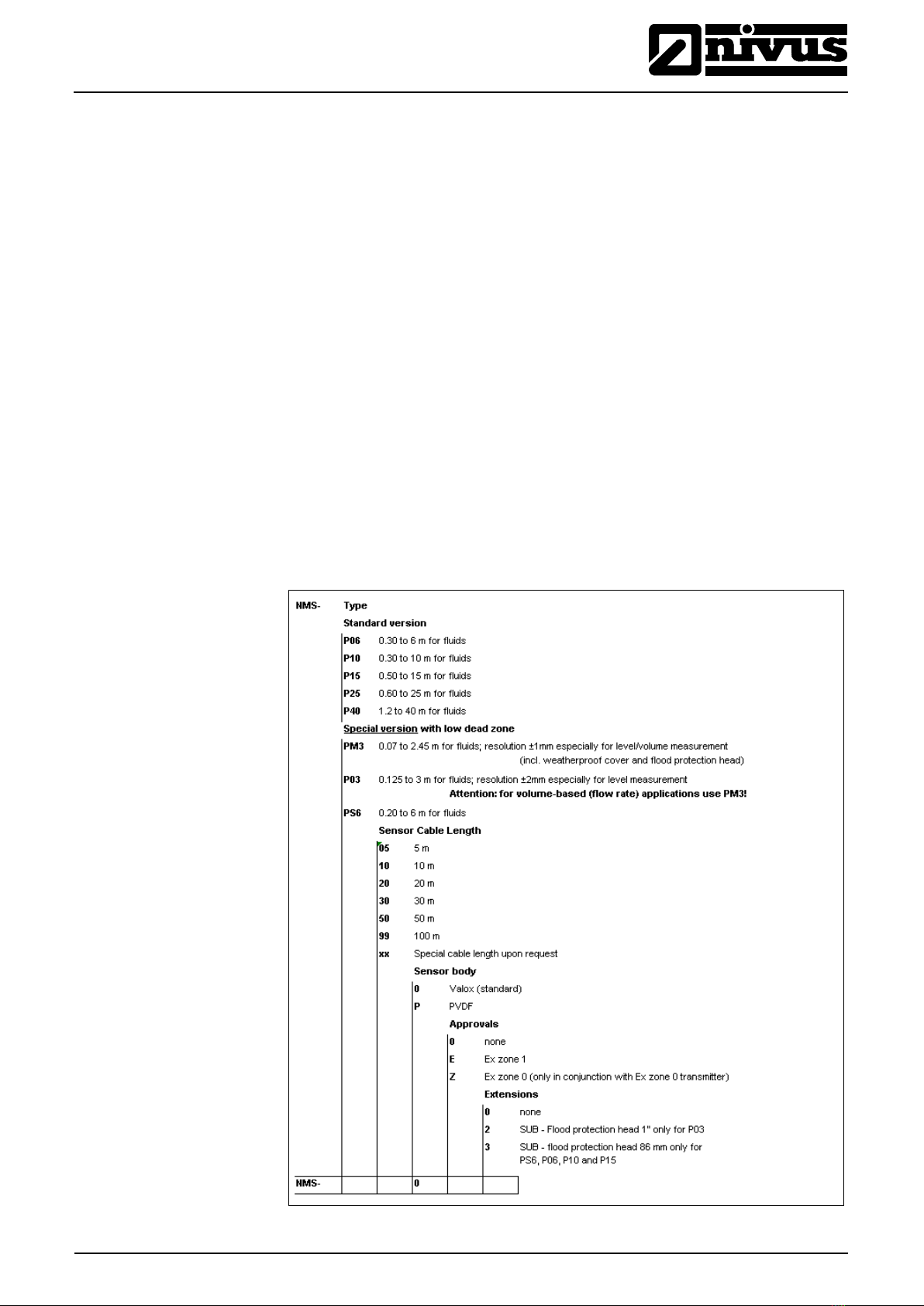

4.2 Device Versions

The NivuMaster Sensors are available in different versions. The tables below

give a brief overview on the various possibilities.

Fig. 4-1 Type key for ultrasonic sensors

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 14 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

4.2.1 Flood protection sleeve (Option)

The flood protection sleeve causes an air cushion to form in front of the sensor

face in case of immersion. Electronic components detect this defined condition.

Please observe that measuring however is not possible until the flood situation

has been reached as soon as material is getting into the blanking distance area!

There is a risk of measurement errors if foam should get into the sleeve!

The flood protection sleeve is also available as upgrade kit.

Please observe the following during installation of the flood protection

sleeve (here: P 06/P 10):

1. Clean sensor and flood protection sleeve (surface must be oil-

free).

2. Put sensor into sleeve.

3. Seal remaining gap between sleeve and sensor with silicone.

4. Allow approx. 48 hrs. at 20 °C (68 °F) for hardening.

Fig. 4-2 Flood protection sleeve for P-Series sensors

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 15

4.2.2 DIN-Flange Versions (Option)

NivuMaster sensors are available in various DIN-Flange versions.

If you should have questions please contact the NIVUS head office.

Fig. 4-3 Dummy flanges according to DIN 2527 for P-Series sensors

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 16 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

5 Storing, Delivery and Transport

5.1 Receipt

Please check your delivery according to the delivery note for completeness and

intactness immediately after receipt. Any damage in transit must be instantly re-

ported to the carrier. An immediate, written report must be sent to NIVUS GmbH

Eppingen as well.

Please report any delivery incompleteness in writing to your representative or di-

rectly to NIVUS Eppingen within two weeks.

Mistakes cannot be rectified later!

5.1.1 Delivery

The standard delivery of the NivuMaster Ultrasonic-Sensors contains:

- the instruction manual with the certificate of conformity. Here, all necessary

steps to correctly install and to operate the measurement system are listed.

- 1 Ultrasonic-Sensor

- 2 x screw nuts (G1“ PVC)

Additional accessories depending on order. Please check by using the delivery

note.

5.2 Storing

The following storing conditions must be strictly adhered to:

NivuMaster Sensor:

max. temperature: + 95 °C (203 °F)

min. temperature: - 40 °C (-40 °F)

The devices must be protected from corrosive or organic solvent vapours, radio-

active radiation as well as strong electromagnetic radiation.

5.3 Transport

The Sensors are conceived for harsh industrial conditions. Despite this do not

expose them to heavy shocks or vibrations.

Transportation must be carried out in the original packaging.

5.4 Return

The units must be returned at customer cost to NIVUS Eppingen in the

original packaging.

Otherwise the return cannot be accepted!

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 17

6 Installation

6.1 General

For electric installation the local regulations in the respective countries

(e.g. VDE 0100 in Germany) must be referred to.

NivuMaster sensor power supply is allowed to be carried out via the NivuMaster

transmitter exclusively.

Before feeding the rated voltage the transmitter and sensor installation must be

correctly completed. The installation should be carried out by qualified personnel

only. Further statutory standards, regulations and technical rulings have to be

taken into account.

The sensor protection rating is IP 68.

Please check if the power supply of the accompanying transmitter must be inte-

grated into the facility’s emergency shutdown conception.

6.2 Installation and Connection of NivuMaster Sensors

6.2.1 General

The sensors mounting place has to be selected according to certain criteria.

Please strictly avoid:

- heat emitting objects (max. ambient temperature: +95 °C (203 °F))

- objects with strong electromagnetic fields (e.g. frequency converters, electric

motors with high power consumption or similar)

- corrosive chemicals or gas

- mechanical shocks

- vibrations

- radioactive radiation

- installation close to footpaths or travel ways

Removing or loosening cable glands results in leakage and causes a failure in

the measurement / the sensor.

No sensor parts are allowed to be removed on principle!

To avoid disturbances from electrical interferences, the sensor cable must not

be laid close to (or parallel to) engine (motor) lines or main power lines.

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 18 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

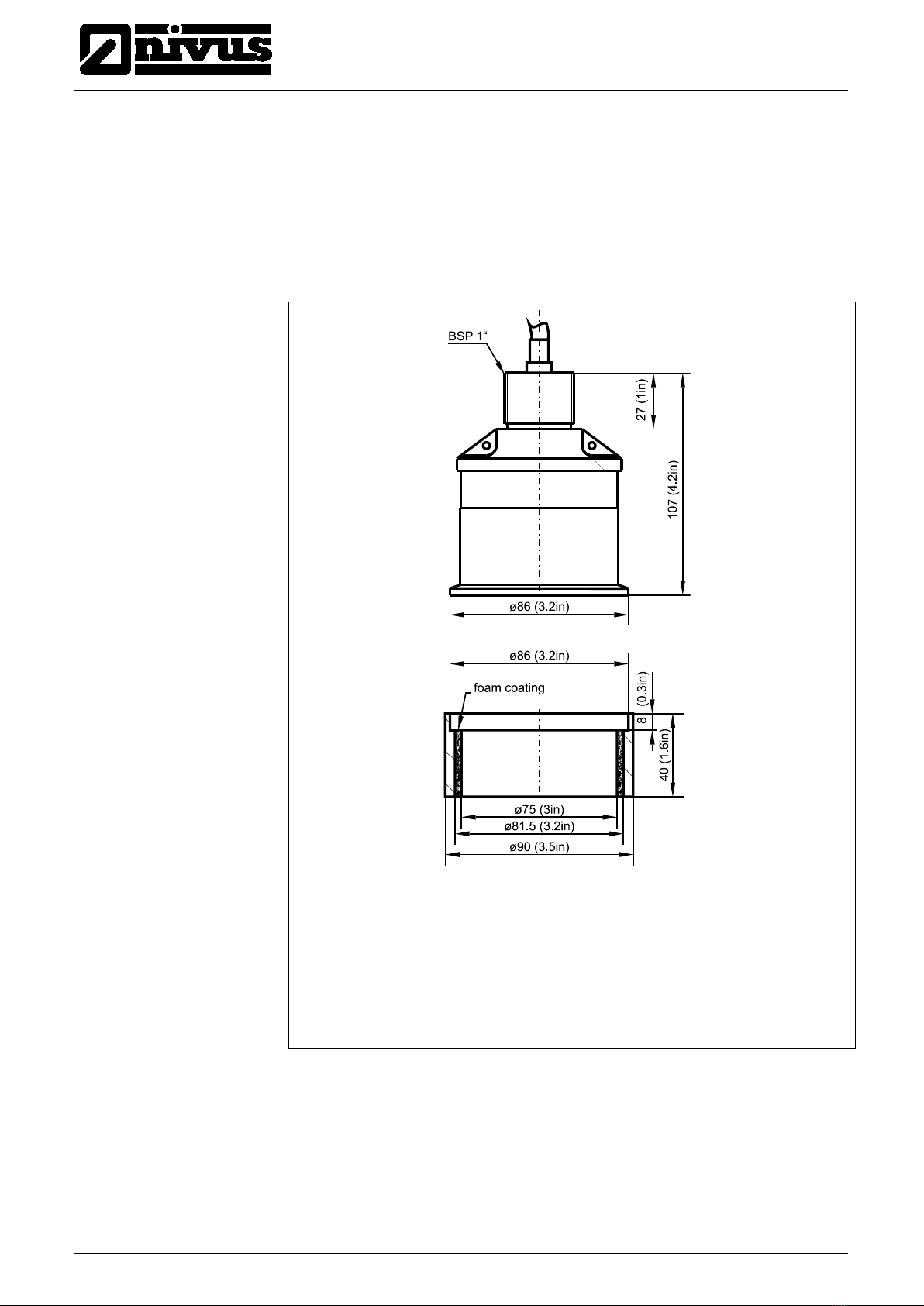

6.2.2 Sensor Dimensions

Dimensions in mm (inch)

1 Protective cover

2 Flood protection sleeve

3 Fastening screws

Fig. 6-1 P-M3 ultrasonic sensor dimensions

Fig. 6-2 P 03 ultrasonic sensor dimensions

Instruction Manual

NivuMaster Ultrasonic Sensors

®

NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011 Page 19

Fig. 6-3 P 06 and P 10 ultrasonic sensor dimensions

Fig. 6-4 P 15 ultrasonic sensor dimensions

®

Instruction Manual

NivuMaster Ultrasonic Sensors

Page 20 NivuMaster Ultrasonic Sensors - Rev. 06 as of 29.07.2011

Fig. 6-5 P 25 ultrasonic sensor dimensions

Fig. 6-6 P 40 ultrasonic sensor dimensions

Table of contents

Other Nivus Accessories manuals