Nivus NivuBar Plus II User manual

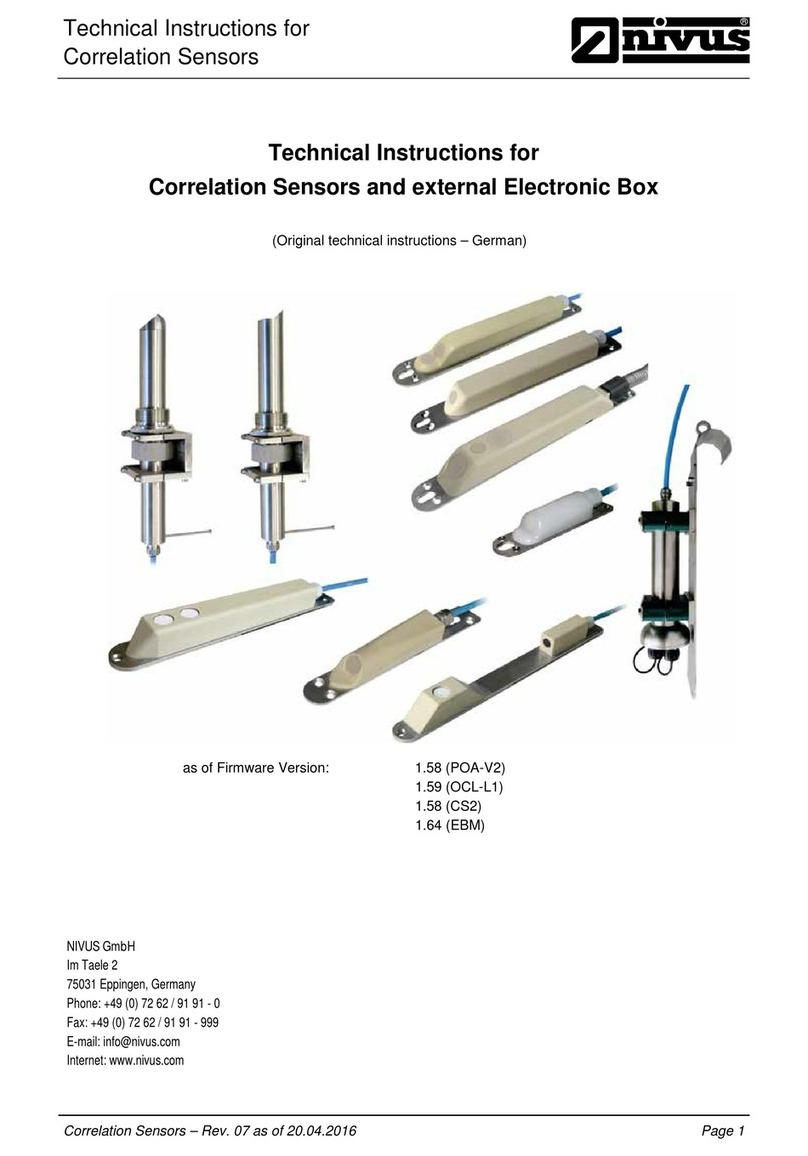

Instruction manual for

Pressure and Level Sensors:

NivuBar Plus II, NivuBar G II, NivuBar H III,

HydroBar G II, UniBar E II, AquaBar II

rev. 09 / 12.10.2017

Original Instruction Manual – German / rev. 09 / 20.03.2017

NIVUS GmbH

Im Täle 2

75031 Eppingen, Germany

Tel.: 072 62 - 91 91 - 0

Fax: 072 62 - 91 91 - 999

www.nivus.com

page 2 Pressure and Level Sensors - rev. 09 / 12.10.2017

NIVUS AG

Burgstraße 28

8750 Glarus, Switzerland

Phone: +41 (0)55 6452066

Fax: +41 (0)55 6452014

www.nivus.de

NIVUS Austria

Mühlbergstraße 33B

3382 Loosdorf, Austria

Phone: +43 (0) 2754 567 63 21

Fax: +43 (0) 2754 567 63 20

www.nivus.de

NIVUS Sp. z o.o.

ul. Hutnicza 3 / B-18

81-212 Gdynia, Poland

Phone: +48 (0) 58 7602015

Fax: +48 (0) 58 7602014

www.nivus.pl

NIVUS France

14, rue de la Paix

67770 Sessenheim, France

Phone: +33 (0)3 88071696

Fax: +33 (0)3 88071697

www.nivus.fr

NIVUS U.K. Ltd.

Wedgewood Rugby Road

Weston under Wetherley

Royal Leamington Spa

CV33 9BW, Warwickshire

Phone: +44 (0)8445 3328 83

www.nivus.com

NIVUS Middle East (FZE)

Building Q 1-1 ap. 055

P.O. Box: 9217

Sharjah Airport International

Free Zone

Phone: +971 6 55 78 224

Fax: +971 6 55 78 225

www.nivus.com

NIVUS Korea Co. Ltd.

#2502 M Dong, Technopark IT Center,

32 Song-do-gwa-hak-ro, Yeon-su-gu,

INCHEON, Korea 21984

Phone: +82 32 209 8588

Fax: +82 32 209 8590

www.nivus.com

NIVUS Vietnam

21 Pho Duc Chinh, Ba Dinh

Hanoi, Vietnam

Phone: +84 12 0446 7724

www.nivus.com

NIVUS Chile

Viña Cordillera Oriente 4565

Puente Alto, Santiago

Phone: +562 2266 8119

www.nivus.com

Copyrights and property rights

Pressure and Level Sensors - rev. 09 / 12.10.2017 page 3

Copyrights and property rights

This document and its contents are proprietary to NIVUS GmbH and are

not to be reproduced or copied without the express written permission of

NIVUS GmbH.

Violations oblige to compensation.

Important Note

This instruction manual may exclusively - even in parts - be

copied or translated in any other way with the express writ-

ten consent of NIVUS GmbH.

Translation

If the device is sold to a country in the European Economic Area (EEA)

this instruction manual must be translated into the language of the coun-

try in which the device is to be used. Should the translated text be un-

clear, the original instruction manual (German) must be consulted or the

manufacturer contacted for clarification.

Copyright

No part of this publication may be reproduced, transmitted, sold or dis-

closed without prior permission. Damages will be claimed for violations.

All rights reserved.

Names

The use of general descriptive names, trade names, trade-marks and the

like in this manual does not entitle the reader to assume they may be

used freely by everyone. They are often protected registered trademarks

even if not marked as such.

Instruction manual

Pressure and Level Sensors

page 4 Pressure and Level Sensors - rev. 09 / 12.10.2017

1General....................................................................................5

2Safety Instructions.................................................................7

2.1 Used symbols and signal words.........................................................7

2.2 Safeguards and Precautions..............................................................8

2.3 Liability disclaimer..............................................................................9

2.4 User’s Responsibilities.....................................................................10

3Overview and use in accordance with the requirements 11

3.1 Overview..........................................................................................11

3.2 Use in accordance with the requirements ........................................12

3.4 Device identification .........................................................................14

4Technical Data......................................................................16

5Delivery and Transport........................................................19

5.1 Reception inspection........................................................................19

5.2 Delivery............................................................................................19

5.3 Transport..........................................................................................19

5.4 Return ..............................................................................................19

5.5 Installation of spare parts and parts subject to wear and tear..........20

6Construction and Function.................................................21

6.1 Construction.....................................................................................21

6.2 Functional principle ..........................................................................22

6.2.1 General ............................................................................................22

6.2.2 Sensor versions ...............................................................................22

7InstallationInstallation and Connection ............................29

7.1 General Installation Instructions.......................................................29

7.2 Installation........................................................................................29

7.2.1 General ............................................................................................29

7.2.2 Dimensions ......................................................................................31

7.2.3 Connection.......................................................................................40

7.2.4 Pin configuration ..............................................................................42

7.2.5 Circuit...............................................................................................42

7.2.6 Power supply....................................................................................43

8Initial Start-up.......................................................................44

9Maintenance and Cleaning .................................................45

9.1Interval .............................................................................................45

9.2 Cleaning...........................................................................................45

9.3 Dismantling/Disposal........................................................................46

10 Index......................................................................................47

11 Certificates and Approvals.................................................48

General

Pressure and Level Sensors - rev. 09 / 12.10.2017 page 5

1 General

Important

READ CAREFULLY BEFORE USE!

KEEP IN A SAFE PLACE FOR LATER REFERENCE.

Read this instruction manual carefully and completely prior to installation

and connection since it contains relevant information on this product.

Observe the notes and particularly follow the warning notes and safety

instructions.

This Instruction Manual for Pressure and Level Sensors is intended for

the initial start-up or the connection of the sensors and probes depicted

on the title page to NIVUS transmitters.

This Instruction Manual is part of the pressure and level sensor standard

delivery and shall be available to users at any time. The safety instruc-

tions contained therein must be followed.

Keep this manual in a safe place and make sure it is available for the us-

ers of this product at any time.

In case of selling the sensors this instruction manual shall be provided to

the purchaser.

If you should have problems to understand information contained within

this instruction manual either contact the manufacturer or one of the dis-

tributors for further support. The manufacturer cannot be held responsi-

ble for damage to persons or material due to incorrectly understood in-

formation in this instruction.

Detailed information on how to operate the pressure and level sensors in

connection with NIVUS transmitters can be found in the accompanying

transmitter instruction manual.

This manual suits for next models

5

Table of contents

Other Nivus Accessories manuals