Nixie Clock Spectrum 18 Configuration guide

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 1 -

Assembly Instructions

And

User Guide

Nixie Clock Type

‘Spectrum 18’

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 2 -

REVISION HISTORY

Issue

Number

Date Reason for Issue

2 15 Feb 2015 Errors in Resistor values corrected

Resistor networks not polarized

1 10 Feb 2015 New document

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 3 -

1. INTRODUCTION

Here are the key features of the SPECTRUM 18:

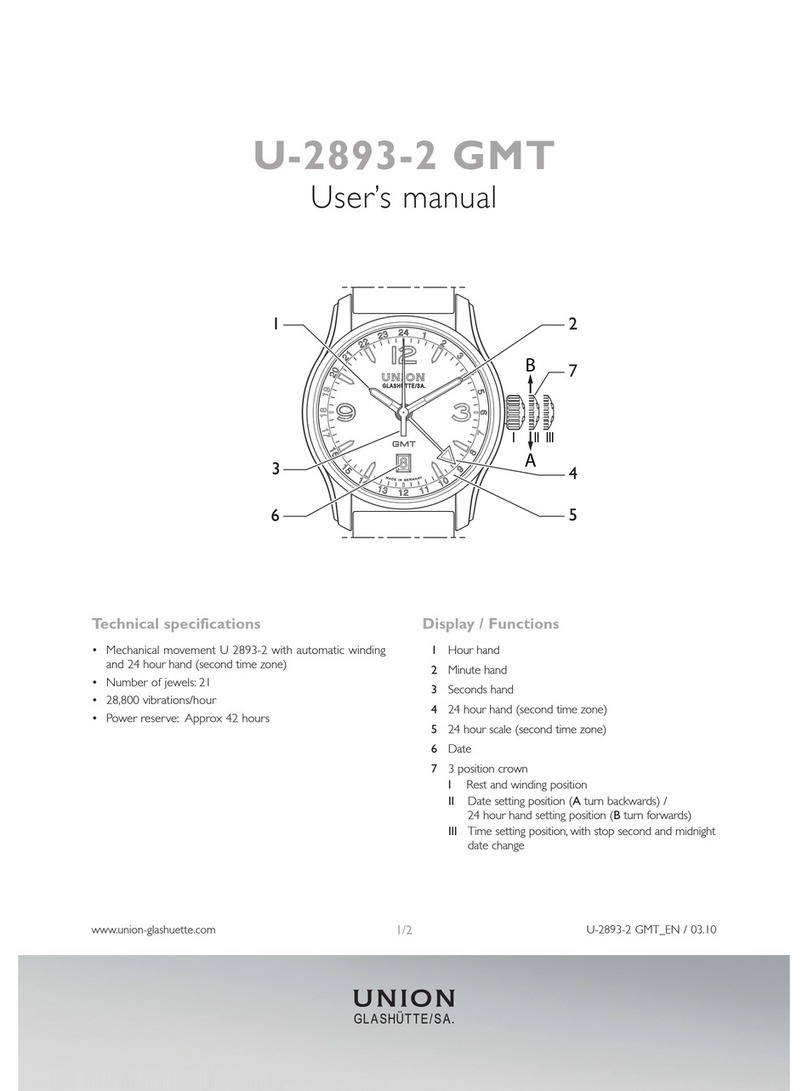

• Hours Minutes and Seconds display on Six IN-18 Nixie Tubes

• 40mm (1.5”) Digit height

• Noiseless Direct Drive giving optimum digit clarity

• Dedicated plug-in High Voltage Module (Included)

• Uses a Quartz Crystal Oscillator as the timebase

• 12 or 24 hour modes

• Programmable leading zero blanking

• Date display in either DD.MM.YY or MM.DD.YY or YY.MM.DD format

• Programmable date display each minute

• Scrolling display of date or standard display

• Alarm with programmable snooze period

• Optional DCF / MSF / GPS synchronisation with status indicator LED

• Dedicated DST button to switch between DST and standard time

• Supercapacitor backup. Keeps time during short power outages

• PIR Motion Sensor input and accessory available. Configurable timeout

period

• Temperature display in Celsius or Fahrenheit. Configurable. (every

minute/ every 10 minutes / every hour)

• Simple time setting using two buttons

• Programmable leading zero blanking

• Double dot colon neon lamps

• 11 colon neon modes including AM / PM indication (top / bottom or left /

right) railroad (slow or fast) etc.

• Seconds can be reset to zero to precisely the set time

• Programmable night mode - blanked or dimmed display to save tubes or

prevent sleep disturbance

• Rear Indicator LEDs dim at night to prevent sleep disturbance

• Weekday aware ‘Master Blank’ function to turn off HV/ tubes and LEDs on

weekends or during working hours

• Separate modes for colon neons during night mode

• Standard fading or crossfading with scrollback display modes

• ‘Slot Machine’ Cathode poisoning prevention routine

• Programmable RGB tube lighting – select YOUR favourite colour palette

• 729 colours possible. Have a different colour or your choosing every

hour or autochanging colours

• Configurable Auxiliary Alarm Output for activating additional peripherals

on Alarm

• Provision for adding switches for independently switching off RGB LEDs

and / or tubes

• Not AC frequency dependent – works in all countries

• All user preferences stored to non-volatile memory

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 4 -

1.4 SAFETY

DANGER: The clock pcb includes a switched-mode voltage booster

circuit. This generates nominally 170 Volts DC. Assembly may only be

undertaken by individuals who are suitably qualified and experienced in

electronics assembly and are familiar with safe procedures for working

with high voltages. If in doubt refer to a suitably qualified engineer

before proceeding.

The voltages generated by this circuit can give a potentially

LETHAL ELECTRIC SHOCK.

DISCLAIMER: This product is supplied as a kit of parts intended only for

suitably qualified electronic engineers who are suitably qualified and

experienced in electronics assembly and are familiar with safe

procedures for working with high voltages. The supplier his agents or

associates accept no liability for any damage injury or death arising from

the use of this kit of parts.

This is not a finished product and the person assembling the kit is

responsible for ensuring that the finished product complies with any

applicable local regulations governing electrical equipment eg. UL CE

VDE.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 5 -

2. TOOLS AND EQUIPMENT REQUIRED

2.1 Tools required to assemble the PCB.

The following tools will be required to assemble the PCB:

- Soldering iron with a small tip (1-2 mm).

- Wire cutters to trim the excess component leads after soldering.

(TIP: A small pair of nail clippers works very well for this function).

- Wire strippers (TIP: A small pair of scissors is quite suitable).

- Multimeter for voltage tests and for identifying the resistors.

- A small hot air gun will be needed to shrink the heat shrink tubing

over the neon lamp wires.

2.2 Materials you will need.

Solder – lead / tin solder is highly recommended.

USE LEAD/ TIN SOLDER!

Lead free solder as now required to be used in commercial products in

Europe has a much higher melting point and can be very hard to work

with.

Desoldering wick (braid) can be useful if you accidentally create solder

bridges between adjacent solder joints.

2.3 Other items you will need.

The clock kit does not include a power adapter.

The following type of adapter should be obtained and used with the kit:

Output 12V DC regulated, minimum power output capability of 1A

Output plug: 2.1mm pin, centre positive.

A suitable adapter is shown below:

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 6 -

3. LIST OF COMPONENTS

3.1 Table of Components – Driver Board

Circuit Designation Part Description

Resistors

R1 6.8 KΩ ¼ Watt

R2 – R7 10 KΩ ¼ Watt

R8 – R11 270 KΩ ¼ Watt

R12 – R14 270 Ω ¼ Watt

R15 6.8 KΩ ¼ Watt

R16 15 KΩ ¼ Watt

R17 – R19 270 Ω ¼ Watt

R20 6.8 KΩ ¼ Watt

RN1 – RN6 Quad Resistor Network 220Ω

Capacitors

C1 C2 220uF Electrolytic 16-25V

C3 10pF Ceramic

C4 15pF Ceramic

C5 100nF Ceramic

C6 0.1F or 0.22F Supercapacitor

C7 – C9 100nF

Transistors

Q1 MPSA42

Q2 – Q4 2N7000 MOSFET

Q15 MPSA42

Diodes

D1 – D3 1N5819

D4 5mm Yellow LED

D5 5mm Green LED

D6 5mm Yellow LED

RGB1 – RGB8 RGB 5mm LED common anode

Integrated Circuits

IC1 LM2576 5V voltage regulator

IC2 PIC16F1938 in socket

IC3 IC4 HV5622 in socket

IC5 DS18B20

Miscellaneous

L1 100uH inductor

AM1 PM1 AM2 PM2 6mm wire ended neon lamp

ALARM SET ADJ DST Miniature push button

IC2 Socket 28 Way narrow IC socket for IC2

IC3 IC4 Socket PLCC44 IC socket for IC3

J1 2.1mm PCB power socket

GPS / RFT and GPS2 Surface mount 3.5mm jack socket

PIR and PIR2 Surface mount 3.5mm jack socket

LS1 Piezo sounder

FUSE 500mA fuse

VR1 1KΩ Potentiometer

X1 32.768KHz watch crystal

HV Module High Voltage Module in header

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 7 -

3.2 Parts list / Packing Sheet - Component Bag

Part Description Quantity

Resistors

270 Ω ¼ Watt 6

6.8 KΩ ¼ Watt 3

10 KΩ ¼ Watt 6

15 KΩ ¼ Watt 1

270 KΩ ¼ Watt 4

220 Ω Resistor Network 6

Capacitors

10pF Ceramic 1

15pF Ceramic 1

100nF Ceramic 4

220uF 16-25V Electrolytic 2

0.1F or 0.22F 1

Transistors

MPSA42 2

2N7000 MOSFET 3

Diodes

1N5819 3

5mm Green LED 1

5mm Yellow LED 2

5mm RGB LED 6

Integrated Circuits

LM2576 5V voltage regulator 1

PIC16F1938 8-bit microcontroller 1

HV5622 2

DS18B20 1

Miscellaneous

100uH inductor 1

6mm wire ended neon lamp 4

Miniature push button 4

28 way narrow IC Socket for IC2 1

PLCC44 IC Socket 2

2.1mm PCB power socket 1

Surface mount 3.5mm jack socket 2

Piezo sounder 1

1A fuse 1

1KΩ Potentiometer 1

2 way header with jumper 1

6 way female header 0.1” 1

32.768KHz watch crystal 1

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 8 -

3.3 Parts list / Packing Sheet - Additional parts

• PCB

• 6 X 15mm M3 hex spacers with screws

• HV Module with male header and glue dot

• 2 X Glass neon covers

• 30cm Clear heat shrink insulation for neons

• 6 X Socket holders and 66 sockets

The resistors used in the kit are 1% tolerance metal film. They are

marked with 4 coloured bands to identify the value. However it is

sometimes unclear in which direction the bands should be read.

Therefore we recommend that the resistors be identified with a

multimeter.

Please note the fuse will look like one of the pictures below. It can

easily be confused for a capacitor. It is a self-resetting fuse.

3.4 Special Note:

Please note that several components can be possibly mounted on

either side of the PCB and white component print for the part is on

both sides of the PCB. This is to offer maxiumum flexibility of the

kit: For our clear cases most components will be soldered on the

top (tube) side of the PCB so they are visible on the finished clock.

However for the Viso case and for customers making their own

case it is possible to mount some of the taller components on the

bottom of the PCB so that the PCB can fit inside a case with the

tubes protruding. Please follow carefully the instructions. Unless

specified otherwise please solder all components on the top of the

PCB.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 9 -

4. ASSEMBLY OF THE PCB

DUE TO PRODUCT DEVELOPMENT AND IMPROVEMENTS,

YOUR PCB MAY NOT LOOK EXACTLY LIKE THE ONE

PICTURED.

4.1 Assembly of the tube sockets

Remove the protective film from both sides of the six laser-cut

tube socket holders and identify the side that is engraved

‘SOCKETS THIS SIDE’.

For each socket holder you need to push in 11 socket receptacles.

Push them in from the ‘SOCKETS THIS SIDE’ side. Push them with

the 2 open jaws going in first. Look at the photo below.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 10 -

Push all the sockets firmly into place until they stop. You will end

up with 6 socket assemblies. Put them to one side. Do not solder

them to the PCB yet.

4.2 Resistor Networks RN1 – RN6

Solder the 6 resistor networks on the bottom side of the PCB as

shown below. These parts are not polarized so the orientation

does not matter.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 11 -

4.3 Nixie Tube Sockets.

Now you can solder the 6 Nixie sockets that you assembled in step

4.1. Push each socket assembly into the PCB so that the flat is

aligned as shown below. There is only one way the socket can be

inserted so it should be impossible to orient incorrectly.

After soldering all 66 contacts clip off the lower very thin part of

the connector.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 12 -

4.4 Low Voltage Generator components.

Fuse

D1, D2, D3 (1N5819

C1, C2 (220uF

J1, L1

IC1 (LM2576

Bend the legs of IC1 to a 90 degree angle so that the component

lies along the PCB. Solder it so it does not quite touch the PCB. But

is approx 2-3 mm from it. (1/8”)

C1 and C2 are polarized. The light stripe on the body of the

component indicates the negative side. This must match the cross

hatched side on the PCB Marking.

Please note that J1 and L1 must be soldered on the bottom

of the PCB is all cases.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 13 -

4.5 Testing Low Voltage Power Supply.

Identify the test GND 5V and HV test points as shown below.

Plug in the power supply and then test using a DC voltmeter:

Touch the black probe on the GND test point and the red probe on

the 5V test point. The voltage should measure between 4.8 and 5.2

Volts. If not disconnect power and check your work. Do not

proceed with the assembly until the error is corrected. Once the

test is completed disconnect the power.

4.6 High Voltage Generator Components.

6 Way female header

28 Way IC socket for IC2

R1 (6.8 KΩ

VR1 (1 KΩ Potentiometer

HV Module

Start by soldering the 6 way male header to the HV Module.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 14 -

then solder the parts to the main PCB: 6 way female header on

bottom of PCB and VR1 and R1 on the top of the PCB. Also solder

the socket for IC2 noting the orientation of the small notch at one

end:

Here you can see how the 6 way female header is soldered on the

bottom of the PCB:

And now you can push the HV Module into place:

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 15 -

Later at the end of the assembly when the clock is ready to be

put into its case you can use the small adhesive dot on the top of

the HV Module’s 4.7uF 250V capacitor to stick it to the bottom of

the PCB to keep it from moving. Do this later.

4.7 High Voltage Generator Test.

- Refer to the warnings on page 5

- Insert IC2 into its socket. Orient the notch on the IC with the

notch on the IC socket and the PCB marking.

- Power up the PCB and using the GND and HV test points

measure the high voltage generated using a voltmeter on DC

setting. Adjust the brass screw on VR1 until the HV is close to

170V.

Disconnect power and remember that the HV module can still hold

charge at 170V. carefully remove the HV module and place it safely

away until later.

4.8 Tube Drive Components

R2 – R7 (10 KΩ

C5, C8, C9 (100nF

Sockets for IC3 and IC4

Be very careful when inserting the two IC sockets. Make sure the

flattened corner of the IC socket is oriented with the matching

flattened corener marking on the PCB.

4.9 C3 (10pF

C4 (15pF

X1 (32.768KHz Crystal

4.10 First Tube test

Now it is time to make a first test of the tube drive circuit. Start by

replacing the HV module and also if you removed IC2 place this

back in its socket. Also now insert IC3 and IC4 into the sockets

taking great care the flat at one corner of the IC matches the flat

on the IC socket.

This is a good time to attach the six M3 X 15mm hex spacers so

the PCB will sit neatly during the tube test.

With great care and looking carefully at tube alignment (tube

faces forwards) insert six IN-18 Nixie Tubes into the sockets.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 16 -

Power up the PCB and watch the tubes. They should count 0

through to 9 and back to 0 again and repeat this sequence. If any

digits or tubes do not light go back and check your work. If any

tube does not light swap it with a known working tube to check if

it is the tube or the location that is faulty.

Once all is well power off carefully remove the tubes and with

care remove the HV module.

4.11 R8 – R11 (4 X 270 KΩ

R12 – R14, R17 – R19 (6 X 270 Ω

R15, R20 (2 X 6.8 KΩ

R16 (15 KΩ

4.12 Q1, Q15 (MPSA42

Q2 – Q4 (3 X 2N7000

4.13 C6 (0.22F

C7 (100nF

2 Way pin-header and jumper

Take care that C6 is mounted with its arrows matching the arrows

on the PCB.

Note: C6 and the 2 Way jumper need to be soldered on the

bottom side of the PCB if you are mounting the clock in the

Visio case.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 17 -

4.14 D4, D6 (5mm Yellow LED

D5 (5mm Green LED

SET, ADJ, ALARM, DST (buttons

GPS / RFT (3.5mm Jack socket

PIR (3.5mm Jack socket

If your own case design favours it you can mount these

components on the bottom of the PCB. For our Visio and Prisma

cases mount them all on the top (tube) side of the PCB.

The LEDs are best mounted pointing vertically upwards for the

Prisma case as shown below:

To solder the GPS / RFT and PIR connectors: First wet one pad on

the PCB with solder. Then place the connector in position and re-

touch the pad with the soldering iron. This will anchor the

component and then you can solder the remaining pads.

4.16 LS1 (Piezo Buzzer

The Piezo Buzzer is soldered on the bottom of the PCB.

4.17 RGB LEDs

There are 6 RGB LEDs one under each Nixie Tube. Note that there

are a further 2 locations for RGB LEDs under the neon colon

separators. These are not supplied and not installed because the

RGB lighting from the tube LEDs provides sufficient illumination of

the colon neons.

Start by bending the leads of each RGB LED as shown below

noting the orientation of the longest lead.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 18 -

If you follow the bending instructions above then the longest lead

should go into the hole marked with 2 small circles at each RGB

LED location. Solder each LED and clip the leads short.

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 19 -

4.18 IC5 (DS18B20 temperature sensor

The Temperature sensor looks like a transistor however it is an IC.

It needs to be soldered on the bottom of the PCB as far from the

PCB as possible. Just push the leads a very short distance into the

holes on the PCB and solder. It will protrude through a hole in the

bottom of the Visio or Prisma cases.

4.19 AM1, AM2, PM1, PM2 (4 X 6mm Neon lamps

Each neon is separately addressable and many flashing and

indicatation modes are implemented – see the configuration setup

later in the manual.

The AM1 and PM1 neons are taller and mounted on the rear 2

locations. The leads of the two rear neons need to be extended.

Use pieces of wire cut from leads of resistors to extend the wires

so they are at least 500 (2”) long:

Next cut the clear heat shrink tubing into 8 lengths: 4 lengths of

20mm and 4 lengths of 45mm:

Nixie Tube Clock ‘Spectrum 18’

Issue 2 (15 February 2015

www.pvelectronics.co.uk

- 20 -

Slip the insulation over the neon lamp leads and with a hot air gun

shrink the tubing:

Finally solder the neons in place on the PCB with the taller neons

at the back. The glass cover tubes can be placed over later.

Table of contents

Other Nixie Clock Watch manuals