NJ PHILLIPS Powermaster User manual

15ml Variable Dose Powered Injector

PAGE 2

IMPORTANT SAFETY WARNING

The injector, associated equipment and injectable chemicals

each pose inherent risks to human health and safety if used

incorrectly and without appropriate safety precautions.

All owners of the injector, including employers and self-

employed persons, are reminded of their strict obligations

to ensure the health and safety of employees and all other

persons in the place (ie workplace) in which the injector,

associated equipment, and veterinary chemicals are used

and stored.

In particular, employers and self-employed persons MUST

make appropriate arrangements to ensure safety and the

absence of risks to health in connection with the use, handling,

storage, maintenance and transport of the injector, associated

equipment, and all chemicals.

Such arrangements include but are not limited to the provision

of appropriate protective gloves, clothing, eye wear and

respirators, ensuring the injector, associated equipment and

all chemicals are stored at all times safely out of the reach

of unauthorised persons, and ensuring that the injector and

associated equipment is assembled, used, cleaned and

maintained strictly in accordance with the directions in this

Handbook.

In addition, employers and self-employed persons MUST

provide such information, instruction, training and supervision

in connection with the use, handling, storage and transport

of the injector, associated equipment and chemicals as is

necessary to ensure the health and safety in the workplace

of employees and all other persons.

Employers and self-employed persons MUST take particular

care to ensure the appropriate instruction, training and

supervision of employees and others who are under-age,

inexperienced, unskilled and/or have difculties reading or

speaking the English language.

Employers and self-employed persons MUST ensure that

this Handbook is kept with the injector at all times, and that

its warnings and instructions are referred to each time the

injector is used.

INTRODUCTION

The Powermaster, is designed for the administration of

selected injectable animal health pharmaceutical products,

within the injector’s dose range. The injector must not be

used for the treatment of horses, as injury or danger to

the health of the animal may occur.

The injector is product specic, and is NOT suitable for use

with EVERY type of animal health product available. For further

information about the product you wish to use with this injector,

please contact your stockist, local distributor or NJ Phillips

customer service.

All information contained in this handbook relating to the use

of compressed air or gas ttings is applicable, and must be

strictly adhered to.

No liability will be accepted by the manufacturer if the injector

is used for any purpose other than for the injectable treatment

of livestock.

Prior to setting up the injector for the injectable treatment of

livestock, for the protection of the injector operator and livestock,

please carefully read this handbook, the pharmaceutical/

chemical manufacturer’s product instructions for use, material

safety data sheets, or safety instructions on label of the

chemical container.

To ensure continued high performance from the injector,

attention to cleanliness is essential. Cleaning and care

instructions must be adhered to.

The WARNING STATEMENTS shown below covering use

of the injector in this handbook, MUST be read and applied

prior to use of the injector by the operator.

All products produced by NJ Phillips Pty Limited, are identied

by a unique batch number. This identication number is afxed

to the product to allow traceability by the manufacturer and must

not be removed or claims may not be able to be processed.

As our policy is one of continuous improvement the

manufacturer reserves the right to alter these specications

at any time.

WARNING STATEMENT

1. As this injector may be dangerous in the hands of children, it MUST be kept in a safe place, out of the reach

of children and to stop use by unauthorised persons.

2. Do not place the injector near any heat source.

3. Lubricants other than those indicated may damage rubber components in this injector.

4. Setting of the injector dose levels, and use of the animal health injectable products should be carried out

in strict accordance with the pharmaceutical manufacturer’s administration instructions, otherwise injury to

livestock may occur, and the health of the injector operator may be at risk.

5. Components in this injector may be affected by some commonly used farm chemicals. No responsibility

or liability will be accepted by the manufacturer, should the injector be used with any product other than

injectable chemicals recommended by your stockist/local distributor or NJ Phillips.

6. Care must be taken to ensure the air or gas pressure supplied from the compressor or gas cylinder does

not exceed 690 Kpa (100 psi) otherwise damage to the regulator, and or injector may occur.

7. Unless an approved in line compressed air lter/lubricator is installed, moisture and or foreign matter will

enter the trigger valve system of the injector, which will cease to operate in a satisfactory manner.

8. Care must be taken to ensure the pharmaceutical/chemical manufacturer’s instructions and material safety

data sheets (MSDS) or any other product or health or safety information are followed in regard to safe

use and storage of injectable chemicals, otherwise injury to the health of personnel and/or livestock may

occur.

PAGE 3

Contents

PAGE NO.

Important Safety Warning, Introduction & Warning Statements 2

SECTION 1: INJECTOR PARTS IDENTIFICATION AND SCHEMATIC DIAGRAMS

Schematic Diagram No 1: NJ Phillips15ml Powered Injector. 4

SECTION 2: SETTING UP THE INJECTOR READY FOR USE

Schematic Diagram No 2: Handpiece Component Breakdown. 4

1. Handpiece Injectable Products 5

2. Injector Operated by LP-GAS Portable or Processor 5

Schematic Diagram No 3: Injector setup for operation by LP-Gas Portable or Processor 6

3. Injector Operated by Compressed Air 7

Schematic Diagram No 4: Injector setup for operation by Compressed Air 6

SECTION 3: CARE AND MAINTENANCE OF INJECTOR 8

SECTION 4: TROUBLE SHOOTING GUIDE 9

SECTION 5: WARRANTY AND SERVICE 10

PAGE 4

35

30

34

33

28

27

29

36

32

36

40

38

31

188

17 19

18

4

15

22 23

21

20

23567

39

16 26

37

24 25

11

35

9

36

10 12 13

14

1

2

6

3

4

5

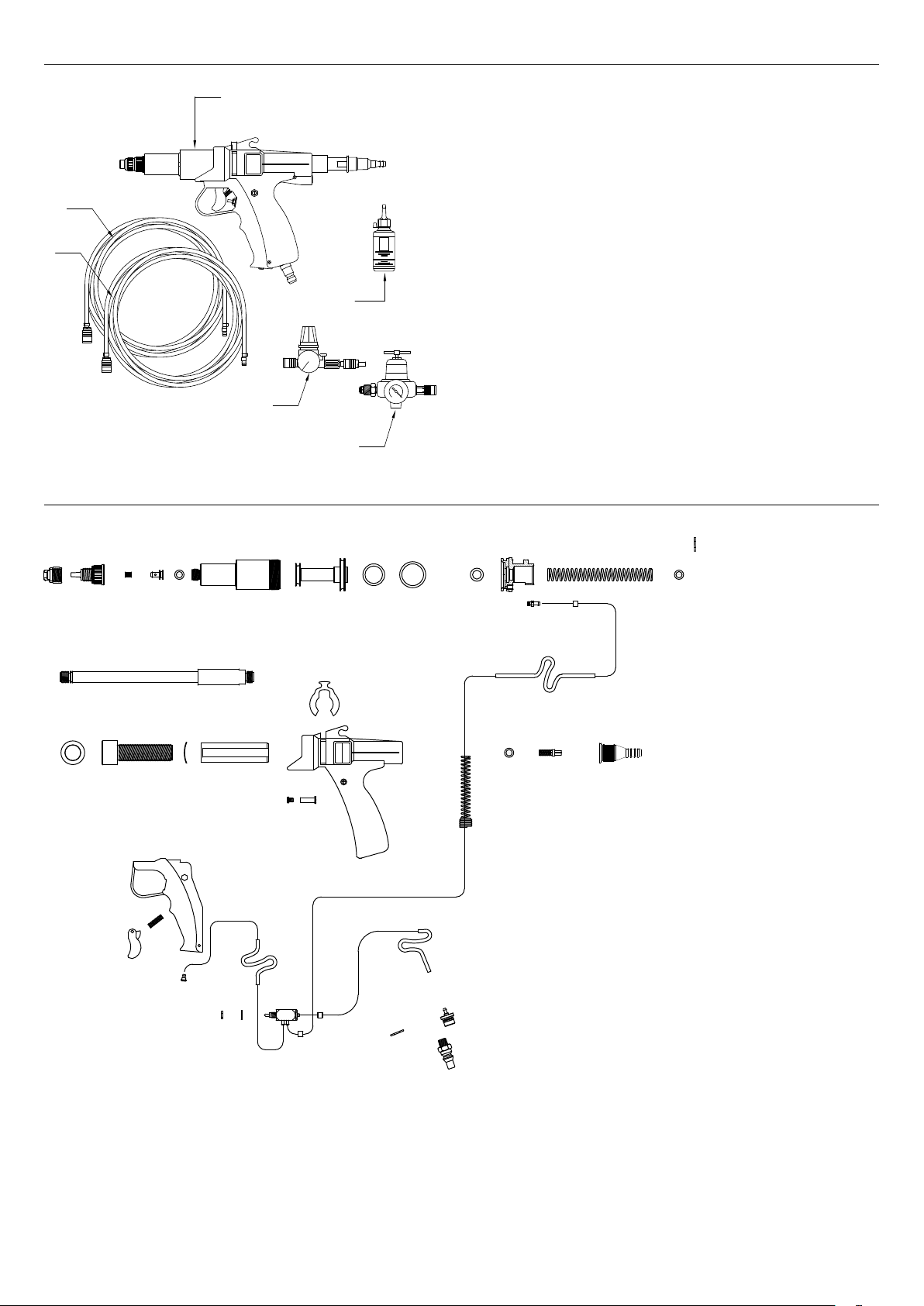

SECTION 1: INJECTOR PARTS IDENTIFICATION AND SCHEMATIC DIAGRAMS

Schematic Diagram No 1: NJ Phillips15ml Powered Injector.

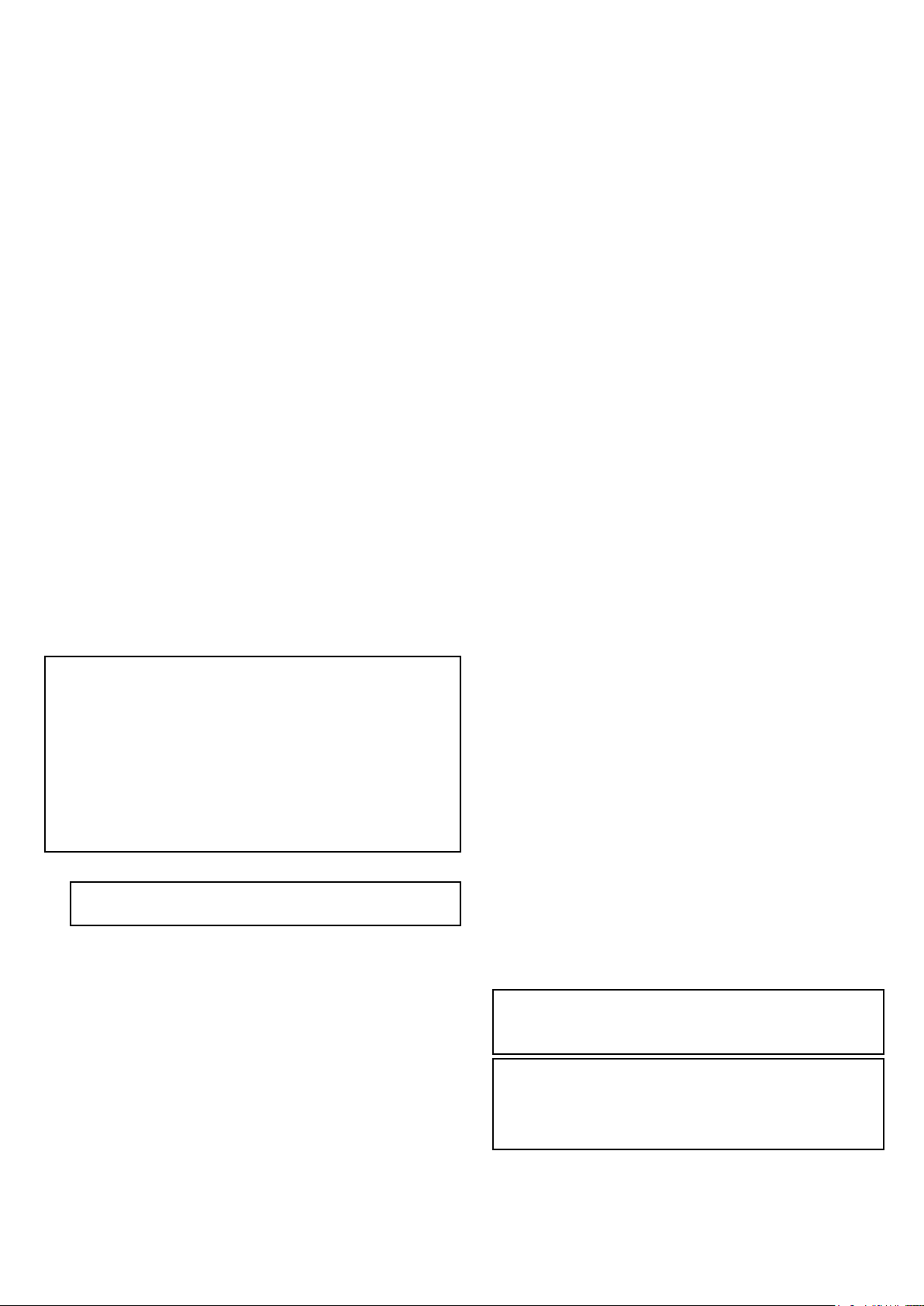

SECTION 2: SETTING UP THE INJECTOR READY FOR USE

Schematic Diagram No 2: Handpiece Component Breakdown.

1. NEEDLE NUT

2. NEEDLE MOUNT

3. VALVE SEAT

4. FRONT VALVE RETAINER

5. SEAL RING

6. CYLINDER

7. PISTON

8. SEAL RING

9. SEAL RING

10. HANDLE PLUG

11. AIR FITTING

12. RETURN SPRING

13. CIRCLIP

14. SEAL RING

15. PUSHROD

16. SPACER BUSH

1. 15ml Powered Injector

2. 10 metre Air Line

3. 10 metre Gas Line

4. Air Regulator Assembly

5. Gas Regulator Assembly

6. NJ Phillips Lubricant

17. DOSE ADJUSTOR - THREADED

18. WAVE WASHER

19. DOSE ADJUSTOR SLEEVE

20. HANDLE CLIP

21. HANDLE

22. LOCK SCREW

23. HANDLE LOCK SLEEVE

24. SEAL RING

25. REAR VALVE

26. INLET FITTING

27. TRIGGER

28. TRIGGER RETURN SPRING

29. LEVER

30. EXHAUST ADAPTOR

31. AIR TUBE - EXHAUST

32. TRIGGER VALVE ASSEMBLY

33. WASHER - TRIGGER

34. TRIGGER VALVE LOCK NUT

35. AIR TUBE - INLET

36. AIR TUBE RETAINER

37. ANTI KINK SPRING

38. CIRCLIP

39. ADAPTOR - AIR FITTING

40. MALE GAS FITTING

PAGE 5

1. HANDPIECE INJECTABLE PRODUCTS

Refer schematic diagram No 2: Handpiece component

breakdown.

Before commencing, attention must be given to following

the chemical manufacturer’s safety instructions at all times

and gloves must be worn at all times to prevent chemicals

contacting the hands. Please ensure the handpiece and

feed tube have been thoroughly cleaned and ushed out as

covered by section III of this booklet, care and maintenance

of injector.

a. The injector has been supplied with a 15ml injectable

cylinder.

Please refer to the pharmaceutical manufacturer’s

administration instructions for selection of needle to be

used.

b. Fit the selected needle as specied in the pharmaceuticals

manufacturer’s administration instructions, to the luer

tting (diag. 2 -1).

c. Using pliers and 9/16” AF open ended spanner, unscrew

the inlet adaptor (diag. 2 - 26) from the handpiece

and check that the inlet valve and spring (diag. 2 -

25) are clean, and facing in the direction as shown in

the handpiece diagram. Re-t the inlet adaptor to the

handpiece and hand tighten with pliers and open ended

spanner.

dThe handpiece is now set up ready for connection

to the draw off system for the injectable treatment of

livestock.

2. INJECTOR OPERATED BY LP-GAS PORTABLE

OR PROCESSOR

Refer Schematic Diagram No 3: Applicator setup for

operation by LP-Gas Portable or Processor.

WARNING: You must not t or use faulty, poor quality

or incompatible associated parts or components, and in

particular the use of a gas regulator and valve assembly

other than those components supplied with the product.

You must not repair, alter or modify the product, other

than those carried out by NJ Phillips Pty Limited or it’s

authorised agent, and in particular interference with or

modication in any way to the injector gas tube or other

components relating to the use of LP gas to operate the

product. Any occurence of these issues will VOID the

warranty. See warranty statement page 10.

a. Fill the gas cylinder with liquid propane gas (LPG).

WARNING: Gas cylinders must only be lled by

authorised lling agents.

NOTE: DO NOT OVERFILL GAS CYLINDER: It is

important not to overll the gas cylinder as liquid gas

may enter the injector and freeze the trigger valve. When

lling, shut off the lling exhaust valve as soon as the

rst cloudy vapour is observed coming from the valve.

Do not ll until liquid gas is pouring out and freezing up.

If liquid gas enters the gas tube, release the regulator

tting on the gas tube, and the liquid will vaporise.

b. Connect the gas regulator and valve assembly to the gas

cylinder as covered by the instruction leaet supplied

with the regulator and valve assembly, and detailed in

sections 1 to 5 of that procedure.

c. Connect the gas tube to both the injector and the outlet

port on the regulator, and hand tighten.

Set the gas operating pressure at 414 to 550 Kpa (60-80

psi) on the pressure gauge as covered by sections 6 and

7 in the instruction leaet supplied with the regulator and

valve assembly.

NOTE: The gas pressure may require adjustment by the

regulator within the specied limits to achieve satisfactory

delivery of injectable products, and may vary depending

on climatic conditions, use of the injectable product in the

upright or inverted position, or the type of needle used.

d. The injector is now set up ready for the vaccine bottle to

be connected to the appropriate feed tube and the feed

tube to the injector.

e. Connect the one end of the feed tube to the inlet adaptor

on the applicator and the other to the draw off system.

Ensure the feed tube springs are securely screwed over

the feed tube in an anticlockwise direction. This will

prevent the feed tube kinking.

i. NOTE: The injector must only be used with the gas

cylinder placed in the upright or vertical position, so

that gas and NOT liquid LPG passes through the

valve on the gas tube. Otherwise the liquid LPG

will freeze up the valve and the injector will cease

to operate. In this case, release the regulator tting

on the gas tube for the liquid LPG to vaporise, then

re-tighten.

ii. It is essential, to prevent injury to the user, that you

refer to the WARNING STATEMENTS relating to

the use of the injector when operated by LP gas, as

covered in the Powermaster handbook page 2, and

the instruction leaet supplied with the regulator and

valve assembly, instructions for connection of gas

regulator to LP gas cylinder.

f. To prime the injector set the dose at 15ml and with the

instrument held vertically with the needle pointed upwards

depress the trigger a number of times until the injectable

product is expelled from the needle in an unbroken

stream and all air bubbles have been eliminated from

the cylinder.

g. To Set Required Dose:

iDose levels and application of the injectable product

must be set in accordance with the pharmaceutical

manufacturer’s administration instructions.

ii. Turn the dose adjustor in an anticlockwise direction to

decrease dose, and a clockwise direction to increase

the dose, as indicated by graduations on the dose

adjustor sleeve.

iii. To be sure of complete accuracy, the dose must be

checked with a calibrated measuring cylinder.

iv. Cylinder ll rate and delivery pressure can be varied

with adjustment to the gas pressure on the regulator

between 414 to 550 Kpa (60 - 80 psi).

The minimum pressure should be used to achieve

acceptable lling rate and delivery speed.

h. The injector is now set up ready for the injectable

treatment of livestock.

i. WARNING: Care must be taken to ensure the liquid

does NOT come into contact with any part of the

operators body. Chemicals may injure the operator.

WARNING: At the close of each days work, or

on completion of treatment of livestock, to avoid

possible unsafe or hazardous situations, the

regulator valve must be fully closed by turning in a

clockwise direction, as indicated

PAGE 6

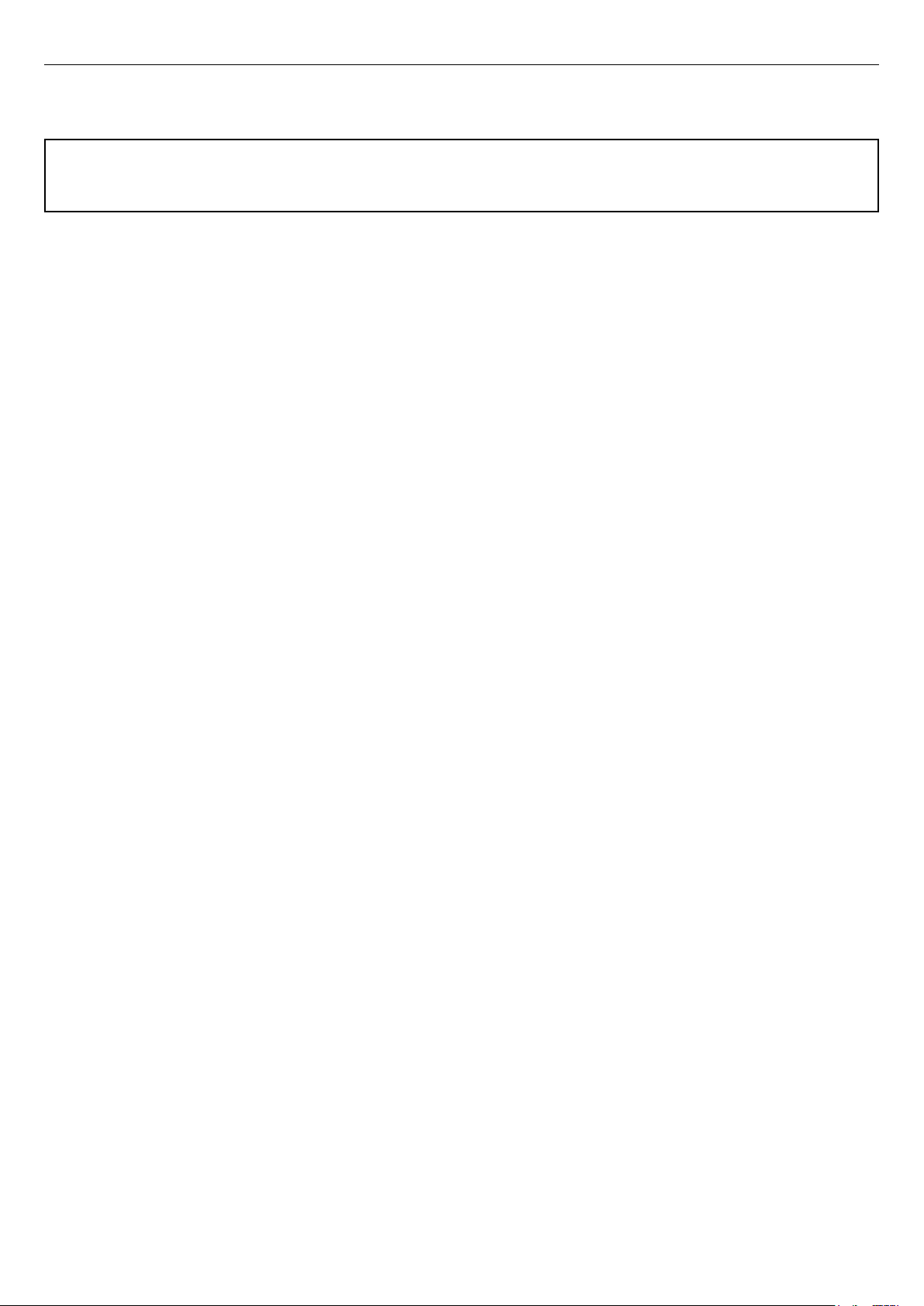

Schematic Diagram No 3: Injector setup for operation by LP-Gas Portable or Processor

TO AIR COMPRESSOR

10 METRE AIR LINE

TO INJECTABLE

CHEMICAL. VIA

PORTABLE OR

GAS LINE

TO INJECTABLE

CHEMICAL. VIA

TO GAS CYLINDER

PROCESSOR

FEED TUBE

FEED TUBE

Schematic Diagram No 4: Injector setup for operation by Compressed Air

TO AIR COMPRESSOR

10 METRE AIR LINE

TO INJECTABLE

CHEMICAL. VIA

PORTABLE OR

GAS LINE

TO INJECTABLE

CHEMICAL. VIA

TO GAS CYLINDER

PROCESSOR

FEED TUBE

FEED TUBE

PAGE 7

3. APPLICATOR OPERATED BY COMPRESSED AIR

Refer Schematic Diagram No 4 page 6: Applicator setup

for operation by compressed air.

When compressed air is used to operate the injector for the

treatment of livestock, to prevent moisture and or other foreign

matter entering the applicator and affecting the operation of the

trigger valve system, the manufacturer strongly recommends

that an approved lter/lubricator suitable for compressed

air systems, MUST be installed in the compressed air line

connected to the regulator and applicator. Otherwise, moisture

and or foreign matter will enter the trigger valve system

(diag. 2-32) of the applicator, which will cease to operate in

a satisfactory manner. Warranty claims will not be accepted

for damage caused by moisture or foreign matter entering the

trigger valve system due to the installation of an unapproved

lter/lubricator.

The manufacturer recommends 10mm inside diameter

compressed air hose and suitable 10mm ttings should be

used for connection of the applicator pressure regulator to

the compressed air supply hose, and the compressor unit

supplying the compressed air to the applicator be set to

operate at a maximum of 690 Kpa (100 psi).

a. Connect the regulator assembly to one end of the

compressed air hose by a suitable hose clamp, and

connect an approved compressed air in line lter/lubricator

to the other end of the compressed air hose at the outlet

from the air compressor.

b. Connect the 10m air line (diag. 1-2) to both the applicator

and the outlet port on the regulator and hand tighten.

c. Turn on the air compressor, and when the air pressure

has reached its operating level (max 690 Kpa - 100 psi),

fully open the brass inlet valve on the regulator by turning

in an anticlockwise direction.

d. Set the air operating pressure of the applicator at 414 to

550 Kpa (60 - 80 psi) on the pressure gauge by turning the

black control knob on the regulator in a clockwise direction

to increase pressure. If the pressure is too high, reduce

by turning the black control knob in an anticlockwise

direction, operate the applicator a few times, and adjust

for optimal pressure setting. When the optimal air pressure

is achieved, fasten the lock nut on the black control knob

screw against the regulator body with a 12mm AF open

ended spanner.

NOTE: The air pressure may require adjustment by the

regulator within the specied limits to achieve satisfactory

delivery of injectable products, and may vary depending

on climatic conditions, use of the injectable product in the

upright or inverted position, or the type of needle used.

e. The injector is now set up ready for the vaccine bottle to

be connected to the appropriate feed tube and the feed

tube to the injector.

f.Connect the one end of the feed tube to the inlet adaptor

on the applicator and the other to the draw off system.

Ensure the feed tube springs are securely screwed over

the feed tube in an anticlockwise direction. This will

prevent the feed tube kinking.

g. To prime the injector set the dose at 15ml and with the

instrument held vertically with the needle pointed upwards

depress the trigger a number of times until the injectable

product is expelled from the needle in an unbroken

stream and all air bubbles have been eliminated from the

cylinder.

h. To Set Required Dose:

i. Dose levels and application of the pour-on product

must be set in accordance with the pharmaceutical

manufacturer’s administration instructions.

ii. Turn the dose adjustor (diag. 2-17) in an anticlockwise

direction to decrease dose, and a clockwise direction

to increase the dose, as indicated by graduations on

the push rod (diag. 2-15).

iii. To be sure of complete accuracy, the dose should be

checked with a calibrated measuring cylinder.

iv. Cylinder ll rate and delivery pressure can be varied

with adjustment to the compressed air pressure on

the regulator between 414 to 550 Kpa (60 - 80 psi).

The minimum compressed air pressure should be used to

achieve acceptable lling rate and delivery speed.

i. The applicator is now set up ready for the injectable

treatment of livestock.

j. WARNING: Care must be taken to ensure the liquid

does NOT come into contact with any part of the

operators body. Chemicals may injure the operator.

WARNING: At the close of each days work, or on

completion of the pour-on treatment of livestock,

to avoid possible unsafe or hazardous situations,

the regulator valve must be fully closed by turning

in a clockwise direction, as indicated by arrow on

the valve, and turn off the air compressor. Failure

to do this may result in excess pressure build up in

the regulator causing it to fail which may injure the

operator.

PAGE 8

To ensure continued high performance from the injector, attention to cleanliness is essential, both for the protection of the

user and livestock. On completion of each use of the injector the injector and feed tube MUST be thoroughly cleaned in

accordance with the following procedure.

WARNING: For the protection of the operator, gloves must be worn at all times whilst carrying out

this procedure. Also avoid skin, body contact or inhalation of chemicals, which may cause injury to

the health of the operator.

1. Leave the power source connected to the instrument.

2. Place the injector feed tube into a clean container with a mix of approximately 1 litre of warm water and 0.5ml of non-

corrosive detergent.

3. Set dose of injector to 15ml and pump the solution through the injector and feed tube by depressing trigger a number

of times until the injector cylinder and feed tube are clean.

4. Hand wash exterior of injector, feed tube and springs with a soft brush.

5. Rinse the injector and feed tube by ushing through with clean water and pump dry by depressing trigger a number

of times.

6. Wipe injector, feed tube and springs dry, disconnect the feed tube from injector and place aside.

7. Using the NJ Phillips Lubricant supplied in the tool box, immerse the injector inlet tting into a small clean container

of Lubricant and draw a small quantity of Lubricant into the cylinder by depressing the trigger several times.

Fully close regulator valve by turning in a clockwise direction, disconnect the air or gas tube from both the regulator

and injector, and place aside.

8. Switch off the air compressor or gas cylinder and release pressure in hose. Disconnect the tting adaptor from the

snap-in barb coupling on the hose. Disconnect the tting adaptor from the regulator and valve assembly and place

both parts into toolbox.

9.

a. Remove the cylinder assembly from the injector handpiece by unscrewing in an anticlockwise direction, taking

care not to damage the seal rings on piston and place cylinder assembly aside.

b. Check seal rings (diag. 2-8) for any sign of wear or damage and replace if necessary.

c. Take the cylinder assembly, check the inside is thoroughly clean, otherwise wash out with a mixture of warm

water and detergent, rinse with clean water and wipe dry. Lubricate inside of the cylinder, piston rings, and push

rod shaft behind the piston, with a small quantity of NJ Phillips Lubricant . Carefully place the cylinder over the

piston and screw into handle in a clockwise direction and hand tighten. Place the injector with cylinder attached,

into tray of toolbox.

SECTION 3: CARE AND MAINTENANCE OF INJECTOR

PAGE 9

SECTION 4: TROUBLE SHOOTING GUIDE

CORRECTIVE ACTION - CHECK POINTSPROBLEM PROBABLE CAUSE

Injector lacks power or not

functioning

Bottle Gas. Check:

i. gas

ii. No leaks in gas hose.

iii. Check gas bottle is full and set to 414 to

550kpa (60-80psi)

Inadequate gas pressure. Reset pressure on regulator. Wind black knob

fully out and then wind in until pressure on gauge

reaches 414 to 550 kpa (60-80 psi).

Regulator outlet port and

ttings not rmly attached to

the regulator.

Ensure outlet port and brass ttings are rmly

screwed into regulator.

Injector leaking Fault in tube connections

from pressure regulator to

trigger on injector

Fully close regulator valve, disconnect injector from

regulator and return injector to stockist or local

distributor for service.

Injector will not deliver full

dose

Injector not primed or dose

not set correctly

Prime the injector and set dose as covered by

instructions .

Inlet valve and seal ring not

sealing, caused by foreign

matter lodged under the inlet

valve

Remove the inlet adaptor and inlet valve from

injector, clean with water and replace in injector.

Foreign matter lodged in

the delivery valve assembly

or a blockage in the needle

mount.

Remove needle mount and delivery valve

assembly from the injector, clean the delivery valve

assembly, and re-assemble .

Slow injector (ll and/or

delivery rate of product)

Incorrect pressure setting on

regulator (diag 1-4 or 5)

Check and adjust regulator pressure to operate

injector between 414 to 550 kpa (60 – 80 psi).

Kinking or restriction of the

feed tube

Remove the restriction or re-position the feed tube

to avoid kinking.

Piston seal rings are dry or

have not been lubricated

Remove cylinder from handpiece and lubricate the

piston seal rings with NJ Phillips Lubricant.

Spitting of product from

needle or air being drawn

into the cylinder from

the needle mount end of

injector

Foreign matter lodged in the

delivery valve and assembly.

Remove needle mount and delivery valve

assembly, clean valve by rinsing and wiping with a

soft cloth. Clean valve and re-assemble.

1.

2.

3.

4.

5.

Air compressor. Check:

i. Compressor supply adequate air pressure.

ii. No leaks in air hose.

PAGE 10

Scope of this warranty

This warranty entitles you to repairs or replacement (at no charge) of any parts

of the NJ Phillips 15ml powered injector (“Product”) found to be defective in

materials or workmanship. Repair or replacement is at the option of NJ Phillips

Pty Limited (“Company”) or its authorised agent. This warranty is in addition

to any rights and remedies extended to the owner under applicable laws, and

is not intended to negate or restrict such rights and remedies except where it

is competent to do so.

What is not covered by this warranty

Repair or replacement under this warranty is not available for faults or failure

due to:

• ordinary wear and tear;

• accident, contamination, misuse, neglect, abuse or tampering;

• incorrect installation or maintenance;

• failure to follow the Company’s warnings, instructions, and recommendations

for safe and effective use;

• the tting or use of faulty, poor quality or incompatible associated parts or

components, and in particular the use of a gas regulator and valve assembly

and/or gas cylinder other than those component parts supplied with the

Product;

• use of the injector other than for its designed purpose;

• use of the injector with any product other than products specically

recommended by your stockist/local distributor or NJ Phillips Pty Limited.

• repairs, alterations or modications carried out other than by the Company

or its authorised agent; or

• any other cause occurring after the Product left the Company’s, stockist’s

or local distributor’s control.

Subject to the operation of any laws to the contrary, this warranty does not

cover:

• the costs of travelling or transportation of the Product or parts to and/or

from the Company or its authorised agent;

• loss of the injector or parts while in transit to or from the Company or its

authorised agent; or

• personal injury, property damage, or economic and consequential loss or

damage, howsoever caused.

The Company and its authorised agents reserve the right to charge their

reasonable costs in investigating and correcting faults and failure caused other

than by defects in materials or workmanship.

How to claim under this warranty

If service is necessary, contact the Company or an authorised agent, and

provide details of the alphanumeric batch code number located on the handle

of the Product, and the date of purchase.

SECTION 5: WARRANTY AND SERVICE

QL520-R3

NJ PHILLIPS Pty Limited ABN 36 000 082 002

44 Gindurra Road Somersby NSW 2250, Australia

Locked Bag 8 Gosford NSW 2250, Australia.

Thank you for purchasing this NJ Phillips Pty Limited precision

instrument. Norman Phillips founded the Phillips reputation on

reliability, accuracy and innovation in 1931. It is by not deviating

from these original ethics that NJ Phillips Pty Limited is able to

guarantee this instrument is not only the best you can buy today,

but that tomorrow’s NJ Phillips instrument will be even better.

N. John Phillips

EXECUTIVE CHAIRMAN

Table of contents

Other NJ PHILLIPS Laboratory Equipment manuals