NJIT Makerspace Cura User manual

Ultimaker 3 and Cura Quick Start Guide

Ultimaker Cura – Import STL File

Page 2

Ultimaker Cura – Prepare (Slice) a Print

Page 3

Ultimaker 3 Printer – Start a Print

Page 6

Ultimaker 3 Printer – Remove a Print

Page 7

Ultimaker 3 and Cura

Quick Start Guide

Revision A

1

Quick Tips:

Definitions

• Ultimaker Cura: slicing software (Cura)

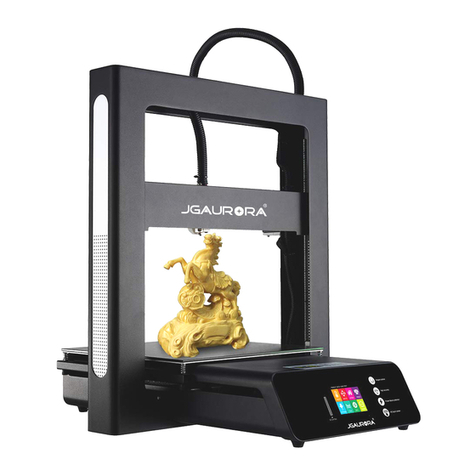

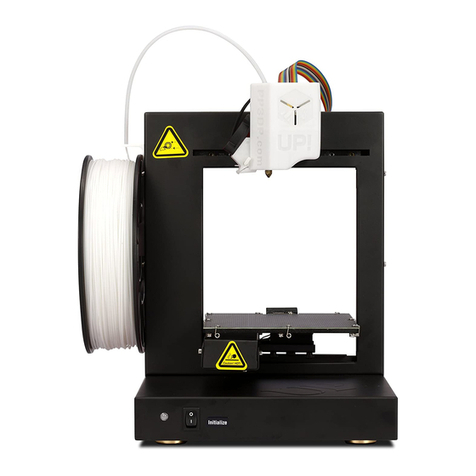

• Ultimaker 3 (Printer)

• IPA: Isopropyl Alcohol

• STL: Stereolithography File

• PLA: Polyacetic Acid (thermoplastic polymer plastic filament)

Supplies

• USB Flash Drive

• MatterHackers PLA or PETG filament

• Wire Cutter

• Hair Spray

• Spatula

Work Flow

• Import STL to Cura

• Prepare (slice) print job

• Fill out NJIT Makerspace 3D Printing information card, get staff member approval

• Pay for 3D printing

• Start print job on Ultimaker printer

• Job completion

• Remove from printer, sign NJIT Makerspace 3D Printing information card

to confirm pick up

• Pick up print at front desk, sign NJIT Makerspace 3D Printing information

card to confirm pick up

Ultimaker 3 and Cura

Quick Start Guide

Revision A

2

Ultimaker Cura – Import STL File

• Export an STL file from CAD software – use “fine” settings for smooth geometry.

• (Or download one from a site like Thingiverse)

• Open Ultimaker Cura software.

• Open STL file in Cura:

• Click the “Open File” button at the top left:

• Navigate to your STL file.

• Click “Open”.

Ultimaker 3 and Cura

Quick Start Guide

Revision A

3

Ultimaker Cura – Prepare (Slice) a Print

Use the adjustment tools to manipulate the selected part:

• Move: Move part in reference to build plate (enter values for x/y coordinates, or

drag triad arrows to move selected part).

• Scale: Adjust the size of the part by percentage or to specific dimensions. Leave

“Uniform Scaling” ON to maintain proportionality.

• Rotate: Rotate part about 3 axis to determine the best print orientation that

avoids unnecessary waste of supports and build time by determining the best

print orientation. You can rotate by dragging the colored rings of the rotation

triad. Be sure a flat face remains on the bed for print adhesion!

• Seek assistance from Makerspace staff if you are unsure of the ideal print

orientation.

• Support Blocker: Select areas where no supports should be, effectively

“blocking” the area off from support structures. Use this feature only if support

printing is enabled and certain regions should NOT have supports.

Ultimaker 3 and Cura

Quick Start Guide

Revision A

4

For general 3D printing, apply the following “Print Setup” settings:

• Extruder: Ensure “Extruder 1” is selected, Material is set to “PLA”, and Print

Core is set to “AA 0.4”.

• Print Setup: Use the “Recommended” configuration options.

• Layer Height: Use 0.2mm for general printing. Use 0.15mm or 0.1mm if

finer layer resolution is required (for example, printing screw threads)

• Infill: 20% for general printing.

• Generate Support: IF REQUIRED, enable with Extruder 1.

• Seek assistance from Makerspace staff member if you are

uncertain about need for support.

• Build Plate Adhesion: Enable for most prints.

• Print Preview: Preview 3D print with Print Setup settings applied.

• Click “Prepare” at bottom right corner of window to slice current print job.

• Set 3D view to “Layer view” to graphically visualize print paths and

individual layers. Everything in the view should be shown as “Extruder 1”

color. “Helpers” include build plate adhesion and support structures.

Ultimaker 3 and Cura

Quick Start Guide

Revision A

5

Follow NJIT Makerspace procedure before starting print:

• Take and fill out NJIT Makerspace 3D Printing information card.

• Maker Information: Fill in your first name, last name, and NJIT email

address. Write clearly so the information is readable!

• Print Job Start: Transcribe information directly from Cura. See following

example:

• File Name: “UM3_test_print”

• Print Time: 00:32

• Print Weight: 4g

• Print Material: PLA

• Filament Color: (based on which color will be used)

• Maker Approved: (your signature here)

• Consult Makerspace Staff.

• Staff member will verify that the information on the card matches the

information displayed by Cura.

• Staff member will process payment.

• Staff member will sign off in “Staff Approved” box.

• Export print job from Cura.

• Plug in USB flash drive.

• Click “Save to Removable Drive”.

• Click “Eject” button and remove USB flash drive.

Ultimaker 3 and Cura

Quick Start Guide

Revision A

6

Ultimaker 3 Printer – Start a Print

• Ensure build plate is clean.

• If residue is present, use small amount of IPA and a blue towel sheet to

wipe print area. Towel is reusable so please do not discard.

• Apply hair spray for build adhesion.

• Quickly spray a very light layer of hair spray on the glass build plate where

the part will print.

• Place staff approved (paid) NJIT Makerspace 3D Printing Information Card

in card holder.

• Insert USB Flash Drive and start your print.

• Using the Select Button, select Print and choose your file to start print.

• Ensure first layer is printed successfully before walking away.

Jog Wheel &

Select Button

Ultimaker 3 and Cura

Quick Start Guide

Revision A

7

Ultimaker 3 Printer – Remove a Print

• Wait for the glass bed to cool. The 3D printed part(s) are easy to remove when

the bed is near ambient temperature. If the bed is cool, the part can likely be

removed without use of any tools.

• Use a spatula. Gently work the blade of the spatula under the print at

approximately a 15 degree angle and slightly wiggle it back and forth until the

base of the print is released.

• Clean the glass bed. Remove any excess plastic and hair spray.

• Bring NJIT Makerspace 3D Printing information card to front desk to

approve and document Print Job Pickup.

• If Ultimaker printer maintenance or repair is necessary, or if a spool of filament

needs to be replaced, please contact NJIT Makerspace Staff for assistance!

Table 1: Ultimaker 3 - Self Serve Stations Maintenance - STAFF

What

How

When

Material

Check back of printer and ensure material is loaded.

Repeat for all printers.

Start of Day

Build Plate

Ensure material or hair spray is not accumulated on build

plate

Start of Day

Supplies

Ensure table supplies are not missing. Check both

tables.

End of Day

Ultimaker

Overall Functionality

End of Week

Table 2: Document Revision History

Rev.

Description

Date

Approved By

A

Initial Release

11/30/2018

R. BURGHART

This manual suits for next models

1

Other NJIT Makerspace 3D Printer manuals