The cool-down performed during shut-down ensures that the fans are only switched off after the

heating elements could shed all residual heat.

For switching the RepRap Industrial into standby

tap the shut-down button. The system will then

perform the cool-down sequence for safety

reasons before deactivating the preheating and

the build chamber.

The 3D Printer is in standby mode when:

the screen turns black,

the illuminated ring of the wake button

dims,

the build chamber lighting switches off.

To wake the machine from standby see Starting

the 3D printer.

Always use this button for regular shutdown.

For completely shutting down the 3D printer,

perform the procedure described above and set

the main switch at the rear cover to <0> (OFF)

afterwards. The 3D printer is now powered off

and the green status indicators of the limit

switches darken.

To reactivate the 3D printer see Starting the 3D

printer.

INFO

For day-to-day use, the power

supply should stay connected to

mains power (main switch in

position <I> (ON).

Emergency stop

NOTICE

The emergency stop function does not provide a cool down sequence. Do not use the emergency

stop button to abort current print jobs, as this may lead to damage of the 3D printer due to

uncontrolled heat accumulation. Do not use the main switch as an emergency stop button. You risk

loosing or corrupting data.

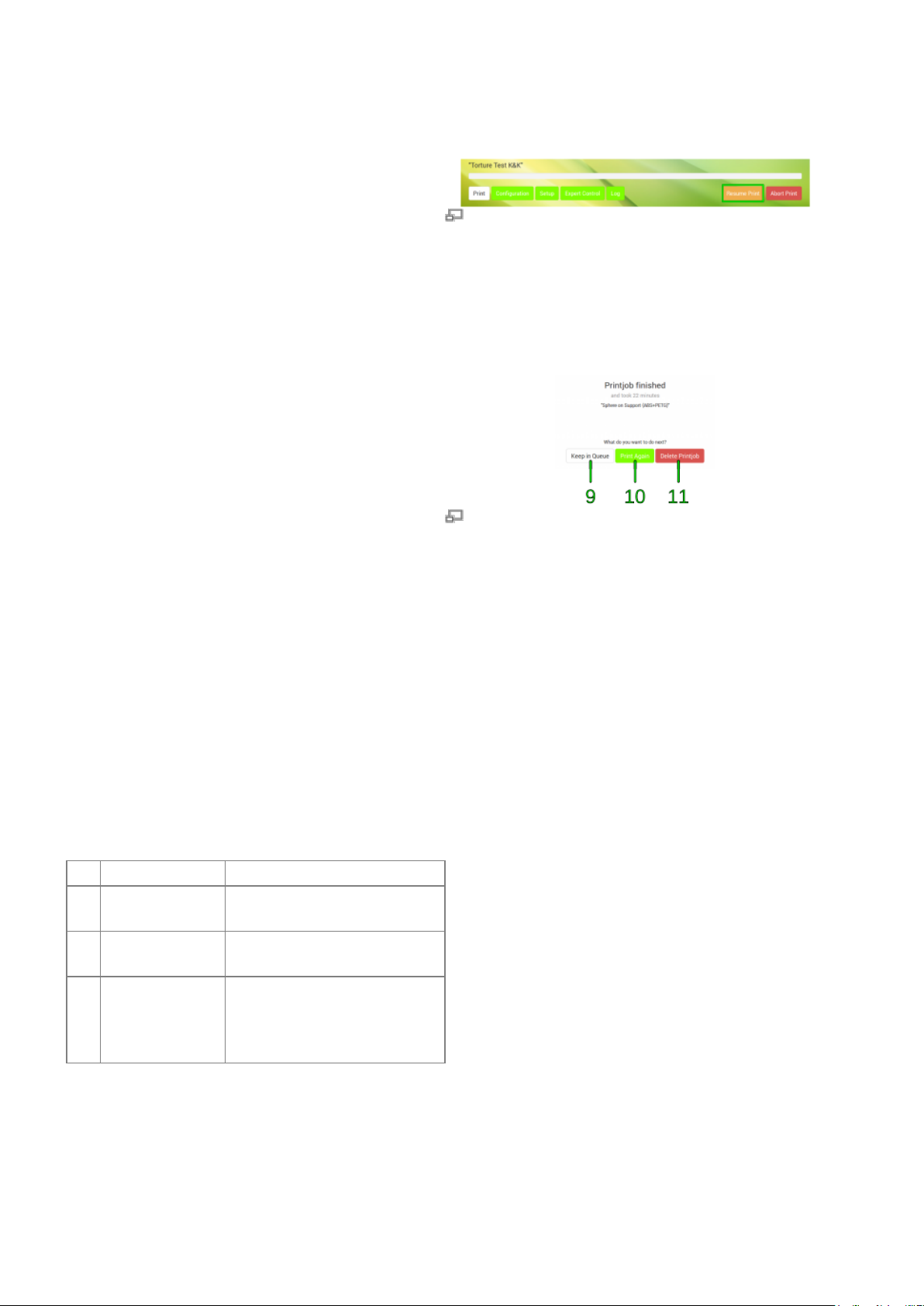

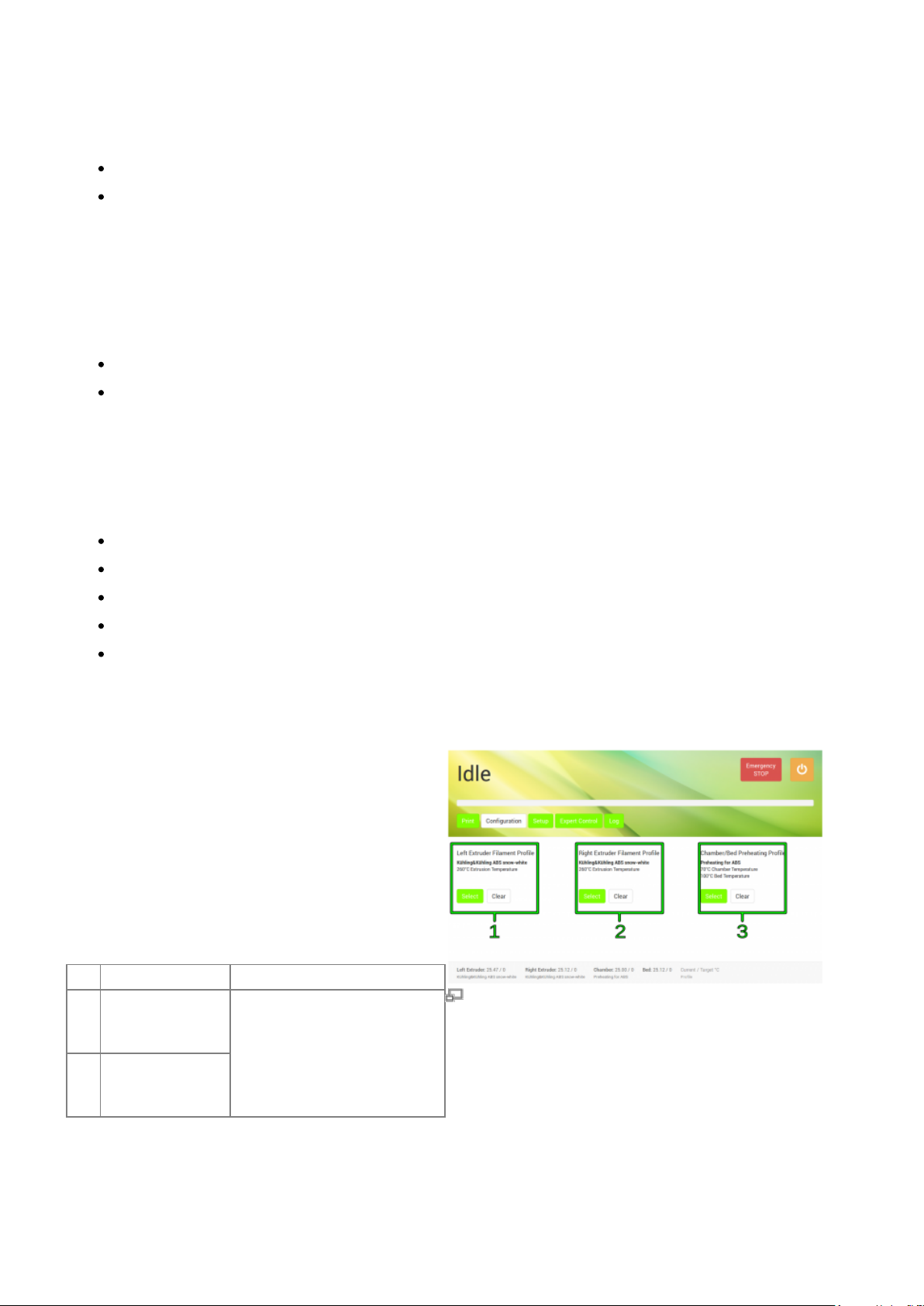

When the emergency stop is triggered:

The microcontroller board is reset, all

movement of the axes stops, lights,

heaters and fans are turned off. The status

indicator displays Emergency Stop! .

After a few seconds the microcontroller

returns to Idle state.

Status display after triggering the emergency

stop. The 3D printer returns to IDLE state after a

short time. The emergency stop is written into

the log-file.