NK TECHNOLOGIES AGL1 Series User manual

INSTRUCTIONS

1. Runallcurrentcarryingconductorsthrough

sensor window

A. Use anauxiliaryCTifconductors do notfit. Consult

Factory for CT selection.

2. Mount the sensor to a surface if needed.

3. Connect output & power wiring.

A. Use up to 14 AWG copper wires.

B. Make sure power and load matches those shown on

the senors’label.

4. Test

A. Pressing the “TEST”button teststhe sensors internal

circuits. CAUTION: The output and any connected

loads will switch!

AGL1 - NOR1 - 120 - LA - 005-N

Model Number KeySpecifications

Know Your Power Quick “How To” Guide

Power Supply Notes

AGL1, 2 & 3 SERIES

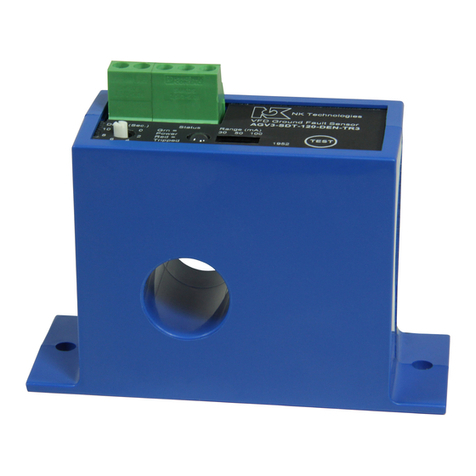

Ground Fault Sensors

with Latching Relay Outputs

AGL SeriesLatching. 3.0 06/10, P/N 49-068-0004

Output Type

NOR1 SPST (Normally open, closes on fault)

NCR1 SPST (Normally closed, opens on fault)

Power Supply

24U 24 VAC/DC

120 120 VAC

Setpoint Range

1 5-100mA, Adjustable

2 80-950mA, Adjustable

3 Tri-Set, 5, 10 & 30 mA, Jumper Select

AGL Series Ground Fault Sensor

Options

LA Normally De-energized

Setpoint

005 to 950 Factory Adjusted

Setpoint in mA (specify

when ordering)

TR3 Tri-Set, 5, 10 & 30 mA,

Jumper Select

Setpoint Range AGL1 Series: 5-100mA Field Adjustable

AGL2 Series: 80-950mA Field Adjustable

AGL3 Series: Tri-Set, 5, 10 & 30 mA,

Jumper Select

Voltage Range Up to 1,500 VAC (Monitored Circuit)

Frequency Range 50-400Hz (Monitored Circuit)

Output Description: Electromechanical relay

1.0A @ 120 VAC, 2A @ 30 VDC

Status (Red) LED = Relay has operated

Response Time 200 ms @ 5% over setpoint.

60 ms @ 50% over setpoint.

15 ms @ 500% over setpoint

Power Supply 120 VAC Operates from 66-132 VAC

(50-400hz)

Optional Power 24 VAC or 24 VDC Operates from

19.2-28.8 Volts)

Power (Green) LED=Power supply

energized

Power Consumption 2.5 Watts

Dimensions 4.25”H x 3.0”W x 3.25”D,

(108x76x83mm), aperture 1.82” (46mm)

dia.

Case UL 94V-O Flammability Rated

Environmental 5 to 158 DegF (-15 to 70 DegC), 0-95%

RH, Non Condensing

Terminal torque 5.3 inch-pounds

System Grounding

3511 Charter Park Drive, San Jose, CA 95136Toll free:

800-959-4014, Phone: 408-871-7510

Fax: 408-871-7515

[email protected], www.nktechnologies.com

Know Your Power

Other NK Technologies Products Include:

AC & DC Current Transducers

AC & DC Current Operated Switches

1φ& 3φPower Transducers

Current & Potential Transformers (CTs&PTs)

All low-current Ground-Fault Sensors are sensitive devices

that require reasonable care in system design to avoid false

trips caused by high electrical noise levels. Keep in mind

that the best way to reduce noise in a system is to suppress

it at its source.

1. Keep the sensor power isolated from noisy circuits.

2. Donotpower thesensorwiththesamecircuitthatswitches

contactors or other high current, inductive loads.

Good design practice and code require that all AC power

systems be grounded. AGL Series sensors are designed to

workongroundedAC powersystems. Theymay notoperate

properly on ungrounded systems.

Options

None (Blank)

N Electical Noise Immun.

Description

Operation

Principal of Operation

Under normal conditions, the current in one wire of a two

wire load is equal in strength but opposite in sign to the cur-

rent in the other wire. The two wires create magnetic fields

that cancel, acondition known as“Zero Sum Current”.If any

current leaks to ground (Ground Fault), the two currents be-

come unbalanced and there is a net resulting magnetic field.

The AGL sensor detects this minute field and changes the

output state. This concept extends to three phase systems

such as 3 wire Delta and to 4 wire Wye.

AGLSeries sensors work in the same environment as mo-

tors, contactors, heaters, pull-boxes, and other electrical

enclosures. They can be mounted in any position or hung

directly on wires with a wire tie. Just leave at least one inch

distance between sensor and other magnetic devices. Run

all current carrying conductors through the opening in the

sensor. (See “Principal of Operation”) Be Sure all wires

are oriented so current flows in the same direction.

Installation & Wiring

AGL Series sensors monitor all current carrying wires in

single or three phase systems to detect ground faults. They

provide a contact output that can operate relays, contactors

or signal automation systems.

Wiring

Use up to 14 AWG copper wire and tighten terminals to

5.3 inch-pounds torque. See Diagram.

Power

Connect power wiring to Terminals 3 & 4. Be sure that

the power supply matches the power rating on the sensor

label. Green LED (Power) will light.

Output

Connect output wiring to Terminals 5 & 6.

Reset Switch

Connect a momentarydry contactto the reset terminals(1&

2.) Limit wire run to 200’ of 18 AWG or larger wire.

Momentary Reset

The sensor will not work properly if the reset terminals are

closed (shorted) continuously. Only close thereset terminals

momentarily.

Parallel Reset Connection

Multiple sensors may be connected to the same reset switch

in parallel. Only the sensors that have detected a fault and

have latched will be reset. Asensor will not reset unless the

fault has dropped below setpoint.

AGLSeriesLatchingGroundfaultsensorsoperateinoneof

two states: Reset or Latched. If control power is removed,

the sensor remains in it’s last state (latched or reset). The

sensor will unlatch if the power supply is cycled off and

then on again.

To test operation, gently press the TESTbutton. This simu-

lates a fault and tests the internal switching circuits.

CAUTION: Any circuit connected to the sensor will be

operated.

The normally open contact closes on sensed fault current

over the set point, and the normally closed contact opens

on fault.

Set point adjustment, CW

to adjust higher located

under label

Test button (activates

output relay!)

Red Status LED

(On when tripped)

Green Power LED (On

when powered)

Power Supply

Input (3&4) External Reset

Button (1&2)

When used with an external CT, the sensor will be set to

trip at a point much lower than without the CT. This set

point adjustment should be done with the load passing

through the CT in that application.

Single Phase (Phase

& Neutral or Phase to

Phase)

3 Phase Delta (Include

neutral if the load uses

neutral)

3 Phase Wye (Include

neutral if load uses

neutral)

3 Phase Load, using an auxiliary Current Transformer.

Contact factory for details.

Field Setpoint Adjustment

While not as precise as having it set at the factory, the set

point can be adjusted in the field through use of the small

potentiometer located beneath the label to the right of the

leads exiting the case. Though not receommended, if a

field adjustment of setpoint is desired, the recommended

steps are as follows:

1. Develop a load of the magnitude at which you want

the sensor to trip; e.g., a 4000 ohm resistor at 120 VAC

should provide a load of 30 mA while 4 watt “night light”

bulb would create a load of approximately 3.333 mA.

2. With the load energized and passing through the sens-

ing aperture, turn the potentiometer clockwise (CW) until

the sensor trips. Then turn the pot back (CCW) one eighth

of a turn.

NOTE: The tri-set models cannot be adjusted higher nor

lower than the factory settings.

SUPPLY POWER

24V or 120V

01

02

05 06

03

04

NO OR NC

COMMON

EXTERNAL RESET

OUTPUT CONNECTION

TRIP POINT SELECTION (IF USED)

STATUS LED POWER LED

TEST

TRIP ADJUSTMENT

(UNDER LABEL)

Output Connection

(5 & 6), NO closes

on fault, NC opens

on fault

The triple range, field selectable models use a jumper

to select the trip point. With the jumper off the pins, the

sensor will trip at the lowest set point. The jumper can

be placed over two pins to set the trip point at the me-

dium level, or the other two pins to be set at the highest

trip point.

This manual suits for next models

2

Other NK TECHNOLOGIES Accessories manuals