NK TECHNOLOGIES AG1 Series User manual

INSTRUCTIONS

1. Run all current carrying conductors

through sensor window

A. Use an auxiliary CT if conductors do not fit. Con-

sult Factory for CT selection.

2. Mount the sensor to a surface if needed.

3. Connect output & power wiring.

A. Use up to 14 AWG copper wires.

B. Make sure load matches the output shown on the

sensors’ label.

•Sensors labeled “xxAC” will only switch AC.

•Sensors labeled “xxDC” will only switch DC.

C. Make sure power supply matches the power input

shown on the label.

4. Test

A. Pressing the “TEST” button tests the sensors inter-

nal circuits. CAUTION: The output and any con-

nected loads will switch!

AG1-NCAC-120 -FS - 005

Model Number KeySpecifications

Quick “How To” Guide

Power Supply Notes

AG 1, 2 & 3 SERIES

Ground Fault Sensors

Auto-Reset

Output Type

NCAC Normally Closed 1A @ 240 VAC

NOAC Normally Open 1A @ 240 VAC

NCDC Normally Closed 0.15A @ 30 VDC

NODC Normally Open 0.15A @ 30 VDC

NCR Normally Closed, 0.5A @ 120 VAC, 0.25A

@ 240 VAC, 2A @ 30 VDC

NOR Normally Open, 0.5A @ 120 VAC, 0.25A @

240 VAC, 2A @ 30 VDC

Power Supply

24U 24 VAC/DC

120 120 VAC

240 132-264 VAC

Setpoint Range

1 5-100mA, Adjustable

2 80-950mA, Adjustable

3 Tri-Set, 5, 10 & 30 mA, Jumper Select

AG Series Ground Fault Sensor

Setpoint Range AG1 Series: 5-100mA Field Adjustable

AG2 Series: 80-950mA Field Adjustable

AG3 Series: Tri-Set, 5, 10 & 30 mA, Jumper

Select

Voltage Range Up to 1,500 VAC (Monitored Circuit)

Frequency Range 50-400Hz (Monitored Circuit)

OutputOptions (See Product Label)

Solid State AC Switch 1A @ 240 VAC (2A for 10 Min)

Solid State DC Switch 0.15A 30 VDC (500mA

momentary)

Relay Output 0.5A @ 120 VAC, 0.25A @ 240

VAC, 2A @ 30 VDC

Response Time 150 mS @ 5% above setpoint.

100 mS @ 50% above setpoint.

Power Supply Operates from 55-110% of nominal voltage

NominalVoltages 120, 240 VAC (50-400 Hz)

Green LED=Power

Optional Power 24VAC or 24 VDC Operates +/- 20%

Power Consumption 2.5 Watts

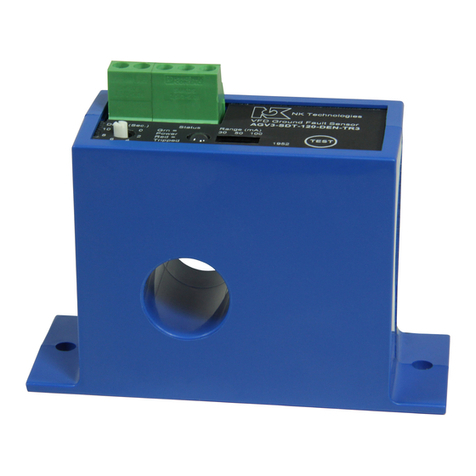

Dimensions 2.5"H x 2.8"W x 1.5"D, (64x71x38mm),

aperture 0.75" (19mm) dia. (See Diagram)

Case UL 94V-O Flammability Rated

Environmental 5 to158 DegF (-15 to 70 DegC), 0-95% RH,

Non Condensing

Listings UL 1053, Class 1 Recognized, CE Certified

(Not all option combinations are recognized.

See product label)

System Grounding

Know Your Power

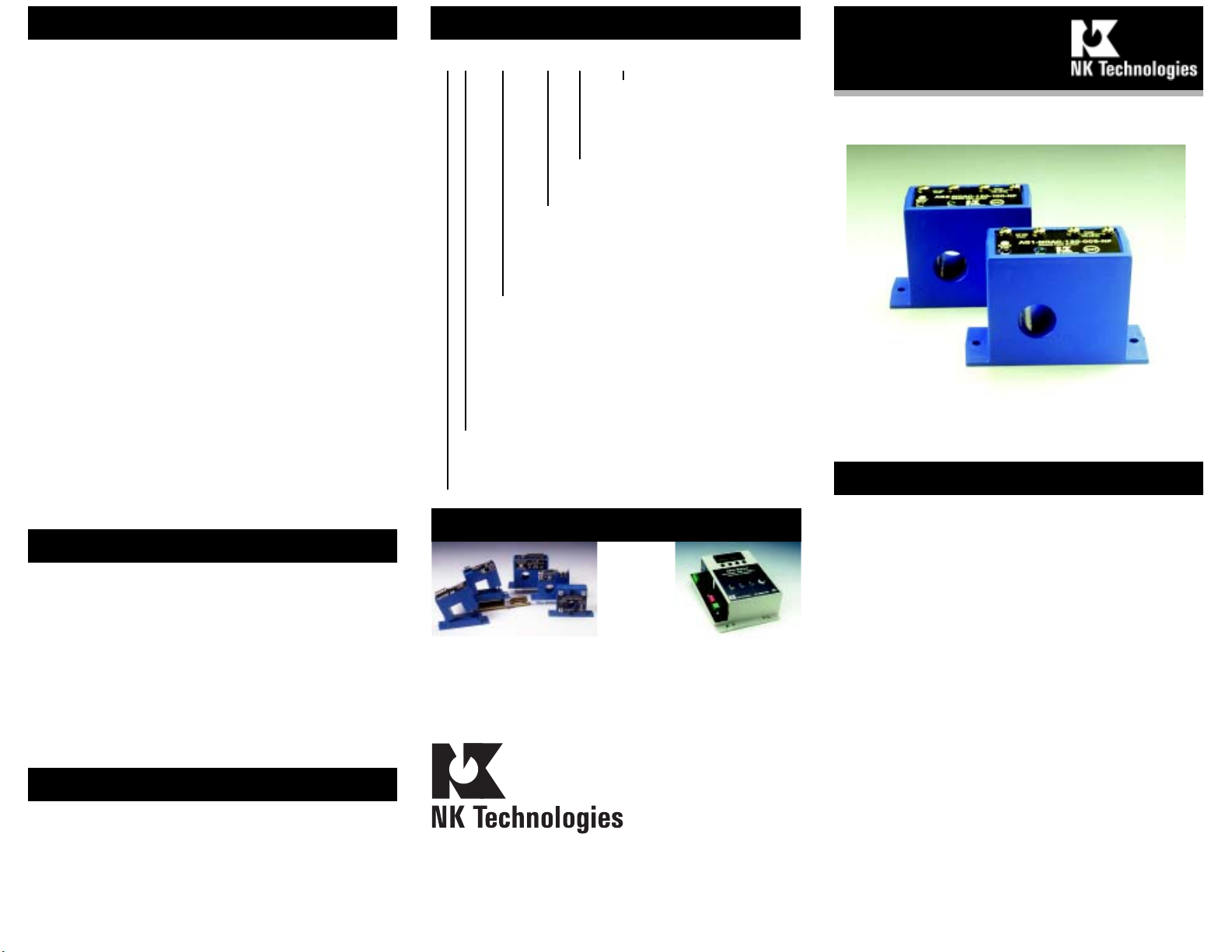

Other NK Technologies Products Include:

AC & DC Current Transducers

AC & DC Current Operated Switches

1φ& 3φPower Transducers

Current & Potential Transformers (CTs&PTs)

All low-current Ground-Fault Sensors are sensitive devices

that require reasonable care in system design to avoid false

tripscausedbyhighelectricalnoiselevels. Keepinmindthat

the best way to reduce noise in a system is to suppress it at its

source.

1. Keep the sensor power isolated from noisy circuits.

2. Do not power the sensor with the same circuit that

switchescontactorsorotherhighcurrent,inductiveloads.

Good design practice and code require that all AC power

systems be grounded. AG Series sensors are designed to

workongroundedACpowersystems. Theymaynotoperate

properly on ungrounded systems.

Setpoint

005 to 950 Factory Adjusted

Setpoint in mA (specify

when ordering)

TR3 Tri-Set, 5, 10 & 30 mA,

Jumper Select

Options

FS Normally Energized

NF Normally De-energized

Normally Energized Models (-FS) Detects Ground Faults and loss of control power

CONTROL POWER APPLIED

NO POWER No Fault Fault Detected

Output Style Output LED Output LED Output LED

N.C. Normally Closed CLOSED Off OPEN ON CLOSED OFF

N.O. Normally Open OPEN Off CLOSED ON OPEN OFF

Normally De-Energized Models (-NF) Detects Ground Faults only.

CONTROL POWER APPLIED

NO POWER No Fault Fault Detected

Output Style Output LED Output LED Output LED

N.C. Normally Closed CLOSED Off CLOSED OFF OPEN ON

N.O. Normally Open OPEN Off OPEN OFF CLOSED ON

Description

Operation

Principal of Operation

AG Series sensors work in the same environment as mo-

tors, contactors, heaters, pull-boxes, and other electrical en-

closures. They can be mounted in any position or hung

directly on wires with a wire tie. Just leave at least one inch

distance between sensor and other magnetic devices.

Run all current carrying conductors through the sensor

apeture in the same direction. (See “Principal of Opera-

tion)

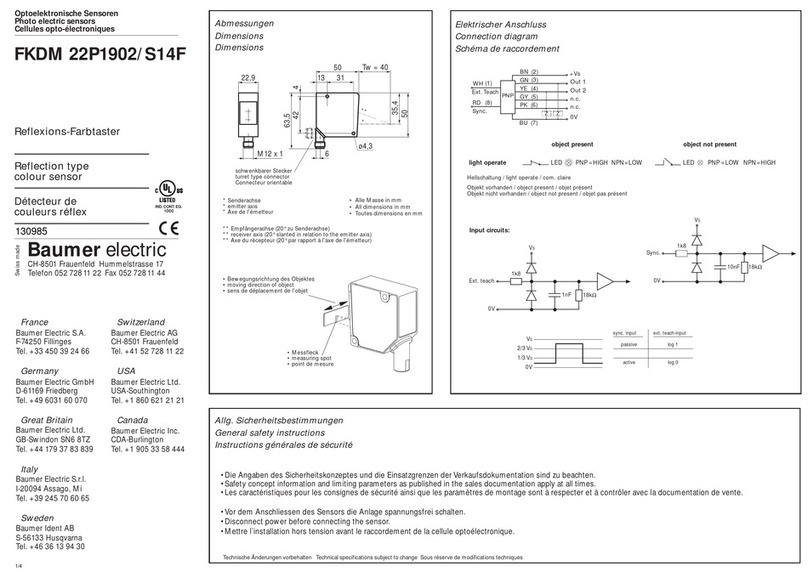

Connect power wiring to the sensor. Be sure that the power

supply matches the power rating on the sensor label. Use

up to 14 AWG copper wire and tighten terminals to 7 inch-

pounds torque.

Installation & Wiring

Connect output wiring to the sensor. Be sure that the out-

put load is less than or equal to than the output rating on

the sensor label. Use up to 14 AWG copper wire and tighten

terminals to 7 inch-pounds torque.

Totestoperation,gentlypressthe

TEST button. This simulates a

faultandtests theinternalswitch-

ing circuits.You should observe

the following operation.

CAUTION: Any circuit con-

nected to the sensor will be op-

erated.

Power Output

G

X

Control Power

Match Sensor Rating

(See Label)

Setpoint Adjust

Factory calibrated &

covered. Remove cover,

adjust & relabel if required.

Load

Contactor, Relay, Shunt Trip Breaker, etc.

Do not exceed Rating (See Label)

Output Power

Match Sensor Rating

(See Label)

TEST

(+)

(_)

For DC Output Version

ObservePolarity

Setpoint Adjustment

AG1 & AG2 Series sensors are factory calibrated to trip at

the setpoint specified at the time order. We highly recom-

mend leaving this factory calibrated setpoint alone. If you

must change the factory setpoint, follow these steps:

A. Setup

Connectcontrolpowerandoutputcircuits. Runaconductor

through the aperture with current equal to your desired set

point .

B. Adjust Setpoint to Maximum

Remove the Setpoint Cover. Turn the adjustment pot 4

revolutionsCCW(CounterClockwise)tothemaximum (least

sensitive) setpoint. The Status LED should be OFF. The

adjustment pothasaslipclutchsoyoucannotfeelordamage

the end point.

C. Dial in new Setpoint

Turn the pot slowly CW (Clockwise) until the LED turns

ON. The sensor is now adjusted to trip at the current that is

passing through the aperture. Reset the sensor.

D. Relabel Sensor

Relabel the sensor with the new setpoint. Use a label maker

or tape with a permanent marker.

AG3 Move the jumper to the desired setpoint as shown on

the label.

Under normal conditions, the current in one wire of a two

wire load is equal in strength but opposite in sign to the

current in the other wire. The two wires create magnetic

fields that cancel, a condition known as “Zero Sum Cur-

rent”. If any current leaks to ground (Ground Fault), the

two currents become unbalanced and there is a net resulting

magnetic field. The AG sensor detects this minute field and

changes the output state. This concept extends to three

phase systems such as 3 wire Delta and to 4 wire Wye.

AG Series sensors monitor all current carrying wires in

single or three phase systems to detect ground faults. They

provide a contact output that can operate relays, contactors

or signal automation systems.

Contact Status LED

Power Supply LED

This manual suits for next models

3

Other NK TECHNOLOGIES Accessories manuals

Popular Accessories manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs NJ10-30GM50-E2-V1-3G-3D instruction manual

Hukseflux

Hukseflux FHF05 Series user manual

IMI SENSORS

IMI SENSORS HT640B02 Installation and operating manual

Keysight Technologies

Keysight Technologies N6841A user guide

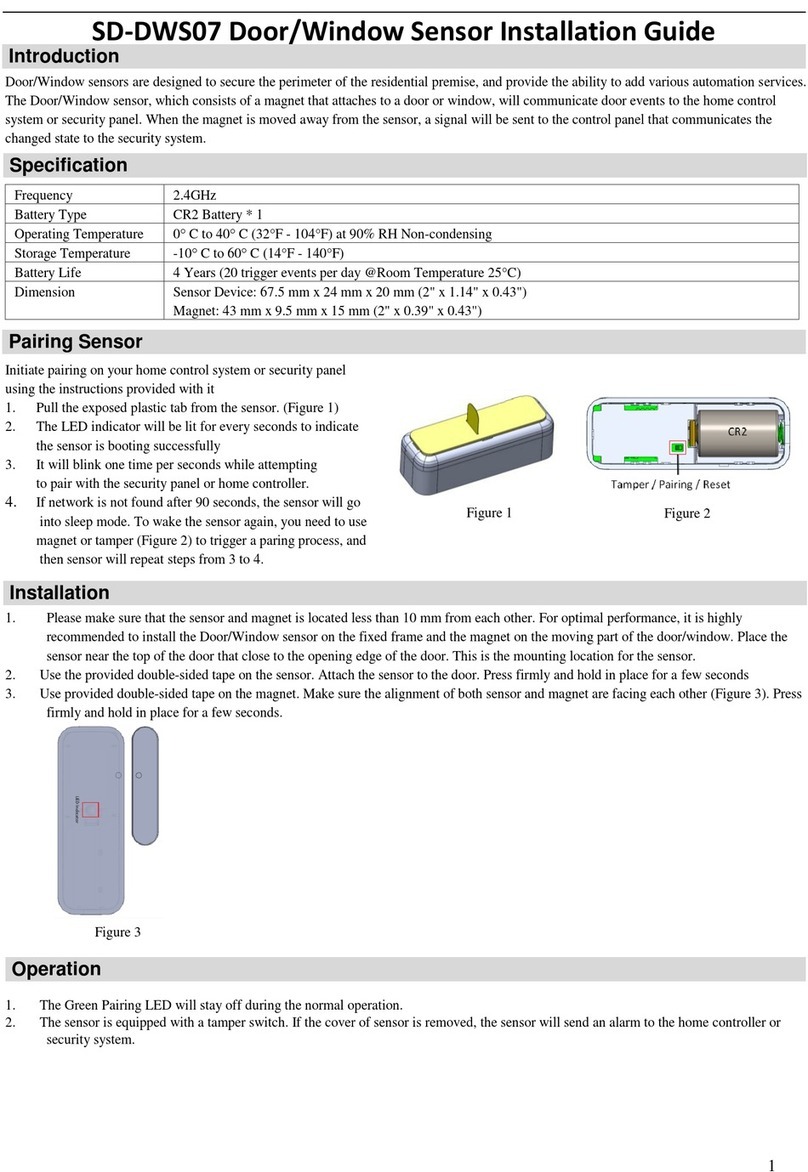

Sercomm

Sercomm SD-DWS07 installation guide

Kohler

Kohler K-4709 Homeowner's guide