NK TECHNOLOGIES ATS Series User manual

1. Mount the sensor to a suitable surface if required.

2. Run the wire to be monitored through aperture.

3. Connect output wiring.

A. Use 30-12 AWG copper conductors only.

B. Ensure the power supply voltage matches the

model you are installing.

C. Energize the power to the sensor.

4. Adjust Setpoint.

A. LED will display the RMS value of AC current

which will cause the output to change state.

B. Turn the potentiometer until your target current

value is displayed.

5. Analog Signal Output

A. The analog outputs are powered from the sensor

power source.

B. The signal is proportional to the sensor range

selected.

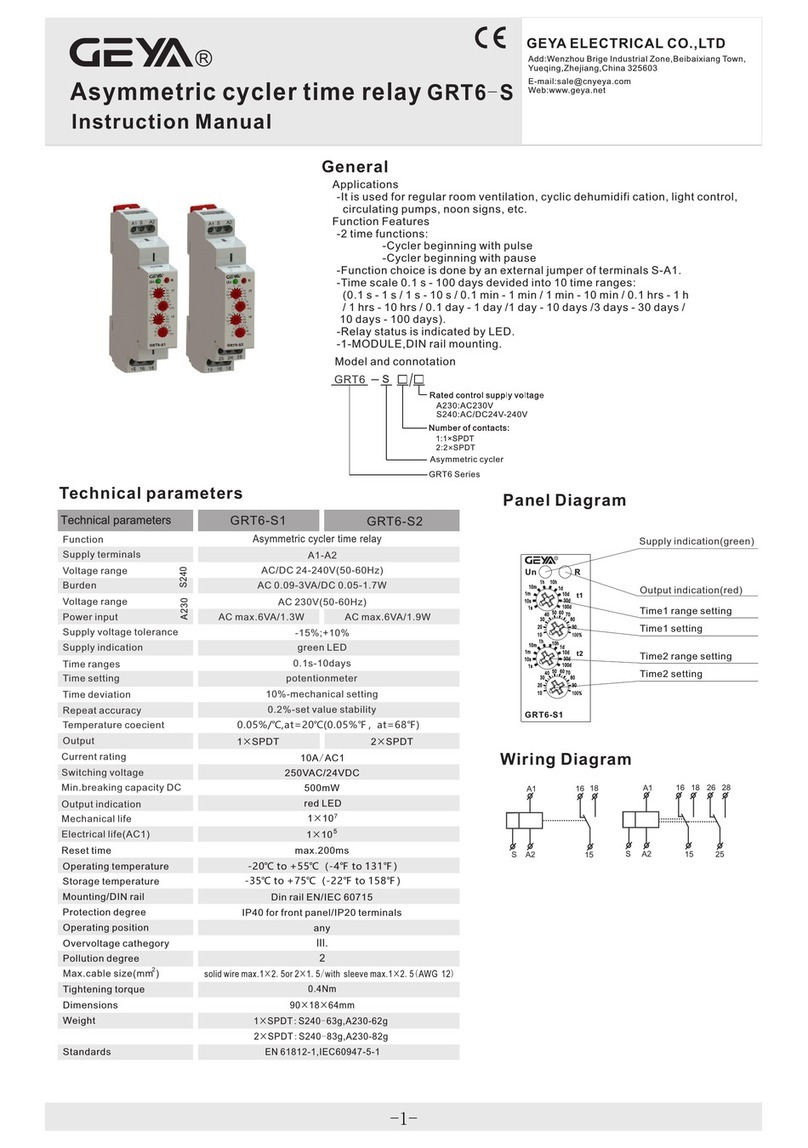

ATS 1- 420 - NOAC - 24U - FL

CASE STYLE:

FL - Solid-Core

OUTPUT:

NOAC - Normally Open solid-state contact,

1 A @ 240 VAC maximum

NCAC - Normally Closed solid-state contact,

1 A @ 240 VAC maximum

SENSOR TYPE:

ATS - AC current operated switch, LED display of the

adjustable trip point.

Model Number KeySpecifi cations

Power Supply 24 VAC/VDC (18-28 V)

Power Consumption 160 mA

Output Operations Isolated solid-state switch and

Analog signal output combination

Output Rating (Switch) 1 A @ 240 VAC maximum (general use)

Response Time <500 ms for 5% over setpoint

(Switch Output) <200 ms for 50% over setpoint

<150 ms for 100% over setpoint

Hysteresis 5%

Setpoint Range ATS1: 1-50 A (adjustable)

ATS2: 4-200 A (adjustable)

Setpoint Adjustment Single turn potentiometer

Setpoint displayed on sensor

Analog Signal 4-20 mA - 500 ohm max impedance

0-5 VDC -5K ohm min impedance

0-10 VDC -5K ohm min impedance

Response Time Average responding

(Analog Output) <250 ms 90% step change

<500 ms 99.5% step change

<2000 ms 100% step change

Accuracy +/-1%, FS

Isolation Voltage Tested to 1480 VAC

Frequency Range 40-100 Hz

Sensing Aperture 0.75” (19.1 mm)

Operating -4 to122°F (-20 to 50°C)

Environmental Surrounding air

0-95% RH, Non-condensing

Pollution Degree 2

Altitude to 6561 ft (2000 meters)

Listings UL/cUL, CE

Quick “How To” Guide

893020010 Rev 3

3511 Charter Park Drive, San Jose, CA 95136

Phone: 800-959-4014 or 408-871-7510

Fax: 408-871-7515

[email protected], www.nktechnologies.com

Know Your Power

POWER SUPPLY:

24U - 24 VAC/VDC

RANGE:

1 - 0-50 Amps AC (setpoint 1-50 A)

2 - 0-200 Amps AC (setpoint 4-200 A)

ANALOG OUTPUT:

420 - 4 to 20 mA

005 - 0-5 VDC

010 - 0-10 VDC

INSTRUCTIONS

ATS SERIES

AC Current Operated Relay

Single Range with Solid State Output and

Analog Signal

Caution! Risk of danger

Safe operation can only be guaranteed if the

transducer is used for the purpose for which it was

designed and within the limits of the technical speci-

fi cations When this symbol is used, it means you

should consult all documentation to understand the

nature of potential hazards and the action required to

avoid them.

Caution! Risk of electrical shock

When operating the transducer certain parts may

carry hazardous live voltage (e.g. Primary conductor,

power supply). The transducer should not be put into

operation if the installation is not complete.

For products intended for the EU market, the following is ap-

plicable to the CE compliance of the product:

The ATS Series may comply with EN 61010-1 CAT III 300 V

max line-to-neutral measurement category. If insulated cable is

used for the primary circuit, the voltage rating of the measure-

ment category can be improved according to the characteristics

given by the cable manufacturer.

Use twisted pair for all connections.

24 Volt AC or DC Power Supply

Fuse at 5 amps maximum

Overvoltage Category I

ATS Series are externally powered, current-operated switches with

0-50 A or 0-200 A analog signal. The contact trips when sensed cur-

rent level exceeds the adjusted setpoint. The normally open contact

closes on current rise, the normally closed contact opens on current

rise. The output resets when current falls 5% below the set point.

The contact alarm point can be used by itself, or the analog signal

can be used alone or both can be used together. There is no need to

short the analog output if it is not used.

ATS sensors can be located in the same environment as motors,

contactors, heaters, pull-boxes, and other electrical enclosures. The

sensor can be installed in any position using the screw holes in the

mounting tabs, or hung directly on wires using a wire tie. Ensure at

least one inch clearance exists between sensor and other magnetic

devices.

Run wire to be monitored through aperture (opening) in the sen-

sor. The direction that the wire passes through the opening is not

important.

Connect the output contact to the load to be switched, being sure

that the load does not exceed the capacity of the output contact. The

contact is solid-state, and will be able to control any AC circuit from

2 to 240 VAC, and up to one amp at any voltage.

Connect the power supply voltage to the appropriate terminals, being

sure that the supplied power matches the sensor designed voltage.

Energize the sensor power supply.

Initially the LED display will show the range maximum.

Set the desired trip point by turning the potentiometer counter-

clockwise. The display will show the amount of AC current needed

to trip the output.

A normally open contact will close at this setpoint, and a normally

closed contact will open.

If used, connect a panel meter or controller input module to the analog

output terminals of the ATS sensor. The sensor output will produce a

signal proportional to the AC current fl owing in the monitored circuit.

The ATS1-420-NOAC-24U-FL will give an output signal of 4mA

with the monitored circuit off , rising to 20 mA at 50 amps.

The ATS2-420-NOAC-24U-FL will give an output of 4 mA with the

monitored circuit off , rising to 20 mA at 200 amps.

Installation Output Wiring

ATS Series setpoint is adjusted using a a single turn poten-

tiometer. The LED three digit display will show the amount

of current needed to cause the output to change state. The

setpoint adjustment can be done before the monitored load

is energized, improving the safety of the installation. The

sensor must be powered to operate the display.

The adjustment is made by turning the screw clockwise to

raise the setpoint, counter clockwise to decrease the setpoint.

The ATS1 models can be set to trip at any current level

from one to 50 amps. The ATS2 or models can be set to trip

between four and 200 amps.

1. Sensor is always tripped

A. The setpoint may be too low. Turn the potentiometer

CW to a higher setting.

B. Switch has been overloaded and contacts are burned

out. Check the output load, remembering to include

inrush on inductive loads (coils, motors, ballasts).

2. Sensor will not trip

A. The setpoint may be too high. Turn the potentiometer

CCW to a lower value.

B. Monitored current is below minimum required. This

sensor can be set to trip at a minimum of 1 amp (ATS1)

or 4 amps (ATS2). Loop the conductor through the

sensing window twice to reduce the trip point to 0.5

(or 2) amps.

C. Switch has been overloaded and “contacts” are burned

out. Check the output load, remembering to include

inrush on inductive loads (coils, motors, ballasts).

D. Current is DC or of a lower frequency than 40 hertz

The sensor can be used to monitor 40-100 hertz AC

current only.

3. Sensor analog signal stays at 4mA (zero voltage)

A. The connection to the load (panel meter, PLC etc.) may

be reversed. Try reversing polarity.

B. The monitored load is not on. Check to be sure there

is voltage at the load terminals.

C. The monitored load is DC or the frequency is below

40 hertz. The ATS can only be used to monitor AC

current.

D. There is more than one phase through the aperture.

Thread only one current carrying conductor through

the aperture, or multiple conductors connected to the

same phase. Do not pass the grounding wire through

the sensor. The neutral can be monitored if the load is

single phase, but do not install both hot and neutral.

Trouble Shooting

Setpoint Adjustment

Connect control or monitoring wires to the sensor. Use

30-12 AWG copper wire rated 75/90°C, and tighten termi-

nals to 5-7 inch-pounds torque. Be sure the output load

does not exceed the switch rating.

CAUTION Incandescent lamps can have “Cold Filament

Inrush” current of up to 10 times their rated amperage. Use

caution when switching lamps with solid-state “contacts”.

Analog Signal

The analog output is proportional to the full range of the

sensor, either 0-50 or 0-200 amps AC. This signal is powered

from the sensor power and no other external (loop) power

is needed. Once the sensor is powered with no primary AC

current through the sensing window, the output will read 4

mA (or 0 VDC). The output signal will rise as the current

increases, up to 20 mA (or 5 VDC or 10 VDC). The ATS1

will produce this signal at 50 amps, and the ATS2 will pro-

duce the signal at 200 amps.

The zero and span calibration is done at the factory, and there

is no need to make any adjustments in the fi eld.

The analog signal is RMS responding, with accuracy of

+/-1% of scale when the current wave shape is sinusoidal.

893020010 Rev 3

The ATS series current relays are externally powered

AC current sensors which utilize a revolutionary meth-

od to set the point where the primary current actuates

the solid-state output. By turning a potentiometer, the

set point will be changed. An LED display on the top of

the sensor shows the value in amps where the contact

will change.

In addition, the ATS sensor produces an analog signal

(choice of 4-20 mA, 0-5 or 0-10 VDC) to be used as an

input to a PLC, panel meter, data acquisition system

or similar. Models with output ranges of 0-50 or 0-200

amps can be selected.

Description

This manual suits for next models

1

Popular Relay manuals by other brands

IFM Electronic

IFM Electronic G1501S Original operating instructions

Emerson

Emerson White-Rodgers 829A-832 installation instructions

Eaton

Eaton ESR5-NV3-30 manual

CD Automation

CD Automation Revo S user manual

Schrack

Schrack LSTD Series operating instructions

Mitsubishi Electric

Mitsubishi Electric CBV2-A01D1 instruction manual