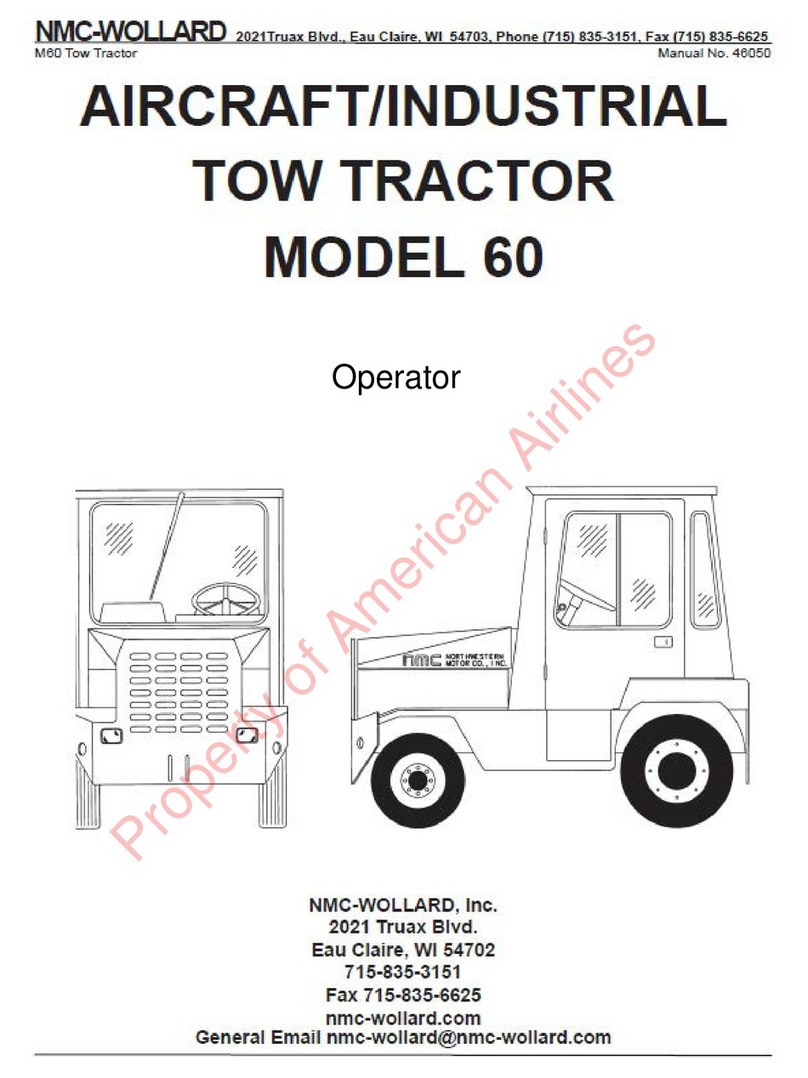

NMC-WOLLARD MB-4 200-DF User manual

M200 MB4 Tow Tractor Manual No. 42975

FLIGHT LINE

TOW TRACTOR

MB-4

16,000 DBP

OPERATION, MAINTENANCE AND PARTS

MANUAL

MODEL 200-DF

NSN: 1740-01-375-5849 YW

PART # 2016 (NON-AIR EQUIPPED)

AND

NSN: 1740-01-487-3996YW

PART # 2016AIR (AIR EQUIPPED)

TO: 36A10-3-46-1

NMC-WOLLARD, Inc.

2021 Truax Blvd.

Eau Claire, WI 54702

715-835-3151

Fax 715-835-6625

nmc-wollard.com

M200 MB4 Tow Tractor Manual No. 42975

PAGE 2

JULY 15, 2001

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of

its constituents are known to the

State of California to cause cancer,

birth defects, and other reproductive

The information contained in this manual is

subject to change without notice.

Copyright 2000

NMC-Wollard, Inc.

This manual is available on CD-ROM P/N 43532

Keep a copy of your NMC-Wollard, Inc. manuals on your computer or CD-ROM! You will be

able to print pages and adjust page view anywhere between 25%-400%. Our view-only

manuals contain hypertext links in the tables of contents, so by mouse-clicking on a table of

contents entry, the page containing that item will automatically be displayed.

Requirements (minimum): PC with Windows 95 or newer, 486 processor (586 recom-

mended), 8MB RAM, VGA monitor, mouse.

IMPORTANT SAFETY NOTICE

There are numerous variations in procedures, techniques, tools, and parts for servicing tow

tractors, as well as in the skill of the individual doing the work. This manual cannot possibly

anticipate all such variations and provide advice or cautions as to each. Accordingly, any-

one who does not follow the instructions provided in this manual must first make sure that

they do not endanger their personal safety or tractor integrity by their choice of methods,

tools, or parts.

M200 MB4 Tow Tractor Manual No. 42975

PAGE 3

JULY 15, 2001

Prior to starting any task, first read the

WARNINGS or CAUTIONS included in

the text for that task.

CAUTION is used in this manual to indicate hazards or

unsafe practices which could result in equipment dam-

age.

WARNING is used in this manual to indicate hazards or

unsafe practices which could result in personal injury or

death.

TO: HOLDERS OF NMC-Wollard, Inc. OPERATION AND MAINTENANCE MANUAL num-

ber 42975

REVISION NO. 1 DATED 02/09/01

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 1 dated 02/09/01.

Chapter/Page No. Description of Changes Effectivity

Revision added

Effectivity Code page updated

9/5 Change lug nut torque specs from 550

to 420; remove lubed torque

10/3-7 Parts Index updated

10/42 & 43 Drawing update and added new parts

10/56 & 57 Drawing update and added new part A

TO: HOLDERS OF NMC-Wollard, Inc. OPERATION AND MAINTENANCE MANUAL num-

ber 42975

REVISION NO. 2 DATED 03/31/01

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 2 dated 03/31/01

Chapter/Page No. Description of Changes Effectivity

All

M200 MB4 Tow Tractor Manual No. 42975

PAGE 4

JULY 15, 2001

TO: HOLDERS OF NMC-Wollard, Inc. OPERATION AND MAINTENANCE MANUAL num-

ber 42975

REVISION NO. 3 DATED 07/15/01

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 3 dated 07/15/01

Chapter/Page No. Description of Changes Effectivity

All Funk Transmission Repair Parts Added All

All Air Brakes System Operation, Maintenance

And Repair Parts Added All

TO: HOLDERS OF NMC-Wollard, Inc. OPERATION AND MAINTENANCE MANUAL num-

ber 42975

REVISION NO. 4 DATED 10/30/01

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 4 dated 10/30/01

Chapter/Page No. Description of Changes Effectivity

½ Changed towing load weight from

16,000 lbs to 160,000 lbs

TO: HOLDERS OF NMC-Wollard, Inc. OPERATION AND MAINTENANCE MANUAL num-

ber 42975

REVISION NO. 5 DATED 01/15/02

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 5 dated 01/15/02

Chapter/Page No. Description of Changes Effectivity

Intro/5, 7, 17 Updated Page Revision & TOC

10/1 Updated TOC

10/5-9 Updated Part Index

10/161 38906 Hitch added

PAGE 5

JANUARY 15, 2002

M200 MB4 Tow Tractor Manual No. 42975

REVISION NO. 6 DATED 06-30-02

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 6 dated 06/30/02

Chapter/Page No. Description of Changes Effectivity

Cover Revised to correct model designation all

Introduction/6,7 Revision record updated all

10/16,17 Axle spring part added all

10/141,146,147 Wheel/Tire parts updated

Relays, engine accessories updated all

REVISION NO. 7 DATED 01-02-03

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 7 dated 01-02-03

Chapter/Page No. Description of Changes Effectivity

6,7 Rev 7 added All

1-6,7 Air Brake instruction updated All

10-1,2,5-9,32,33,36-41,44-46,

95,96-105,111,118-121,161,1

62

TOC updated,Index updated, battery,decals and cab

updated. Park brake pads added. Exhaust, frame, fuel sys.

Updates,Trans Sensor added, #NW35892 was corrected,

air sys. updated. Hitch option added.

All

REVISION NO. 8 DATED 07-31-03

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 8 dated 07-31-03

Chapter/Page No. Description of Changes Effectivity

Intro/14-17 TOC updated All

3/2-4,10-16 TOC updated, accumulator maintenance added All

6/6.1,6.2,7 Effectivity Codes moved to pg. 6.2, Rev 8 added All

1/10,15,17,18 Axle lube specs added. Air diagram updated, Fig 9,

Fig 10 Updated

All

2/2,2-7 Air Brake instructions updated. Emergency stop

revised.

All

8/5,6 Park Brake Service added all

10/5-9,13,39,55,94,95,101,102,103

118-121,133,136,137,142-145,162

Parts Index updated, duplicate filler deleted, Caliper

Components added, 43481-1 added, door handle

parts revised,filter element revised, NW35401

Components added, air system updated, 203004

added, blower motor parts added shifter components

added. Alarms added. Winterization kit added.

All

M200 MB4 Tow Tractor Manual No. 42975

PAGE 6

JULY 31, 2004

REVISION NO. 9 DATED 01-31-04

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 9 dated 01-31-04

Chapter/Page No. Description of Changes Effectivity

Intro/6.1,7,12-16 Rev. 9 added, TOC updated, pages renumber All

10/1,2,5-9,21,23,25,27,31,37,39,45

,57-93,95,102-104,143

TOC Updated, Parts index updated, Axle parts

updated,Vendor Part Nos. corrected,YZ17606

added,Funk Transmission Parts updated, heater

updated, NW030236 added

All

REVISION NO. 10 DATED 07-31-04

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 10 dated 07-31-04

Chapter/Page No. Description of Changes Effectivity

Intro/6.1-6.2 Rev. 10 added, Added Eff B&C All

Chapt. 1/1,5-7,12,14,15,17,18 TOC update, park brake indicator added, Updated

schem.#43840, 42989, 43748, 42958 & 43886.

All

Chapt. 2/2-7 Parking brake instructions, pages reformat All

Chapt. 8/1,5-8 TOC update, parking brake service added. Revised

8.10, revised figure 8-3, added figure 8-4.

All

Chapt. 10/1,2,5-9,34-35,94-95,

118-121,

142-147,153,157,161-164

TOC Updated, Parts index updated, updated park

brake lever ill & parts list, added item 9A, update

schem 43840 w/ 44704 parts (EffB&C),#29was

#27, added 37247, NW035383, deleted 41441, added

2 relays and switch to firewall, updated harnesses,

added 44782, pages renumbered

All

REVISION NO. 11 DATED 11/30/05

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 11 dated 11/30/05

Chapter/Page No. Description of Changes Effectivity

Intro/Cover,6.1, 7 Rev. Cover, Rev. 11 added All

2/TOC.2-3.9-10 Update TOC.Update Operator’s Control.Added Certification Letter All

3/TOC.4,6-15 Update TOC.Update Trans. Lubrication, misc. text flow. Add

air/hyd actuator service & inspect air system.

All

8/TOC.5.6-8. Update TOC.Delete Brake Pedal Angle Adjusment. Update adjust

Park Brake Lever, misc. Text flow.

All

10/5-9. 45,49,51.

58-95. 119

Update Parts Index.Misc chgs. Trans repair kits added. Changed

43730 to 45545, add chap 5 ref - 2 places

All

11/ Mfr’s info added for Mico Air/Hyd actuators, Bendix Air Dryer,

Allied Signal Air Brake Valve

All

M200 MB4 Tow Tractor Manual No. 42975

PAGE 6.1

NOVEMBER 30, 2005

REVISION NO. 12 DATED July 31, 2006

Pages that have been revised are outlined below, together with highlights of the revision.

Please delete the affected pages and enter Revision No. 12 dated 07/31/06

Chapter/Page No. Description of Changes Effectivity

Intro/6.2, 7 Revision 12 added All

1/1/18 Update 43886 All

3/1-16 Periodic maintenance wheel bolt torque revised. Pintle hitch

re-torque added. Wheel bolt, 400 ft-lbs was 550.

All

Air brake maintenance added (3.6.5.2 and 3.6.6). All following

pages renumber. TOC updated

All

9/4,7 Wheel bolt, 400 ft-lbs was 550. All

10/21. 39. 45. 162 Kit 45868 added. NW035744-45 added. Kits 45866-7 added. Pintle

hitch bolts updated

All

10/42,43 U-Joint parts and repair kits updated All

REVISION NO. 13 DATED January 31, 2007

Chapter/Page No. Description of Changes Effectivity

Intro/6.2, 7 Revision 13 added All

1/3 It is not uncommon to hear clutches engage........added All

1/9 Bolt torque SAE reference updated All

6/2 Fuel tank removal procedure corrected All

10/42,43 Trans & Axle ends of drive shaft switched, corrected All

REVISION NO. 14 DATED July 31, 2007

Chapter/Page No. Description of Changes Effectivity

3/10-15 Note to restart hydraulic system after draining fluid added, pages

renumber.

Hydraulic

Brakes

EFFECTIVITY CODE

This manual is effective on units having the following serial numbers:

Effectivity Code Serial Numbers

A 13013-00 & later

B 13084-03 & earlier

C 13085-03 & later

M200 MB4 Tow Tractor Manual No. 42975

PAGE 0-7

JULY 31, 2007

REVISIONS RECORD

PAGE 0-7

JULY 31, 2007

M200 MB4 Tow Tractor Manual No. 42975

Rev.

#

Issue

Date

Date

Inserted

Initial

1 02/09/01 02/09/01 NMC-Wollard,

Inc.

2 03/31/01 03/31/01 NMC-Wollard,

Inc.

3 07/15/01 07/15/01 NMC-Wollard,

Inc.

4 10/30/01 10/30/01 NMC-Wollard,

Inc.

5 01/15/02 01/15/02 NMC-Wollard,

Inc.

6 06/30/02 06/30/02 NMC-Wollard,

Inc.

7 01/02/03 01/02/03 NMC-Wollard,

Inc.

8 07/31/03 07/31/03 NMC-Wollard,

Inc.

Rev.

#

Issue

Date

Date

Inserted

Initial

9 01/31/04 01/31/04 NMC-Wollard,

Inc.

10 07/31/04 07/31/04 NMC-Wollard,

Inc.

11 11/30/05 11/30/05 NMC-Wollard,

Inc.

12 07/31/06 07/31/06 NMC-Wollard,

Inc.

13 01/31/07 01/31/07 NMC-Wollard,

Inc.

14 07/31/07 07/31/07 NMC-Wollard,

Inc.

GENERAL SPECIFICATIONS

M200 MB4 Tow Tractor Manual No. 42975

PAGE 8

JULY 15, 2001

Type of Vehicle:

Four Wheel Drive, Four Wheel Steer, Model 200 Towing Tractor

Gross Weight -----------------------------19,600 lbs.

Drawbar Pull -----------------------------16,000 lbs.

DBP/GVW may vary ±15%. DBP measured at 14”.)

Turning Radius (4 Wheel) --------------------------130”

Turning Radius (2 Wheel) --------------------------210”

Speed, Front ----------------------------25mph+/-1.5

Speed, Rear -------------------------------2.4mph

Fuel Tank

Capacity ----------------------------20.7 Gals. (78.3 L)

Cooling System

Capacity ----------------------------------40qts.

Pressure Cap--------------------------------14psi.

Front Axle

Make -----------------------------Clark Hurth (Dana)

Ratio ------------------------------------12.3:1

Type ---------------------------Steerable, Fixed Center

Rear Axle

Make -----------------------------Clark Hurth (Dana)

Ratio ------------------------------------12.3:1

Type -------------------------Steerable, Oscillating Center

ENGINE AND TRANSMISSION SPECIFICATIONS

Transmission

Make ................ Funk

Type . . Power Shift W/Torque Converter

Model ................ 2000

Fluid .................. C3

Filter ....Converter Mounted Cartridge

Part No. ............ NW32664

Suction Screen Assembly Part No. 37075

Gear Ratios

Forward

F1.................. 5.5:1

F2................. 3.53:1

F3................. 2.94:1

F4................. 2.00:1

F5................. 1.41:1

F6.................. .80:1

Reverse

R1.................. 5.2:1

R2................. 3.53:1

R3................. 1.41:1

Engine For Tractor w/Hydraulic Brake

Model..........Cummins6BT5.9

Displacement .............5.9

Horsepower @2200 RPM.... 152BPH

Torque @1200 RPM......414ft.lbs.

Number of Cylinders...........6

Firing Order .......... 1.5.3.6.2.4

Aspiration.........Turbo Charged

Cooling ..................

Coolant Capacity ..........40qt.

Thermostat ..........181deg. F

Oil Capacity............17.3 qt.

Engine For Tractor w/Air Brakes

Model..........Cummins6BT5.9

Displacement .............5.9

Horsepower @2200 RPM.... 148BPH

Torque @1600 RPM......440ft.lbs.

Number of Cylinders...........6

Firing Order .......... 1.5.3.6.2.4

Aspiration.........Turbo Charged

Cooling ...............Liquid

Coolant Capacity ..........40qt.

Thermostat ..........181deg. F

Oil Capacity 17.3 qt.

CORROSION PROOFING

All frame and body surfaces are shot

blasted, primed and painted with weather

resistant paint. Standard bolts are SAE

grade 5, zinc-phosphate coated to resist

corrosion.

STANDARD EQUIPMENT

Four wheel drive

Power Shift transmission

Four wheel steering, coordinated/crab/2

wheel

Engine shutdown system

Spark arresting muffler

Cab assembly

Heater/defroster

Suspension seat, driver’s

Passenger seat

Seat belts

Mirror kit

Gauges, full instrumentation

Hi-low beam headlights

Rotating beacon, amber

Spotlight, rear center

Turn signals

Fire extinguisher (2)

Coupler-Holland PH30 front and rear

Air transportable per MIL-STD-1791

Paint: Dark green or desert sand

OPTIONAL EQUIPMENT

Undercoating

Ozone protection for tires

M200 MB4 Tow Tractor Manual No. 42975

PAGE 9

JULY 15, 2001

1 YEAR LIMITED WARRANTY

NMC-Wollard, Inc.

NMC-Wollard, Inc. warrants to the original owner that all components of the equipment are

free from defects in material and workmanship under normal use and service for 12 months

or 1,000 hours, whichever comes first, from the date of shipment.

This warranty provides for NMC-Wollard, Inc. equipment components that fail because of

defects in material or workmanship during the warranty period, without charge to the owner

for parts or labor. The owner must provide prompt notice of the defect and allow a reason-

able time for replacement or repair.

This warranty applies only to parts manufactured by NMC-Wollard, Inc. Components in-

stalled on NMC-Wollard, Inc. equipment but not manufactured by NMC-Wollard, Inc. shall

be covered under the original manufacturer's warranty. NMC-Wollard, Inc. will assist in ad-

ministering all such warranties, with the exception of tires, battery, and other expendable

parts, for which the owner will be required to deal directly with the original manufacturer for

warranty service. Neither tune-ups, normal maintenance and repair or replacement of ex-

pendable parts (such as oil, lubricants, belts, filters, tires, battery, etc.) are covered by this

warranty.

This warranty does not cover damage resulting from carelessness or neglect; accidents,

fire, or other casualties; improper repair, operation, transportation, or storage; or failure to

provide necessary or appropriate maintenance. This warranty does not cover deterioration

or failure caused by chemicals, falling objects, dirt and sand, or excessive heat or moisture.

The NMC-Wollard, Inc. equipment must be maintained according to the instructions pro-

vided with it or this warranty may be considered void. Warranted components must be re-

placed with parts manufactured or approved by NMC-Wollard, Inc. Warranty determination

will be made after NMC-Wollard, Inc. inspects the failed part.

NMC-Wollard, Inc. is not liable for damage or injury resulting from improper installation,

use, abuse, inability to use or misapplication of NMC-Wollard, Inc. equipment, nor is

NMC-Wollard, Inc. liable for damage resulting from equipment repaired or modified by per-

sons not authorized by NMC-Wollard, Inc. NMC-Wollard, Inc. does not warrant any part or

product to meet local, municipal, state, provincial, or national laws or regulations.

This Limited Warranty is in lieu of all other warranties, whether express, implied, or statu-

tory. No other express warranty is given or authorized by NMC-Wollard, Inc. NMC-Wollard,

Inc. expressly disclaims any implied warranty of merchantability or fitness for a particular

purpose or otherwise. NMC-Wollard, Inc. shall not be liable for loss of use of equipment,

loss of time, loss of business, or for any other incidental, or consequential damages. No

authorized NMC-Wollard, Inc. representative has the right to change or modify this war-

ranty in any respect.

This warranty is non-transferable.

M200 MB4 Tow Tractor Manual No. 42975

PAGE 10

JULY 15, 2001

TO OBTAIN WARRANTY SERVICE

Warranty can be obtained by contacting NMC-Wollard, Inc., 2021 Truax Blvd., Eau Claire,

WI. 54702, (Phone 715 835-3151) (Fax 715 835-6625).

What should you do when you receive a new unit?

Check that you have received all the equipment ordered. Check inside the product manual

for engine warranties. Some OEM manufacturers supply a registration card that must be

filled out and returned immediately to initiate the warranty. If a survey card or delivery

checklist is enclosed from NMC-Wollard, Inc. please return it.

What should you do when you discover a possible warranty problem?

Call NMC-Wollard, Inc. (715-835-3151). We will require the serial number, number of hours

on the unit, and a description of the problem. You will be given a warranty authorization

number and assistance in troubleshooting.

IMPORTANT!

Clear and immediate communication with the factory is the key to obtaining a satisfactory

and timely resolution of your warranty problem.

Every warranty situation is different and so there are no hard rules. We will work with your

maintenance personnel and service managers to equitably resolve all claims.

What should you do after warranty problem has been resolved?

Complete and return the warranty claim form within 10 days. Place the assigned warranty

authorization number we gave you when you first called us with the problem on your claim.

Return defective parts immediately. Your claim cannot be processed until all defective parts

have been returned to NMC-Wollard, Inc. Identify returned parts with the assigned warranty

authorization number.

What should you use for labor rate and labor time?

Labor rate are reviewed annually, if you do not have an established rate, call NMC-Wollard,

Inc. We do not publish a rate book; instead, we have accumulated average times for re-

pairs. We will authorize repair time once we have approved the repair. If unforeseen cir-

cumstances cause a significantly greater repair time than originally approved, please

contact us before submitting your claim.

M200 MB4 Tow Tractor Manual No. 42975

PAGE 11

JULY 15, 2001

TABLE OF CONTENTS

PAGE 12

JANUARY 31, 2004

M200 MB4 Tow Tractor Manual No. 42975

Intro TOC

INTRODUCTION AND DESCRIPTION OF TRACTOR ...............1-1

OPERATION .....................................2-1

PREVENTIVE MAINTENANCE AND GUIDELINES FOR REPAIR .........3-1

ENGINE........................................4-1

TRANSMISSION ...................................5-1

FUEL TANK......................................6-1

STEERING ......................................7-1

BRAKES .......................................8-1

AXLES, DRIVE SHAFTS, AND WHEELS ......................9-1

ILLUSTRATED PARTS BREAKDOWN .......................10-1

GENERAL SAFETY PRECAUTIONS

INSTRUCTIONS FOR OPERATORS

Safety is your business. Obey the rules of the road, be alert at all times, operate the vehicle

defensively, stop at all intersections, be aware of all clearances, and obey special safety

regulations.

1. When approaching other traffic, slow down, sound horn, and if vision is obstructed, keep

right. Under all conditions, with a load or without, operate at a speed that will permit you to

come to a stop safely.

2. Use special care when operating on inclines. Travel slowly and do not angle or turn.

3. Do not operate on excessive grades.

4. Tow the tractor only with the drive shafts disconnected. Failure to do so will damage the

transmission.

5. Maintain a safe distance from the edge of ramps and platforms.

6. Observe all traffic regulations including speed limits.

7. Under normal traffic conditions, keep to the right.

8. Maintain a safe distance from the vehicle ahead and always keep the tractor under con-

trol.

9. Conform to local traffic regulations when operating on public roads.

10. Never allow anyone to ride on the tractor with you except in the passenger seat.

PAGE 13

JANUARY 31, 2004

M200 MB4 Tow Tractor Manual No. 42975

IMPORTANT!

There are numerous variations in procedures, techniques, tools, and parts for servicing

the tractor, as well as in the skill of the individual doing the work. This manual cannot pos-

sibly anticipate all such variations and provide advice or cautions as to each. Accordingly,

anyone who does not follow the instructions provided in this manual must first make sure

that they do not endanger their personal safety or tractor integrity by their choice of meth-

ods, tools, or parts.

This manual describes processes which might require the use of chemicals, solvents,

paints, or other commercially available material. Users of this manual should obtain the

material safety data sheets (OSHA Form 20 or equivalent) from the manufacturers or sup-

pliers of any materials to be used.

Know and follow the instructions provided by the manufacturer/supplier for the safe han-

dling, use, storage, and disposal of these materials.

Prior to starting any task, first read

the WARNINGS or CAUTIONS in-

cluded in the text for that task.

11. Avoid abrupt moves. Be a professional driver and HANDLE WITH CARE.

12. When towing loads, take extra care in securing and transporting the load.

13. Watch out for obstructions. Check overhead clearances.

14. If the tractor has to be parked on an incline, set the parking brake and chock the wheels.

15. Report accidents involving persons, building structures, and equipment to the proper au-

thority.

INSTRUCTIONS FOR MAINTENANCE PERSONNEL

1. Before attempting to repair the tractor, read and understand the maintenance proce-

dures.

2. Only qualified and authorized persons should be permitted to maintain, repair, adjust, and

inspect the tractor.

3. Properly vent the work area.

4. Avoid fire hazards and have fire protection equipment present. Do not use open pans of

fuel or flammable fluids for cleaning parts.

5. Brakes, steering mechanisms, warning devices, lights, safety guards, etc., should be in-

spected regularly and maintained in a safe operating condition.

6. Keep the tractor clean to lessen fire hazards and allow loose or defective parts to be better

seen.

7. Before working on the tractor, make sure jacks and jack stands have a lifting capacity of at

least 10,000 lbs.

8. Prevent water from entering into internal tractor parts. Before cleaning, be sure all open-

ings are closed or covered.

9. Sparks or open flames in the maintenance area are dangerous. Explosive vapor can eas-

ily escape from a vehicle into the work area.

10. Never add engine oil from a jug or a bottle. The chance of contamination is too great. Use

oil from a sealed container.

11. Keep unnecessary personnel away from tractor while it is running.

12. Only one person must control the engine.

13. Operate engine only from the driver’s seat.

14. Properly disposal of all used fluids. If you do not know the proper disposal procedures,

read the labels or ask your supervisor.

PAGE 14

JANUARY 31, 2004

M200 MB4 Tow Tractor Manual No. 42975

PRODUCT SAFETY

A brief description of signal words that may be used in this manual:

Indicates an imminently hazardous situation that, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided could result

in death or serious injury, and indicates hazards that are exposed when guards are re-

moved.

Indicates a potentially hazardous situation that, if not avoided may result in

minor or moderate injury.

PAGE 15

JANUARY 31, 2004

M200 MB4 Tow Tractor Manual No. 42975

B,C (CALIFORNIA ONLY)

D (ON RADIATOR)

(SEE SAFETY DECALS

ON NEXT PAGE)

Read all safety signs on the machine and in this manual. Replace any

lost or damaged signs by ordering the part numbers shown on the safety decals

page.

SAFETY DECALS

SAFETY SIGN CARE

•Keep Safety Signs Clean And Legible At All Times.

•Replace Safety Signs That Are Missing Or Have Become Illegible.

•Replaced Parts That Displayed A Safety Sign Should Also Display The Current Sign.

•Safety Signs Are Available Form Your Dealer.

•

HOW TO INSTALL SAFETY SIGNS

•Be Sure That The Installation Area Is Clean And Dry.

• Remove The Smallest Portion Of The Split Backing Paper.

• Align The Decal Over The Specified Area And Carefully Press The Small Portion With The

Exposed Adhesive Backing In Place.

• Remove Second Backing And Press Remaining Decal In Place.

PAGE 16

JANUARY 31, 2004

M200 MB4 Tow Tractor Manual No. 42975

WARNING

PARKING BRAKE NOT TO BE

USED FOR SERVICE BRAKE

APPLY PARKING BRAKE

BEFORE STARTING ENGINE

APPLY PARKING BRAKE

BEFORE LEAVING VEHICLE

DECAL B. PART NO. NW17237

DECAL C. PART NO. 41472

DECAL D. PART NO. 1018145

1 INTRODUCTION AND DESCRIPTION OF TRACTOR

PAGE 1-1

JULY 31, 2004

M200 MB4 Tow Tractor Manual No. 42975

Chapter 1 TOC

1.1 PURPOSE OF THIS MANUAL ...........................2

1.2 ARRANGEMENT OF THIS MANUAL........................2

1.3 DESCRIPTION OF THE TRACTOR ........................2

1.3.1 FRAME ....................................2

1.3.2 ENGINE FOR TRACTOR W/HYDRAULIC BRAKES .............2

1.3.3 ENGINE FOR TRACTOR W/AIR BRAKES ..................2

1.3.4 COOLING SYSTEM ..............................2

1.3.5 TRANSMISSION ...............................2

1.3.6 LUBRICATION SYSTEM ...........................3

1.3.7 FUEL SYSTEM ................................3

1.3.8 FUEL CAPACITY ...............................3

1.3.9 AIR CLEANER ................................3

1.3.10 EXHAUST SYSTEM .............................3

1.3.11 CORROSION PROOFING ..........................3

1.3.12 TIRES ....................................3

1.3.13 ELECTRICAL SYSTEM ...........................3

1.3.13.1 BATTERY ...............................4

1.3.13.2 ALTERNATOR .............................4

1.3.13.3 CURRENT REGULATOR .......................4

1.3.13.4 STARTER ...............................4

1.3.13.5 LIGHTS AND ACCESSORIES .....................4

1.3.14 INSTRUMENT PANEL FOR TRACTOR W/HYDRAULIC BRAKES .....5

1.3.15 INSTRUMENT PANEL FOR TRACTOR W/AIR BRAKES ..........5

1.3.16 DRIVE/STEERING AXLES .........................7

1.3.17 BRAKE SYSTEM ..............................7

1.3.17.1 SERVICE BRAKE ...........................7

1.3.17.2 PARKING BRAKE FOR TRACTOR W/HYDRAULIC BRAKES ....7

1.3.17.3 PARKING BRAKE FOR TRACTOR W/AIR BRAKES .........7

1.3.17.4 PARKING BRAKE SHUTDOWN ....................7

1.3.18 STEERING SYSTEM ............................7

1.3.19 BOLT TIGHTENING DATA .........................9

1.3.20 FLUID SPECIFICATIONS .........................10

1.3.21 SCHEMATICS AND DIAGRAMS ......................11

1.1 PURPOSE OF THIS MANUAL

This manual is meant to provide the infor-

mation necessary to operate, maintain, and

repair the aircraft towing tractor (“tractor”),

model number 200, manufactured by

NMC-Wollard, Inc., Eau Claire, WI 54702,

phone 715-835-3151.

1.2 ARRANGEMENT OF THIS MANUAL

This manual is divided into Sections. Sec-

tions 1 through 9 are the introduction, spec-

ification, preventive maintenance,

operation, and repair sections.

Section 10 is the Illustrated Parts Break-

down (IPB). The IPB shows all parts and

part numbers necessary for support of the

tractor. The IPB can be used for requisition-

ing and identifying parts. It is arranged in al-

phabetical order.

1.3 DESCRIPTION OF THE TRACTOR

The tractor is designed for towing loads

weighing up to 160,000 lbs. Towing cou-

plers are on the front and rear of the tractor.

The four-wheel-drive tractor operates like

most automotive vehicles powered by an in-

ternal combustion engine. The major differ-

ence between this tractor and an

automobile having a similar size engine is

the higher gear ratio in the rear axle. The

higher gear ratio allows great pulling (tow-

ing) ability.

1.3.1 Frame

Heavy-duty precision aligned, 1-piece struc-

ture. Main frame plates are 1.25” thick. Side

panels and fenders are .75” thick. Front and

rear bumpers are 1.00” thick.

1.3.2 Engine for Tractor w/Hydraulic

Brakes

Cummins 6BT5.9, 6 Cylinder, 5.9 Liter, 152

BPH @ 2200 rpm, Torque 414 ft. lbs. @

1200 rpm.

1.3.3 Engine for Tractor w/Air Brakes

Cummins 6BT5.9, 6 Cylinder, 5.9 Liter, 148

BPH @ 2200 rpm, Torque 440 ft. lbs. @

1600 rpm.

1.3.4 Cooling System

40 quart coolant capacity for engine-radia-

tor system. Radiator insulated from vibra-

tion.

1.3.5 Transmission

Standard Funk 2000 Power Shift automatic

with 6 speed forward and 3 reverse, full

time four wheel drive (4x4), canister type oil

filter, separate transmission fluid cooler,

gear-driven pump for power steering and

brakes. Integral no-spin differential allows

front and rear axles to rotate independently-

prevents drive line windup and stress. No

spin feature joins axles together for maxi-

mum tractive effort if wheel slippage occurs.

Forward and reverse speed ranges are ob-

tained through the use of hydraulically actu-

ated multiple disc clutches. these clutches

are power absorbing members that can be

engaged at full engine power. Shifting un-

der full engine power makes this model a

full power shift for the forward and reverse

motion in all four speeds.

The clutches in this unit are hydraulically

applied and spring released. Because

wear, which eliminates the need for adjust-

ment. Each clutch uses eleven semi metal-

lic friction plates, and eleven polished steel

M200 MB4 Tow Tractor Manual No. 42975

PAGE 1-2

OCTOBER 30, 2001

Table of contents

Other NMC-WOLLARD Tractor manuals

Popular Tractor manuals by other brands

AGCO

AGCO FENDT 1000 Vario Operator's manual

AGCO

AGCO Massey Ferguson 4400 Series manual

Euro Systems

Euro Systems Euro5RG EVO Translation of original user instructions

Ventrac

Ventrac 3000 Owner's/operator's manual

MacDon

MacDon M2170NT Unloading and assembly instructions

Takeuchi

Takeuchi TW9 operating instructions

AGCO

AGCO Challenger MT255B Service manual

Minsk Tractor Works

Minsk Tractor Works Belarus 1221B.2 Disassembly-assembly manual

Kalmar

Kalmar DCF100-45E7 Operator's manual

TYM

TYM 5025C Operator's manual

AGCO

AGCO Challenger MT845E Workshop service manual

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries BD2G manual