Noble 495HTGW22 User manual

NOBLE WAREWASHING - GLASSWASHER - 495HTGW22

USER MANUAL

GENERAL INSTRUCTIONS

FOR INSTALLATION, USE

AND MAINTENANCE

Glasswasher

495HTGW22

12318950

495HTGW22 User Manual Revised 09/22

9900857

CONFORMS TO UL STD. 921

CERT. TO CSA STD. C22.2 Nº168

9900857

CONFORMS TO STD.

NSF/ ANSI 3-2019

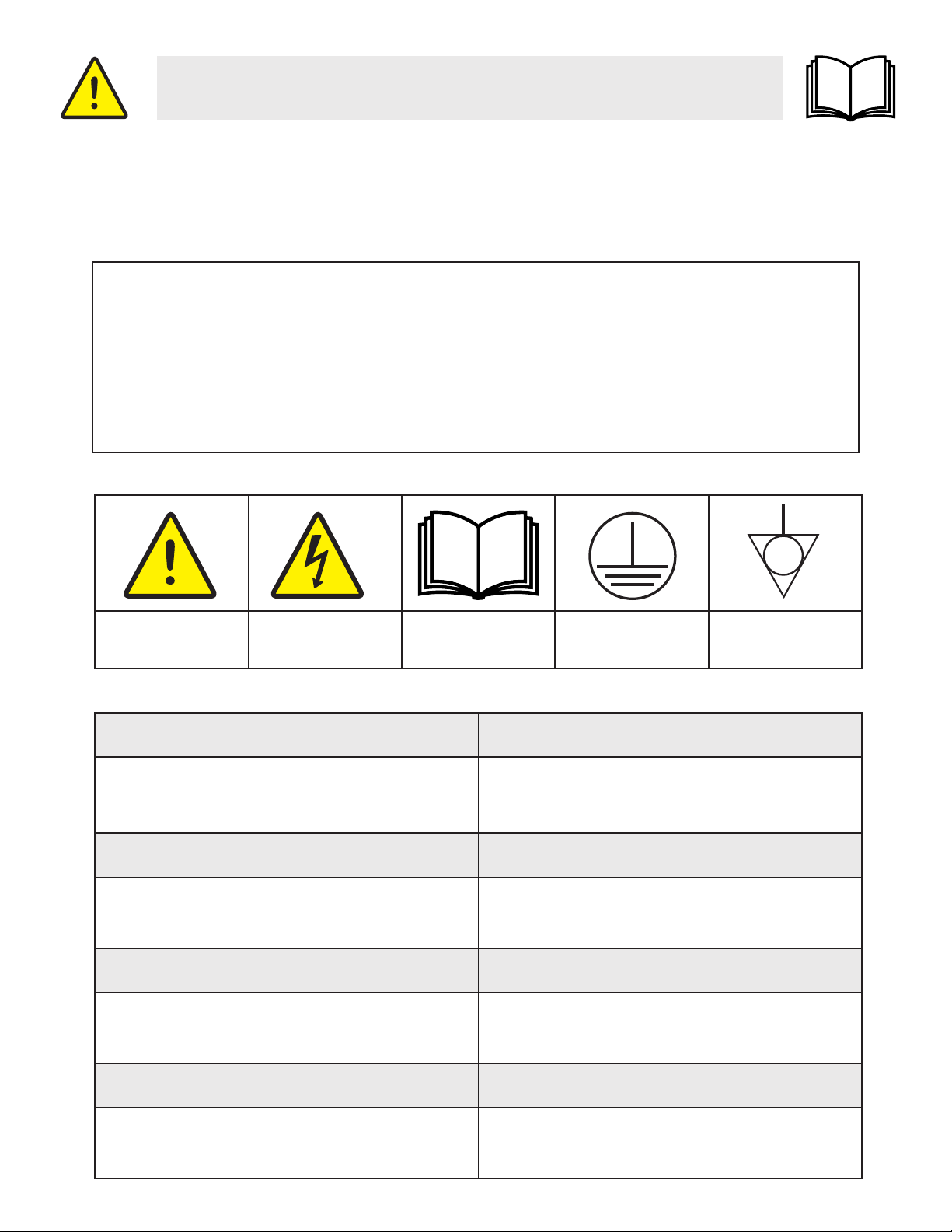

READ FIRST

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING HAZARDOUS

VOLTAGE

PLEASE READ

INSTRUCTIONS

PROTECTIVE

EARTH

EQUIPOTENTIAL

BONDING

Model: Purchased From:

495HTGW22

Serial: Location:

Date Purchased: Date Installed:

Purchase Order: For Service, call:

TABLE OF CONTENTS

3

1. INDEX

1. INDEX ..................................................................................................................................... 3

2. GENERAL INFORMATION AND WARNINGS ....................................................................... 4

3. GENERAL MEASUREMENTS AND CONNECTIONS .......................................................... 5

4. QUICK STARTUP GUIDES ................................................................................................... 6

5. ELECTRICAL DIAGRAMS..................................................................................................... 7

6. ELECTRIC DIAGRAMS LEGEND ......................................................................................... 8

7. PRODUCT DETAILS ............................................................................................................. 9

7.1 Technical specications ................................................................................................ 10

8. INSTALLATION INSTRUCTIONS ........................................................................................ 11

8.1 Removal of packaging ................................................................................................. 11

8.2 Positioning and leveling ............................................................................................... 11

8.3 Electrical connection .................................................................................................... 12

8.4 Water connection ......................................................................................................... 13

8.5 Drainage connection..................................................................................................... 14

8.6 Liquid rinse aid dispenser ............................................................................................ 16

8.7 Detergent dispenser .................................................................................................... 16

8.8 Recycling ..................................................................................................................... 18

9. USE AND MAINTENANCE INSTRUCTIONS ...................................................................... 19

9.1 Operation ..................................................................................................................... 19

9.1.1 Control panel symbols .............................................................................................. 19

9.1.2 Switching on the machine ......................................................................................... 19

9.1.3 Hygiene practices ..................................................................................................... 20

9.1.4 Preparation of the dishes .......................................................................................... 21

9.1.5 Selecting the wash cycle .......................................................................................... 21

9.1.6 Stopping the wash cycle and end of wash cycle ...................................................... 22

9.1.7 Drainage of the machine ........................................................................................... 22

9.1.8 Switching off the machine ......................................................................................... 24

9.1.9 Cleaning the machine at the end of the day ............................................................. 24

9.2 Cleaning and Maintenance Instructions ....................................................................... 24

9.2.1 Routine maintenance ................................................................................................ 24

9.2.2 Rinse aid and detergent ............................................................................................ 25

9.2.3 Prolonged non use .................................................................................................... 25

10. FAULTS AND TROUBLESHOOTING ................................................................................. 26

GENERAL INFORMATION AND WARNINGS

4

2. GENERAL INFORMATION AND WARNINGS

This manual has been created to help you understand the operation, installation and maintenance

of the machine. It contains all the necessary information and warnings to ensure that the appliance

is installed and used correctly, together with information about the characteristics and possibilities

offered, so that you may enjoy your machine to the fullest.

BEFORE STARTING THE APPLIANCE, PLEASE READ THE INSTRUCTIONS

CONTAINED IN THIS MANUAL CAREFULLY.

The manual should be kept safely on hand for future reference.

If the machine is sold or transferred, please pass the manual to the new user.

THIS APPLIANCE IS EXCLUSIVELY FOR PROFESSIONAL USE AND SHOULD ONLY

BE USED BY QUALIFIED PERSONNEL.

• The positioning and installation, and all repairs or modications, should always be carried out

by an AUTHORIZED TECHNICIAN, in accordance with the applicable local legislation. The

manufacturer does not accept liability if the machine is incorrectly installed.

• The installation, incorrect adjustment, inappropriate maintenance or use of the appliance may

cause material damages and injuries.

• The dishwasher should be correctly leveled, and care taken to ensure that none of the electric

cables, water or drainage hoses are trapped or kinked.

• DO NOT climb on top of the dishwasher or place heavy objects on top of the machine as it has

only been designed to bear the weight of the basket of plates to be washed.

• The dishwasher is designed for washing plates, glasses and other kitchenware with

traces of human food. Any other objects must not be washed in the machine.

• If your machine breaks down, please contact authorized dealer.

• Unqualied or unauthorized personnel must NOT try to repair the machine.

• Use of spare parts other than original parts will cancel the guarantee.

• During all maintenance operations, the dishwasher must be disconnected from the main

power supply at the mains power switch, and the water intake tap must be closed.

• Abrasive or corrosive products, acids, solvents and chlorine-based detergents must

NOT be used to clean the appliance, as this may damage the components.

• Detergents or sanitizers shall not be manually added to the machine.

• This appliance has been designed for use in ambient temperatures between 41 ºF

and 104 ºF

Failure to comply with these instructions or the incorrect use of the appliance shall

relieve the manufacturer of any obligations regarding the guarantee or possible

claims.

GENERAL MEASUREMENTS

5

3. GENERAL MEASUREMENTS AND CONNECTIONS

Glasswasher 495HTGW22

A B C D E F G

Water Inlet Drain Hose

Power Supply

Cable Strain

Relief

Connection

Strip (Inside) Rinse Aid Inlet Detergent

Inlet

Equipotential

Bond

QUICK STARTUP GUIDES

6

4. QUICK STARTUP GUIDES

8

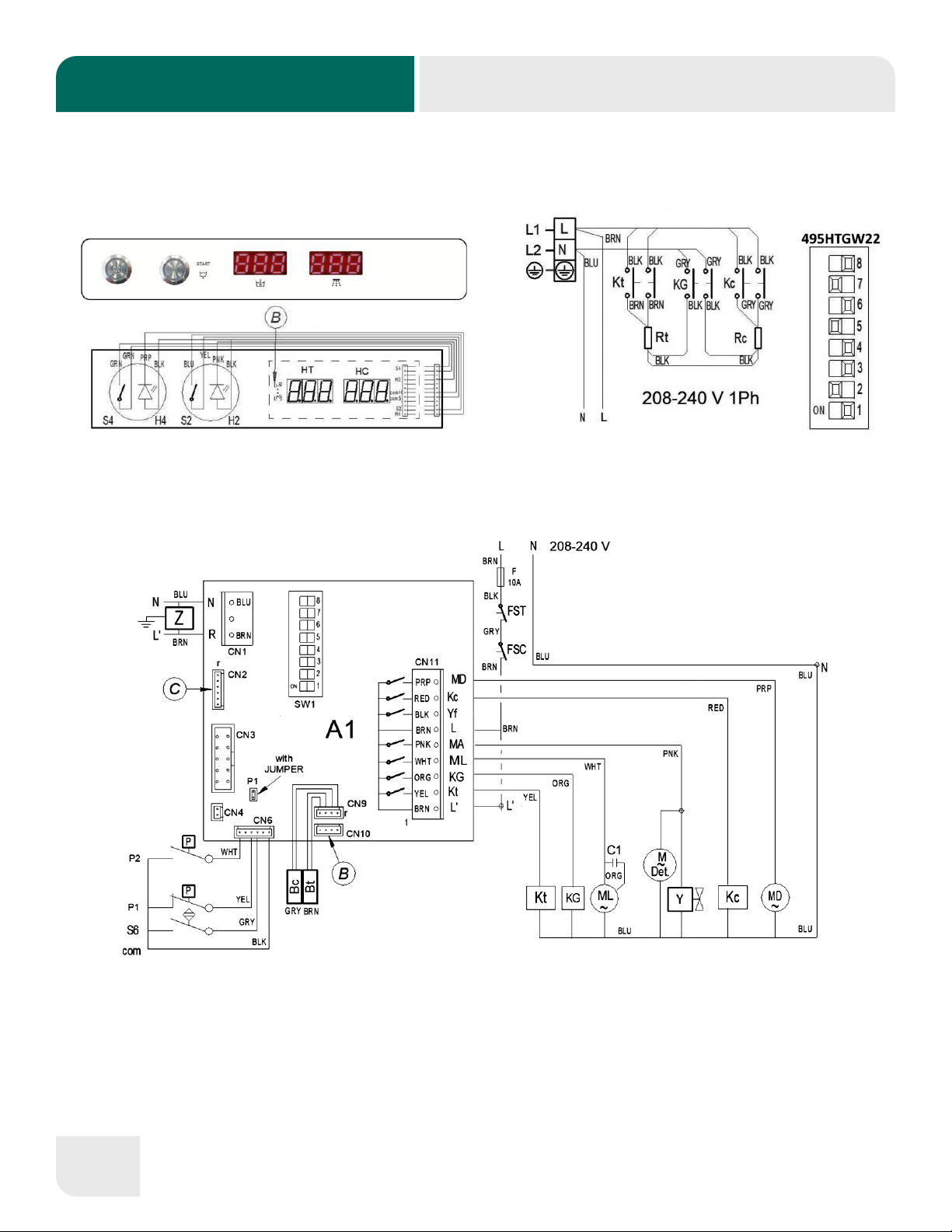

ELECTRICAL DIAGRAMS

7

5. ELECTRICAL DIAGRAMS

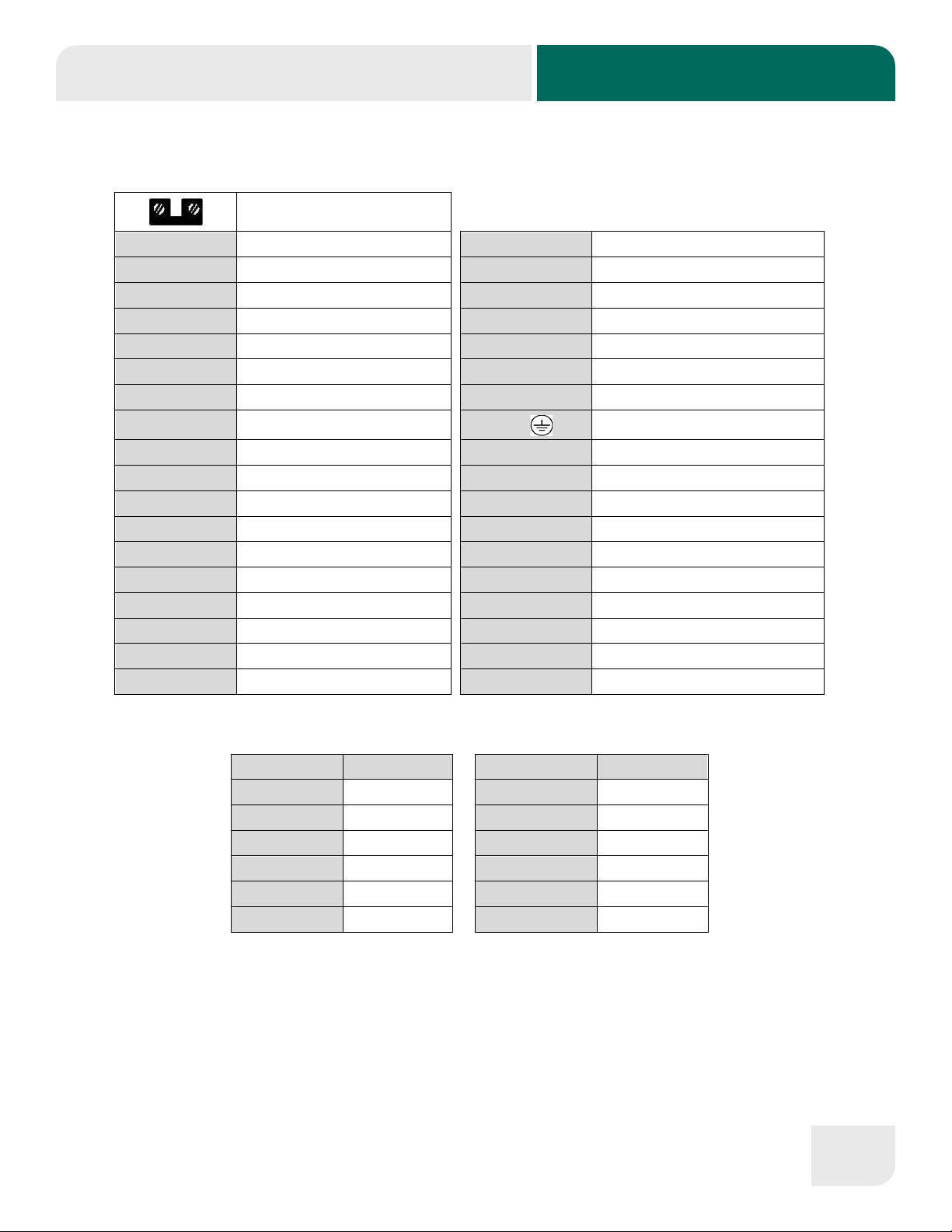

ELECTRICAL DIAGRAMS LEGEND

8

6. ELECTRICAL DIAGRAMS LEGEND

11

5. ELECTRIC DIAGRAMS LEGEND

Terminal block bridge

A1, A2

Electronic Board

MD

Drain Pump

A1-P1

Electric Bridge / Jumper

MDet

Detergent Dispenser

Bc

Boiler temperature probe

ML, ML1, ML2

Wash Pump

Bt

Tank Temperature Probe

N

Neutral

C1, C2

Capacitor

P1

Tank Pressure Switch

F

Fuse

P2

Tank Safety Pressure Switch

FSC

Boiler Safety Thermostat

P3

Boiler Pressure Switch

FST Tank Safety Thermostat PE /Earth Ground

H1, H2, H3

Cycle Light

RC

Boiler Heating Element

H4

Power On Light

RT

Tank Heating Element

HC

Boiler temperature Display

S1, S2, S3

Program/Cycle Push button

HT

Tank Temperature Display

S4

ON/OFF Push button

KC

Boiler Heating Contactor

S6

Door Switch

KG

Main Relay

SW1

DIP-SWITCH

KT

Tank Heating Contactor

TRF

Transformer

L, L1, L2, L3

Power Supply Phases

Y

Tank Filling Solenoid valve

MAbr

Rinse Aid Dispenser

Yf

Boiler Filling Solenoid valve

MA

Rinse Pump

Z

EMC Filter

COLOR COLOR

BLK, bk, n

Black

PNK, pk, rs

Pink

BLU, bl, a

Blue

PRP, pr, vi

Purple

BRN, bn, m

Brown

RED, rd, r

Red

GRN, gn, ve

Green

WHT, wh, b

White

GRY, gy, g

Grey

YEL, yw, am

Yellow

ORG, or, na

Orange

YW/GN, am/ve

Yellow / green

PRODUCT DETAILS

9

7. PRODUCT DETAILS

As it is an industrial product, it is characterized for having a high dishwashing capacity. The

characteristics of the product are listed below to help you understand your machine better.

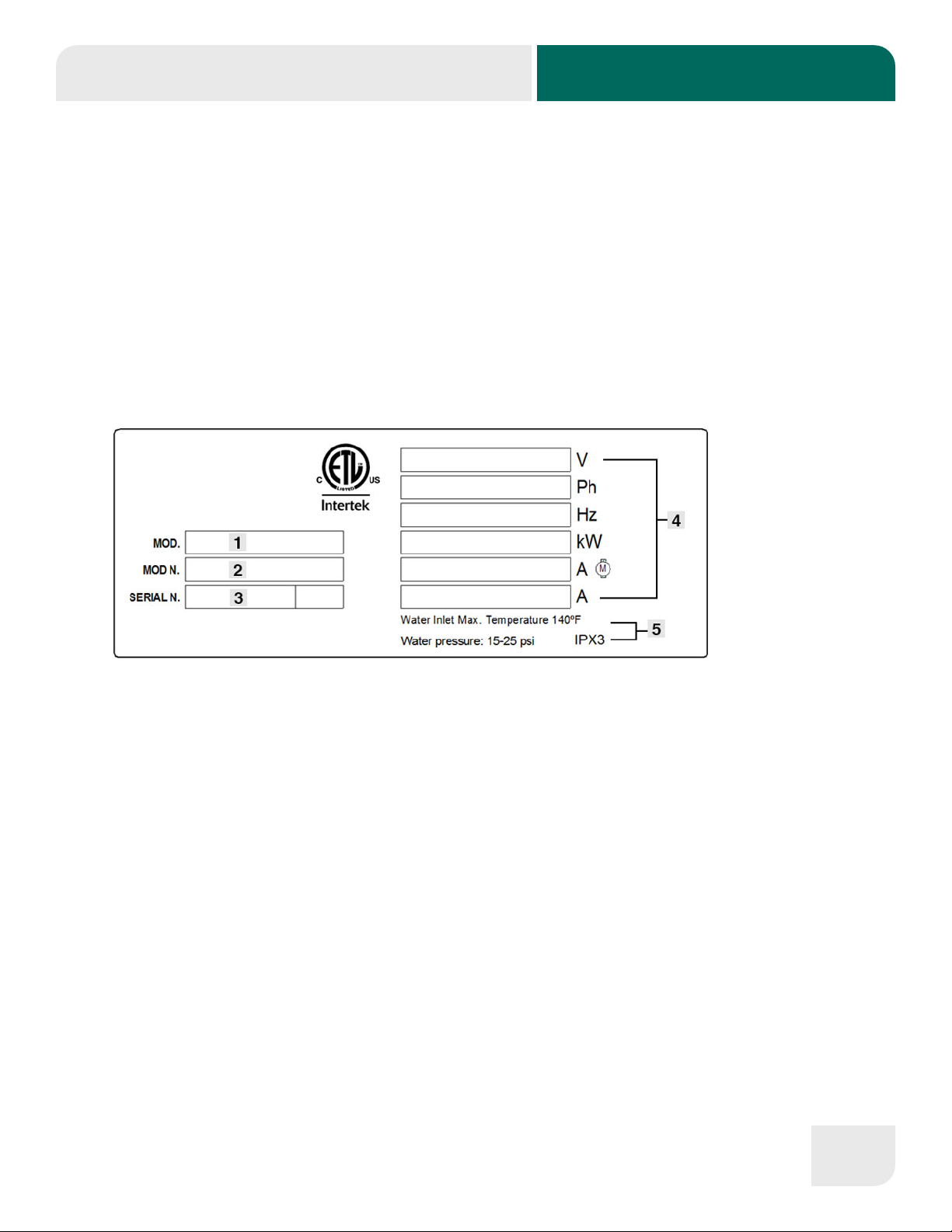

All the appliances have a nameplate which identies the appliance and indicates its technical

characteristics. Under no circumstances should the data plate be removed from the unit. The data

plate is essential to identify the particular features of your machine and is of great benet to installers,

operators and maintenance personnel. It is recommended that, in the event the data plate is removed,

you copy down the essential information in this manual for reference before installation.

DATA PLATE

☐1: APPLIANCE MODEL NAME

☐2: APPLIANCE REFERENCE

☐3: SERIAL NUMBER + MANUFACTURE DATE

☐4: ELECTRICAL SPECIFICATIONS

☐5: WATER INLET SPECIFICATIONS

These details should be quoted when the technical service is called.

PRODUCT DETAILS

10

7.1 Technical Specications

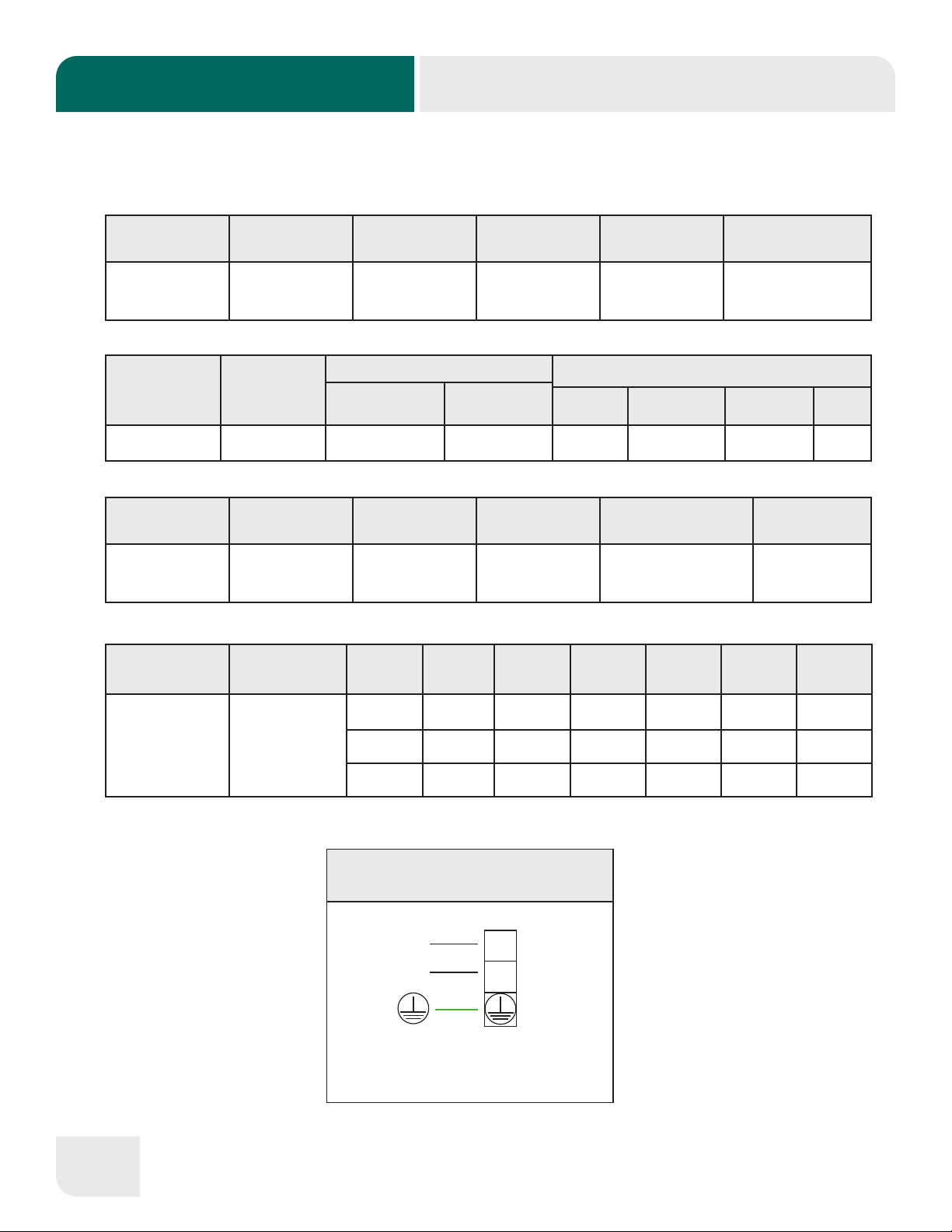

MODEL RACKS PER

HOUR

WASH TANK

(Gal)

GALLONS PER

CYCLE

WATER INLET

MAX TEMP.

WATER INLET

PRESSURE

Glasswasher -

495HTGW22 22 4 0.53 140º F At Pressure Gauge

20psi ± 5psi

MODEL WIDTH DEPTH HEIGHT MAX CLEARANCE

FOR DISHWARE RACK

Glasswasher -

495HTGW22 20 7/8” 26 3/4” 35 10 5/8” 16” x 16”

MODEL WASH PUMP

MOTOR

HEATING ELEMENTS OPERATING CYCLE TIME (s)

WASH TANK (kW) BOILER (kW) WASH DWELL RINSE TOTAL

Glasswasher -

495HTGW22 1/3 hp 2.15 3 101 5 14 120

MODEL CONNECTION

TYPE

VOLTAGE

(V)

TOTAL

LOAD (A)

TOTAL

POWER

(kW)

PUMP

LOAD (A)

PUMP

POWER

(kW)

TANK

POWER

(kW)

BOILER

POWER

(kW)

Glasswasher -

495HTGW22

208-240V

60Hz

1Ph

208V 12.03 2.50 1.02 0.21 1.64 2.29

220V 12.73 2.80 1.08 0.24 1.83 2.56

240V 13.88 3.33 1.18 0.28 2.18 3.05

Glasswasher - 495HTGW22

L1

L

L2 N

208-240V, 60HZ, 1PH

INSTALLATION INSTRUCTIONS

11

8. INSTALLATION INSTRUCTIONS

The dishwasher shall be installed in accordance with local codes, or in the absence of

local codes, installed in accordance with the applicable requirements in the National

Electrical Code, NFPA 70, Canadian Electrical Code (CEC), Part 1, CSA C22.1, and

Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations,

NFPA 96.

The positioning and installation, and all repairs or modications, should always

be carried out by an AUTHORIZED TECHNICIAN, in accordance with the applicable

legislation of the country.

The installation, incorrect adjustment, inappropriate maintenance or use of the appliance

may cause material damages and injuries.

8.1 Removal of packaging

Remove packaging from the machine and check for damage during transportation. If any damage is

observed, immediately notify the supplier and the transport company. In the event of doubt, do not use

the machine until the problem has been assessed.

Packaging (plastic, expanded polyurethane, staples, etc…) must not be left

in the reach of children, they are a potential hazard.

The machine should be moved using a fork-lift truck or similar to avoid damage to the structure.

Transport the machine to the installation location and then remove packaging. All the packaging

can be recycled. Dispose of packaging correctly.

8.2 Positioning and leveling

This appliance has adjustable feet. This is done by turning the leveling stands to the desired height.

For optimum operation, it is essential that the machine is correctly leveled. The ooring on which the

machine is to be installed must be able to bear the full weight of the machine.

INSTALLATION INSTRUCTIONS

12

8.3 Electrical connection

• Refer to the wiring diagram, the machine data plate and technical specications for service

size requirements.

• Check that the mains voltage corresponds to that indicated on the nameplate.

• The power-supply cord shall be Type S, SE, SO, SOO, ST, STO, or STOO (with or without

W at the end).

• The power supply cord wire size must be suitable for the rated current of the machine

(amperage load). Use copper conductors only.

• The appliance must be grounded using the ground connection of the terminal block of the

appliance.

• An all phase Circuit Breaker must be installed near to the appliance between the power

supply and the appliance in accordance to required consumption guidelines. Switch the

circuit breaker to “OFF” when servicing the appliance. It is recommended that it has lockout-

tagout capabilities. The manufacturer will not be held liable for damage originated by failure

to observe this requirement.

• A suitable safety switch / Residual current device must be installed near the appliance

between the power supply and the appliance. The manufacturer will not be held liable for

damage originated by failure to observe this requirement.

• If any faults are observed during the installation, the supplier should be notied immediately.

When a number of appliances are installed in line, they should all be ground bonded at the point

provided for that purpose.

To access the connection strip when a permanent connection needs to be made, release the cover

of the machine’s front (see Section 2 - General Measurements and Connections). The power cable is

connected to the connection strip. It is also possible to change the machine conguration here.

The manufacturer will not be held liable for any personal or material damage to the

machine resulting from incorrect installation or failure to comply with the manufacturer’s

specications.

INSTALLATION INSTRUCTIONS

13

It is the personal responsibility and obligation of the customer to contact a qualied

electrician to assure that the electrical installation is adequate.

8.4 Water connection

The new hoses supplied with the appliance should be used (do not reuse old hoses).

Before connecting the machine to the water supply, the water quality should be tested.

Recommended water quality:

17

•Refer to the wiring diagram, the machine data plate and technical specifications

for service size requirements.

•Check that the mains voltage corresponds to that indicated on the nameplate.

•The power-supply cord shall be Type S, SE, SO, SOO, ST, STO, or STOO (with

or without W at the end).

•The power supply cord wire size must be suitable for the rated current of the

machine (amperage load). Use copper conductors only.

•The appliance must be grounded using the ground connection of the terminal

block of the appliance.

•An all phase Circuit Breaker must be installed near to the appliance between the

power supply and the appliance in accordance to required consumption

guidelines. Switch the circuit breaker to “OFF” when servicing the appliance. It is

recommended that it has lockout-tagout capabilities. The manufacturer will not be

held liable for damage originated by failure to observe this requirement.

•A suitable safety switch / Residual current device must be installed near the

appliance between the power supply and the appliance. The manufacturer will not

be held liable for damage originated by failure to observe this requirement.

•If any faults are observed during the installation, the supplier should be notified

immediately.

When a number of appliances are installed in line, they should all be ground bonded at the point

provided for that purpose.

To access the connection strip when a permanent connection needs to be made, release the cover of

the machine’s front (see chapter 2. General measurements and connections). The power cable is

connected to the connection strip. It is also possible to change the machine configuration here.

The manufacturer will not be held liable for any personal or material damage to the

machine resulting from incorrect installation or failure to comply with the

manufacturer’s specifications.

It is the personal responsibility and obligation of the customer to contact a

qualified electrician to assure that the electrical installation is adequate.

8.4

The new hoses supplied with the appliance should be used (do not reuse old hoses).

Before connecting the machine to the water supply, the water quality should be tested.

Recommended water quality:

pH:

6.5 to 7.5

Alkalinity:

Less than 50 ppm (mg/L)

Free Chlorine:

Less than 0.2 ppm (mg/L)

Total Dissolved Solids (TDS):

Less than 60 ppm

Chlorides:

Less than 30 ppm (mg/L)

Sulfates:

Less than 40 ppm

Hardness:

Less than 3 gpg (52 ppm)

Iron:

Less than 0.1 ppm

Conductivity:

400 –1.000 µS/cm

Copper:

Less than 0.05 ppm

Silica:

Less than 12 ppm (mg/L)

Manganese:

Less than 0.05 ppm

Water installation is carried out as shown in . :

S→SHUT-OFF COCK

F→FILTER

H→WATER HOSE

E→WATER VALVE

. Direct connection of water input hose.

Use 3/4” copper tubing inlet line.

It is necessary to remove all foreign debris from the water line that may potentially get trapped in the

valves or cause an obstruction, prior to connecting to the machine.

Use only the supplied hoses (3/4” Female hose connector) at the water connections. Failure to do so

may result in damage to the solenoid valve threads and leaking. Tighten by hand. Connect the bent

side of the hose to the machine. Adaptor supplied for ¾” female garden hose connection.

FOR HARD WATER SUPPLIES WITH A HARDNESS OF OVER 3 gpg OR 5ºfH AND PH BEYOND

THE RANGE OF 6.5 – 7.5, A WATER CONDITIONER/DESCALER MUST BE INSTALLED.

In addition to water quality, the pressure of the mains water supply must be considered. This is

important to ensure the machine operates correctly.

INSTALLATION INSTRUCTIONS

14

Glasswasher (495HTGW22):

Required water dynamic pressure measured at pressure gauge 20psi ± 5psi.

CAUTION: Do not confuse static pressure with ow pressure. Static pressure is the line

pressure in a “no ow” condition (all valves and services are closed). Flow pressure is the

pressure in the ll line when the solenoid valve is opened during the lling or cycle.

In areas where the pressure uctuates or it is higher than the recommended pressure, a water pressure

regulator shall be installed between the shut-off cock and the water hose (Fig. 1.).

If the water pressure is less than required, installation of a water pump is required.

The hot water heater should be set to deliver 140 ºF (not lower than 122 ºF) water temperature to the

dishwasher for best results.

Slowly turn on the water supply to the machine after the incoming ll line and the drain line have been

installed. Check for any leaks and repair as required. All leaks must be repaired prior to placing the

machine in operation.

The following requirements are necessary for the correct hydraulic installation of the machine.

• The hydraulic circuit must be tted with a valve to shut-off the water supply.

• Check that the mains pressure is within the range indicated.

• To optimise the work of the machine, the water temperature at the machine intake should be

within the following range: 122 ºF (50 ºC) < Hot water Temp < 140 ºF (60 ºC)

• If using hot water, the water temperature must not exceed 60 ºC / 140 ºF.

• All the machines should have a 3/4” screw-on connection.

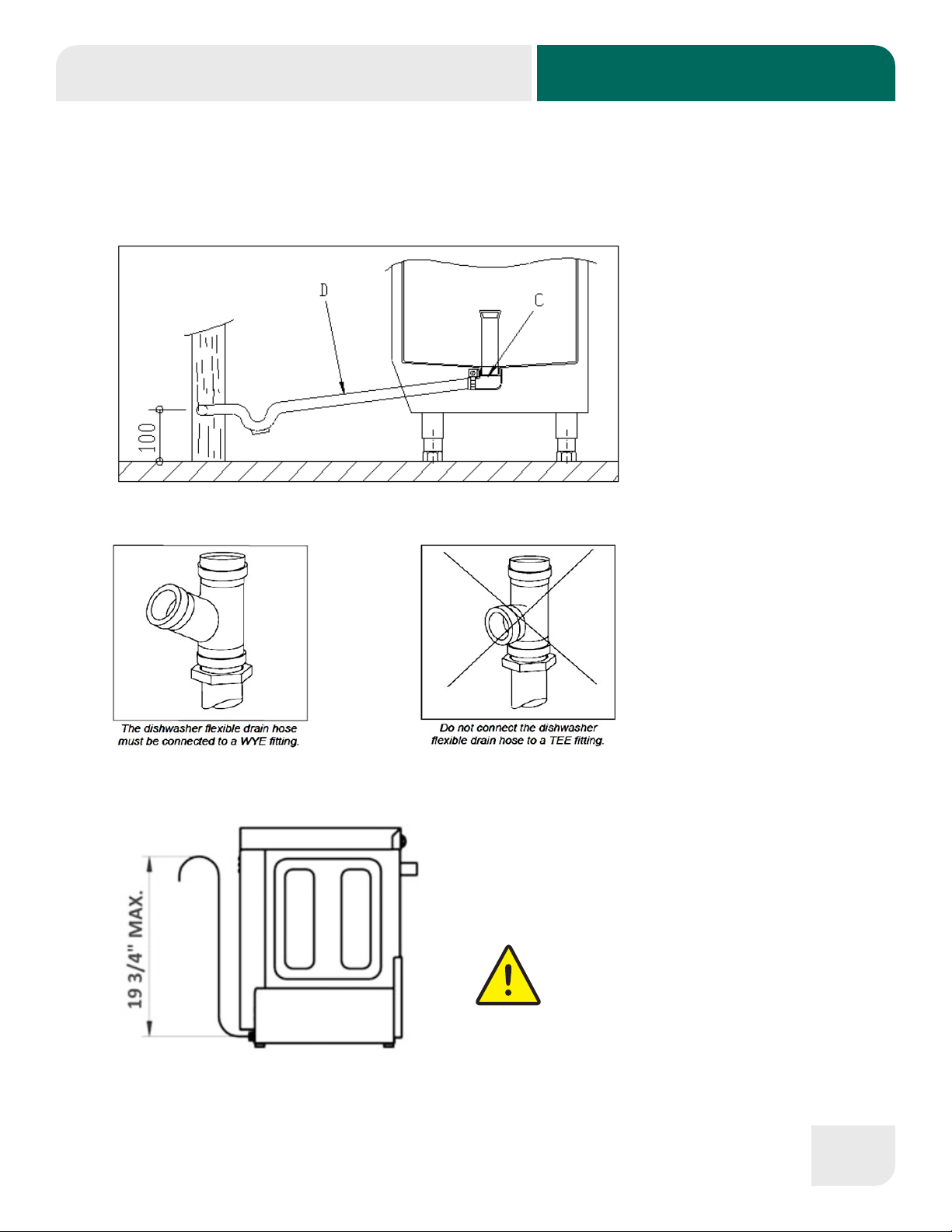

8.5 Drainage connection

Attach the drain hose as shown in Fig. 2 (on next page). The drainage pipe must always be tted on a

siphon to prevent the return of odours.

All piping from the machine to the drain must be a minimum 1-1/2” I.P.S. There should also be an air

gap between the machine drain line and the drain. For natural overow efciency use oor drain.

The water draining from the machine must ow freely and therefore the drainage pipe should be lower

than the drainage outlet (Fig. 2).

INSTALLATION INSTRUCTIONS

15

If the drainage pipe is not lower, a drainage pump will be required. This must not be mounted at a

height of more than 19 3/4” for glasswashers (Fig. 3). In this case, the pump may be requested at the

time of purchase or subsequently.

Fig. 2. Drainage installation

D: Drain hose

C: Drain collector

Fig. 3. Installation of drainage at a height using

drainage pump.

THE DRAINAGE PUMP MUST

ONLY BE INSTALLED BY

PERSONNEL AUTHORIZED BY

THE MANUFACTURER, AND THE

MANUFACTURER DOES NOT

ACCEPT LIABILITY IN THE EVENT OF

INCORRECT INSTALLATION.

INSTALLATION INSTRUCTIONS

16

8.6 Liquid rinse aid dispenser

Installation: Take the tube located in the back or your machine marked “Rinse Aid” and place inside

rinse container.

Tubes are transparent to make it visible that the chemicals are being dispensed.

Operation: This dispenser absorbs the rinse aid when it detects a loss in pressure during rinsing.

That is, when the lling solenoid valve closes, a vacuum is created that makes the rinse aid dispenser

absorb the uid to which it is connected.

Adjustment: The dispenser should be adjusted when the machine is installed to ensure that the wash

is optimized from the start. The setting should be adjusted according to the type of rinse aid and the

water hardness.

WATER PRESSURE MUST BE MINIMUM 20 PSI AT THE PRESSURE GAUGE FOR THE RINSE AID

DISPENSER TO OPERATE PROPERLY.

Rinse Aid

Filter

Regulation

Rinse Line

8.7 Detergent dispenser

This machine must be operated with an automatic detergent feeder including a visual means to verify

that detergent is delivered or a visual or audible alarm to signal if detergent is not available for delivery

to the respective washing system. Please see instructions for electrical and plumbing connections

located in this manual and in the feeder equipment manual.

The detergent dispenser ensures that the correct measure of detergent is supplied to the machine.

Use ONLY Commercial Grade, High Temperature, Low Suds Liquid Detergent. Noble doesn’t

recommend any specic brand name of chemicals. Contact your local chemical distributor for questions

concerning your chemical needs.

Installation: the detergent dispenser input is in the wash tank front part, above the maximum water

level.

Take the tube located in the back or your machine marked “Detergent” and place inside detergent

container.

INSTALLATION INSTRUCTIONS

17

Tubes are transparent to provide you visible means that chemicals are being dispensed.

Operation: the detergent dispenser is activated when the machine is taking water, whether

it is in rinse cycle or whether it is lling.

Settings: the quantity of detergent used should be adjusted on installation to ensure hat the

wash is optimized from the start.

Time-Pause Regulation

Wash Tank

Water Valve

Electrical Connection

Detergent

Filter

It is recommended that the detergent and the dispenser setting are dened by a

technician specialized in the use of chemical products in order to ensure a

more efcient wash.

If you require the installation of a NON-NOBLE Detergent and/or Rinse pump, a form

MUST be ll out prior to installation by your installer. Failure to do so will void your

Warranty. This form can be located inside your dishwasher. If lost, please contact

Noble to get a copy.

and rinse.

INSTALLATION INSTRUCTIONS

18

8.8 Recycling

The product packaging consists of:

• A wooden pallet.

• Cardboard.

• A polypropylene band.

• Expanded polyethylene.

All the packaging used around the machine can be recycled. The correct disposal of these products

will help to protect the environment. For further information regarding the recycling of these products,

please refer to your local recycling authority.

USE AND MAINTENANCE INSTRUCTIONS

19

9. USE AND MAINTENANCE INSTRUCTIONS

BEFORE STARTING THE APPLIANCE, PLEASE READ THE INSTRUCTIONS

CONTAINED IN THIS MANUAL CAREFULLY.

THE APPLIANCE IS EXCLUSIVELY FOR PROFESSIONAL USE AND SHOULD

ONLY BE USED BY QUALIFIED PERSONNEL.

9.1 Operation

The steps required to optimise the operation of your dishwasher are shown below, with all

the available options.

9.1.1 Control panel symbols

495HTGW22 (Glasswasher)

ON/OFF - LON WT RT

P1 - L1

ON/OFF ON/OFF Button

P1 Wash Cycle 1 / Drainage Button

LON ON/OFF Pilot Light

WT Wash Tub thermometer

RT Rinse boiler thermometer

L1 Blinking: Cycle pilot light

Steady: Wash tub over 150ºF

9.1.2 Switching on the machine

Before switching on the machine, check the following:

✓ The mains switch must be on.

✓ The water stop cock must be open.

✓ There must be water in the mains network.

✓ The corresponding lters must be in place.

✓ The overow should be mounted in place.

To switch on the machine just press the ON-OFF button once for 2 seconds.

USE AND MAINTENANCE INSTRUCTIONS

20

9.1.2.1 Filling and heating

In the Glasswasher model, when the machine is switched on, it will start to ll the

machine. First the rinse boiler is lled and then the wash tub. The lling process

may last a few minutes. Once the wash tub is full, the boiler and the tub start to heat

up. Although it is possible to start the wash process, this is not recommended as

the water inside the machine is not yet at the ideal temperature. When the machine

has reached the ideal temperature for washing the dishes properly, a light comes

on, advising the user that the machine is ready. The required temperature of the

machine is over 180 ºF in the rinse boiler (see thermo-stop chapter) and over 158

ºF in the wash tub. It is recommended that the water in the dishwasher is changed

every 40/50 washes or twice a day.

The machine you have purchased has a safety thermostat in the boiler and another

for the tub, so that in the event of the breakdown of any of the main thermostats, the

safety thermostats switch off the corresponding heating.

9.1.3 Hygiene practices

• Operators must strictly observe all hygiene requirements when handling clean dishes

and cutlery.

• Do not touch clean dishes with dirty or greasy hands. Handle the dishes/cutlery with

gloves or clean hands to prevent contamination. Be careful as the dishes will be hot.

• Use clean sterilized cloths to thoroughly dry the dishes. Do not dry the plates with

kitchen towels or cloths that are not sterile.

• Wait until the machine reaches the correct wash temperature to ensure a thorough

disinfection and wash. To obtain optimum results wash the dishes when the machine is

ready.

• Drain the wash tub and rinse the lters at least twice a day or every 40-50 wash cycles.

• Make sure that the quantities of detergent and rinse aid dispensed are correct (as

recommended by supplier). At the start of the work day, check that the quantity of

product in the reservoirs is enough for the daily requirement.

• The dishwasher should be kept perfectly clean and maintained.

Table of contents

Other Noble Dishwasher manuals