NOCO Genius CURTIS DC Series User manual

Other NOCO Genius Controllers manuals

Popular Controllers manuals by other brands

KRIWAN

KRIWAN INT280-60 quick start guide

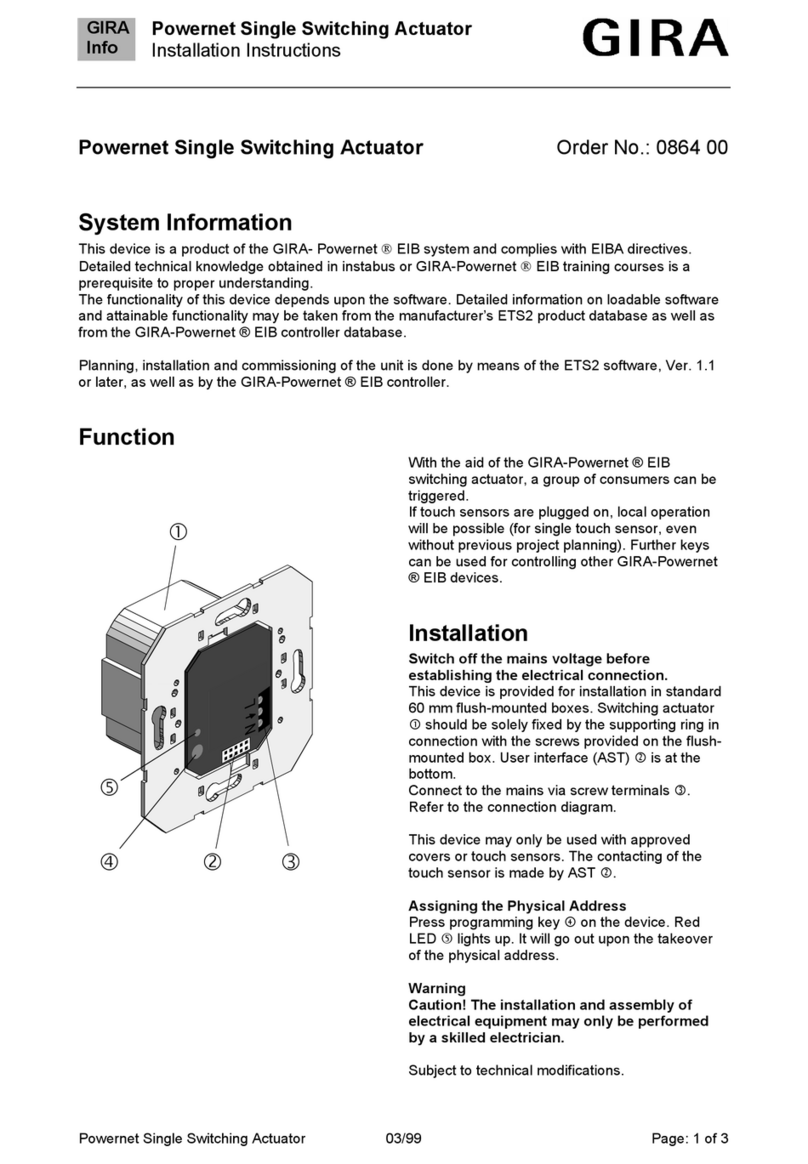

Gira

Gira Powernet Single Switching Actuator installation instructions

Fireye

Fireye PPC6000 Series manual

Love Controls

Love Controls 2600 SERIES instructions

Panasonic

Panasonic WVCU161C - SYSTEM CONTROLLER operating instructions

Smart-M

Smart-M StretcherPro-HD user manual

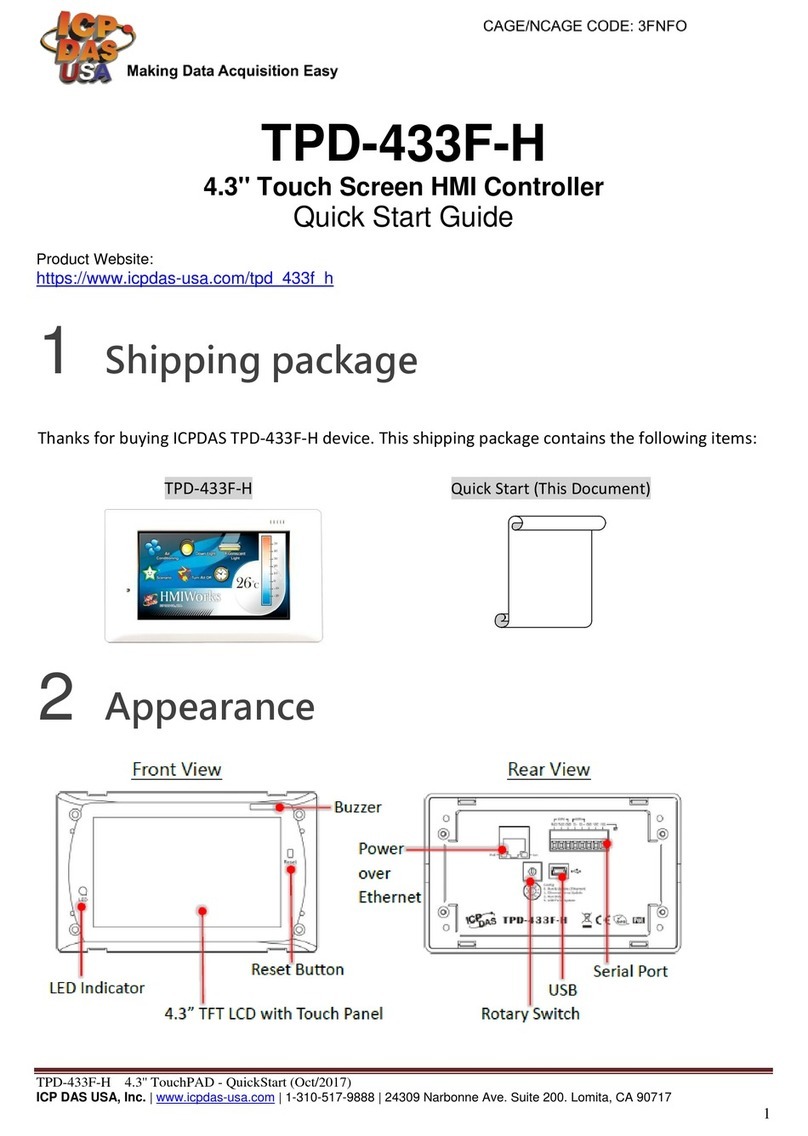

ICPDAS

ICPDAS TPD-433F-H quick start guide

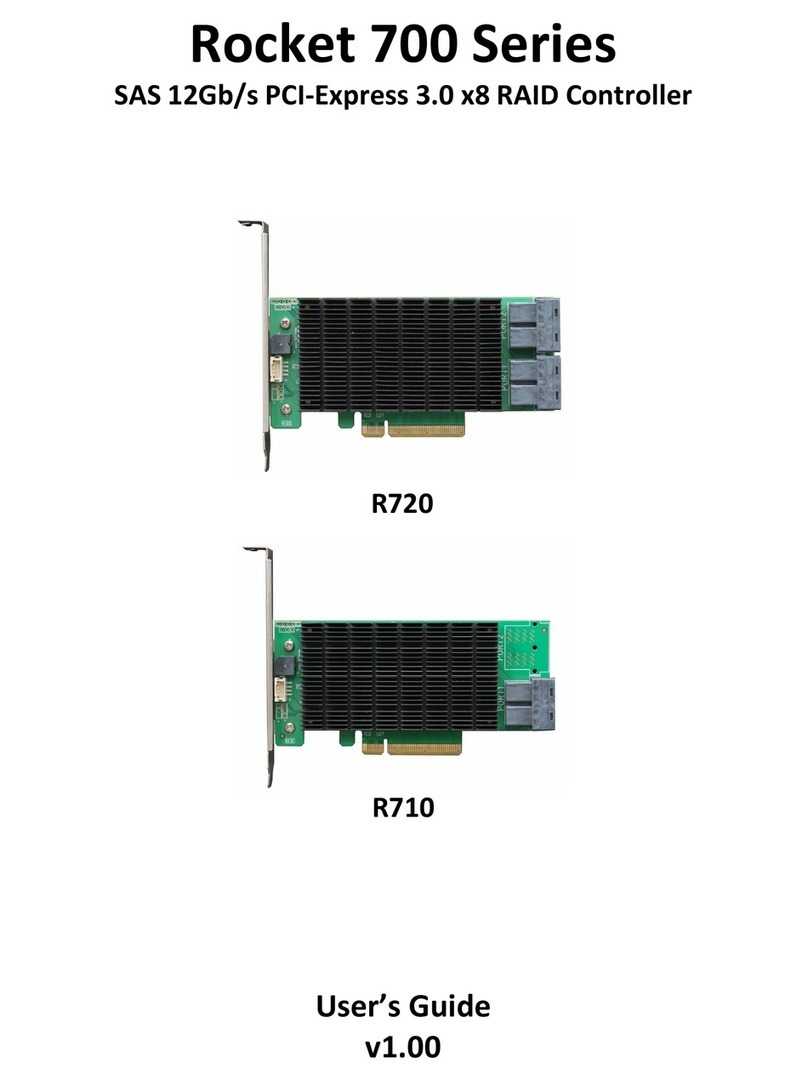

HighPoint

HighPoint Rocket 700 Series user guide

Siemens

Siemens OpenAir G..B181.1E/KN Series Technical Basics

SSS Siedle

SSS Siedle EC 602-03 Programming instructions

McQuay

McQuay MicroTech II Operation manual

National Instruments

National Instruments FlexRIO NI-7931R user manual

Dakota Digital

Dakota Digital PAC-2700 manual

Kenwood

Kenwood KCA-R10 instruction manual

Hewlett Packard Enterprise

Hewlett Packard Enterprise Aruba 7240-US Product End-of-Life Disassembly Instructions

TIS

TIS TIS-CBL-MGR installation manual

Murphy

Murphy Cascade CD101 Installation and operation manual

fluidra

fluidra Astral Pool SLX Light Connect Lite installation instructions