5

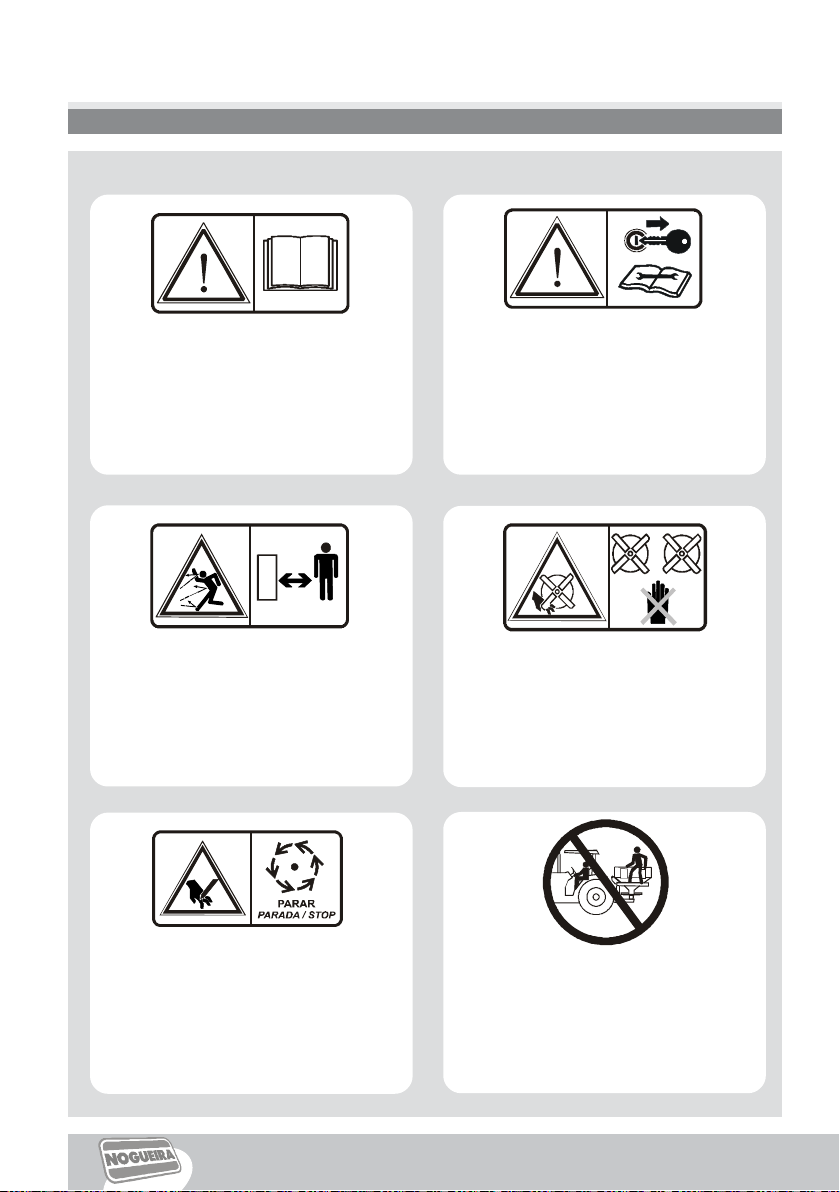

SAFETY

•Observe the machine surroundings

before putting it into operation. Keep

children, animals and watchers at safe

distance and out of the distribution

range. Be especially careful with

children. Check if there are no tools or

other objects on the machine before

turning it on.

•Tie long hair and do not use loose

clothes,orwithpartsthatmaygetstuck

in the mobile components. Remove

rings, necklaces etc.

•Keep hands and feet away from the

moving part.

•Never try to clean or clear the machine

when it’s on. Always turn the machine

off before performing any cleaning or

maintenance in the Extractor.

•Use personal protective equipment

when operating the machine. The

prolonged exposure to the noise can

cause hearing impairment or loss. Use

earplugs and safety goggles.

•Never operate with the Cardan shaft

without the safety protection. Keep the

protection in good conditions and

prevent it from spinning, locking it with

the existing chains.

•Before regulating, lubricating or

carrying out any maintenance service

in the Harvester, turn off the power take

off, the tractor engine and remove the

key from the ignition.Always be aware!

•Keep the safety stickers in good

conditions and readable. Substitute

them whenever necessary.

•Be especially cautious when coupling

and uncoupling the machine from the

tractor!

•Incaseyou observe vibrations,different

noises etc, turn the machine off

immediately. Check and eliminate the

cause before turning it back on.

•The hydraulic system liquid escape

may be unnoticeable. Use wood or

cardboardinsteadofyourhands to look

for leaking. Protect the hands and body

since fluids at high pressure can

cause severe injuries. In case of

accident, consult a doctor immediately.

•Due to inertia, the mobile components

will keep moving for a while after the

machine has been turned off. Before

substituting any component, turn of the

power supply, look and listen to check

if there are any movement evidences.

Only touch a component if you’re sure

it’s still. Always be aware!

•Never operate the machine without the

safety protections.

•Never operate the machine indoors or

in unventilated environments. The

fumes released by the tractor engine

are toxic and highly harmful to health.

•When driving the machine on public

places, observe the local traffic and

safety. Get information about the

current legislation in regards to the

maximum width and height permitted

for transportation. Beware of the

transportation height, especially under

bridges.